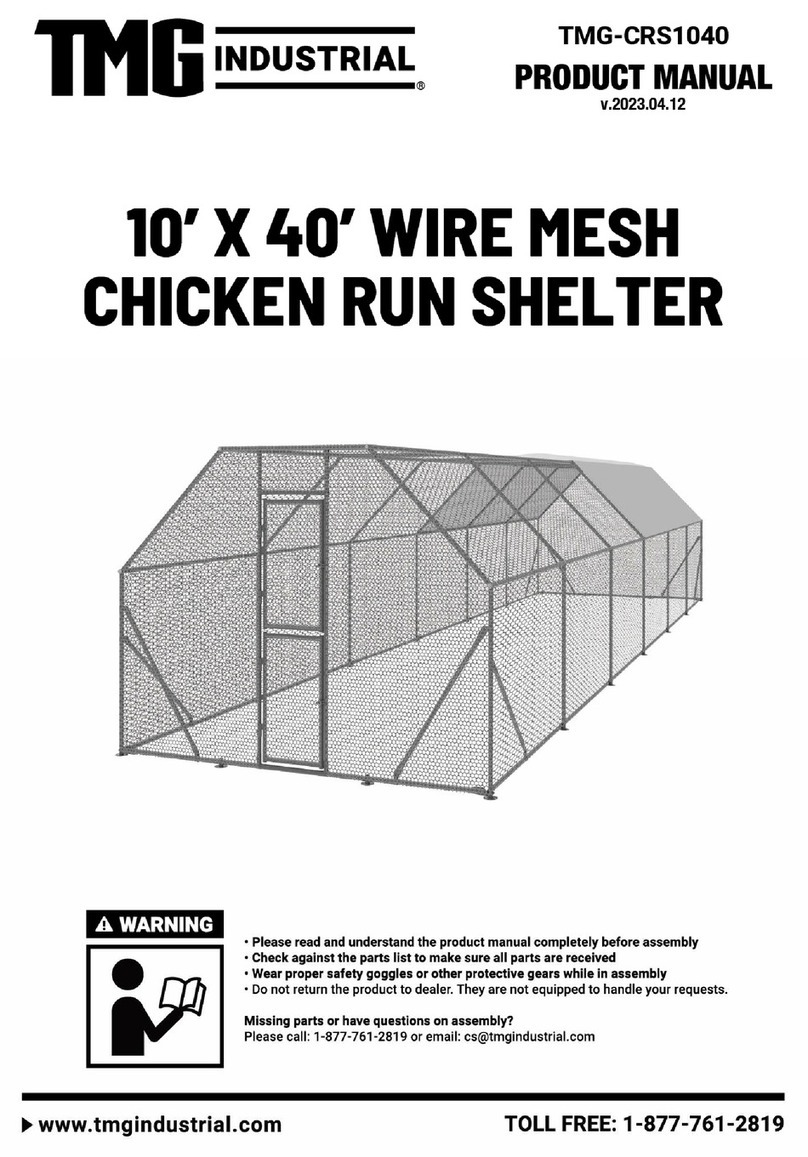

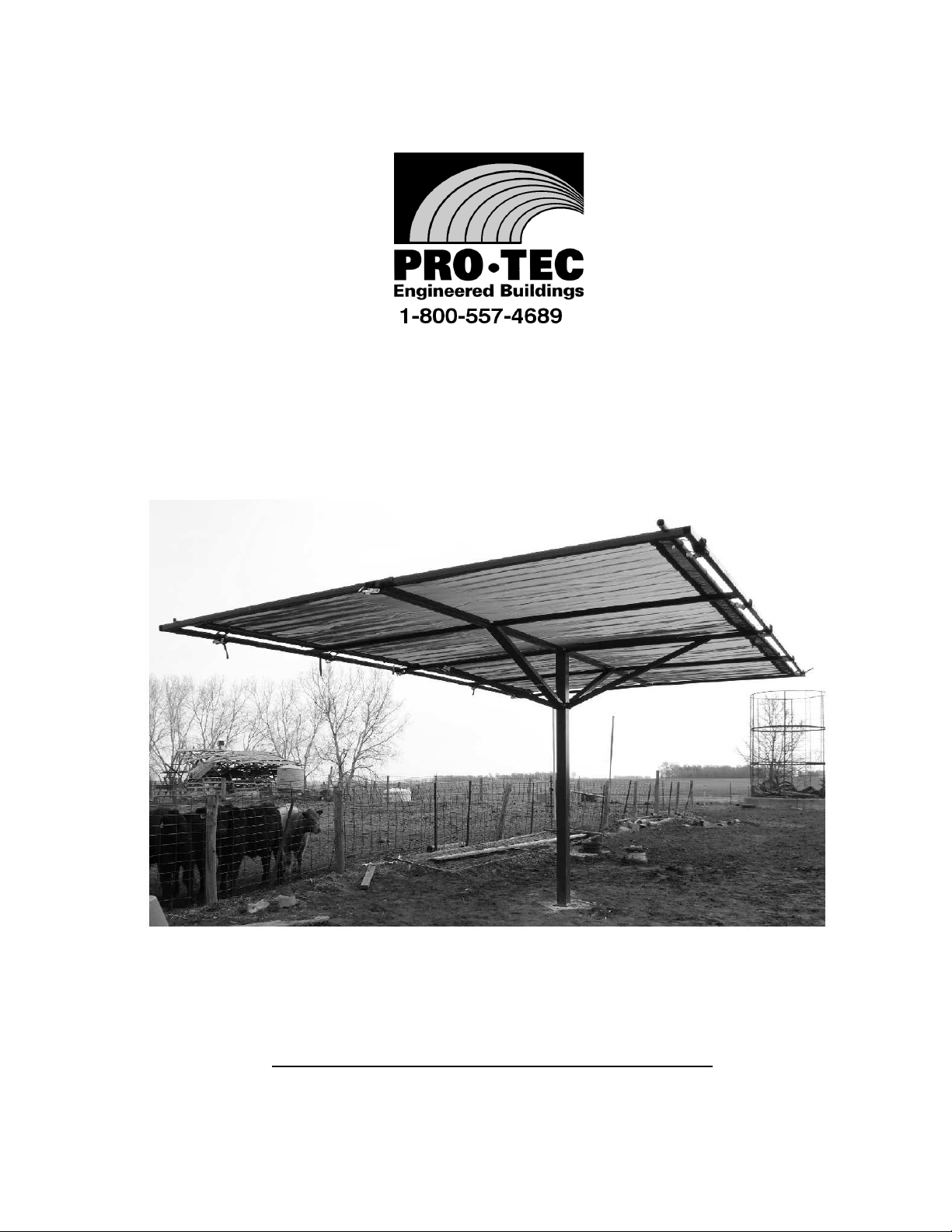

Pro-tec SAFEGUARD LIVESTOCK SHADE SHELTER 16' X 24' User manual

PRO-TEC SAFEGUARD

LIVESTOCK SHADE SHELTER- 16' X 24'

IMPORTANT - TO THE DEALER OR ERECTOR:

RETURN THIS MANUAL TO THE OWNER FOR THEIR FUTURE REFERENCE

SIOUX STEEL COMPANY, P.O. BOX 126 , SIOUX FALLS, SOUTH DAKOTA 7101

1-800-557-4689

MANUAL NO. 197440

KAG 2/27/13

REV A-9/1/17 ECN 17-141

Dear Livestock Shade Owner,

We would like to take this opportunity to thank you for purchasing a SIOUX

STEEL PRO-TEC SAFEGUARD LIVESTOCK SHADE SHELTER. We believe

that it will serve you well for many years. The framework uses quality certified

structural grade steel tubing. All welded assemblies are powder coated to provide

maximum corrosion protection. We believe in providing QUALITY, RELIABILITY,

DURABILITY, VERSATILITY, and COMMITMENT to meet the needs of our

customer. Should you have any questions or comments during or following the

installation, please feel free to call your SIOUX STEEL PRO-TEC dealer or

manufacturer. We will be glad to assist you in any way we can.

IMPORTANT

Improper Site Preparation, Assembly, and Maintenance may invalidate warranty

and cause unnecessary and costly mistakes.

READ MANUAL FIRST

If you have any questions, contact your local dealer or Call:

Sioux Steel Co. at 1-800-557-4689

1

TABLE OF CONTENTS

SAFETY PAGE 3

GENERAL INFORMATION PAGE 4

COMPONENTS PAGE 5-6

TOOLS & EQUIPMENT PAGE 7

FOUNDATION PAGE 8

FRAME ASSEMBLY PAGE 9-12

SHADE INSTALLATION PAGE 13-14

MAINTENANCE SCHEDULE PAGE 15

WARRANTY STATEMENTS PAGE 16

2

SAFETY

Watch for this symbol. It points out important safety

precautions. It means “Attention – Be Alert!”

DEFINITIONS:

CAUTION: Indicates a hazardous situation, which, if not avoided, could result in

minor or moderate injury.

WARNING: Indicates a hazardous situation, which, if not avoided, could result

in death or serious injury.

DANGER: Indicates a hazardous situation, which, if not avoided, will result in

death or serious injury.

When assembling livestock shade:

Use appropriate safety practices during assembly of shade. Hard hats are

recommended to prevent injury to head. Gloves and other heavy clothing are

recommended to prevent cuts and abrasions to hands and other body parts.

Beware of all pinch points when assembling shade components. Appropriate

erection equipment and proper training in the operation of this equipment, are

important factors for the safe erection of shade. Reading, understanding, and

following the instructions in this book are also very important for the safe

assembly of this building. Sioux Steel Company includes all reasonable means

for accident prevention, except a safe and careful operator.

If any decals become damaged, detached, or illegible, contact your dealer or

Sioux Steel Company at (800)-557-4689 for free replacements.

After livestock shade is complete:

To ensure shade remains safe, follow the maintenance schedule found at the

end of this manual.

If livestock shade is damaged:

If damage to shade occurs, access in or around shade should be restricted to

inspection only. Immediately contact your dealer or Sioux Steel Warranty

Department at (800) 557-4689. Repair of damages should be implemented as

soon as practical, with appropriate PRO-TEC replacement parts.

3

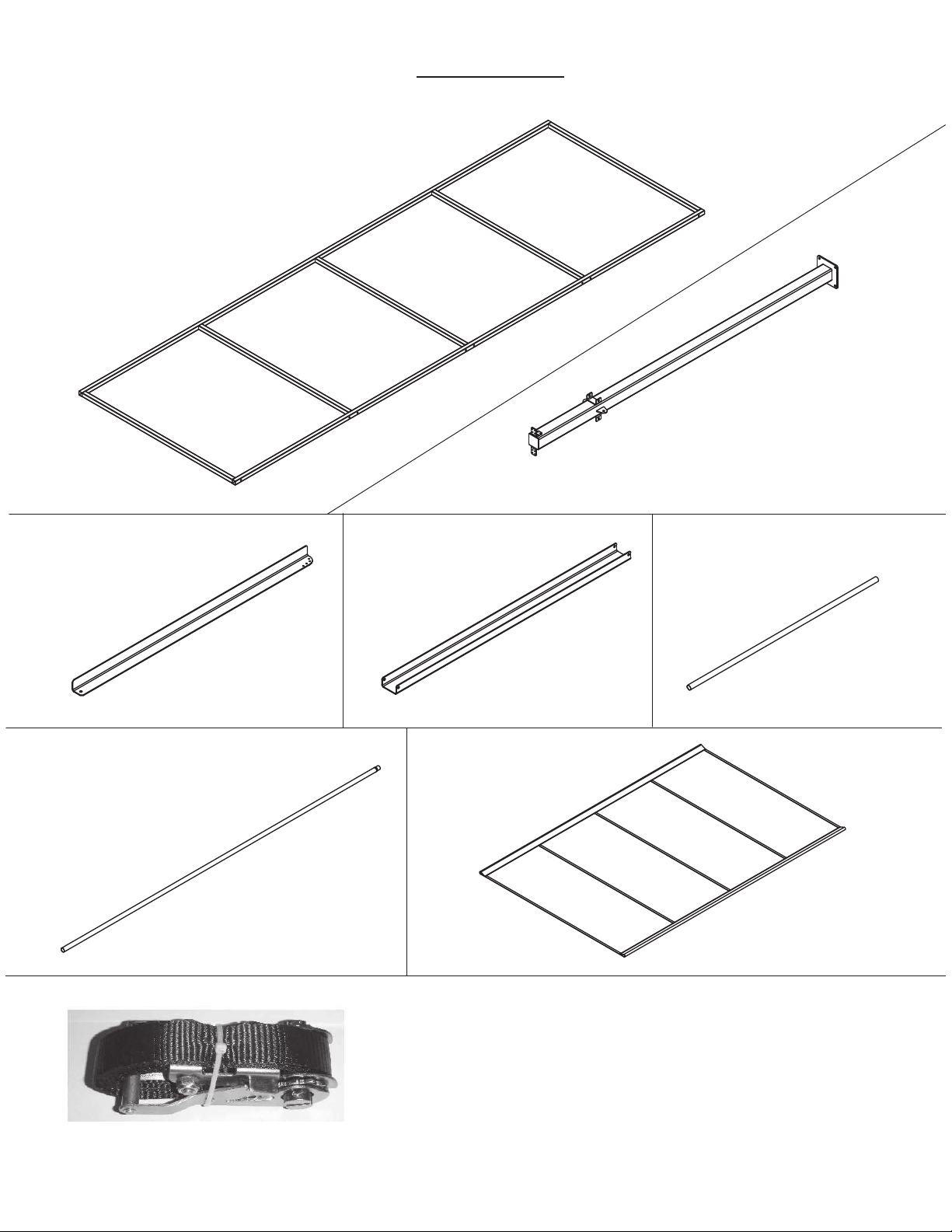

S185800A

COLUMN WLDT- 10FT

OR

S199082

COLUMN WLDT- 15FT

QTY 1

S185801

CHANNEL- BRACE

QTY- 2

S185798

ANGLE- BRACE

QTY- 2

S197159

TUBE- 2" DIA X 96"

QTY- 2

S185797

FRAME WLDT

QTY- 2

S196347

PANEL- 16' X 24'

QTY- 1

COMPONENTS

S192144

1" RATCHET W/ 10' STRAP

(1400# RATING)

QTY- 10

S190007

TUBE- 2" X 16' SWAGED

QTY- 2

4

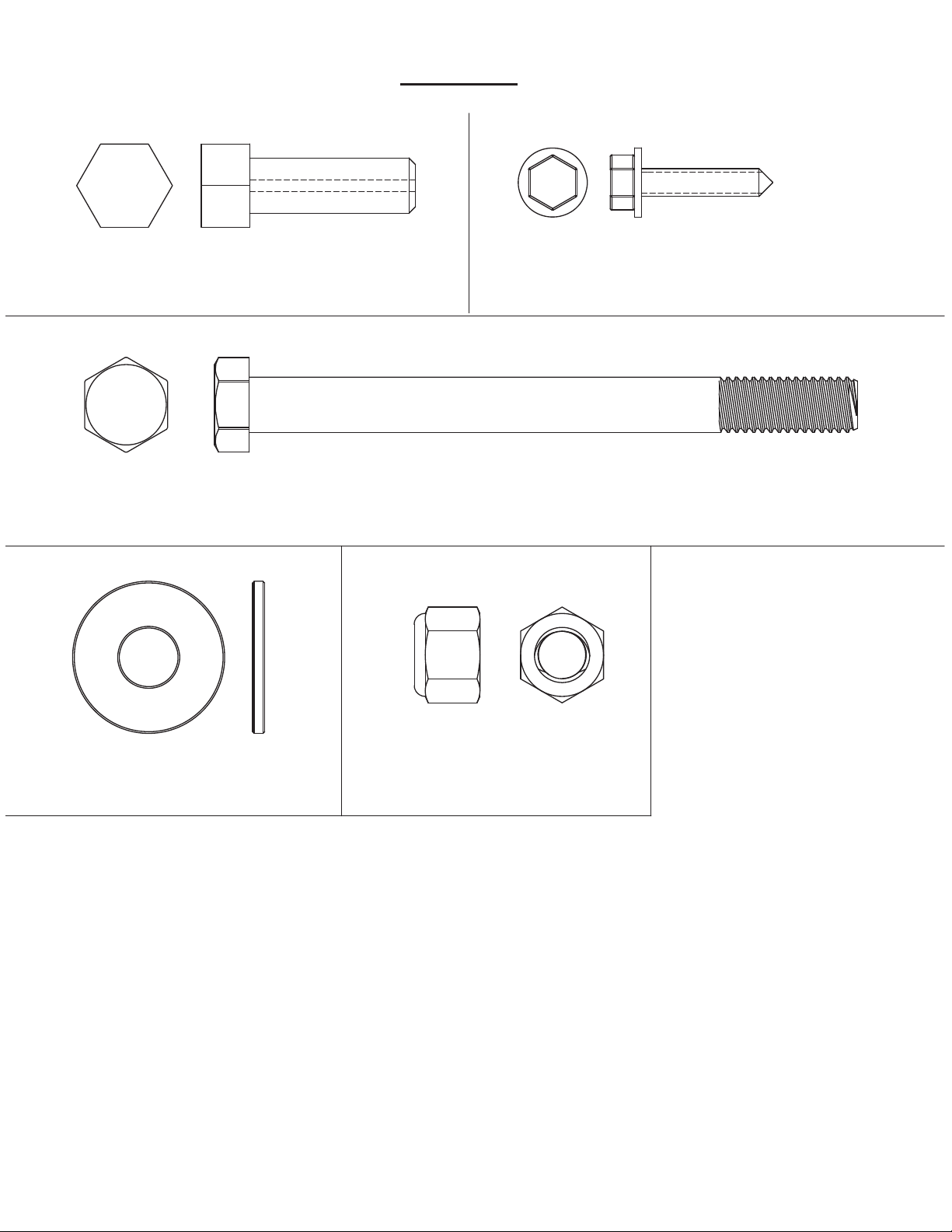

S181886

SCREW- 1/4 X 1 1/4" DRILL

QTY- 25

S154069

WASHER- 1/2" FLAT

QTY- 12

HARDWARE

SCALE 1:1

S189515

NUT- 1/2-13 NYLOCK

QTY- 14

S166164

SCREW- 1/2-13 HHC X 5 1/2"

QTY- 8

S154035

SCREW- 1/2-13 HHC X 1 1/2"

QTY- 6

5

TOOLS AND EQUIPMENT (CUSTOMER SUPPLIED)

Drilling Tools: 3/8” Power Drill (for drill screws)

3/16” drill bit (for pilot drilling drill screws)

Measuring Tools: Tape Measure

4' level

Hand Tools: Drift Pin (for aiding hole alignment)

Socket & Wrench Sizes 3/8” & ¾”

Impact Wrench (pneumatic or electric)

Excavating Tools: Spade Type Shovel

Equipment to dig foundation

Special Tools: Movable Scaffolding, Man Lift, or Ladders

Crane or similar device to safely lift 20 ft’ high

and 700 lbs.

Materials (Customer Supplied):

1/2" washers (4)

1/2" nuts (4)

Anchor bolts, 1/2" thread, 70 ksi min. tensile strength (4)

Duct Tape

Rope or straps to lift assembled frame

BOLT INSTALLATION

Bolts should be installed to a snug-tight condition, which is defined as: the tightness

attained by either a few impacts of an impact wrench or the full effort of a worker with a

wrench that brings the connected plates in to firm contact.

6

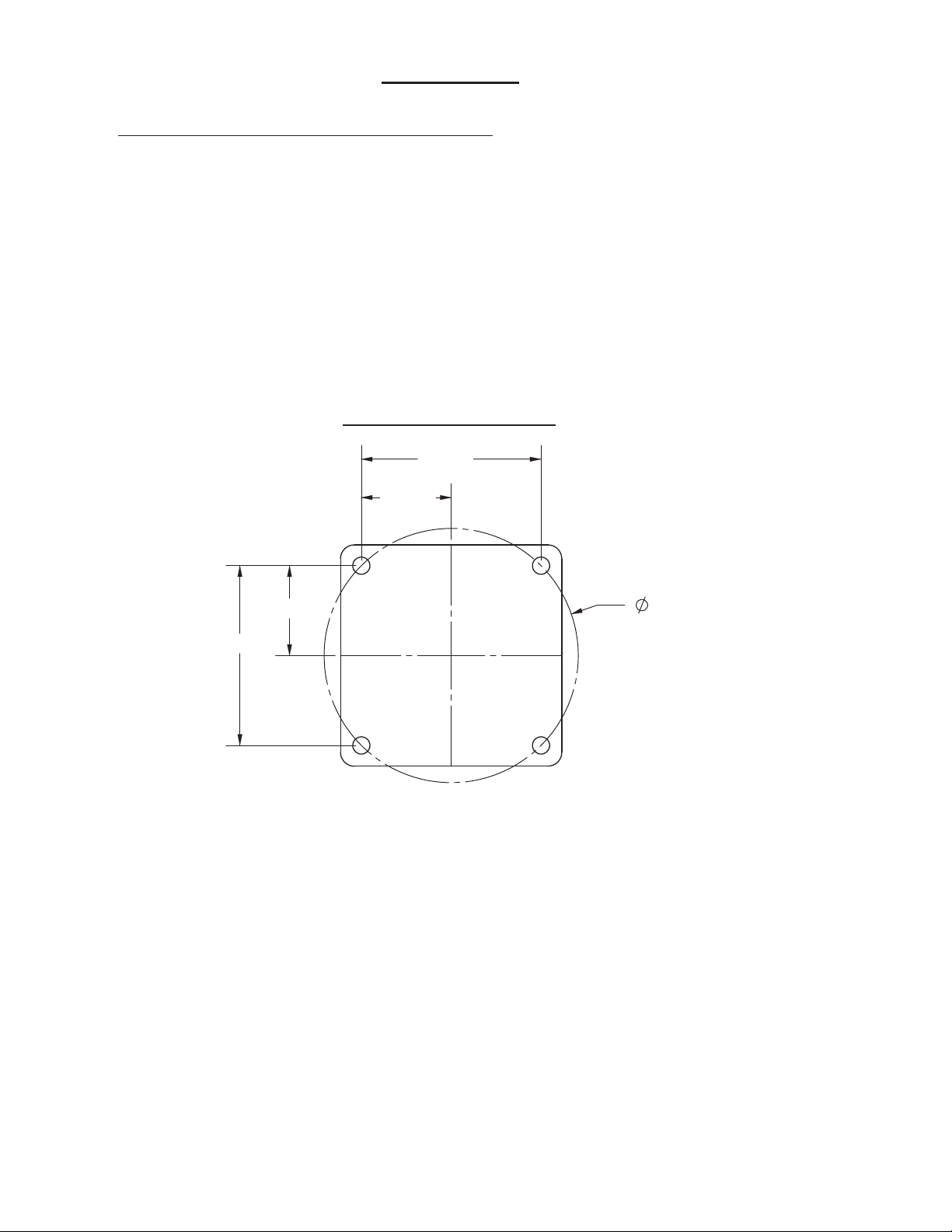

3.250

9.192

3.250

6.500

6.500

FOUNDATION

ANCHOR LAYOUT PATTERN

CONCRETE FOUNDATION RECOMMENDATIONS

- SHELTER SHOULD BE INSTALLED IN COMPACTED SOIL WITH A BEARING

CAPACITY OF 3000PSF.

- POST REQUIRES A 2' DIAMETER DRILLED PIER X 5' DEEP.

- FOUR 1/2" DIAMETER HEADED STUD ANCHORS MUST BE EMBEDDED 8"

WITH 2" EXPOSED ABOVE CONCRETE.

- INSTALL SIX #3 VERTICAL REBAR EVENLY FOR TEMPERATURE & SHRINKAGE.

- INDIVIDUAL FOUNDATIONS SHOULD BE APPROVED BY A FOUNDATION

ENGINEER FOR STRENGTH & SOIL CONDITIONS.

7

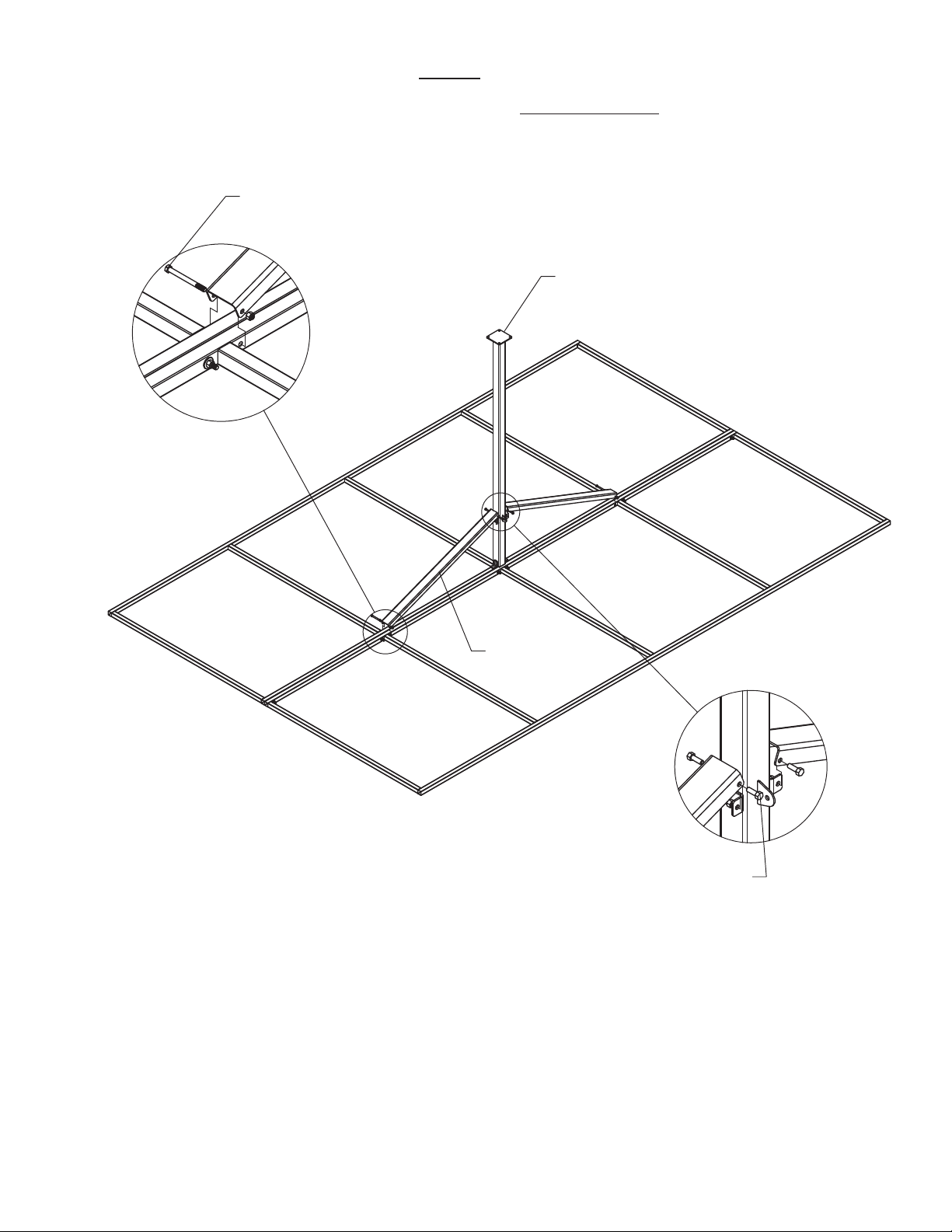

STEP 1

1.1 PLACE FRAME WELDMENTS (2) ON FLAT LEVEL SURFACE WITH DRILLED HOLES IN

THE CENTER.

1.2 BOLT FRAMES TOGETHER AS SHOWN IN ABOVE DIAGRAM. UTILIZE 1/2" X 5 1/2"

SCREW (6), 1/2" WASHER (12), AND 1/2" NYLOCK NUT (6).

BILL OF MATERIAL

S185797 (2)- FRAME WLDT

S166164 (6)- SCREW- 1/2-13 HHC X 5 1/2"

S154069 (12)- WASHER- 1/2" FLAT

S189515 (6)- NUT- 1/2-13 NYLOCK

* NOTE PLACES THAT DO NOT

HAVE SCREW INSTALLED

*

*

(1) S166164

(2) S154069

(1) S189515

8

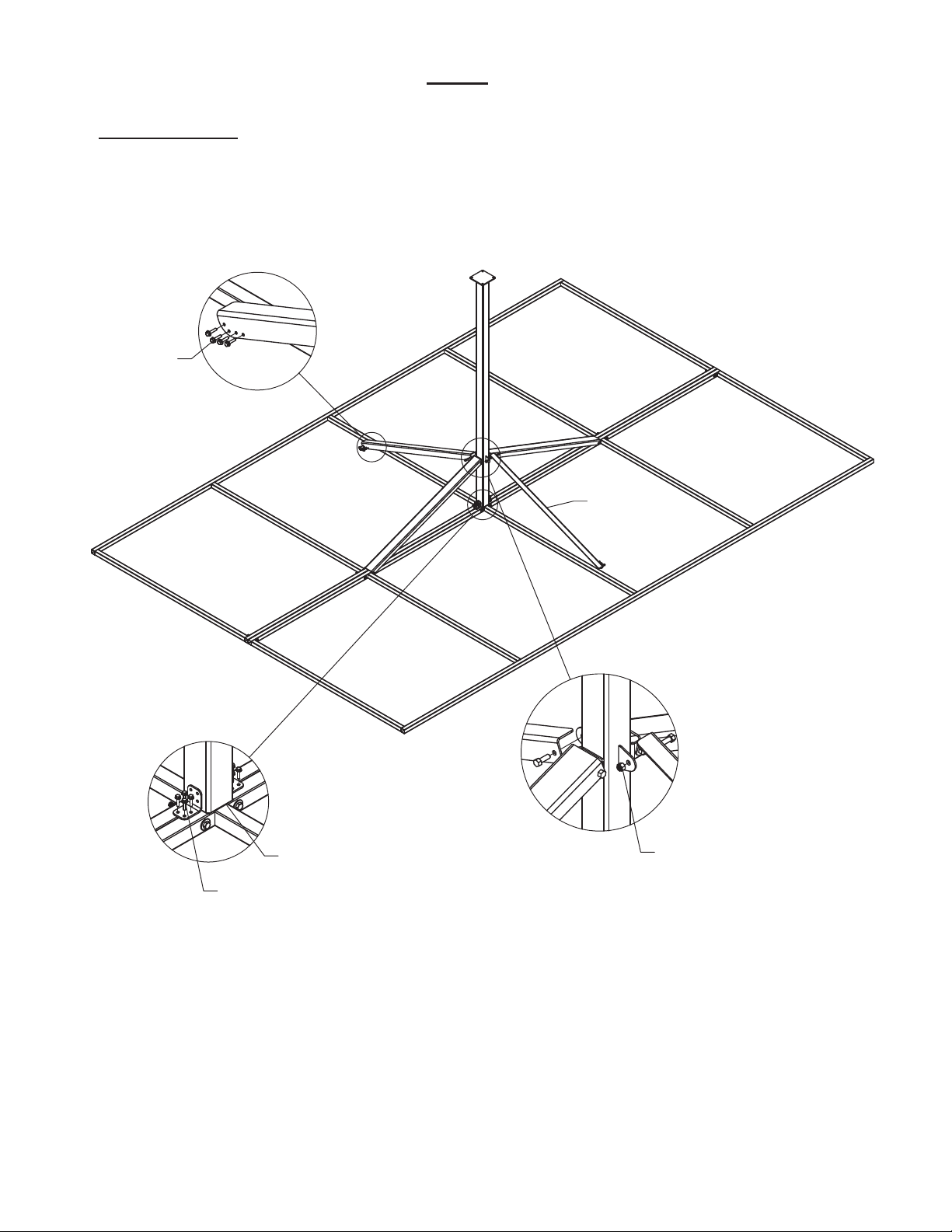

BILL OF MATERIAL

(1) S185800A- COLUMN WLDT- 10FT

OR S199082- COLUMN WLDT- 15FT

(2) S185801- CHANNEL- BRACE

(2) S166164- SCREW- 1/2-13 HHC X 5 1/2"

(4) S154035- SCREW- 1/2-13 HHC X 1 1/2"

(6) S189515- NUT- 1/2-13 NYLOCK

2.1 POSITION CENTER COLUMN IN MIDDLE OF FRAME ASSEMBLY AS SHOWN IN DIAGRAM.

2.2 ATTACH CHANNEL BRACE (2) TO FRAME ASSEMBLY AND CENTER COLUMN. UTILIZE

1/2" X 1 1/2" SCREW (4), 1/2" X 5 1/2" SCREW (2), 1/2" NYLOCK NUT (6).VERIFY CENTER

COLUMN IS PERPENDICULAR TO FRAME.

(1) S185801

STEP 2

(1) S185800A OR S199082

(1) S154035

(1) S189515

(1) S166164

(1) S189515

9

(4) S181886

STEP 3

BILL OF MATERIAL

(2) S185798- ANGLE- BRACE

(2) S154035- 1/2-13 HHC X 1 1/2"

(2) S189515- NUT- 1/2-13 NYLOCK

(16) S181886- SCREW- 1/4" X 1 1/4" DRILL

3.1 ATTACH ANGLE BRACE (2) TO CENTER COLUMN AND FRAME ASSEMBLY. UTILIZE 1/2" X

1 1/2" SCREW (2), 1/2" NYLOCK NUT (2), AND 1/4" DRILL SCREWS (16).

3.2 FINISH SECURING TOP BASE OF CENTER COLUMN TO FRAME ASSEMBLY. UTILIZE

1/4" DRILL SCREWS (8).

(4) S181886

TOP

BASE

(1) S154035

(1) S189515

(1) S185798

10

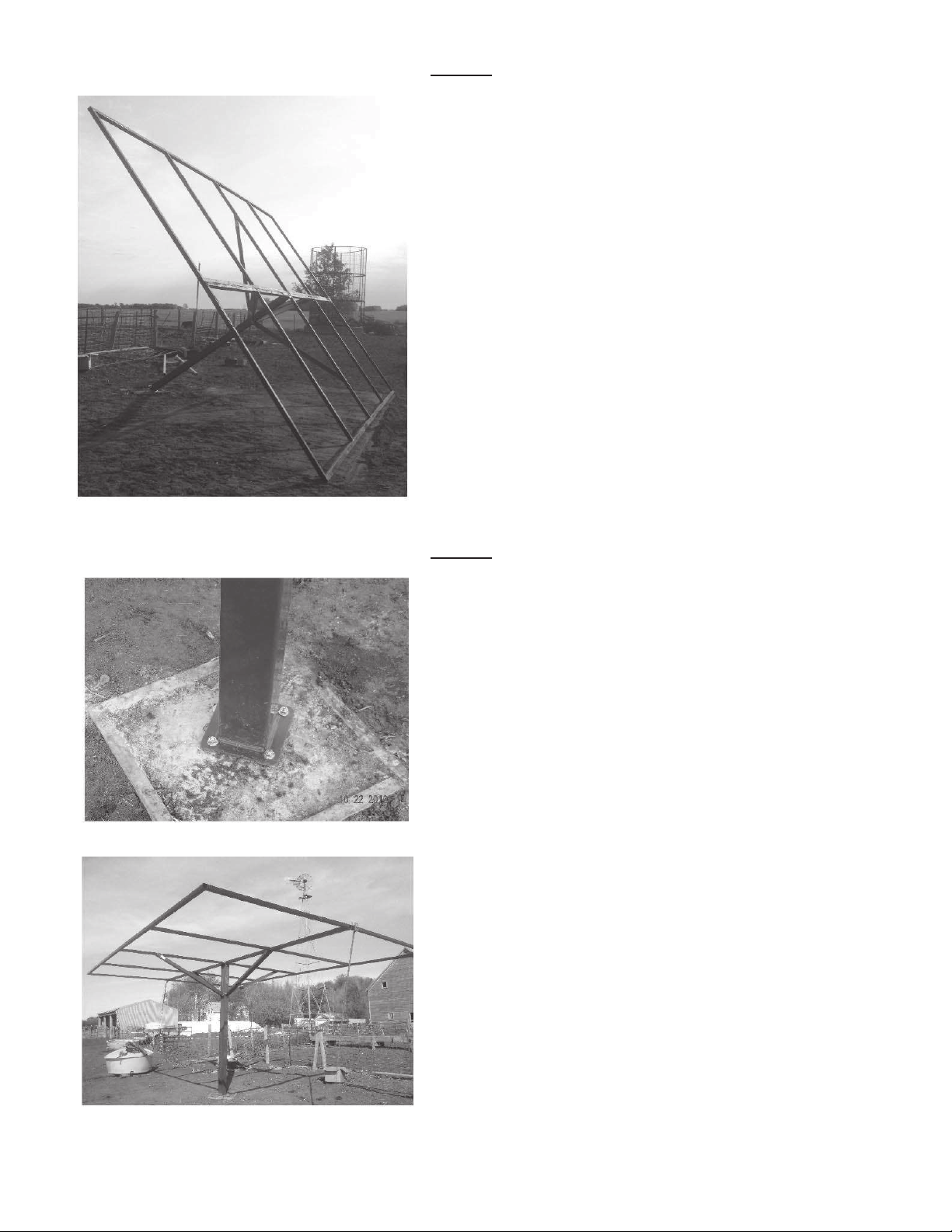

5.1 USING A CRANE OR OTHER SIMILAR DEVICE,

CAREFULLY LIFT FRAME ASSEMBLY INTO PLACE

ALIGNING BOLT PATTERN OF THE COLUMN BASE

PLATE WITH PIER FOUNDATION ANCHORS.

5.2 SECURE BASE PLATE OF COLUMN TO ANCHORS.

UTILIZE CUSTOMER SUPPLIED 1/2" NUTS (4) AND

1/2" WASHERS (4)

STEP 4

4.1 CAREFULLY TIP THE FRAME ASSEMBLY AS

SHOWN IN PHOTO.

4.2 ALIGN END OF COLUMN WITH PIER

FOUNDATION ANCHORS.

STEP 5

11

STEP 6

STEP 7

BILL OF MATERIAL

(2) S190007- TUBE- 2" X 16' SWAGED

(2) S197159- TUBE- 2" DIA X 96"

(4) S181886- SCREW- 1/4" X 1 1/4" DRILL

TUBE ASSY

S196347

POCKET

(4) S181886- SCREW- 1/4 X 1/14" DRILL

(1) S196347- PANEL- 16' X 24'

TUBE ASSY

BILL OF MATERIAL

POCKET

ROLL DIRECTION

STEP 7.1 UNFOLD PANEL ONTO GROUND. ENSURE THERE ARE NO ROUGH OR JAGGED OBJECTS

THAT MAY DAMAGE THE PANEL.

STEP 7.2 INSERT TUBE ASSEMBLIES INTO POCKETS FOUND ON ENDS OF PANEL.

STEP 7.3 INSTALL 1/4" DRILL SCREWS ON ENDS OF TUBE ASSEMBLIES.

STEP 7.4 STARTING AT ONE END OF PANEL, ROLL PANEL UP UTILIZING THE TUBE.

(2) S181886

(1) S197159

(1) S190007

STEP 6.1 ASSEMBLE 2" TUBES AS SHOWN ABOVE AND

SECURE SWAGE CONNECTION WITH 1/4" DRILL

SCREWS (2).

STEP 6.2 WRAP SPLICE WITH DUCT TAPE.

STEP 6.3 REPEAT FOR OTHER SET OF TUBES.

(1) S181886

12

STEP 8.1 USING A MAN LIFT OR LADDERS, PLACE ROLLED UP PANEL ON TOP OF FRAME ASSEMBLY.

STEP 8.2 USING (5) S192144 AT NOTCH POCKET LOCATIONS, WRAP STRAP AROUND TUBE & FRAME,

FEED THRU RATCHET, AND SLIGHTLY TIGHTEN.

STEP 8.3 UNROLL PANEL OVER TOP OF FRAME.

STEP 8.4 SECURE OTHER SIDE OF PANEL USING (5) S192144 AT NOTCH POCKET LOCATIONS, BY

WRAPPING STRAP AROUND TUBE & FRAME, FEED THRU RATCHET, AND SLIGHTLY TIGHTEN.

STEP 8.5 TIGHTEN RATCHETS EQUALLY ON BOTH SIDES OF PANEL, UNTIL PANEL IS TAUT. WHEN

TIGHTENING RATCHETS MAKE SURE PANEL IS SQUARE AND CENTERED ON FRAME.

STEP 8.6 WRAP EXCESS STRAP FROM RATCHETS AROUND FRAME.

STEP 8

13

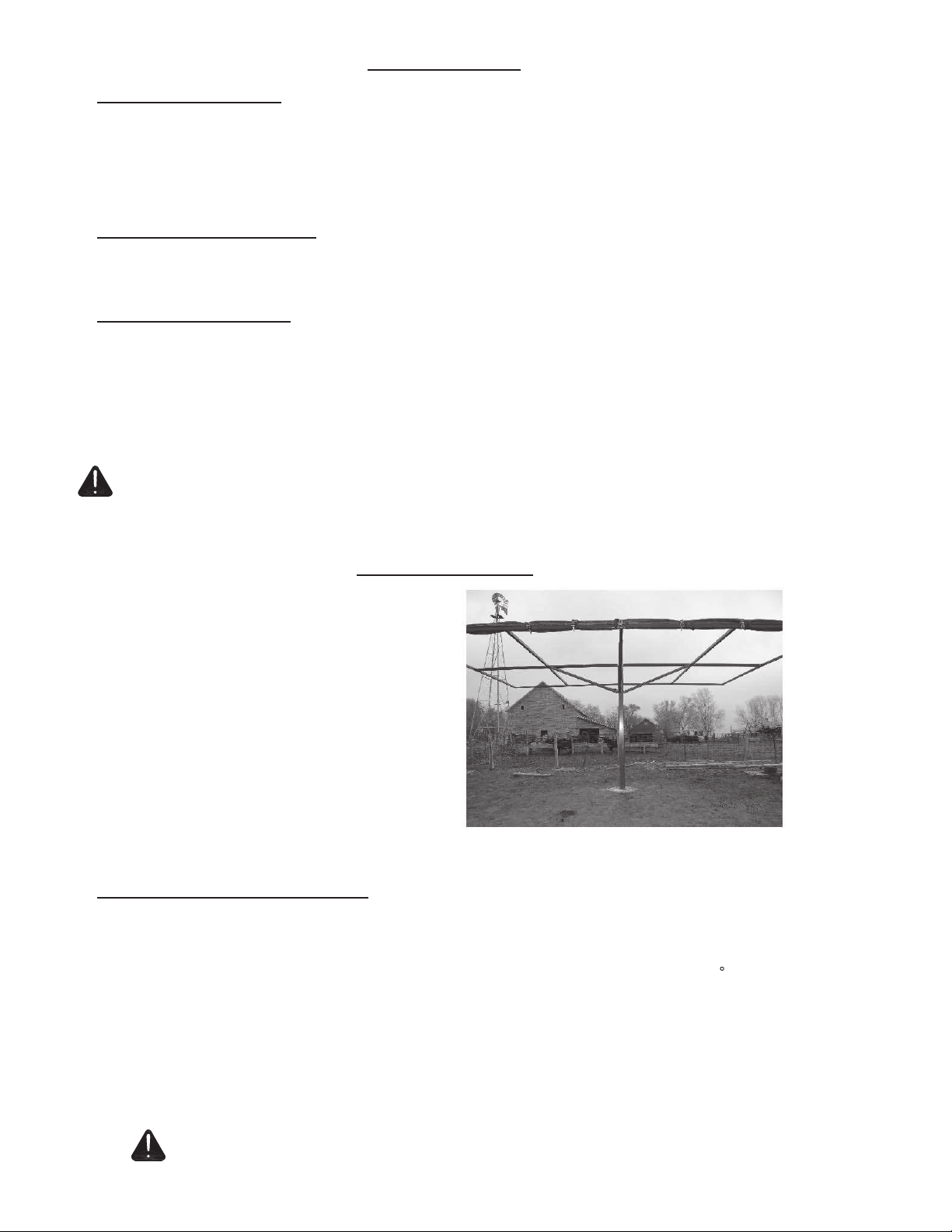

WILL RECEIVE MEASURABLE SNOW

PRIOR TO THE WINTER SEASON. THIS

IT IS RECOMMENDED THAT THE SHADE

IN WARM WEATHER. CHECK TIGHTNESS ON PANELS INSTALLED IN COOLER WEATHER AN THE

NOTE: PANELS INSTALLED IN COOLER WEATHER MAY RELAX MORE THAT PANELS INSTALLED

FIRST AVAILABLE SUNNY DAY AND ADJUST CABLES AS NECESSARY. SEVERE WEATHER CON-

MAINTENANCE

NOTE: FAILURE TO CARRY OUT ABOVE STEPS WILL INVALIDATE WARRANTY.

PANEL IS ROLLED UP IN AREAS THAT

DITIONS MAY ALSO AFFECT THE PANEL. CHECK PANEL AFTER SUCH CONDITIONS OCCUR.

WILL ASSIST IN PREVENTING DAMAGE

WINTER STORAGE

TO THE LIVESTOCK SHADE SHELTER.

WARNING: FLAMMABLE MATERIAL

EXPOSURE TO ANY HEAT SOURCE FOR ANY LENGTH OF TIME COULD RESULT IN DAMAGE TO THE

PANEL MATERIAL. EXHAUST GASES, SPACE HEATER, WELDING SPARKS, ETC. SHOULD NOT BE

ALLOWED TO GET NEAR THE PANEL PORTION OF THE SHADE. SIOUX STEEL COMPANY WILL NOT

BE RESPONSIBLE FOR ANY DAMAGES OR LIABILITIES RESULTING FROM FAILURE TO HEED THIS

WARNING. THE PANEL MATERIAL STARTS TO DETERIORATE AT EXPOSURE TO 180 TEMPERATURE

FOR ANY LENGTH OF TIME. PREVENT PROLONGED CONTACT FROM ANY HEAT SOURCE TO INSURE

MAXIMUM PROTECTION TO THIS MATERIAL. FOR FURTHER INFORMATION CONTACT SIOUX STEEL

COMPANY.

ONE WEEK INSPECTION

- THE KEY VISUAL INDICATOR OF ADEQUATE TENSION ON THE PANEL IS TO ENSURE THE PANEL IS

NOT SAGGING BETWEEN FRAMES. CHECK THE RATCHET STRAPS FOR TIGHTNESS AND ADJUST

AS NECESSARY

- PUNCTURES IN THE PANEL CAUSED BY ACCIDENTAL DAMAGE SHOULD BE REPAIRED IMMEDIATELY.

CONTACT YOUR LOCAL SIOUX STEEL PRO-TEC DEALER OR MANUFACTURER FOR SERVICE

INSTALLATION ADJUSTMENT

- THE PANEL ON YOUR LIVESTOCK SHADE MAY RELAX AFTER INSTALLATION. IT IS CRITICAL TO

KEEP THE PANEL TAUT (SNUG) OVER THE FRAME TO PREVENT WEAR AND ENSURE LONG LIFE.

TIGHTEN RATCHETS AS REQUIRED.

ANNUAL MAINTENANCE

- REPEAT 1 WEEK INSPECTION (LISTED ABOVE) A MINIMUM OF (4) TIMES A YEAR.

- CHECK BASE PLATE ANCHOR STUDS AND NUTS TO ASSURE THEY ARE TIGHT.

- CHECK FOR PREMATURE WEAR OF PANEL, ESPECIALLY WHERE TENSION IS APPLIED AND WHERE

THERE IS DIRECT CONTACT WITH THE STEEL FRAME.

14

Revised 07/14/2017

N

EW

P

RODUCT

W

ARRANTY

P

RO

-T

EC

B

UILDINGS

LIMITED

WARRANTY

FOR

NEW

SIOUX

STEEL

COMPANY

PRODUCTS

A. GENERAL PROVISIONS

. “Sioux Steel” means Sioux Steel Company, 196 1/2 East Sixth Street, Sioux Falls, South Dakota 57104. The warranties

described below are provided by Sioux Steel to the original purchasers of new products purchased from Sioux Steel or from an authorized Sioux Steel Dealer

(the “Products”). Under these warranties, Sioux Steel will, at its option, repair or replace at its factory any Product covered under these warranties which is

found to be defective in material and workmanship during the applicable warranty term or refund the purchase price paid for the defective Product. Customer

will be responsible for labor charges for removing the defective Product and reinstalling the repaired or replacement Product, any premium charge for overtime

labor requested of Sioux Steel and shipping charges to and from Sioux Steel’s factory. These warranties are not transferrable.

B. WARRANTY PERIOD

. Subject to exclusions and limitations set forth herein, each new Product is warranted for the number of years specified

below.

Each warranty term begins from the date of purchase regardless of delay in receipt of the Product by Customer due to the time required to process, handle,

ship, assemble, construct and install the Product. Customer must retain proof of the date of purchase. Replacement parts for and repairs to the Product will

be warranted only for the remainder of the original warranty term. The replacement parts for or repairs to the Product will not extend the warranty term beyond

the original warranty term. Products described below include all parts, components and accessories.

PROTEC BUILDINGS

Pro-Tec Poultry Buildings 1 Year

Safeguard Livestock Shade 1 Year

Pro-Tec Single Tube (24’, 30’, and 36’) Buildings 3 Years

All Other Powder-Coated Pro-Tec Buildings in Livestock (other than Poultry) and Chemical Storage Applications 7 Years, Prorated Monthly

All Other Powder-Coated Pro-Tec Buildings Except those in Livestock and Chemical Storage Applications 15 Years, Prorated Monthly

All Other Hot-Dip Galvanized Pro-Tec Buildings 15 Years, Prorated Monthly

Fabricated Tarp Materials (covers)

15 Years, Prorated Monthly

Fabricated Tarp Materials for End Panels (All Pro-Tec Buildings) ; Rollup Sides; Curtains and Doors; Track Doors; Quarter

Panels and Half Moon End Panels ( On all Building Models) 3 Years, Prorated Monthly

Proration credit will be given toward the purchase price for the replacement of fabric and tarp materials, based on Sioux Steel’s current price list at the time the

warranty claim is made. 15 Year Proration Schedule: 7 Year Proration Schedule:

Year 1 = 93% Year 4 – 73% Year 7 – 53% Year 10 = 33% Year 13 = 13% Year 1 = 86% Year 4 = 43% Year 7 = 0%

Year 2 = 87% Year 5 = 67% Year 8 = 47% Year 11 = 27% Year 14 = 7% Year 2 = 72% Year 5 = 29%

Year 3 = 80% Year 6 = 60% Year 9 = 40% year 12 = 20% Year 15 = 0% Year 3 = 58% Year 6 = 15%

Exclusions specific to Pro-Tec Buildings: Damage or loss of any kind from (1) exposure of the fabric cover or end panel material to any heat source for any

length of time; (2) a failure to properly compact and engineer soils; (3) a failure to properly construct footings and foundations; and (4) exposure to conditions

in excess of the design wind and snow load specifications. NOTICE: Caustic and corrosive environments can result from live animal operations or

storage of caustic materials. Sioux Steel reserves the right to exclude from warranty under D(4) if conditions are deemed by it as extreme.

C. ITEMS COVERED SEPARATELY

. The Sioux Steel warranties do not cover any parts, components or materials that are part of the Product, or used in

conjunction with the Product, that are not manufactured by Sioux Steel. Such parts, components and materials will be subject to the warranties provided by

the manufacturer, if any.

D. WHAT IS NOT WARRANTED

.

Sioux Steel does not warrant and is not responsible for the following: (1) used products; (2) modification or alteration of

the Products; (3) Products that have not been properly installed or not installed in accordance with the instruction manual, improper assembly, or improper

construction by any persons other than Sioux Steel employees; (4) depreciation, damage or loss caused by the use of parts, components or accessories not

provided by Sioux Steel, unauthorized repairs, normal wear, lack of necessary and proper maintenance, a failure to follow operating

instructions/recommendations, misuse, lack of proper protection during storage, vandalism or theft, exposure to the elements or corrosive materials, accidents

or acts of nature including lightning, flooding, hail, straight winds and tornadoes; and (5) cosmetic damage or damage that does not hinder the functionality of

the Products.

E. LIMITATIONS OF WARRANTIES AND CUSTOMER’S REMEDIES

. To the extent permitted by law, neither Sioux Steel, the Dealer n

or any person or

company affiliated with either of them makes any warranties, representations, conditions or promises express or implied as to the quality, performance or

freedom from defects of the Products covered by these warranties other than those set forth herein. THERE ARE NO IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER SIOUX STEEL, THE DEALER, NOR ANY PERSON OR COMPANY

AFFILIATED WITH EITHER OF THEM WILL BE LIABLE FOR ANY DAMAGES, INCLUDING, BUT NOT LIMITED TO, INCIDENTAL, SPECIAL,

EXEMPLARY, CONSEQUENTIAL, LOST PROFITS AND REVENUES, LOST USE OF THE PRODUCTS OR ANY OTHER PROPERTY, BODILY INJURY OR

PROPERTY DAMAGE CLAIMS OF ANY PERSON, LOST COMMODITIES, REMOVAL OR STORAGE COSTS FOR THE PRODUCTS, OTHER EQUIPMENT

AND COMMODITIES, DAMAGE TO THE ENVIRONMENT ARISING FROM OR IN ANY MANNER RELATED TO ANY RELEASE OF HAZARDOUS

MATERIALS, AND REMEDIATION EXPENSES THEREFORE, WHETHER BASED ON CONTRACT, TORT, STRICT LIABILITY OR ANY OTHER LEGAL

BASIS, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN NO INSTANCE WILL SIOUX STEEL, THE DEALER OR ANY PERSON OR

COMPANY AFFILIATEDWITH EITHER OF THEM BE LIABLE TO CUSTOMER OR ANY PERSON IN AN AMOUNT IN EXCESS OF THE PURCHASE

PRICE PAID BY CUSTOMER FOR THE PRODUCT.

F. NO DE

ALER WARRANTY

. THE DEALER HAS NO AUTHORITY TO MAKE ANY WARRANTY, REPRESENTATION, CONDITION OR PROMISE ON

BEHALF OF SIOUX STEEL, OR TO MODIFY THE TERMS OR LIMITATIONS OF THIS WARRANTY IN ANY WAY.

G. GOVERNING LAW/VENUE

. These warranties, and all terms s

et forth herein, are governed by the laws of the State of South Dakota and, where

applicable, the laws of the United States of America. Any and all disputes arising from these warranties, the purchase and use of the Products, bodily injury

and property damage claims or otherwise must be venued in the South Dakota Circuit Court sitting in Minnehaha County, South Dakota. Customer agrees to

such venue and waives any challenge to such court’s jurisdiction based upon lack of personal jurisdiction or inconvenience.

H. SECURING WARRANTY SERVICE

. In order to receive warranty services, customer must give Sioux Steel written noti

ce of a warranty claim within 3

days of the date of discovery of the defective materials or workmanship, and Customer must complete the following steps:

(1) Obtain from Sioux Steel a Return Goods Authorization Number (“RMA Number”) by calling the Customer Service

Department at 1-800-557-4689, and providing the following information:

An explanation as to why the Product is being returned.

The name of the territory representative, Dealer or Sioux Steel salesperson from whom the Product was

purchased.

The Dealer’s identification number.

The invoice number and date of purchase.

Customer’s name, phone number, fax number, mailing address and email address.

The date that the Product will be returned.

(2) Pay the shipping charges to ship the Product to Sioux Steel’s factory, and the return shipping charges.

(3) Ship the Product to Sioux Steel at 196 1/2 East Sixth Street, Sioux Falls, South Dakota 57104.

Table of contents

Popular Shelter manuals by other brands

Gazebo penguin

Gazebo penguin 7171020 instruction manual

Black Diamond Equipment

Black Diamond Equipment MEGAMID Instructions for use

ShelterLogic

ShelterLogic 62656 Assembly instructions

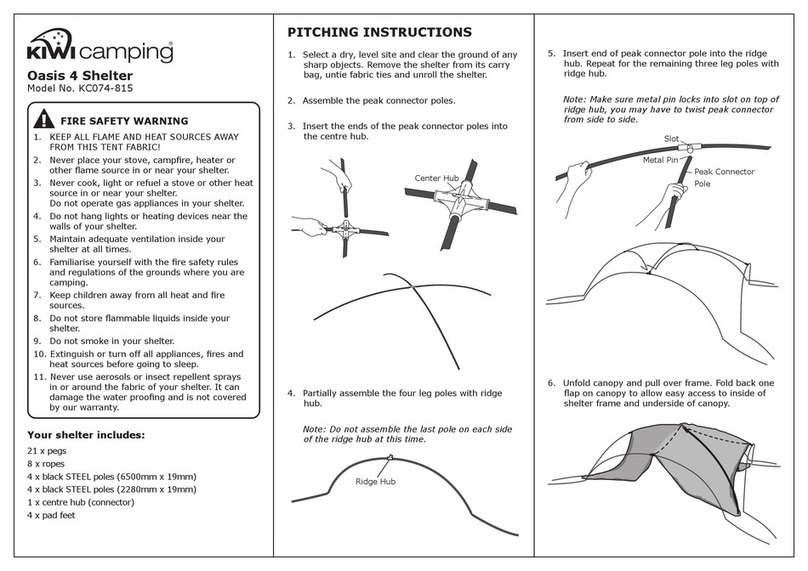

Kiwi Camping

Kiwi Camping Oasis 4 quick start guide

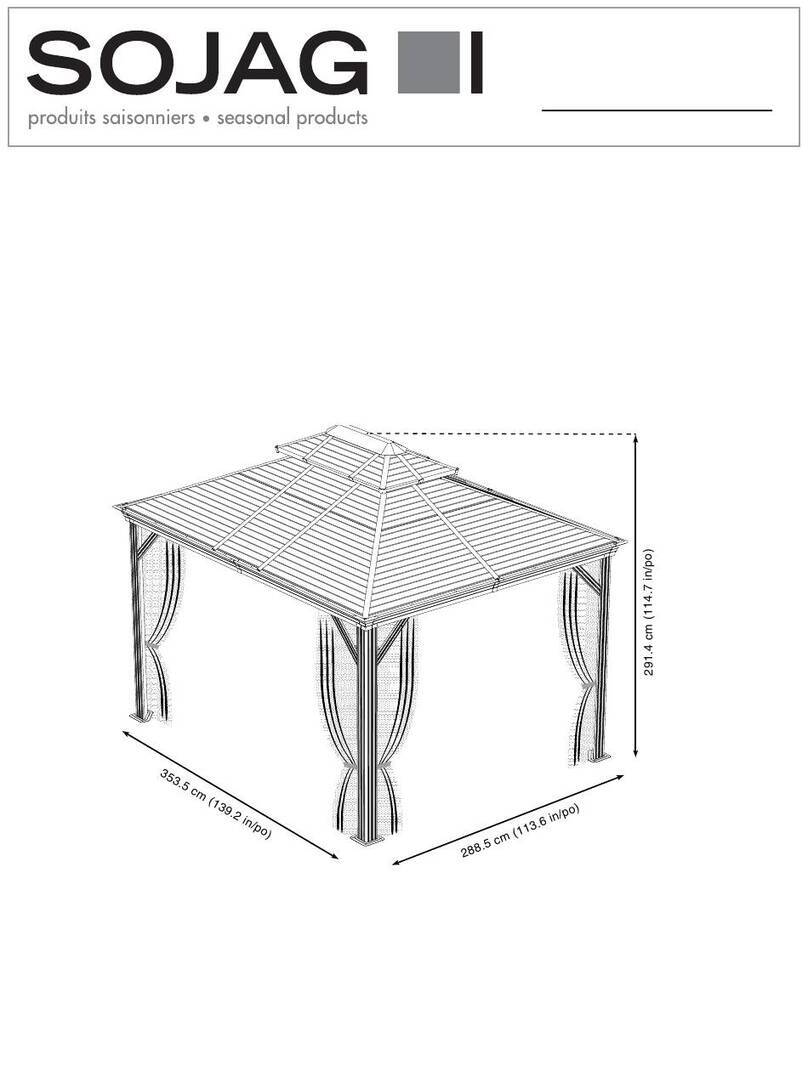

Sojag

Sojag 500-9165463 Assembly manual

TMG

TMG TMG-CRS1020 product manual

No Butts Bin

No Butts Bin SR1562-F Assembly instructions

Storage Canopy

Storage Canopy FB335017P Assembly instructions

Kiwi Camping

Kiwi Camping SAVANNA POD KC074-413 Pitching instructions

Sojag

Sojag Four Seasons Assembly manual

Shappell

Shappell FX200 Series instructions

No Butts Bin

No Butts Bin SR1602 Assembly instructions