Pro-tec FC-120 Instructions for use

- 1 -

Description: This machine is used to weld ferrous or nonferrous metals.

Disclaimer: The information, illustrations and instructions described in this manual

are based on the latest product information available at the time of publication. The

manufacturer and distributors reserve the right to make modifications at any time as

a result of product changes, and such modifications are not obligated to notify any

organization or individual. In addition, welder is a special type of work, and welding

equipment is special equipment. Welding work must be executed by qualified

workers after professional training. Therefore, the manufacturer and distributors are

only responsible for the quality of the product. They shall not be liable for direct or

indirect joint and several liability including loss of profit caused by omissions or

misdescriptions that may exist in this operation manual. This manual will contain as

much as possible the safety operation and preventive measures related to this

equipment, but cannot completely exclude the occurrence of accidents. The

manufacturer and distributors shall not be liable for any direct or indirect joint and

several liability, for any incidental or consequential damages caused by any accident,

that may occur outside of this manual. For more detailed health and safety

information, please contact the relevant professional agencies, welding materials or

welding flux manufacturers if necessary..

No warranty service is available in the following circumstances:

The consumables of the machine are not covered by the warranty, such as

welding wires, welding flux, fuse, quick connector, drive roller, tension roller, etc..

Machine failures caused by incorrect input power voltage or fluctuating power

supply are not covered by the warranty.

Malfunction of the machine and parts damage caused by wrong connection or

incorrect operation.

The warranty will be invalid if the machine is disassembled or refitted without the

permission of the manufacturer, resulting in accidental work or unexpected

damage of the machine.

Accidental damage during transportation, storage, and transshipment.

Problems caused by man-made damage, natural disaster of force majeure and

accidental damage.

- 2 -

CONTENTS

Safety precautions.................................................................................. 3

Warnings...................................................................................................4

Package and transportation........................................................................... 8

Parameters........................................................................................................9

Product description..........................................................................................9

Working principle........................................................................................... 13

Installation and wiring................................................................................... 13

Brief instruction for welding operation........................................................17

Maintenance................................................................................................... 18

Common machine malfunctions and solutions.........................................19

- 3 -

Safety precautions

The equipment is designed for the qualified personnel who have passed professional

training. The operator shall have sufficient professional knowledge of welding, cutting

and circuit, and have obtained the qualification certificate of welder. Only operate the

machine after reading and fully understanding all the safety precautions and warnings

in the manual and of welding operations. Basic safety precautions should always be

followed when using tools, to reduce the risk of personal injury and damage to

equipment. The device is simple and reliable in selecting and performing all of its

functions. The operator must strictly follow the safety precautions below and execute

them as required. Improper use and maintenance will reduce the safety performance

of the machine.

1. The operator must have passed the systematic training and assessment of local

welder's relevant learning institution and obtained the qualified certificate before

operating the equipment.

2. The wire and cable connection of the equipment, as well as the installation, must

be operated by qualified professional and technical personnel.

3. The welding and cutting protective equipment used by the operator must be

provided by the manufacturer or distributor approved by the national safety

supervision department of the local country.

4. Welding and cutting is dangerous work, which may cause harm to you or others,

so sufficient protection should be done during welding and cutting. Please strictly

abide by the relevant safety precautions of the job operation. For more details, please

refer to the relevant safety guidelines for the operators to comply with the

manufacturer's regulations on accident prevention.

5. Please make sure that the welding/cutting machine is reliably grounded when

working. Please contact the professional electrician to solve the problems in time if

there is any doubt that the socket is not grounded or the grounding is not reliable.

6. Before welding/cutting , check whether the insulation layer of all wires and cables

of the machine is damaged or they are wrongly connected timely and fix them in a

timely manner if they are.

7. The faulty machine must be repaired by professional technicians. The machine

must be disconnected from the electricity supply before repair and maintenance.

- 4 -

8. Do not operate the welding/cutting machine in humid environment, otherwise it

may cause electric shock or short circuit accident.

9. It is strictly forbidden to re-modify the equipment or the attached equipment

related to the operation of the equipment without permission, to avoid accidents.

10.The disposal of the scrap equipment must comply with the relevant policies and

regulations of the local government.

Warnings

Welding and cutting is a special type of work, with a certain degree of danger.

Professional training, correct operation and necessary protective measures can

effectively avoid and reduce the damage and loss caused by machine accidents.

Personal and others’ safety protection

When welding and cutting equipment is working, it will generate

noise, strong light and high temperature sparks, which will cause

harm to human hearing, eyes and skin. Correct protective measures

and proper operation training are necessary to prevent injury

accidents.

1

Aprotective helmet with a shading filter must be worn to protect the face and

eyes during welding and cutting operations or when watching welding/cutting

operations.

2

Wear a helmet with the correct filter and cover plate to protect the eyes, face,

neck and ears from arcing sparks and bright light during welding operation or

observation. Warn bystanders not to look at the arc and not to expose their

skin in the area of strong light arc or high temperature spark

3

Wear flame retardant gloves, flame retardant welding/cutting overalls, flame

retardant shoes, and welding/cutting helmets or protective caps to protect

against arcing bright lights, high temperature sparks or hot metal particles. A

flame retardant apron is also available to protect against thermal radiation

and high temperature sparks.

4

Hot sparks or metal can get into rolled-up sleeves, trouser legs or pockets.

Before welding/cutting, sleeves and collars should be buttoned, and clothes

with front pockets should not be worn.

- 5 -

5

Use appropriate flame retardant shields or curtains to protect other persons

from arc radiation and high temperature sparks.

6

Welding slag has high temperature, and can be splashed over a long

distance. During the removal of welding slag, the operator and viewers

should wear additional safety goggles over safety glasses.

7

It is forbidden to touch the welding work piece with bare hands to avoid

accidental scald and burn.

Fire and explosion precaution

During welding and cutting, high temperature flame and arc will be

generated, which will cause fire; high temperature welding slag and

sparks will also cause fire and explosion.

1

Protect yourself and others from flying sparks and hot metal

2

Flammable and explosive items are not allowed to be placed in the

welding/cutting area. Flammable materials that needed to be used in

welding/cutting process must be covered with flame retardant materials.

3

Hot sparks and metal can fly into cracked floors and walls, which need to be

protected against fire hazards.

4

Do not weld and cut on sealed high-pressure gas tanks, which may cause

explosions.

5

Fire extinguishing equipment, such as fire hose, water bucket, sand bucket

or portable fire extinguisher, must be provided in the welding and cutting

area. Furthermore, regularly check the effectiveness of these fire

extinguishing equipment, and carry out the training on the safe use of these

fire extinguishing equipment.

6

After finishing the welding/cutting operation, check whether there is high

temperature spark or metal, which might cause fire and timely dispose. If

necessary, go to the firefighter for help.

- 6 -

Prevention of Electric Shock Injuries

A person contacting with live electrical components or machine can

produce an electric shock, which will cause serious injury to the

human body or death. Do not use welding/cutting machines in

humid environment where movement is limited or there is a risk of

falling.

1

Ensure reliable grounding of the machine to prevent electric shock accident

caused by electric leakage.

2

Make sure that the work piece connected to the ground clamp of the machine

is reliably grounded.

3

Connect the ground clamp with the work piece reliably, or it might cause

electric shock accident.

4

Check the wires and cables frequently, and replace it in time if the insulation

layer is damaged.

5

Keep everything dry when welding/cutting, including clothing, working area,

cables, flashlights, electrode stand and power supply.

6

Make sure that every part of your body will not contact with the live electrical

parts.

7

Never stand directly on metal or the ground when have to work in a narrow or

humid environment. Please stand on dry wood or insulating platform,

wearing shoes with insulated rubber sole.

8

Please wear dry gloves without holes when turn on the machine power.

9

Please turn off the machine before taking off the gloves.

10

It is forbidden to replace the ground cable of the machine with other wires

and cables.

11

There is high voltage inside the machine. Non-professionals are strictly

forbidden to open the casing or start the machine for maintenance.

Protective Measures for Electromagnetic Fields

When an electric current flows through a conductor, it generates an

electromagnetic field, which can be harmful to the human body.

1

Welders with cardiac pacemakers shall consult a doctor if they are suitable

for welding and cutting operations.

- 7 -

2

Human exposed to the electromagnetic field may cause unknown health

effects.

3

Welders should minimize electromagnetic field damage through the following

methods.

3.1

Wrap the electrodes and the working cable with insulating cloth and secure

them with tape if possible.

3.2

Do not wrap wires and cables around arms.

3.3

Do not put cables around your body. Put the cables on one side if possible.

3.4

The clamping position on the work piece, by the working cable, should be as

close as possible to the area to be welded or cut.

3.5

The welding/cutting machine and cable shall not be close to the body during

operation.

Protection Against Fumes and Gas

Welding and cutting produces a lot of fumes and gas, which is

harmful to human health.

1

Keep your head out of the fumes. Do not breathe the fumes.

2

Keep well ventilation in welding/cutting working environment. Do not weld or

cut in a confined space and there must be an air exhaust and dust remove

system.

3

Do not weld in locations near degreasing or spraying operations. The heat

and arc produced in the operation can react with chlorinated hydrocarbon to

form highly toxic and irritating gases, which is harmful to the human body

and might cause birth defects, and in some cases, can lead to cancer.

4

If you experience temporary eye, nose, or throat discomfort during

welding/cutting operation, it may be caused by inadequate ventilation.

Please stop the operation immediately and take measures to improve

ventilation in the working area.

5

For specific ventilation requirements of welding and cutting working area,

please refer to relevant documents of welder profession.

- 8 -

Gas Cylinder Safety

Cylinders connected to welding/cutting equipment may rupture and

leak gas, if not being properly operated. A sudden rupture of a

cylinder valve or relief valve can cause injury or even death to

human body.

1

The cylinder should be away from high temperature and fire source. Do not

use hard objects to scratch on the cylinder body.

2

A suitable gas should be selected and stored in the cylinder during welding

and cutting. The pressure reducing valve should be installed on the cylinder

according to the cylinder manufacturer's operating instructions. Do not use

quick connectors for cylinder gas hose connection and please make sure

that the gas hose and fittings is reliably connected, without any leakage.

3

Keep cylinders fixed upright at all times and the cylinder can be chained or

belted to a suitable trolley, base, wall, post or shelf. Never fix the cylinder to

the work table or machine, to avoid they become part of the circuit.

4

Ensure that the cylinder valve is closed when it is not in use. If there is no

hose connected to the cylinder, put a dust cap on the valve port in time.

Moving Parts Safe Protection

Moving parts, such as fans, rotors and belts, can be

hazardous.

1

Before welding/cutting, keep all doors, panels, covers closed.

2

Only qualified professionals and technicians can remove the machine casing

for maintenance.

3

Make sure that hands, hair, clothing and tools are out of movement range of

the moving parts

Package and transportation

1. During packaging, storage and transportation, please pay attention to the

placement identification, waterproof identification, bearing identification, layer number

identification and other protective identifications on the package.

2. During the transportation and transshipment, it is prohibited to throw the

products at will, and strong impact and vibration are prohibited.

- 9 -

3. Equipment should be stored in a rainproof, moisture-proof and well ventilated

place, and the ambient temperature of storage should be -25℃~55℃.

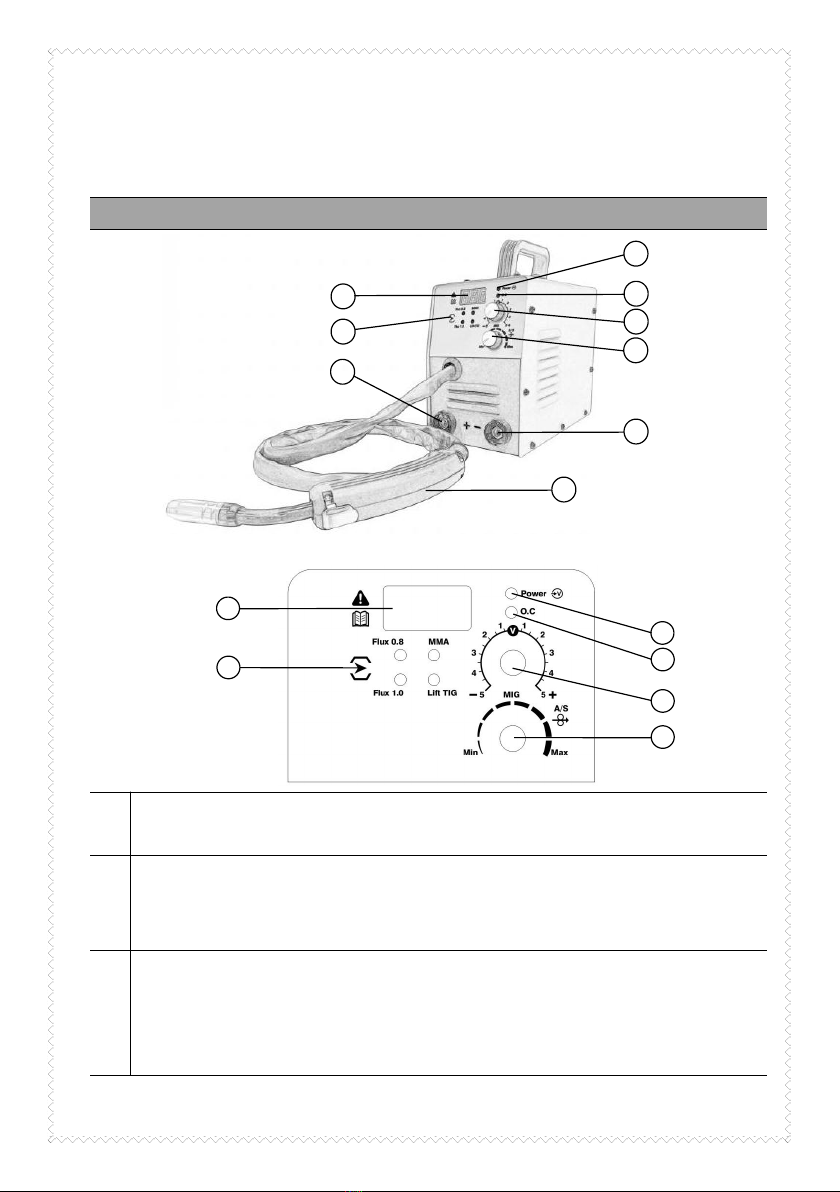

Parameters

Model

FC-120

FC-120ECO

FC-120

Item

Value

Rated input voltage

AC220V±15%

50/60Hz 1PH

AC110V±15%

50/60Hz 1PH

Rated input power

5.1kVA

9.2kVA

Rated input current

23A

42A

Rated duty cycle

60%

Output current range

(A)

30-120(MIG)

20-120(MMA)

130-120

(MIG)

30-120(MIG)

20-120(MMA)

Open circuit voltage

60V

Efficiency

≥85%

Insulation grade

F

IP grade

IP21

Package dimensions

430*220*320(mm)

N.W.(kg)

7.25

7.0

7.25

Product description

This series flux cored wire welding machine inverts 50Hz/60Hz power supply into

high frequency high voltage power supply (up to 33KHz), through a high power device

IGBT, and then after step-down rectifying and pulse width modulation(PWM)

technology, output high power DC supply for welding. Thanks to the advanced

inverter technology, the weight and volume of the main transformer are greatly

reduced, and the efficiency is increased by 30%, which features stable and reliable

quality, lightweight and energy saving performance, etc..

This series of inverter MIG welding machine is a kind of high performance

semi-automatic welding machine for flux cored wire welding. The self-shielded

- 10 -

flux-cored wire protects the droplet and weld pool by the slag forming constituents

and the gas forming constituents of the flux-cored wire which produce gas and slag

under the high temperature of the arc. The self-shielded flux-cored wire welding

carries the advantages that it doesn't required an external shielding gas, simple

welding torch structure with light weight and easy to operate; it delivers good

performance on wind resistance and gas pore resistance. In the welding process, the

shielding gas is formed by the metallurgical reaction of the welding wire itself. It can

be welded under wind class 4 that is particularly suited for field operation; it provides

deep penetration and uses spray transfer method which produces small spatters; It

has excellent operation performance of all position vertical down welding; it also

provides excellent slag detachability. The deposited metal is able to obtain high

low-temperature toughness under the harsh conditions of low temperature, strong

wind and other situations. This machine can weld low carbon steel, low alloy steel,

stainless steel and other components, using Φ0.8-Φ1.0mm diameter flux-cored wire,

and it is widely used in pipeline construction , ocean engineering, outdoor large steel

structure manufacturing, steel structural high-rise building, resurfacing welding and

other industries.

Other than above features, this series of inverter welding machines have good

dynamic performance, stable arc, excellent welding results, easy to control and other

benefits. The machines are manufactured in accordance with IEC60974-1 <Arc

Welding Equipment -- Part 1: Welding Power Sources>, Safety Requirements for Arc

Welding Equipment.

1. This series of welding machines have following features:

1.1. Light weight, simply design, small in size, high efficiency and energy saving,

convenient to move.

1.2. Simple operation interface with synergy control, easy to use.

1.3. The closed-loop control system ensures a more stable welding voltage in the

case of grid voltage fluctuation and the change of arc length; an excellent arc

self-regulation, and a stable welding process.

1.4. Less spatter and high metal deposition rate; nice welding bead and less

deformation.

1.5. MMA function is designed to weld various electrodes like acid, alkaline,

stainless steel, etc with excellent performance. Meanwhile, it can be used to weld

- 11 -

with different diameter electrodes in ø2.0mm/ø3.2mm;

1.6. With overheat and overvoltage protection functions, it is safe, reliable and

convenient for troubleshooting.

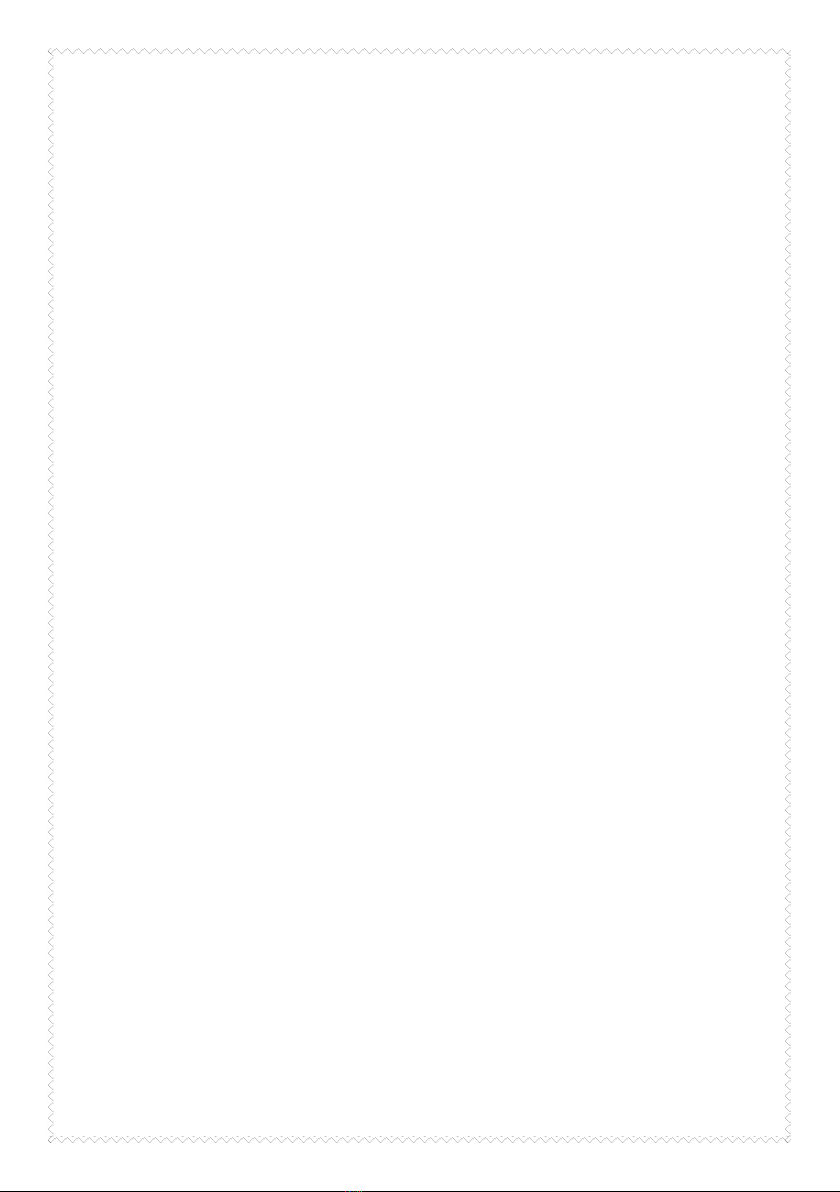

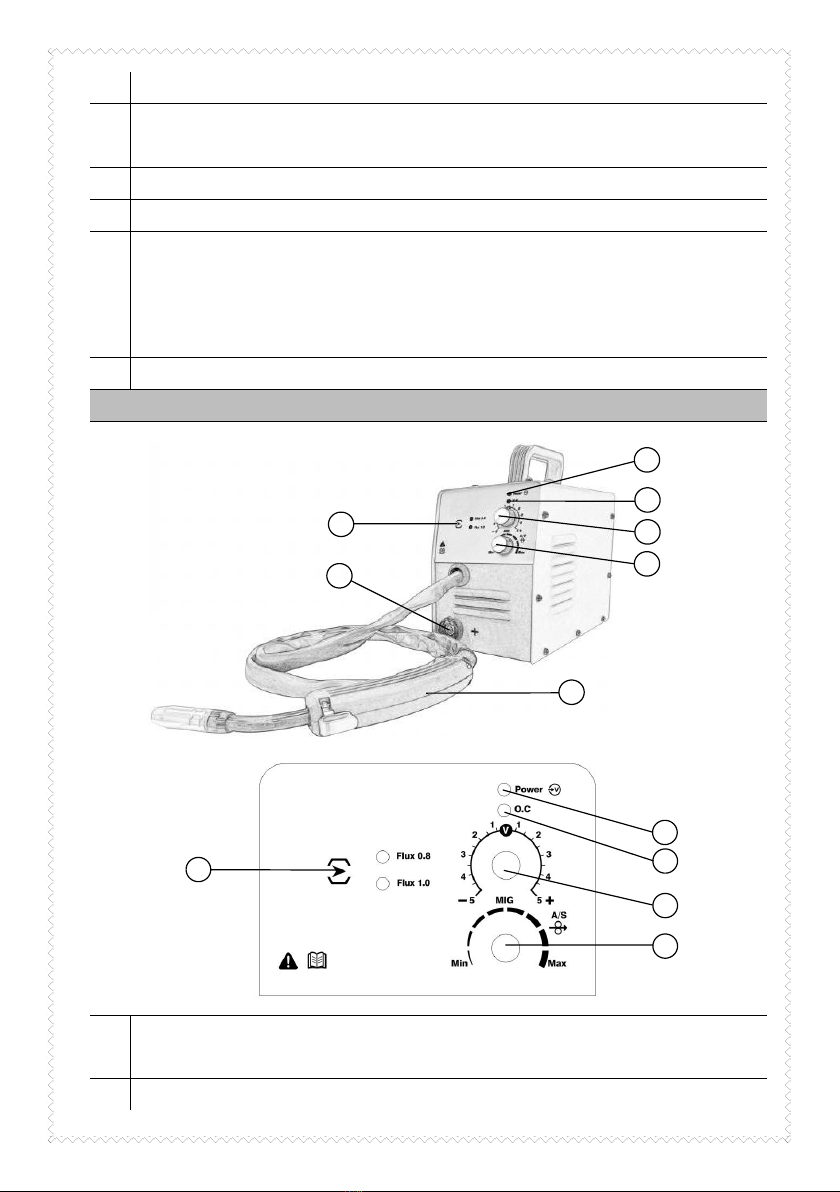

1. Appearance:

FC-120

Panel:

1

'LED display': display real-time current output ; display values during

parameter settings.

2

'Push-button, welding process': Select among Flux0.8、Flux1.0、MMA、Lift

TIG. The machine is working under the process when the corresponding

indicator light is on.

3

'Coupling device, positive pole (+)': connected with earth wire clamp which

clamps the work piece. Under MMA mode, connected with earth wire clamp,

which clamps the work piece in direct current electrode negative way;

connected with electrode holder in direct current electrode positive way.

1

7

8

2

3

9

1

5

6

1

4

1

1

5

6

2

1

4

7

- 12 -

4

'AC110V or AC220V power light.'

5

'Error indicator light': When the machine functions normally, this light is

always off. It will lit when abnormal conditions occur.

6

'Voltage adjustment knob':rotate to regulate the output voltage.

7

'Current adjustment knob':rotate to regulate the output welding current.

8

'Coupling device, negative pole (-)': under MMA mode, connect the

electrode holder to the negative terminal in direct current electrode

negative way, and connect the earth wire clamp which clamps the work

piece to the negative terminal in direct current electrode positive way.

9

'Integrated gas-shielded torch'

FC-120ECO

Panel:

1

'Push-button, wire diameter': select between 0.8 and 1.0. The machine is

working under the process when the corresponding indicator light is on.

2

'Coupling device, positive pole (+)': connected with earth wire clamp which

2

1

3

4

5

6

7

4

5

1

1

3

6

- 13 -

clamps the work piece.

3

'AC220V power light.'

4

'Error indicator light': When the machine functions normally, this light is

always off. It will lit when abnormal conditions occur.

5

'Voltage adjustment knob':rotate to regulate the output voltage.

6

'Current adjustment knob':rotate to regulate the output welding current.

7

'Integrated gas-shielded torch'

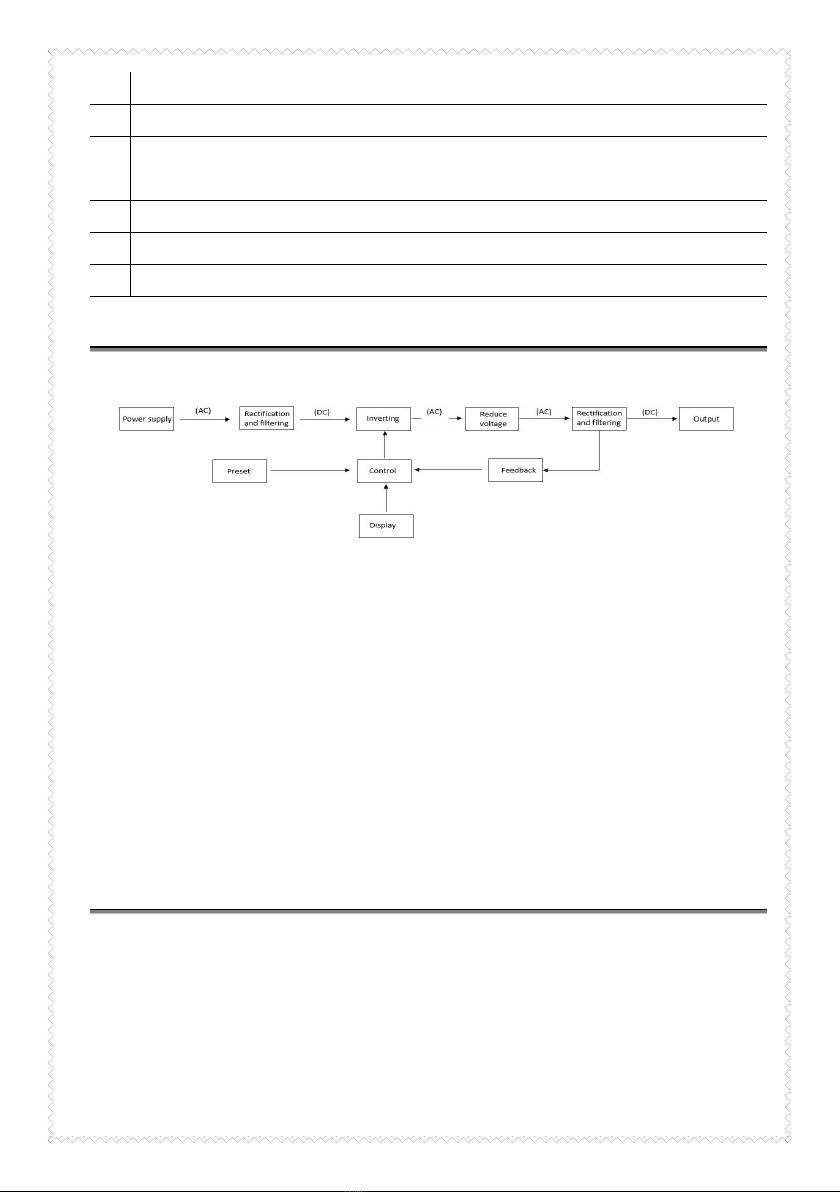

Working Principle

1. Working principle diagram

1.1. Covert the alternating-current input into direct-current output by a bridge

rectifier;

1.2. Under the control of PWM, IGBT inverts the above-mentioned direct current

into 33 KHz alternating-current and transmits power through high-frequency

transformer;

1.3. Output the welding current that meets the requirements set after secondary

rectification and reactor filtering;

1.4. Protection circuit works in time and provides signal to PWM circuit (overheat,

overcurrent);

1.5. The closed-loop control method is adopted to make the cutting power source

have good anti-grid fluctuation ability and excellent cutting performance.

Installation and wiring

1. Requirements for installation location

1.1. The cutting machine should not be installed in a location exposed to direct

sunlight and rain. Install and keep it in a low humidity and little dust environment, and

within the ambient air temperature range of - 10 ℃~ 40 ℃.

1.2. The machine shall not be placed on an inclined surface, the ground surface

shall be flat, and the inclination of the welding machine shall not exceed 10 °.

- 14 -

1.3. Ensure no wind at the working station, and suitable precautions should be

taken to prevent wind.

1.4. Keep at least 20cm space in front and back of the cutting machine body, and

at least 10cm space on the left and right sides to ensure good ventilation conditions

around the machine.

2. Requirements of power input

The power supply waveform should be standard sin wave, the rated voltage is

220V/110V±15% with 50Hz or 60Hz frequency.

Model

FC-120

FC-120ECO

FC-120

Parameters

Value

Power supply:

AC220V±15% 50/60Hz 1PH

AC110V±15%

50/60Hz 1PH

Rated input current:

23A

23A

42A

Input cable:

≥2.0mm2

≥2.0mm2

≥4.0mm2

Output cable:

14mm2

14mm2

14mm2

Ground cable:

≥2.0mm2

≥2.0mm2

≥4.0mm2

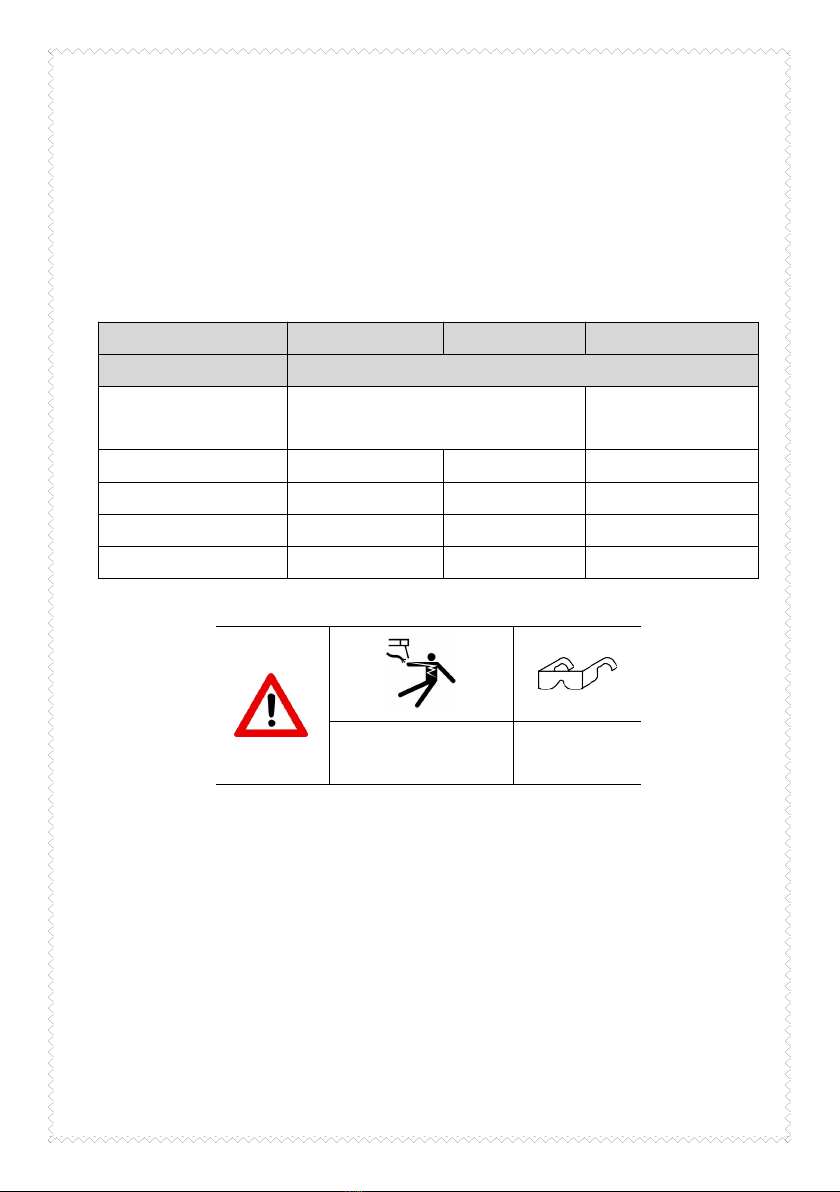

3. Connection of machine power supply

Pay attention to

prevent electric shock

Wear goggles

Warning: The followings should be aware of when connecting the cutting

machine to a power supply

a) The connection of power cord must be carried out by qualified electricians

and technicians.

b) The connection of power cord must comply with national and local policies

and regulations.

c) Before connecting the power supply, the power supply of the electric control

box must be disconnected.

d) A ground cable must be connected from the power supply to the work, and

the ground cable has a reliable grounding terminal. The yellow green earth

- 15 -

wire of the machine must be reliably connected with the grounding cable.

e) Before connecting the power cords, it is necessary to confirm the

parameters of the power supply on the name plate of the machine which

allowed to be connected, and verify the input power supply is consistent

with the allowable power supply of the machine.

f) The thread pressing screws must be pressed tightly, and cannot be loose

and fake connection.

g) Power supply wiring is as follows

Wiring of single phase AC220V/AC110V 50/60Hzwelding machine

No.

Item

No.

Item

1

Cutting machine

3

Live wire terminal block

2

Power cord

4

Electric control box

2a

Live wire L

5

Earth wire terminal block

2b

Neutral wire N

6

GND

2c

Earth wire

7

Overcurrent protection device

2c

2

2b

2a

3

4

7

6

1

5

- 16 -

4. Installation and adjustment of wire spool

4.1. Installation of wire spool

Attention:

Before putting the wire spool into the hub shaft, find the locating pin on the shaft and

the locating hole on the spool; Then align the hole with the pin and push the wire

spool into the hub shaft.

Installation of wire spool

Installation of 5kg(Ø200mm)wire spool

No.

Item

No.

Item

1

Wire spool hub shaft

3

Fixing nut

2

Wire spool

5. Use of the wire feeder

5.1. Introduction

No.

Item

No.

Item

1

Wire feeder motor

3

Drive roll

2

Pressure regulating handle

4

Tensioner roller

1

2

3

locating hole

locating pin

2

3

3

3

1

3

4

3

- 17 -

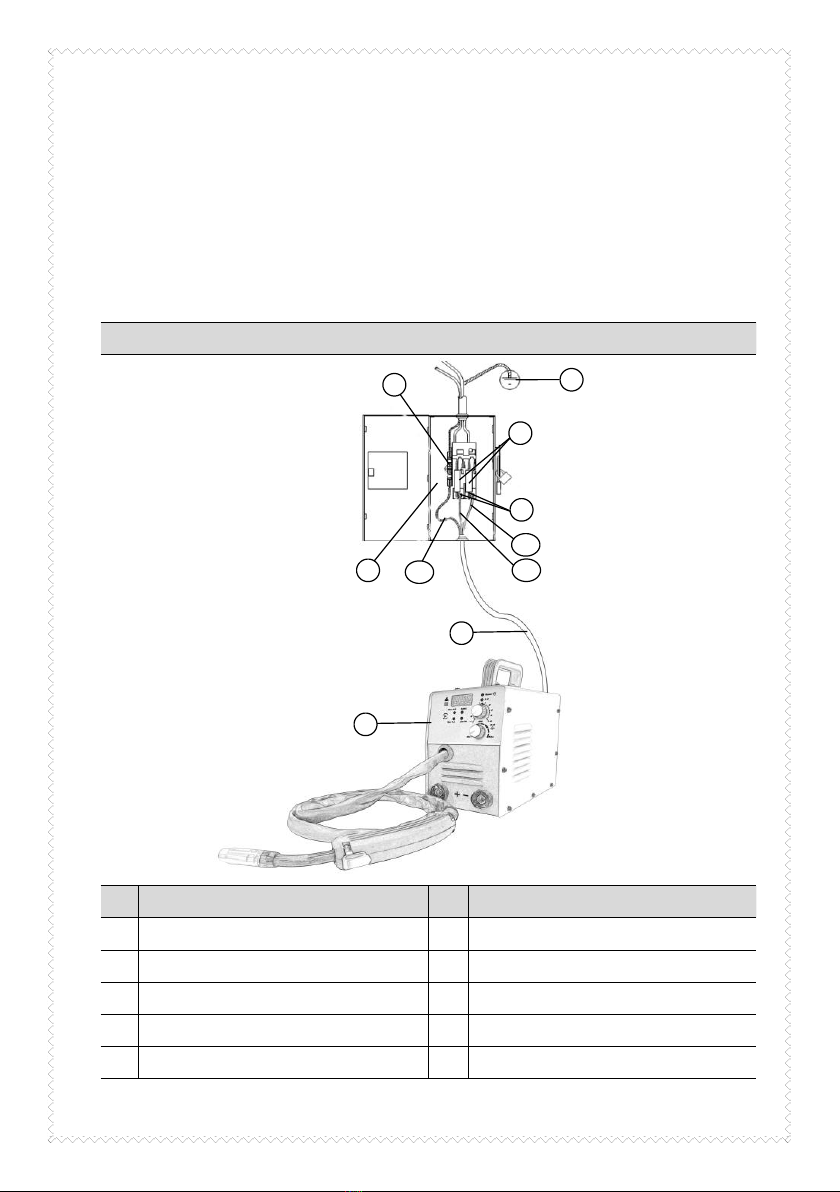

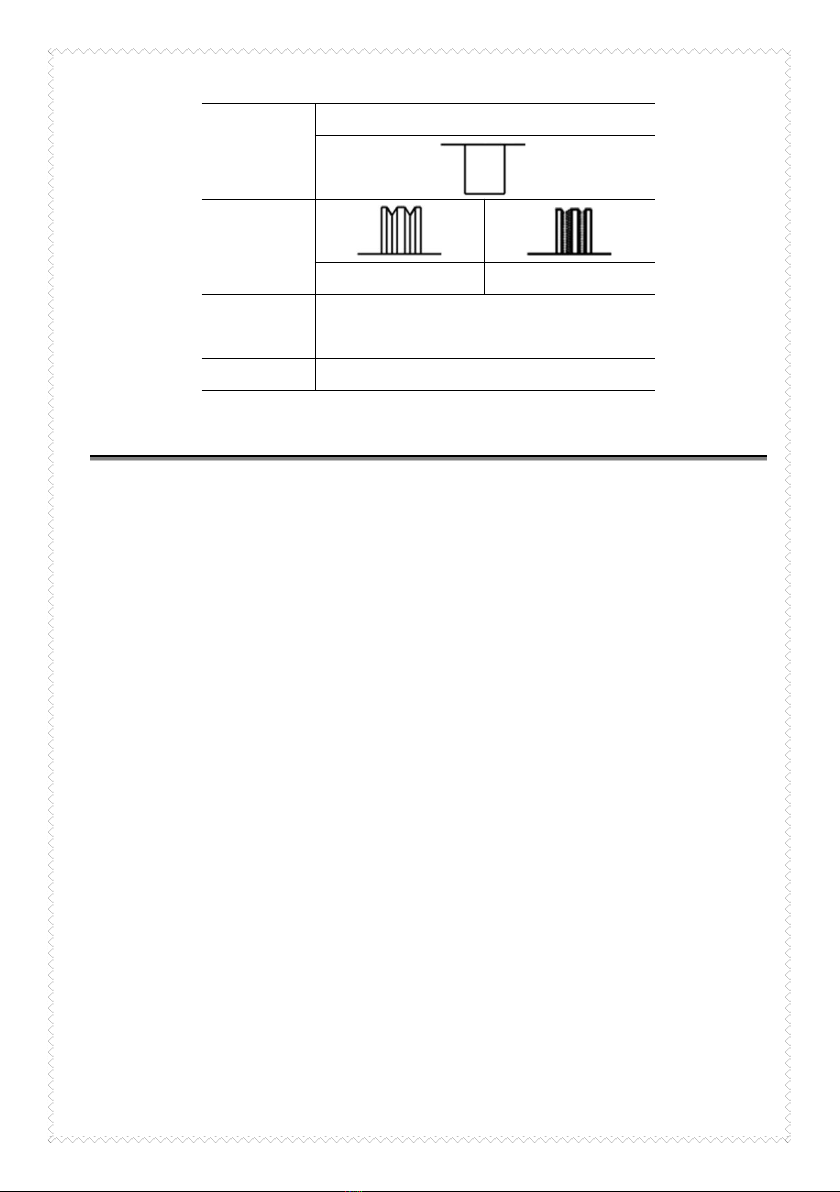

5.2. How to select tensioner roller and drive roll

Tensioner

roller

Non-groove

Drive roller

V groove

knurled

V groove roll:

Suitable for some hard wire like solid

carbon steel wire and stainless steel wire

Knurled roll:

Suitable for flux cored wire

Brief instruction for welding operation

1. Welding operation procedure

1.1 Wear necessary and qualified welding protective equipment, such as helmet,

mask, goggles, earplug, protective clothing, gloves, insulating shoes, etc.

1.2 Check and confirm that the electrical grid to be connected to the welding

machine is consistent with the allowable power supply of the machine.

1.3 Check and confirm that the insulation layer of all wires and cables of the

welding machine is not damaged, the welding cable and the grounding cable are

connect to the welding machine correctly.

1.4 Check and confirm that the ventilation around the welding machine is freely

vented; there are no sundries on the welding machine body.

1.5 Check and confirm that the ventilation opening of the welding machine has not

be covered or blocked, or the cooling system might fail to work.

1.6 Connect quick connector of the earth wire cable to the positive pole (+) below

the front panel of the machine, and tighten it clockwise; the other end, which is the

earth wire clamp, to clamp the work piece.

1.7 Connect the power cord to the distribution box with the corresponding input

voltage level according to the welding machine’s, do not connect the wrong voltage,

and ensure that the error of the supply voltage is within the allowable range.

1.8 Press the power switch to turn on the machine, work LED is lit, and cooling fan

works.

- 18 -

1.9 Select welding process first and set current parameters on the panel according

to the requirements. Then point the torch towards the work piece and press the

trigger to start welding.

1.10 Carry out the welding operation according to the normal procedure. During

welding, the parameters can be modified according to the actual situation.

1.11 After welding operation is completed, turn off the power switch of welding

machine and the switch of the distribution box.

Maintenance

In order to ensure operation safety, please regularly maintain and overhaul the

welding machine. Must turn off the power switch of input distribution box before

checking the connection terminal blocks inside/outside the machine.

1. Daily precautions:

1.1. Whether there is any abnormal vibrations, sounds or smells?

1.2. Whether there is any sign of overheating in cable connection?

1.3. Whether the fan works smoothly after turning on the power switch?

1.4. Whether the power switch is faulty?

1.5. Whether the cable is correctly connected and properly insulated.

1.6. Whether there is any cable damage?

2. Check lists that should be carried out every 3 ~ 6 months

2.1. Dust remove

Inspection by professional maintenance personnel every 3 to 6 months. Clean all

parts inside the welding machine with dry compressed air. After cleaning the inside of

the machine, the removed side plate should be reset before using the machine again.

Note that if the removed side plate is not reset, the cooling effect of the fan will be

invalid, which may lead to the burning of transformer and semiconductor power

devices. Meanwhile, pay attention to check whether the fastening screws of input and

output connecting cable are loose, whether the contact is tight, and whether the

machine shell is grounded or not.

2.2. Inspection of wire and cable

Inspect the wire and cable every time before welding operation to ensure that the

insulation layer is not damaged, the wiring is correct, and the joint piece is not loose.

- 19 -

2.3. Replacement of contact tip and wire feeder

The contact tip and wire feeder should be replaced in time; clean the wire liner

frequently.

Common machine malfunctions and solutions

Warning:

Machine maintenance must be carried out by qualified professional and

technical personnel!

The highest voltage inside the machine can be reach to 600V!!!

For your safety, do not open the machine cover at will. During maintenance,

safety protection such as preventing electric shock should be prepared well.

The power supply of the machine must be turned off when installing the wiring

and replacing the welding torch accessories

Do not overhaul the machine immediately after the welder has just be turned off.

Please wait at least 5 minutes after turning off the power switch of the machine

and distribution box, so that the capacitor inside the welding machine can be

fully discharged .

1. Inspection before overhaul

1.1. Check whether the line voltage of single-phase power supply is within the

range of 200V ~ 240V, and whether there is phase loss phenomenon;

1.2. Check if power cable of the welding machine is correctly and reliably

connected;

1.3. Check if earth wire of the welding machine is correctly and reliably connected;

1.4. Check whether the wiring connection is correct and whether the contact is firm

and reliable;

2. Common machine problems and troubleshooting

This manual suits for next models

1

Table of contents

Other Pro-tec Welding System manuals