MH-D500D

1

Thank you for purchasing our Motor-Driven Resistance Welding Head MH-D500D.

・This operation manual explains its method of operation and precautions for use.

・Before using, read this operation manual carefully; after reading, save it in a proper place

where you can easily access.

Contents

1. Special Precautions

(1) Safety Precautions········································································ 1-1

(2) Precautions for Handling ································································ 1-4

(3) On Disposal ················································································ 1-4

2. Features ························································································· 2-1

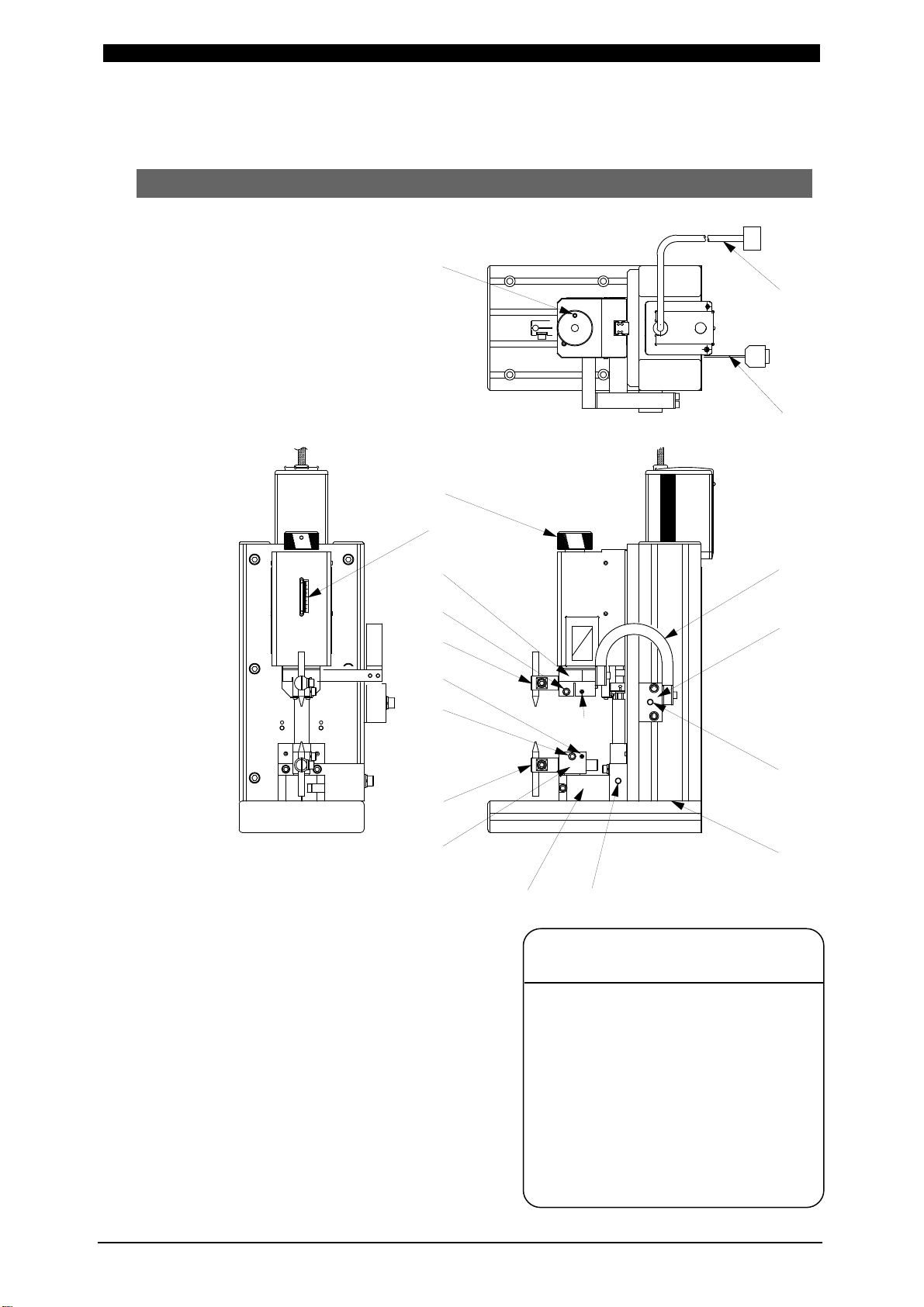

3. Name and Functions of Each Section

(1) Head·························································································· 3-1

(2) Controller Front Panel ··································································· 3-3

(3) Controller Rear Panel ···································································· 3-5

4. Interface

(1) Connection Diagram of External Input/Output Signal···························· 4-1

(2) I/O Connector ·············································································· 4-3

5. Installation and Connection ······························································ 5-1

6. Operation

(1) Getting Started············································································· 6-1

(2) Mode Setting ··············································································· 6-2

(3) Applying Power and Moving to Start Point ········································· 6-3

(4) Auto-Setting of Electrode Position ···················································· 6-4

(5) Manual Setting of Electrode Position ················································ 6-5

(6) Welding Work ·············································································· 6-10

(7) Measuring Weld Force··································································· 6-11

7. Fault Indications ·············································································· 7-1

8. User’s Maintenance

(1) Installing and Replacing Electrode (Separately sold)···························· 8-1

(2) Adjustment of Weld Force ······························································ 8-1

9. Specifications

(1) Specifications ·············································································· 9-1

(2) Accessories················································································· 9-1

(3) Separately Sold Items ··································································· 9-2

(4) Timing Chart················································································ 9-3

10. Data Communication

(1) Communication Specifications························································· 10-1

(2) Connection of Communication Connector·········································· 10-1

(3) Bidirectional Communication··························································· 10-3

11. Welding Head with Load Cell

(1) Connection of Load Cell Sensor to Indicator······································· 11-1

(2) Comparison Functions of Indicator ··················································· 11-1

(3) How to Hold HI-LO Limit Judging and Indicated Value at Indicator ·········· 11-3

(4) Calibration of Load Cell·································································· 11-4

12. Outline Drawings

(1) MH-D500D-00-00/01/30/31 Head····················································· 12-1

(2) MH-D500D-00-40/41 Head ····························································· 12-2