Pro-safe GP477R-EG41-24VP User manual

WARNING

•When connecting a power cable to the GP unit, be sure the cable has been unplugged

from the power outlet, so that you would not get an electric shock.

•High voltage runs in the GP unit, so if you take unit apart, there is a danger of getting an

electric shock. Do not take the unit apart.

•Do not use power beyond the specified voltage range. If you do, it may cause a fire or

an electric shock.

•Do not reconstruct the GP unit. It may cause a fire or an electric shock.

•Do not use the GP in an environment with flammable gas in the surrounding atmo-

sphere. It may cause explosion.

•GP use a lithium battery for backing up its internal clock data. If the battery is incor-

rectly replaced, the battery may explode. To avoid the danger, do not replace the

battery yourself. When the battery needs a replacement, please consult with your

local GP distributor.

•Do not use touch panel switches in life-related or important disaster prevention situ-

ations. For safety related switches, such as an emergency switch. use a separate me-

chanical switch.

•Please design your system so that the machine will not malfunction by a communica-

tion fault between the GP and its host controller. If not, there could be a danger of

injuring a person or damaging materials.

To Prevent From Damage:

•Do not hit the touch panel with a hard or heavy object, or press the touch panel with too

much force, for it may cause irreparable damage.

•Do not use GP in an environment where the surrounding temperature exceeds the

specification range, for it may damage the unit.

•Please ensure that liquids or metal do not enter the GP unit, for it may cause malfunc-

tion or a short.

•Please avoid using the unit in areas where sudden, large changes in temperature may

occur. These changes can cause condensation to form inside the unit, possibly caus-

ing an accident.

•To prevent from heat building up inside the GP, please do not install GP where its

ventilation holes may be blocked, or where heat cannot escape. Also, please avoid

using or storing the GP in an extremely hot place.

•Do not operate the GP in areas with temperatures and humidity in express of those

levels specified to prevent the GP’s touch panel from becoming warped or bent.

•Please avoid using or storing the GP under direct sunlight or in a dusty environment.

•This unit is a delicate equipment, so please avoid using or storing the GP unit in an

environment where it can receive strong impact or vibration.

•Please avoid using or storing GP where vaporized chemicals or chemicals can stick to

it.

•Do not use paint thinner or organic solvents to clean the GP unit or display.

•Because unforeseen circumstances may befall your GP unit, be sure to back up your

screen data.

•After turning this unit OFF, be sure to wait a few seconds before turning ON again. If

the unit is started within a few seconds, it may not start up correctly.

The GP477R-EG41-24VP are UL/cUL(CSA) recognized products.

(UL file No. E182139)

GP477R-EG41-24VP conforms as a component to the following standards:

•EUL508

Industrial Control Equipment

•UL1604

Electrical Equipment for Use in Class I and II Division 2 and Class III Hazardous

(Classified) Locations

•CAN/CSA-C22.2, Nos.142,and 213-M1987

Standard for Safety of Information Technology Equipment, including

Electrical Business Equipment

GP477R-EG41-24VP (UL Registration Model : 2780027-01)

•The GP should be installed in the front face of a metal panel.

•If the GP is installed so as to cool itself naturally, be sure to install it in a verti-

cal panel. Also, be sure that the GP is mounted at least 100mm away from adja-

cent structures and other equipment, otherwise, the heat generated by the GP's

internal components may become higher than that allowed by UL standard re-

quirements.

•The terminal block’s earth terminal is a protective earth terminal. Be sure to

connect this terminal in accordance with UL standards.

Installation and operation instructions are provided with each GP. These installation

instructions contain the following statements.

1. Power, input and output (I/O) wiring must all be in accordance with Class I, Divi-

sion 2 wiring methods, Article 501-4 (b) of the National Electrical Code, NFPA

70, or as specified in Section 18-152 of the Canadian Electrical Code for units

installed within Canada, and in accordance with that location's authority.

2. Suitable for use in Class I, Division2, GroupsA, B, C and D hazardous location, or

nonhazardous locations only.

3. WARNING: Explosion hazard-substitution of components may impair suitability

for Class I, Division2.

4. WARNING: Explosion hazard-do not disconnect equipment unless power has been

switched off or the area is known to be nonhazardous.

5. WARNING: Explosion hazard-when in hazardous locations, turn off power before

replacing or wiring modules.

CE Marking

UL/cUL(CSA) Approval

GP477R-EG41-24VP is CE marked , EMC compliant products.These units also

conform to EN55011 class A , EN50082-2 directives.

The following items are included in the package. Before using, please ensure every-

thing is there.

This unit has been carefully packed, with special attention to quality. However, should

you find anything damaged or missing, please contact your local GP distributor im-

mediately.

Package Contents

Manual

GP477R/577R Series

User’sManual

Extra-Cost Options

Cables

Adapters

Screeneditorsoftware

are optionally available.

For more information, see Digital's cata-

logues.

GPunit

(GP477R-EG41-24VP)

Handlingguide1sheet

(thissheet)

Installationfasteners(4pcs)

Handling

Guide

Digital

GP477R/577R Series

User's Manual

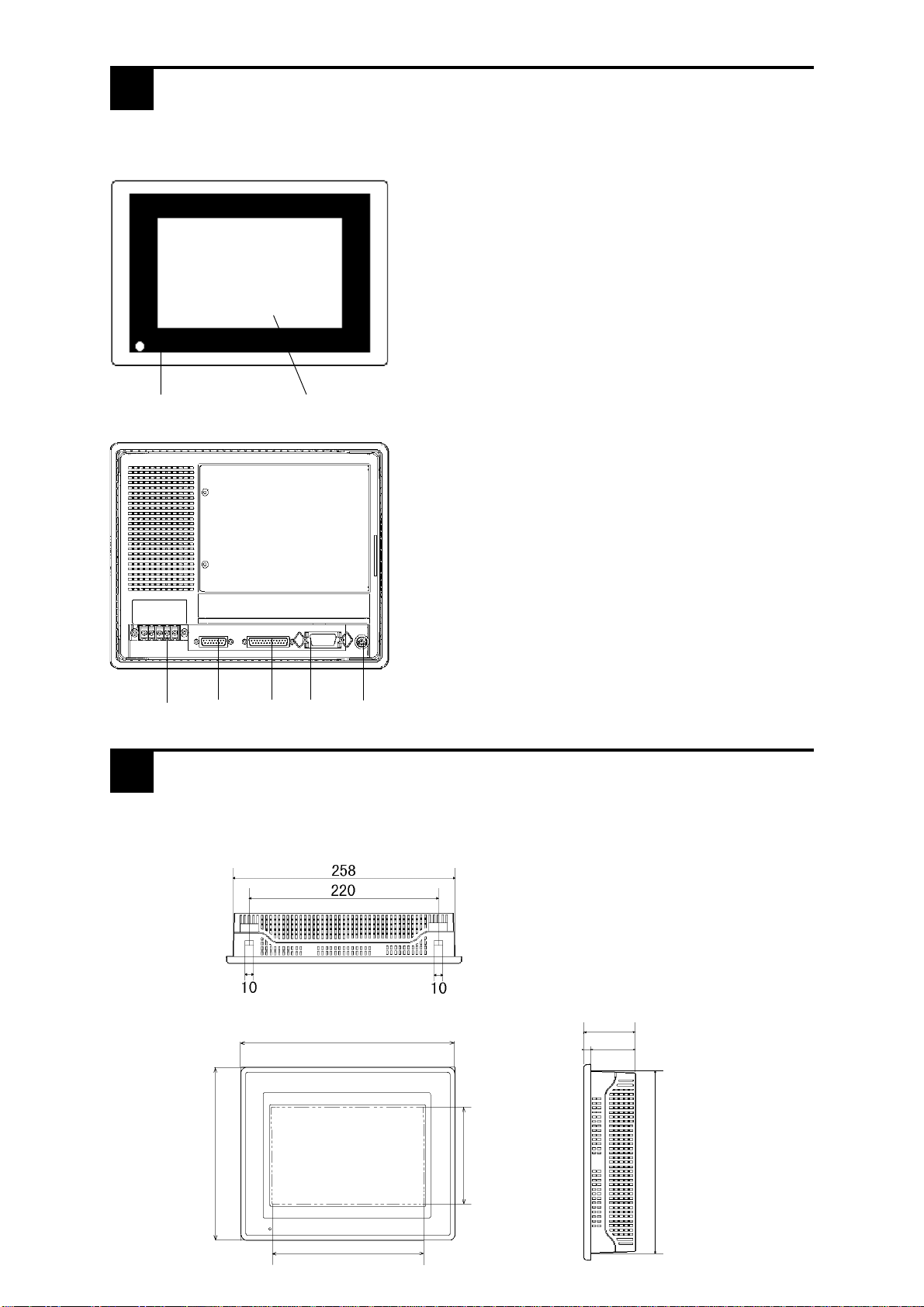

Names and Functions of GP Parts are explained below.

A:Display

The monitor screen that indicates screens and data

of the host.

High intensity EL display

B:Touch Panel

Runs any screen change operations and sends data

to the PLC.

C:Power Lamp

Lights up when the power is turned On.

(Green LED)

D:Power Input Terminal Block

The input and ground terminals for AC power

cable.

E:Auxiliary Input/Output(AUX)

Operates the Touch Switch, System Alarm,

Buzzer, Run outputs, and Remote Reset inputs.

F:Serial Interface

RS-232C, RS-422 (Serial) interface. Connect to

the Host.

G:Printer Interface

Connect the printer here.

H:Tool Connector

Connect the Downloading Cable, or a Bar Code

Reader here.

D FE G H

A,BC

unit:mm TopView

56.5

200

7.5

SideView

1Names and Functions of GP Parts

The drawings below illustrate the dimensions of the GP477R-EG41-24VP unit.

2Dimensions

192

49

FrontView

274

216

120

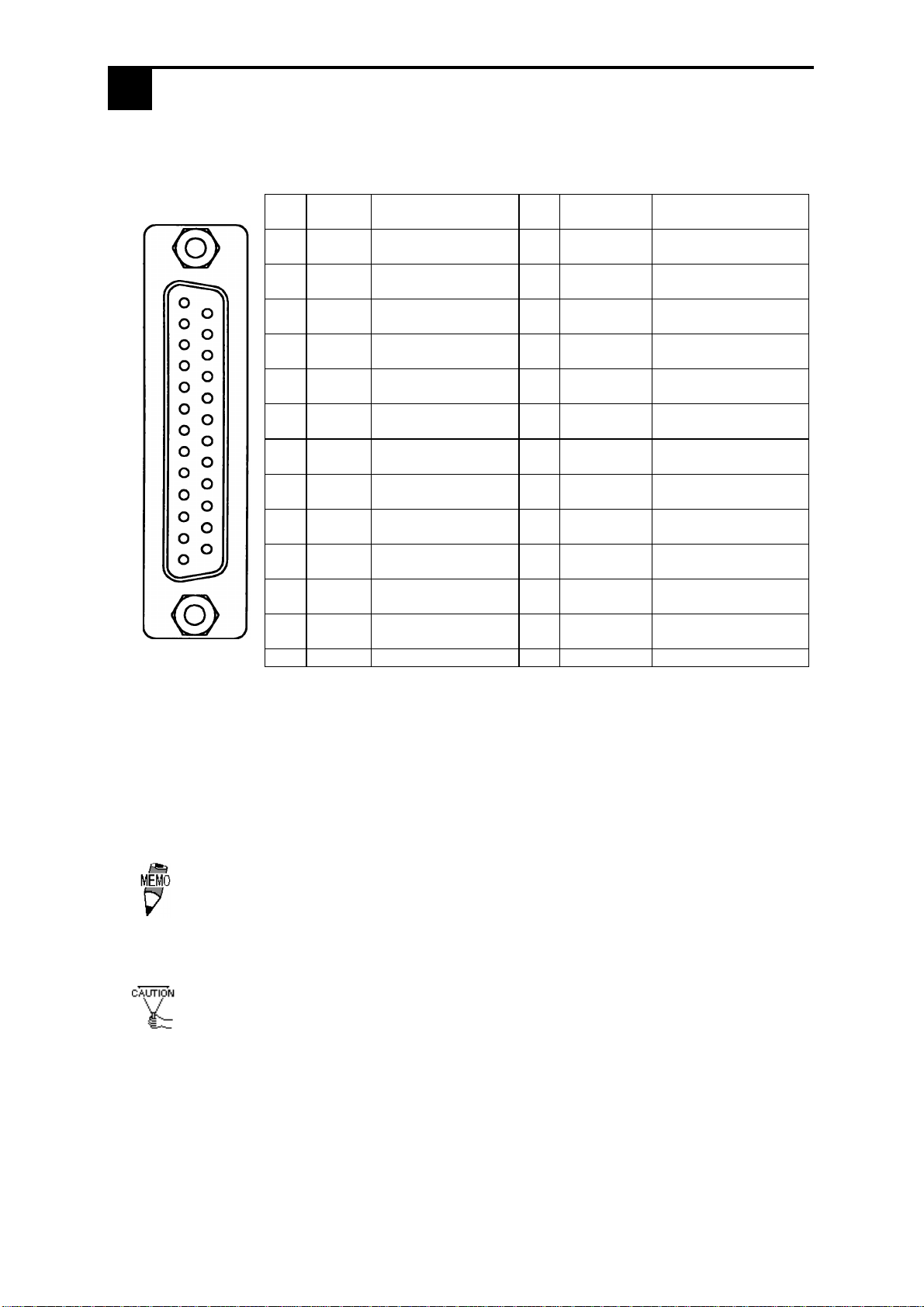

This is GP’s serial port for RS-232C and RS-422 interface. Connect GP’s host here.

3Serial Interface

* Pin # 14 can be used for the power supply for the user's optional equipment con-

nected to the GP.

RecommendedConnector: Dsub25pinplug XM2A-2501 <madebyOMRONCorp.>

RecommendedCover: Dsub25pinCover XM2S-2511 <madebyOMRONCorp.>

JackScrew XM2Z-0071 <madebyOMRONCorp.>

• Use rough metric type M2.6 x 0.45p threads used to hold the cable’s set

(fastening) screws in place.

RecommendedCable: CO-MA-VV-SB5Px28AWG<madebyHITACHICableLtd.>

•Pin # 14 is not protected, so be sure to use it only within its rated range.

•Be sure to connect this unit's SG terminal to the other unit's SG terminal. If

necessary, you may also need to connect the FG terminal to the other unit's

FG terminal depending on the type of the other unit you use.

Pin

#

Signal

Name

Condition

Pin

#

Signal

Name

Condition

1

FG

Frame ground

14

VCC

5V

±

5% output

0.25A *

2

SD

Send data

(RS-232C)

15

SDB

Send data B

(RS-422)

3

RD

Receive data

(RS-232C)

16

RDB

Receive data B

(RS-422)

4

RS

Request send

(RS-232C)

17

NC

No connection

5

CS

Clear send

(RS-232C)

18

CSB

Clear send B

(RS-422)

6

NC

No connection

19

ERB

Enable receive B

(RS-422)

7

GND

Signal ground

20

ER

Enable receive

(RS-232C)

8

CD

Carrier detect

(RS-232C)

21

CSA

Clear send A

(RS-422)

9

TRMX

Termination

(RS-422)

22

ERA

Enable receive A

(RS-422)

10

RDA

Receive data A

(RS-422)

23

RESERVED

Reserved for future

use

11

SDA

Send data A

(RS-422)

24

NC

No connection

12

NC

No connection

25

RESERVED

Reserved for future

use

13

NC

No connection

1

13

14

25

This is the printer interface port in the rear side of GP unit.

*1 When not using the INIT signal, the 10 pin connection becomes

unnecessary.

RecommendedConnector: FCN-787P014-G/R <manufacturedbyFUJITSU,Inc.>

RecommendedCover: FCN-780C014-D/E <manufacturedbyFUJITSU,Inc.>

•Do not connect to pin #12 and #13.

4Printer Interface

7

14

1

8

Pin Connection Pin # Signal

Name

1

PSTB

2

PDB0

3

PDB1

4

PDB2

5

PDB3

6

PDB4

7

PDB5

8

PDB6

9

PDB7

10

*1

INIT

11

BUSY

12

NC

13

NC

14

GND

When making a cable, please be aware of the following:

<For RS-422 Connection>

•The following pairs of pin #’s must be connected to each other

...#18 (CSB) <-> #19 (ERB)

...#21 (CSA) <-> #22 (ERA)

•When connecting the RS-422 cable and the #9 (TRMX) and #10 (RDA)

points, a termination resistance of 100Ωis added between RDA and

RDB.

•When the GP is set as a Memory Link type and the cable type is RS-422,

a 4-line system must be setup.

<For RS-232C connection>

•Do not connect #9 (TRMX), #10 (RDA), #11 (SDA), #15 (SDB), #16

(RDB), #18 (CSB), #19 (ERB), #21 (CSA), and #22 (ERA).

An auxiliary interface for touch switch output, system alarm output, RUN output,

and remote reset input.

*1 The AUX Alarm outputs in the following two cases:

•HardwareAlarm(SCREENMEMORYCHECKSUMERROR)

•Software Alarm (SYSTEM ERROR, incorrect data that makes continuation

of screen operation impossible.)

RecommendedConnector: Dsub 15pinPlug XM2A-1501 <madebyOMRONCorp.>

RecommendedCover: Dsub15pinCover XM2S-1511 <madebyOMRONCorp.>

JackScrew XM2Z-0071 <madebyOMRONCorp.>

•Use rough metric type M2.6 x 0.45p threads used to hold the cable’s set

(fastening) screws in place.

5AUX Interface (Input/Output)

Pin Connection Pin # Signal

Name Contents

1TSW0

2TSW1

3TSW2

4TSW3

5TSW4

6TSW5

7TSW6

8TSW7

Touch Switch Output

(8 bit)

9 RUN Output: On in RUN mode;

Off in standby mode or

when the power is off.

10 ALARM Alarm Output: When On,

GP unit alarm origin *1

11 BUZZ Buzzer Output

12 DC24V Output-Common (DC24V)

13 AIN-C Input-Common (DC24V)

14 AOUT-C Output-Common (GND)

15 RESET Reset Input

1

8

9

15

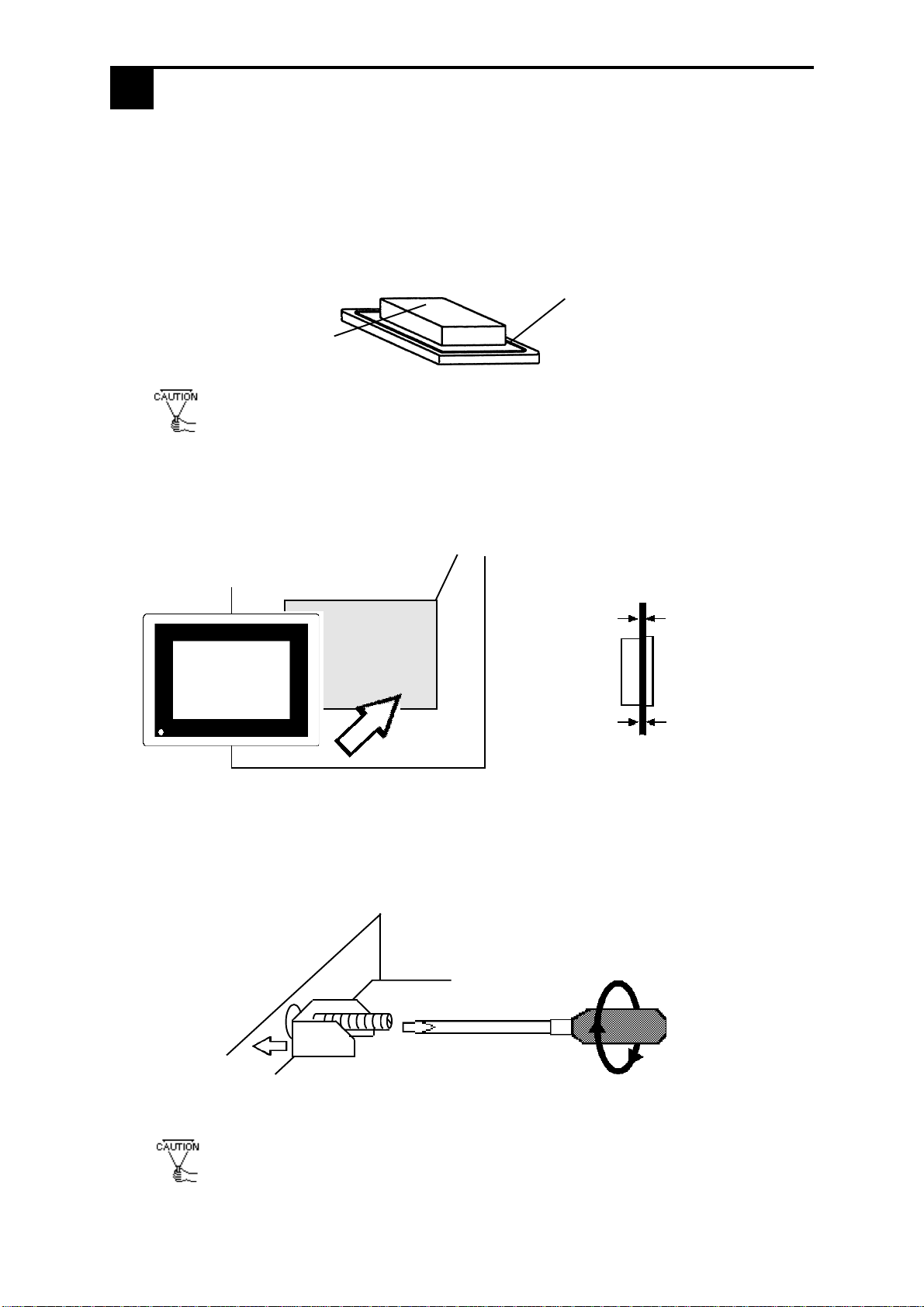

6Installation

259

under 4-R2

201

1.6mmto10mm

Panelthickness

Unit:mm

Cut a hole, and mount the GP to the panel from the front.

Attach the Installation Fasteners from behind.

Fasten the screw of the installation fasteners with a screwdriver.

The fastening torque necessary for waterproofing is 0.5-0.6N•m.

•Tightening the screws with too much force can cause a damage.

Panel GPunit

+1

0

+1

0

•Before installing the GP into a cabinet or panel, check that the Installa-

tion gasket is securely attached to the unit.

Confirm the Installation Gasket’s Seating

It is strongly recommended that you use the gasket.

Place the GP on a level surface with the display panel facing downward. Check

that the GP’s installation gasket is seated securely into the gasket’s groove, which

runs around the perimeter of the panel’s frame.

InstallationGasket

Rear face

•When the FG terminal is connected, be sure the wire is grounded. Not

grounding the GP unit will result in excess noise and vibrations.

•Wherever you can, use thick wires (max. 2 mm2) for power terminals,

and provide an extra twist to the wire during connection.

•Please use Ring Terminals with the size described below.

•To avoid a short among the ring terminals when the screws get loosen,

please use ring terminals with a sleeve.

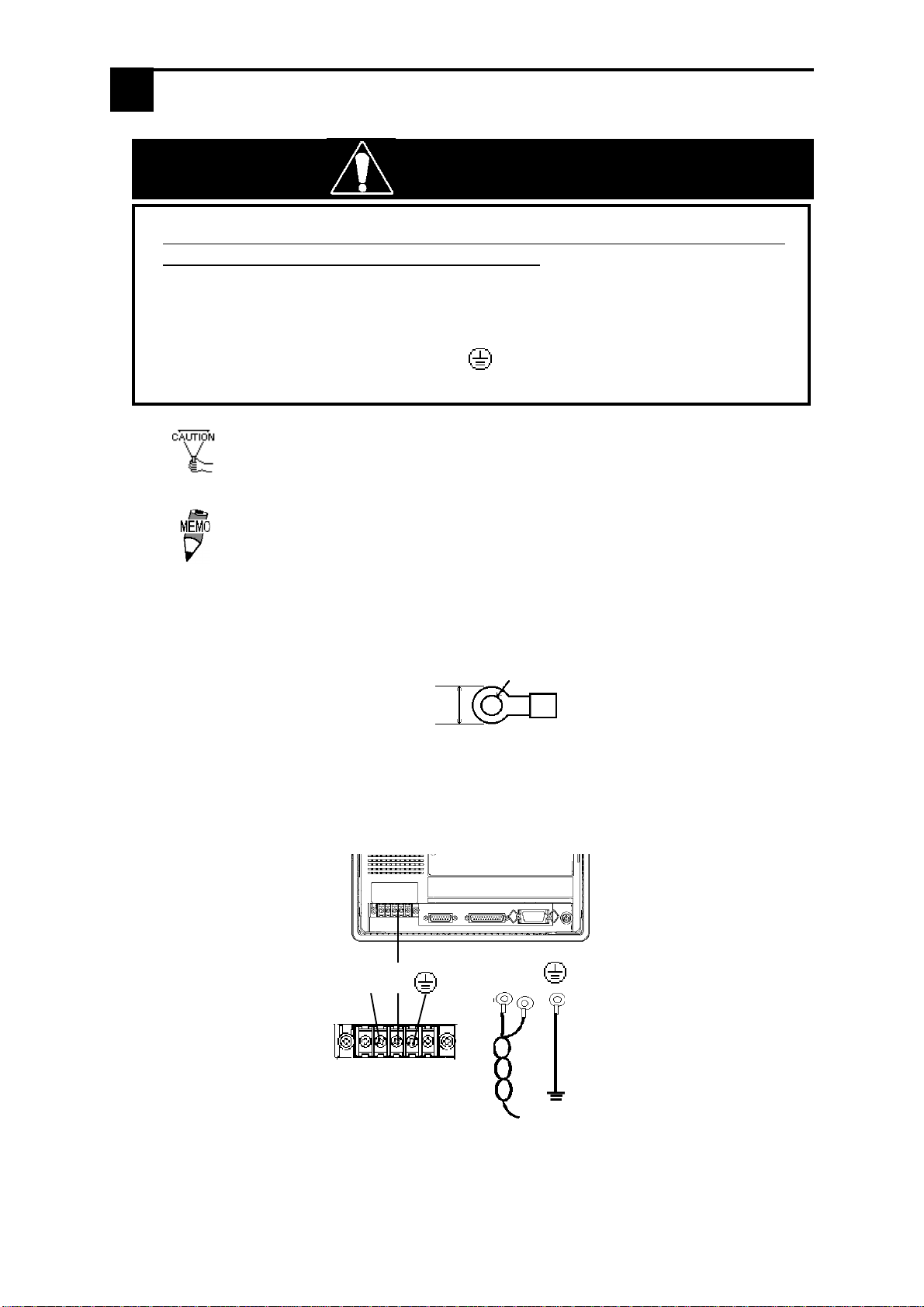

7Wiring

•To avoid electric shock, be sure the Power Cable is unplugged from the power

outlet when connecting the cable to the GP unit.

•GP477R-EG41-24VP can only take DC24V input. If you supply power other

than DC24V, you will damage its power supply and the GP unit.

•There is no power switch on the GP unit, so please use a breaker switch.

•Be sure to earth the ground terminal . If there is an accident, there is the

possibility of an electrical shock from the GP.

Under

6.0mm

Over φ3.2mm

WARNING

*1Ring Terminal to use: V2-MS3 (made by JST)

Rear side

-

++ - Ring Terminals

Power Input

Terminal Block

•From the FG terminal at the rear side of GP unit, please take grounding exclu-

sively [within ground resistance of 100 W].

9Precaution for Grounding

10 Precautions for Input/Output Signal Lines

•Input and Output signal lines must be separated from the power control cables for

operational circuits.

•If this is not possible, use a shielded cable and the shield should be grounded.

Connect the power cable following the steps below.

1. Check to make sure the Power is Off.

2. With a plus screwdriver, remove the cover on the Power Input Terminal Block.

3. Disconnect the screws from the 3 terminals to be used, align the wire rings and

re-insert the screws.

(Please make sure the connection of the wires are correct.)

•The torque necessary for fastening the screws is between 0.5-0.6N•m.

Please pay special attention to the following instructions when connecting the

power cable to the GP unit.

•If the supply voltage exceeds the GP unit range, connect a voltage transformer.

•For between the line and ground, select a power supply that is low in noise. If

there is an excess amount of noise, connect a noise reducing transformer.

•When supplying power to the GP unit, please separate the input/output and opera-

tion unit lines.

•To increase the noise quality, simply twist the power cable before connecting it

to the GP unit.

•The power supply cable must not be bundled or kept close to main circuit lines

(high voltage, high current), or input/output signal lines.

•Connect a surge absorber to deal with power surges.

•To reduce noise, make the power cable as short as possible.

•After turning this unit OFF, be sure to wait a few seconds before turning ON

again. If the unit is started within a few seconds, it may not start up correctly.

8Precautions for Supplying Power

Table of contents