Pro-dig Intelli-Tork H200 User manual

Instruction Manual

Owners Manual

Safety Precautions

Manual number: PROITK

Release Date: June 2021

Operating Instructions

Maintenance

Parts Lists

785.856.2661

WWW.PRO-DIG-USA.COM

WIRELES SCREW

PIER TORQUE

MONITORING SYSTEM

CLOUD BASED

WWW.PRO-DIG-USA.COM 785.856.2661

2.

TABLE OF CONTENTS

Table of Contents/Introduction ................................................................................................2-3

Operation of PRO-DIG®Intelli-Tork Analyzer Rotor................................................................ 3- 6

Locating and Viewing Logged Files ......................................................................................... 7- 8

Torque Alarms and Changing WIFI Channels............................................................................ 9

Exporting Data Files............................................................................................................. 10-11

PRO-DIG® LLC

is document and any information contained therein are condential and the copyright of

PRO-DIG® LLC. Neither the whole, nor any part, may be disclosed, loaned, copied, or otherwise

disseminated for any purpose whatsoever without express written consent from PRO-DIG® LLC.

No liability is accepted for any loss, damage or injury from any cause whatsoever from the use of

this document.

MODEL NO: ___________________________

SERIAL NO: ___________________________

DATE OF PURCHASE:

__________________

WWW.PRO-DIG-USA.COM 785.856.2661 3.

WARRANTY WILL BE VOID IF ANY COMPONENTS OR ACCESS COVERS ARE

REMOVED FROM THE INTELLITORK DEVICE.

INTRODUCTION INTELLI-TORK CLOUD USER MANUAL

(Note: e information provided within this document is applicable to all Intelli-Tork Cloud Systems.)

ere is no power button on the Intelli-Tork hub. Once the user disconnects from the hub,

it will enter sleep mode awaiting connection. Operators must ensure proper disconnection

from the hub to maintain maximum battery life.

e battery life of this system has been designed to exceed 10.5 month of usage running 10

hours a day, 5 days a week in -20° F. Battery replacement will occur automatically during your

yearly calibration.

Communication range for the Intelli-Tork System is 300’ line of sight. Note that obstructions

may diminish the communication range.

Intelli-Tork Hub Operating Temperature Range: -30° F to 130°F

e Intelli-Tork hub has been tested to 12’ submersion depth for 24 hours. At no time should

the hub be subjected to pressurized wash down. e hub should be cleaned with water and

mild detergent as required.

WWW.PRO-DIG-USA.COM

4.

DOS AND DON’TS

1. Ensure the USB cable is attached between the tablet and the black box mounted to

the back of the tablet prior to connecting the tablet to the Intelli-Tork device.

2. Verify that the Hub Serial No. matches the Serial No. stamped on the Intelli-Tork

in use.

3. Do not power o the tablet prior to disconnecting from the Intelli-Tork.

4. Always disconnect from the Intelli-Tork when nished. is is to be treated as a

power o procedure.

5. Do not carry or hang by the USB cable.

6. Do not remove the black box mounted to the back of the tablet.

7. Do not attempt to disassemble the Intelli-Tork unit in any way without communi

cation with supplier.

8. Ensure that the torque and thrust parameters are zeroed prior to connecting a

helical pile.

9. Backup data/sync to cloud dialy to prevent loss.

10. Ensure calibration is up to date prior to starting your job.

WWW.PRO-DIG-USA.COM 785.856.2661 5.

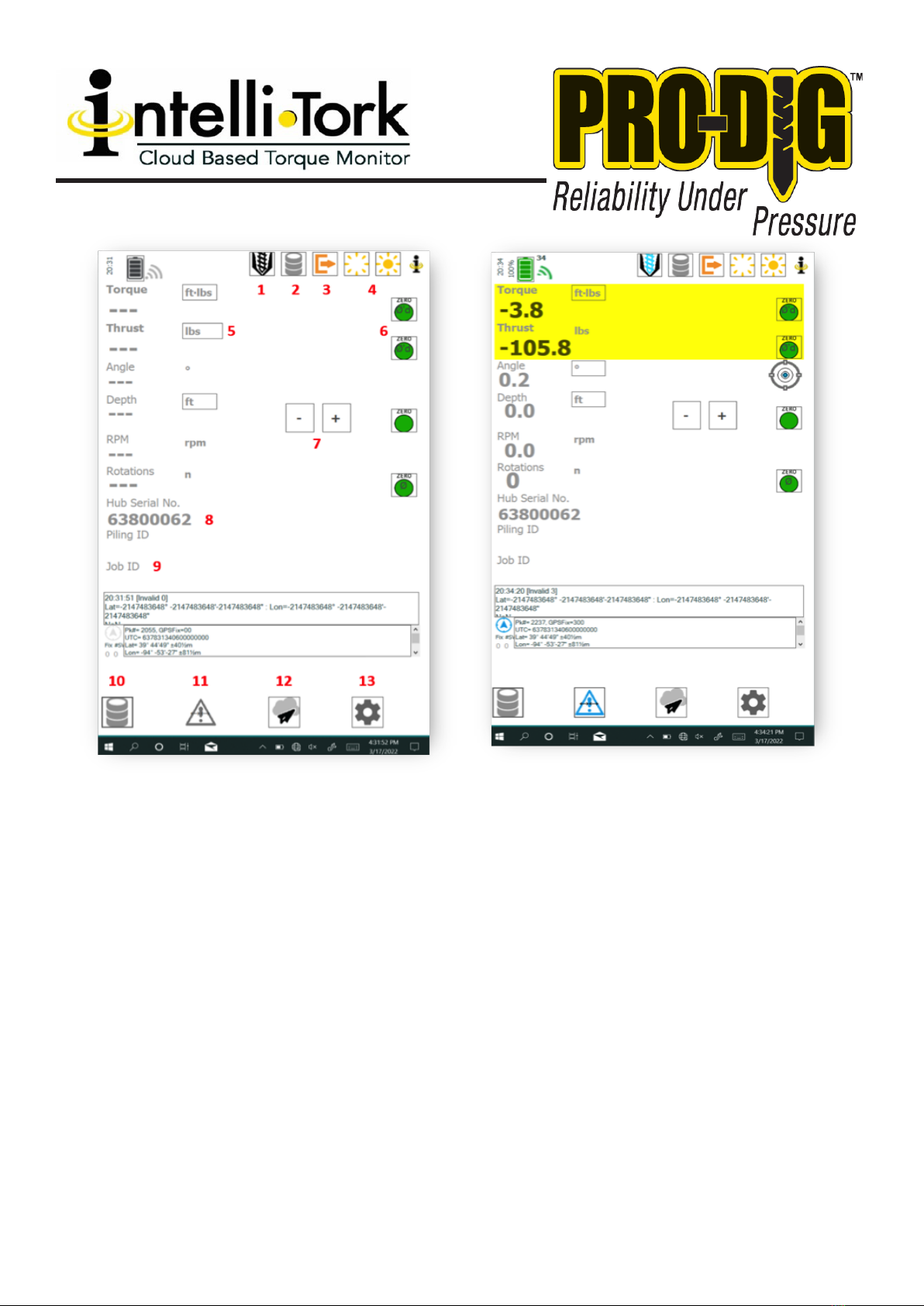

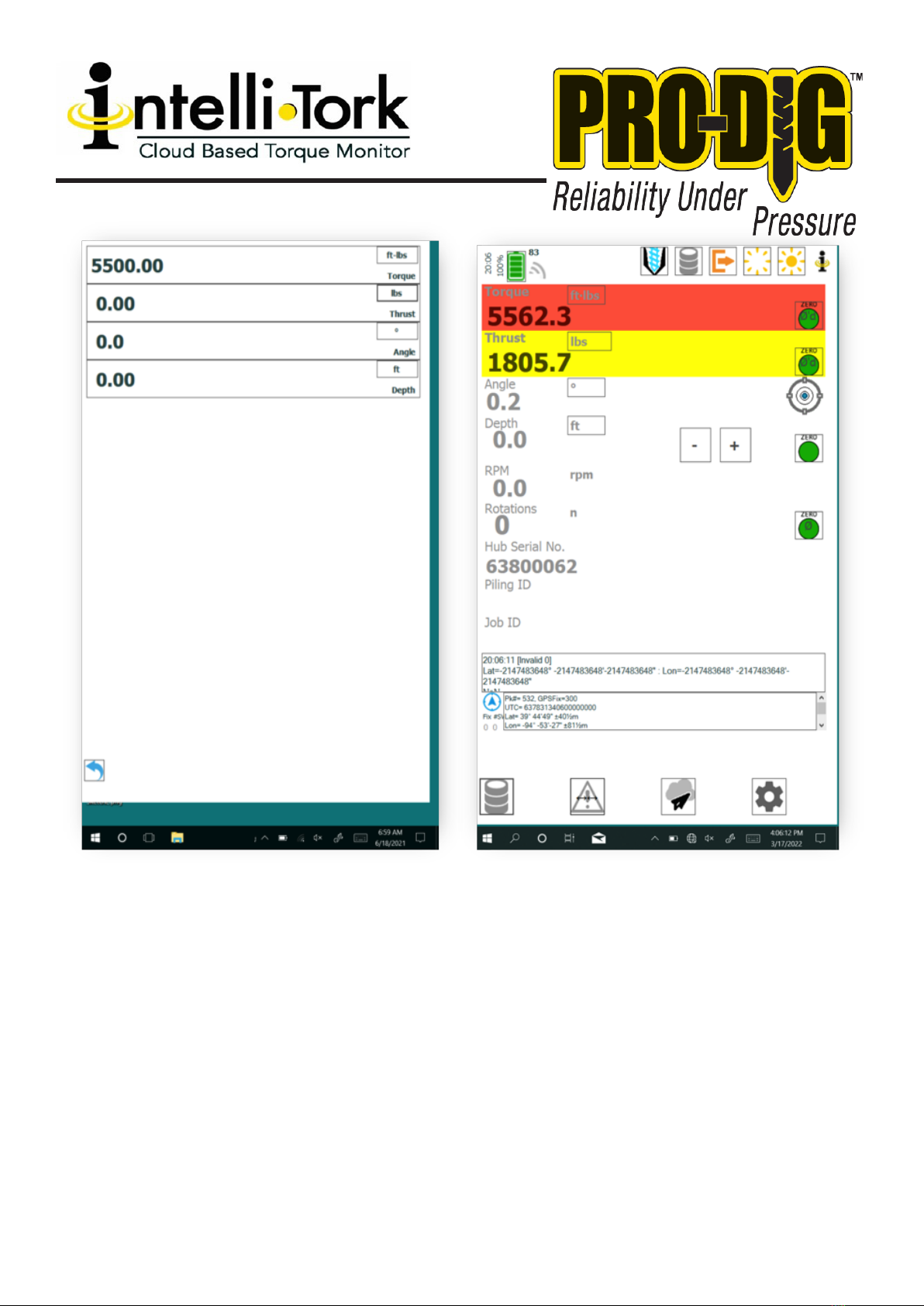

1. Press to connect and disconnect from the Intelli-Tork (ITK). e icon will turn blue once

connected and data will be displayed. Disconnect when the ITK is no longer in use. is is to be

treated as a power o procedure.

2. Pause and restart data logging. User must initiate the log from the log conguration screen to

enable this feature.

3. Exit application and turn o ITK remote.

4. Change screen brightness levels.

5. Change units (rust and Angle can be turned o)

6. Zero associated readings. (Torque and rust should be zeroed at the beginning of each pile

under no load).

7. Depth, manually increase/decrease depth as pile is driven.

8. Shows the hub serial number you are currently connected to or the last hub you were

communicating with.

9. Pile and Job number.

10. Press to setup Project and Pile Number. Icon will turn blue while logging, select logging icon at

the top of the display to start and stop logging. (Data will append to the le called out in item 9)

11. Set alarms.

12. Send all data to the Cloud for automatic processing. (Must be connected to WiFi)

13. Enter Settings.

WWW.PRO-DIG-USA.COM

6.

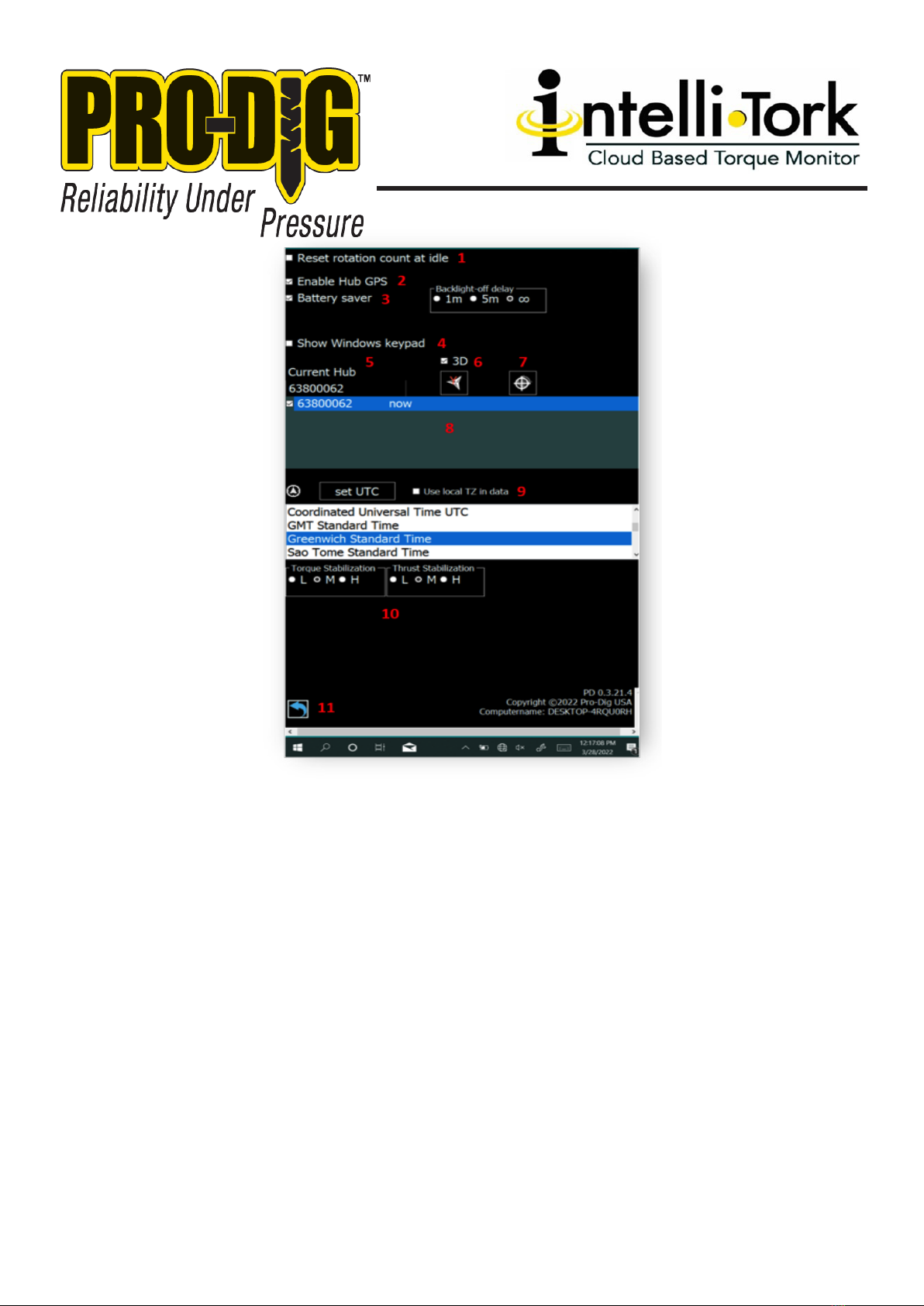

1. Check Box to reset rotation count when idle.

2. Check Box to enable the GPS functionality of the Intelli-Tork.

3. Check Box to help save the tablet battery. Select user prefered Backlight O Delay.

4. Check Box to display Windows key pad.

5. Current hub or last hub that the user has connected to is displayed in the eld. Select current

hub eld and enter serial number of the Intelli-Tork that is stamped into the rounded edge of

the ange. Return to the main menu and press the connect icon.

6. Check Box to set the vertical zero to 90 degrees. Press axis icon selecting X, Y, or Z to monitor

the installation angle relative to the choosen axis.

7. Gyro calibration button. Tap once to begin a calibration for the RPM, rotations and angle

parameters. Ensure the unit is level and stationary prior to calibration. Wait 10 seconds for

the calibration to complete.

8. Displays the serial number of Intelli-Torks that the tablet has recently been paired with.

9. When the user selects the Set UTC icon the GPS obtains global positioning information rela-

tive to your location. Once the connection is established select Look up TZ to capture the

correct time stamp for the log les. A clear view of the sky is required for GPS lock. Check

the “Use local TZ in data” box to display the selected time zone in data logs.

10. Torque and rust Stabilization can be independantly set to Low, Medium, or High. is will

eectively smooth out the displayed values as seen from the main menu.

11. Return to Main Menu.

WWW.PRO-DIG-USA.COM 785.856.2661 7.

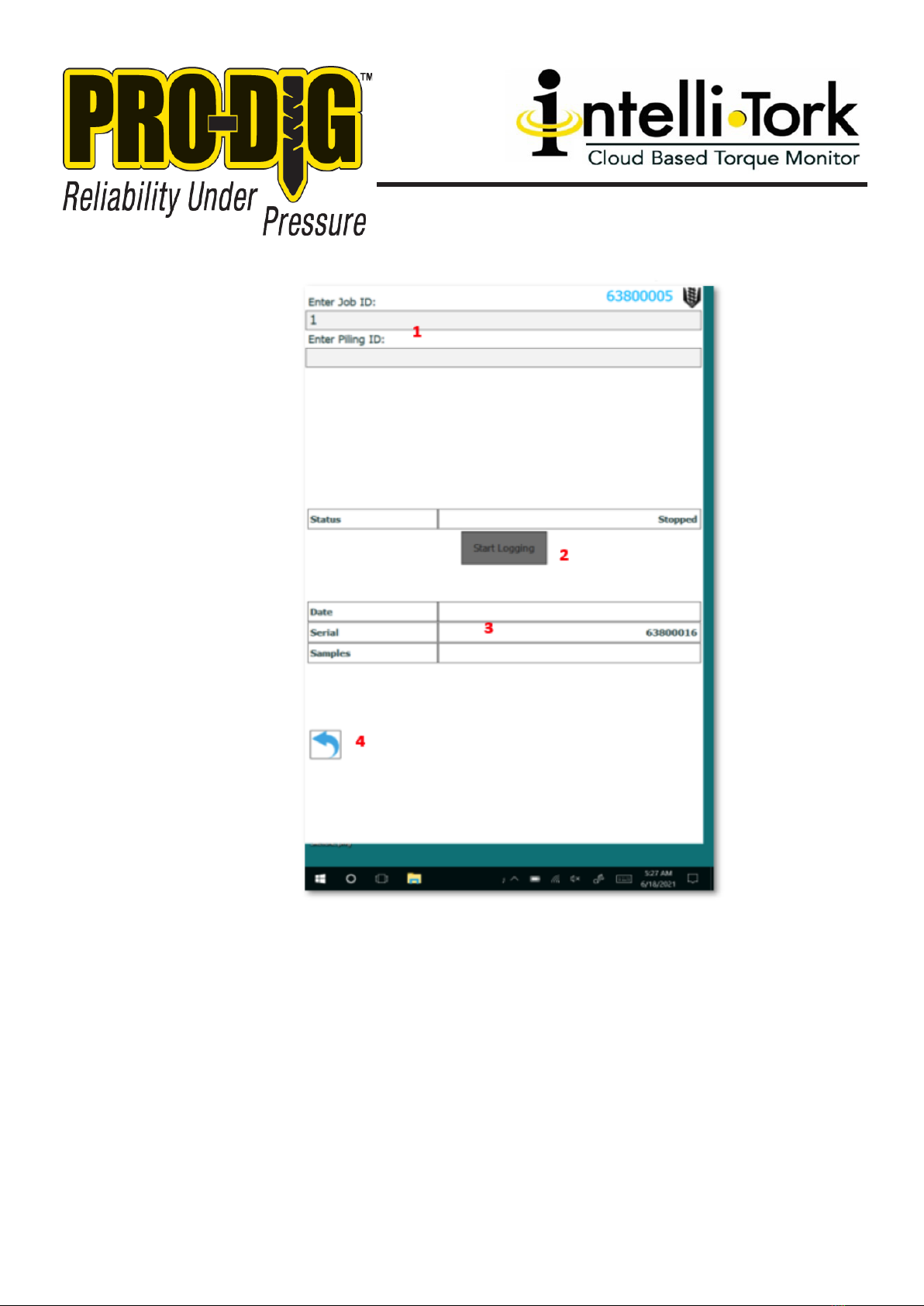

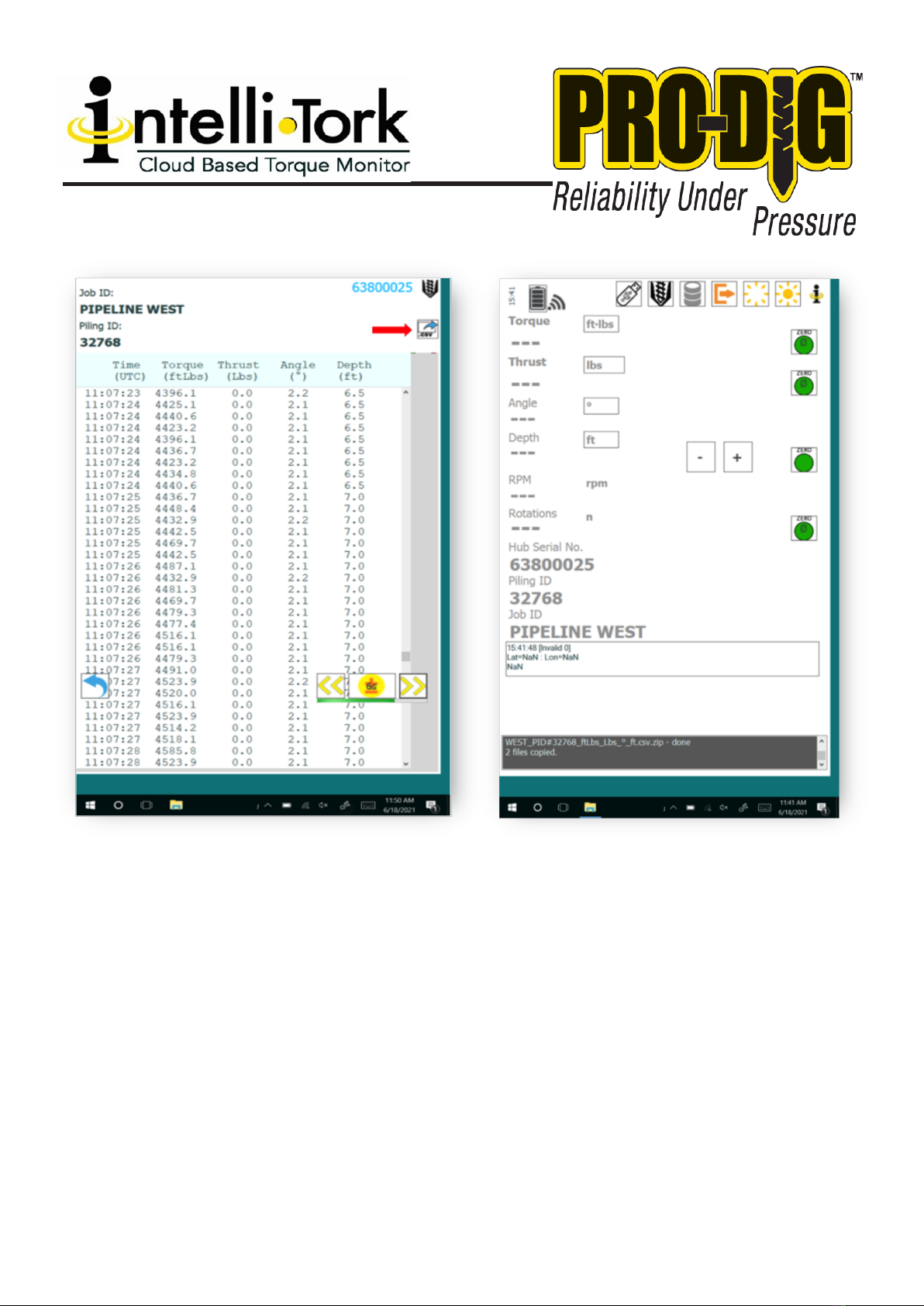

1. Start new log le.

2. Each row displayed is a log le.

3. View Data for that specic log le. Press the View icon to view the associate log le.

Secting the arrows in the lower right of the individual pile log screen allows the

user to advance through the log le. Pressing the center button allow the user to

advance through the log le in 1 & 6 second, 1 minute, and 10-minute intervals.

4. Refresh List. is displays all logs that are currently stored on the tablet.

5. Clean up log le list. Removes existing logs from the log list. e log les remain

saved on the tablet.

6. Return to the Main Menu.

WWW.PRO-DIG-USA.COM

8.

1. Enter new Job ID and Pile ID. e current Job ID will remain in the Job ID eld

until modied.

2. Start Logging Data. (Aer selecting, return to main menu)

3. Log File Information.

4. Return to Main Menu.

WWW.PRO-DIG-USA.COM 785.856.2661 9.

is page allows the user to set alarms and target values in the units displayed on the right.

For Cloud based reporting, targets must be set to report Torque and Depth. Once the Alarm

value is reached the associated value’s background will turn Red while the alarm value is

exceeded, as shown in the gure on the right

10. WWW.PRO-DIG-USA.COM

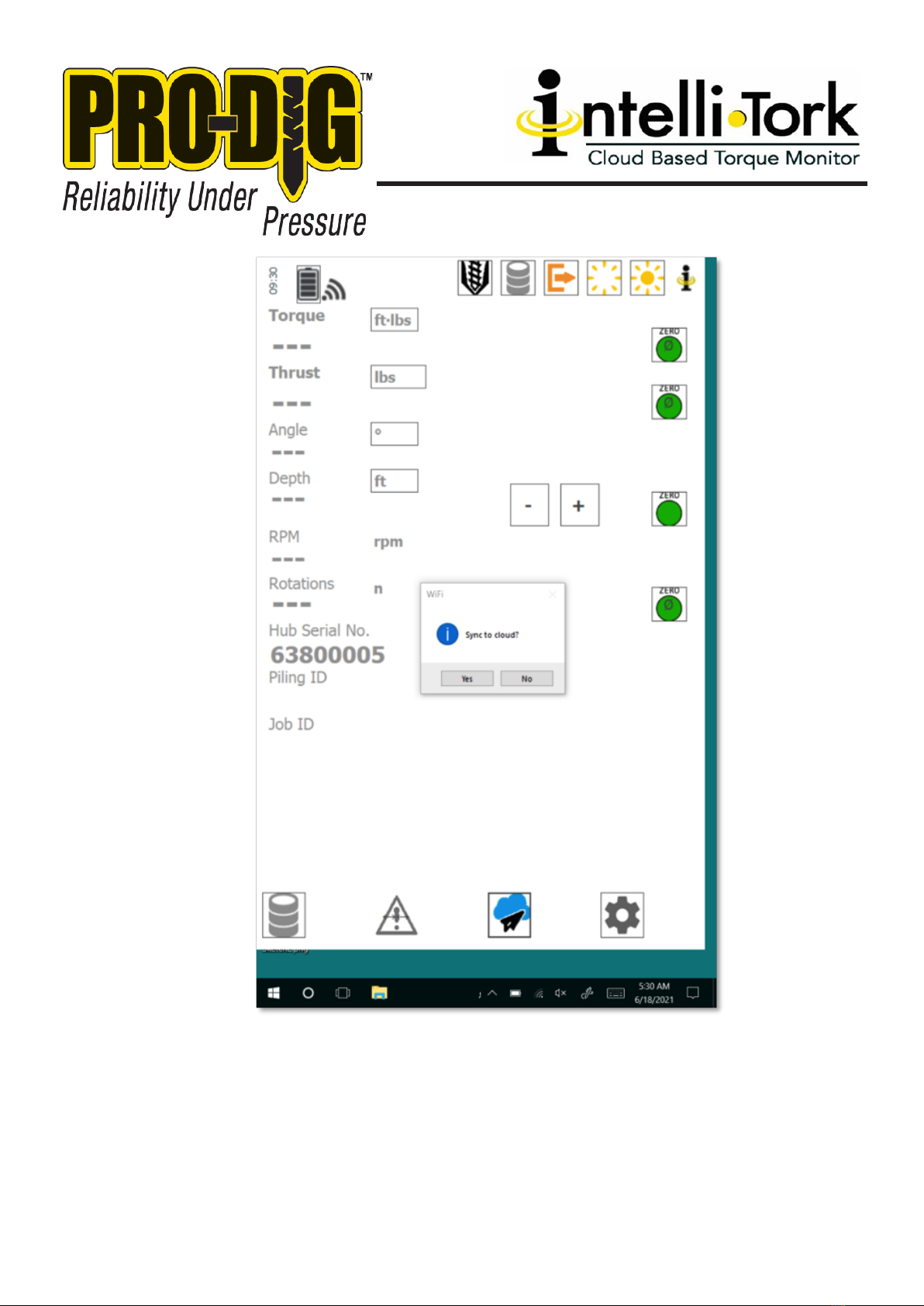

Press “Sync to Cloud” to upload all pile logs to the Cloud for data processing and storage. is

function requires the use of a Hotspot of other wireless connection to the Internet.

Intelli-Tork Cloud Subscription is required to utilize this feature. Alternatively, the user may

download the log les to a USB or Micro SD in a .cvs le format for data processing using MS

Excel. If the user is downloading log les to a memory device WinZip is required for

extraction of zipped les once download to a PC.

785.856.2661

WWW.PRO-DIG-USA.COM 11.

Prior to downloading the log les to a memory device, each individual le log must be

exported to .csv. To export a log le to .csv, start by navigating to the list of logs. On the log

le that you want exported, select the eyeball icon on the far-right side. From this menu,

select view. You will now see a data preview of that individual log. In the upper right corner

of this menu, select the button labeled “.csv”. is will generate the .csv le to later be down-

loaded.

To download the exported log les, the user must insert a USB drive or Micro SD card into

the tablet. Once the memory device is installed, a USB icon will be displayed in the top

center of the Main Menu screen. Press the USB icon to download all log les to the memo-

ry device for later viewing and processing.

12. WWW.PRO-DIG-USA.COM

785.856.2661

WWW.PRO-DIG-USA.COM 13.

NOTES:

14. WWW.PRO-DIG-USA.COM

NOTES:

785.856.2661 15.

WWW.PRO-DIG-USA.COM

NOTES:

1604 ROSEPORT RD

ELWOOD, KS 66024

785.856.2661

WWW.PRO-DIG-USA.COM

PROUD MEMBER OF:

This manual suits for next models

5

Table of contents

Other Pro-dig Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

IN-COMMAND

IN-COMMAND NCSP3 Installation and operation manual

MYIRO

MYIRO MYIRO-1 instruction manual

Lovibond

Lovibond SensoDirect pH200 operating instructions

VoiceCollect

VoiceCollect IR44CF-II user manual

Microplan

Microplan ARCHIMEDE HR user manual

AEA Technology, Inc.

AEA Technology, Inc. Bravo MRI II operating manual