Processor Technology 8KRA Reference guide

55

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

ASSEMBLY

and

TEST

INSTRUCTIONS

Copyright

©

1976,

Processor

Technology

Corporation

Third

Printing,

June,

1977

Manual

No.

202003

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

CONTENTS

SECTION

TITLE

PAGE

I

INTRODUCTION

and

GENERAL

INFORMATION

1.1

Introduction

..................................

1-1

1.2

General

Information

............................

1-1

1.2.1

8KRA

Memory

Description

................

I-rl

1.2.2

Receiving

Inspection

....................

1-2

1.2.3

Warranty

Information

....................

1-2

1.2.4

Replacement

Parts

......................

1-2

1.2.5

Factory

Service

........................

1-2

II

ASSEMBLY

2.1

Parts

and

Components

.............................

II-l

2.2

Assembly

Tips

.....................................

II-l

2.3

Assembly

Precautions

..........................

II-l

2.3.1

Handling

MOS

Integrated

Circuits

........

II-l

2.3.2

Soldering

.................................

II-4

2.3.3

Installing

and

Removing

8KRA

...............

II-4

2.3.4

Installing

and

Removing

Integrated

Circuits

...................................

II-4

2.3.5

Use

of

Clip

Leads

.........................

II-4

2.4

Required

Tools,

Equipment

and

Materials

........

II-4

2.5

Orientation

.......................................

II-5

2.6

Assembly

Procedure

............................

II-5

III

OPTION

SELECTION

3.1

Option

Selection

..............................

III-l

3.2

Waiting

Time

Option

(Area

A)

....................

III-l

3.3

Power-up

Initialization

(Area

B)

..............

III-l

3.4

Memory

Disable

Option

(Area

C)

................

III-2

3.5

Starting

Address

Selection

....................

III-3

IV

THEORY

OF

OPERATION

4.1

General

Description

............................

IV-

1

4.2

Read

Operation

...................................

IV-1

4.3

Write

Operation

................................ IV-

2

4.4

Wait

States

.................................... IV-

3

4.5

Power

Supply

..................................

IV-

4

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

CONTENTS

SECTION

TITLE

V

DRAWINGS

8KRA

Assembly

Drawing

8KRA

Schematic

Drawing

APPENDICES

I

Statement

of

Warranty

II

8080

Operating

Codes

III

Soldering

Tips

IV

Standard

Color

Code

for

Resistors

and

Capacitors

V

Integrated

Circuit

Pin

Configurations

VI

Memory

Test

Programs

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

I

1.1

INTRODUCTION

This

manual

supplies

the

information

needed

to

assemble,

test

and

use

the

8KRA

Static

Read/Write

Memory

Module.

We

suggest

that

you

first

scan

the

entire

manual

before

starting

assembly.

Then

make

sure

you

have

all

the

parts

and

components

listed

in

the

"Parts

List"

(Table

2-1)

in

Section

II.

When

assembling

the

module,

follow

the

instructions

in

the

order

given.

Should

you

encounter

any

problem

during

assembly,

call

on

us

for

help

if

necessary.

If

your

completed

module

does

not

work

prop

erly,

recheck

your

assembly

step

by

step.

Most

problems

stem

from

poor

soldering,

backward

installed

components,

and/or

installing

the

wrong

component.

Once

you

are

satisfied

that

the

module

is

correct

ly

assembled,

feel

free

to

ask

for

our

help.

1.2

GENERAL

INFORMATION

1.2.1

8KRA

Memory

Description

The

8KRA

Static

Read/Write

Memory

Module

has

a

capacity

of

8192

eight-bit

bytes

and

operates

in

a

static

mode.

As

opposed

to

dynamic

memories,

the

8KRA

needs

only

one

power

supply

and

does

not

require

periodic

refreshing.

All

address

and

data

lines

are

fully

buffered,

and

extensive

noise

immunity

circuitry

is

built

into

the

memory.

The

module

fea

tures

switch

selectable

address

selection

which

allows

its

starting

address

to

be

offset

in

IK

increments

from

zero

to

65K.

Maximum

worst

case

access

time

for

the

8KRA

is

520

nsec.

Thus,

in

any

8080

system,

this

memory

will

operate

at

the

same

speed

as

any

other

memory

with

an

access

time

between

50

and

520

nsec.

Both

the

access

time

and

non-refresh

features

of

the

8KRA

mean

no

computer

"waiting"

time

is

required.

The

8KRA

Memory

is

plug-in

compatible

with

the

Altair

8800

bus.

It

requires

+7.5

to

+10

V

de

at

1.9

amp

(max.)

operating

power.

In

addition,

the

low

power

memory

IC

1

s

used

on

the

module

can

oper

ate

in

a

low

power

(+1.6

to

2.5

V

de

at

0.9

amp

max.)

standby

mode.

Data

loss

from

the

8KRA

during

loss-of-power

or

power

interrupt

con

ditions

can

consequently

be

prevented

by

using

two

"D"

size

batteries

for

standby

power.

Provisions

for

easily

adding

this

standby

capa

bility

are

incorporated

in

the

module

design.

1.2.2

Receiving

Inspection

When

your

module

arrives,

examine

the

shipping

container

for

signs

of

possible

damage

to

the

contents

during

transit.

Then

in

spect

the

contents

for

damage.

(We

suggest

you

save

the

shipping

materials

for

use

in

returning

the

module

to

Processor

Technology

1-1

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

I

should

it

become

necessary

to

do

so.)

If

your

8KRA

kit

is

damaged,

please

write

us

at

once

describing

the

condition

so

that

we

can

take

appropriate

action.

1.2.3

Warranty

Information

In

brief,

the

parts

supplied

with

the

module,

as

well

as

the

assembled

module,

are

warranted

against

defects

in

materials

and

workmanship

for

a

period

of

6

months

after

the

date

of

purchase.

Refer

to

Appendix

I

for

the

complete

"Statement

of

Warranty".

1.2.4

Replacement

Parts

Order

replacement

parts

by

component

nomenclature

(e.g.

,

DM8131)

and/or

a

complete

description

(e.g.,

6.8

ohm,

%

watt,

5%

resistor

).

1.2.5

Factory

Service

In

addition

to

in-warranty

service,

Processor

Technology

also

provides

factory

repair

service

on

out-of-warranty

products.

Before

returning

the

module

to

Processor

Technology,

first

obtain

authori

zation

to

do

so

by

writing

us

a

letter

describing

the

problem.

After

you

receive

our

authorization

to

return

the

module,

proceed

as

follows:

1.

Write

a

description

of

the

problem.

2.

Pack

the

module

with

the

description

in

a

container

suitable

to

the

method

of

shipment.

3.

Ship

prepaid

to

Processor

Technology,

6200

Hollis

Street,

Emeryville,

CA

94608.

Your

module

will

be

repaired

as

soon

as

possible

after

re

ceipt

and

return

shipped

to

you

prepaid.

1-2

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

2.1

PARTS

AND

COMPONENTS

Check

all

parts

and

components

against

the

"Parts

List"

(Table

2-1

on

Page

II-2

).

If

you

have

difficulty

in

identifying

any

parts

by

sight,

refer

to

Figure

2-1

on

Page

II-3.

2.2

ASSEMBLY

TIPS

1.

Scan

Sections

II

and

III

in

their

entirety

before

you

start

to

assemble

your

8KRA

Memory

Module.

2.

In

assembling

your

8KRA,

you

will

be

following

a

step-by-

step

assembly

procedure.

Follow

the

instructions

in

the

order

given.

3.

Assembly

steps

and

component

installations

are

preceded

by

a

set

of

parentheses.

Check

off

each

installation

and

step

as

you

complete

them.

This

will

minimize

the

chances

of

omitting

a

step

or

a

component.

4.

When

installing

components,

make

use

of

the

assembly

aids

that

are

incorporated

on

the

8KRA

PC

Board

and

the

assembly

drawing.

(These

aids

are

designed

to

assist

you

in

correctly

installing

the

components.

)

a.

The

circuit

reference

(R3,

CIO

and

IC20,

for

example)

for

each

component

is

silk

screened

on

the

PC

Board

near

the

location

of

its

installation.

b.

Both

the

circuit

reference

and

value

or

nomenclature

(1.5K

and

7400,

for

example)

for

each

component

are

included

on

the

assembly

drawing

near

the

location

of

its

installation.

5.

To

simplify

reading

resistor

values

after

installation,

install

resistors

so

that

the

color

codes

read

from

left-to-right

and

top-to-bottom

as

appropriate

(board

oriented

as

defined

in

Para

graph

2.5

on

Page

II-5

).

6.

Install

disc

capacitors

as

close

to

the

board

as

possible.

7.

Should

you

encounter

any

problem

during

assembly,

call

on

us

for

help

if

needed.

2.3

ASSEMBLY

PRECAUTIONS

2.3.1

Handling

MOS

Integrated

Circuits

The

memory

IC

1

s

used

in

the

8KRA

are

MOS

devices.

They

can

be

damaged

by

static

electricity

discharge.

Always

handle

MOS

IC

1

s

so

that

no

discharge

will

flow

through

the

IC.

Also,

avoid

unneces-

II-l

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

INTEGRATED

CIRCUITS

Table

2-1.

8KRA

Static

Read/Write

Memory

Module

Parts

List.

1

74LS04

(IC79)

2

74LS283

(IC68

and

71)

1

74LS13

(IC72)

2

8T93

(IC77

and

78)

2

74LS132

(IC74

and

75)

2

8T98

or

8098

(

IC69

and

76)

1

74LS136

(IC70)

64

91L02A

or

21L02B

(IC1

through

64

1

74LS138

(IC67)

REGULATORS

DIODES

2

340T-5.0

or

7805UC

(IC65

and

66)

4

1N4001

or

iN4002

(Dl

through

D4)

1

1N270

(

D5

)

RESISTORS

CAPACITORS

1

39

ohm,

2

watt,

5%

26

0.1

ufd,

disc

ceramic

2

470

ohm,

%

watt,

5%

2

1

ufd,

tantalum,

dipped

11

1.5K

ohm,

watt,

5%

or

2.2K

ohm,

watt,

5%

1

15

ufd,

tantalum,

dipped

MISCELLANEOUS

1

8KRA

PC

Board

8

Augat

Pins

on

Carrier

1

Heat

Sink

1

Length

#24

Bare

Wire

1

6

or

7

Position

DIP

Switch

4

6-32

Screws

7

14-pin

DIP

Sockets

4

6-32

Lockwashers

70

16-pin

DIP

Sockets

4

6-32

Nuts

1

Right

Angle

Molex

Connector,

Male

1

Length

Solder

1

Mating

Connector

for

above,

Female

1

Manual

II-2

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

Mylar

Tubular

Capacitor

Metal

Film

1%

Precision

Resistor

Electrolytic

Capacitor

(vertical

mount)

Dipped

Tantalum

Electrolytic

Capacitor

Regulator

IC

or

Power

Transistor

(TO-220)

Transistor

TO-18

Package

(Metal

Can)

Transistor

TO-

92

Package

(Plastic)

PLN

14

Ceramic

Disc

Capacitor

Nore-.

Carbon

Film

Resistor

5%

(gold),

10%

(silver)

Dual

Inline

Package

(DIP)

IC

Socket

(8,14,16,24

or

40

pins)

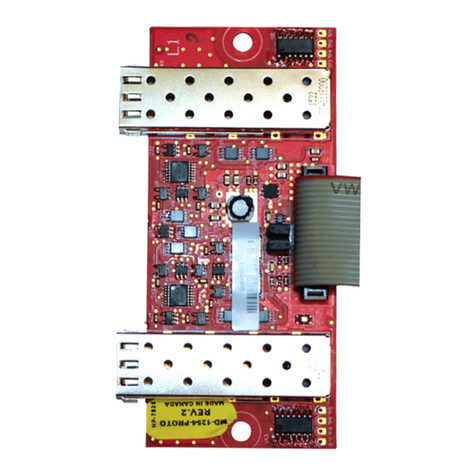

Figure

2-1.

Identification

of

components.

II-3

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

sary

handling

and

wear

cotton

—

rather

than

synthetic

—

clothing

when

handling

these

IC's.

2.3.2

Soldering

"

IMPORTANT

**

1.

Use

a

low-wattage

iron,

25

watts

maximum.

2.

Solder

neatly

and

quickly

as

possible.

3.

DO

NOT

press

tip

of

iron

on

pad

or

trace.

To

do

so

can

cause

the

pad

or

trace

to

"lift"

off

the

board

and

permanently

dam

age

it.

4.

Use

only

60-40

rosin-core

solder.

NEVER

use

acid-core

solder

or

externally

applied

fluxes.

5.

The

8KRA

uses

a

circuit

board

with

plated-through

holes.

Solder

flow

through

to

the

component

(front)

side

of

the

board

can

produce

solder

bridges.

Check

for

such

bridges

after

each

component

is

installed.

6.

The

8KRA

circuit

board

has

an

integral

solder

mask

(a

lac

quer

coating)

that

shields

selected

areas

on

the

board.

This

mask

minimizes

the

chances

of

creating

solder

bridges

during

assembly.

7.

Additional

pointers

on

soldering

are

provided

in

Appendix

III

of

this

manual.

2.3.3

Installing

and

Removing

8

ERA

Module

NEVER

install

the

8

ERA

in,

or

remove

it

from,

the

computer

with

the

power

on.

To

do

so

can

damage

the

module.

2.3.4

Installing

and

Removing

Integrated

Circuits

NEVER

install

or

remove

integrated

circuits

while

power

is

applied

to

the

8ERA.

To

do

so

can

damage

the

IC.

2.3.5

Use

of

Clip

Leads

NEVER

attach

clip

leads

to

the

top

edge

of

the

module

when

power

is

applied

to

the

8

ERA.

To

do

so

will

short

the

+8

V

de

bus

to

the

RAM

chip

enable

lines.

2.4

REQUIRED

TOOLS,

EQUIPMENT

AND

MATERIALS

The

following

tools,

equipment

and

materials

are

recommended

for

assembling

the

8

ERA

Memory

Module:

1.

Needle

nose

pliers

II-4

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

2.

Diagonal

cutters.

3.

Controlled

heat

soldering

iron,

25

watts

4.

60-40

rosin-core

solder

(supplied)

5.

Volt-ohmmeter

2.5

ORIENTATION

The

heat

sink

area

(large

foil

area)

will

be

located

in

the

upper

righthand

corner

of

the

board

when

the

edge

connector

is

posi

tioned

at

the

bottom

of

the

board.

In

this

position,

the

component

(front)

side

of

the

board

is

facing

up.

Subsequent

position

refer

ences

assume

this

orientation.

2.6

ASSEMBLY

PROCEDURE

Refer

to

the

assembly

drawing

in

Section

V.

CAUTION

THIS

DEVICE

USES

MOS

MEMORY

INTEGRATED

CIRCUITS

(IC1

-

64)

WHICH

CAN

BE

DAMAGED

BY

STATIC

ELECTRICITY

DISCHARGES.

HANDLE

THESE

IC's

SO

THAT

NO

DISCHARGE

FLOWS

THROUGH

THE

IC.

AVOID

UNNECESSARY

HAND

LING

AND

WEAR

COTTON

CLOTHING

—

RATHER

THAN

SYNTHETIC

CLOTHING

—

WHEN

HANDLING

THESE

IC's.

(STATIC

CHARGE

PROBLEMS

ARE

MUCH

WORSE

IN

LOW

HUMIDITY

ENVIRONMENTS

.)

(

X

Step

1

.

Check

circuit

board

to

insure

that

there

are

no

s

shorts

between

the

memory

chip

mounting

pads

and

that

neither

the

+8-volt

bus

nor

the

+5-volt

bus

are

shorted

to

ground.

Using

an

ohmmeter

on

its

lowest

scale,

make

the

following

measurements

:

(/)

8-volt

Bus

Test

.

Measure

between

edge

connector

pin

1

or

51

(left

end

of

connector)

and

pin

50

or

100

(right

end

of

connector).

There

should

be

no

continuity.

(

/

5-volt

Bus

Test

.

Measure

between

positive

mounting

pad

/

for

C23

and

pin

50

or

100

of

edge

connector.

Also

mea

sure

between

positive

mounting

pad

for

C22

and

pin

50

or

100

of

edge

connector.

There

should

be

no

continuity

in

either

measurement.

(/)

RAM

Area

Test

.

Measure

between

ground

(edge

connector

pin

50

or

100)

and

each

mounting

pad

(excluding

pad

9

II-5

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

which

is

connected

to

ground)

for

Id.

Also

measure

be

tween

+5-volt

bus

(positive

mounting

pad

for

C23)

and

each

mounting

pad

(excluding

pad

10

which

is

connected

to

+5

volts)

for

IC1.

Then

measure

between

all

combinations

of

vertically

and

horizontally

adjacent

pads

for

Id.

There

should

be

no

continuity

in

any

of

these

measurements.

If

you

measure

continuity

in

any

of

the

preceding

tests,

the

PC

Board

is

defective

and

should

be

returned

to

Processor

Technology

for

replacement.

If

none

of

the

measurements

show

continuity,

proceed

to

Step

2.

)

Step

2

.

Install

heat

sink.

Position

the

large,

black

heat

sink

(flat

side

to

board)

over

the

square

foil

area

in

the

upper

right

corner.

Orient

the

sink

so

that

the

two

triangles

of

mounting

holes

in

the

board

are

under

the

triangular

cut

outs

in

the

sink.

Using

two

6-32

screws,

lockwashers

and

nuts,

attach

heat

sink

to

board.

Insert

screws

from

back

(solder)

side

of

board.

(See

Figure

2-2.)

)

Step

3

.

Install

IC65

and

IC66

(340T-5.0

or

7805UC).

Position

IC65

on

the

heat

sink

and

observe

how

leads

must

be

bent

to

fit

the

mounting

holes.

Note

that

the

center

lead

(3)

must

be

bent

down

at

a

point

approximately

0.2

inches

further

from

the

body

than

the

other

leads.

Bend

leads

so

no

contact

is

made

with

heat

sink

when

IC65

is

flat

against

the

sink

and

its

mounting

hole

is

aligned

with

the

hole

in

the

sink.

Fasten

IC65

to

sink

using

6-32

screw,

lockwasher

and

nut.

Insert

screw

from

back

(solder)

side

of

board.

Solder

and

trim

leads.

Install

IC66

the

same

way

as

you

did

IC65.

(See

Figure

2-2.)

NOTE:

IC65

is

shown

rotated

approximately

position.

130°

(CCW)

from

its

correct

Figure

2-2.

Heat

sink

and

IC65

and

1066

installation

II-6

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

Step

4

.

cation

directly

above

the

heat

sink.

the

longer

pins

at

the

top,

insert

leads

solder

and

trim

leads.

Install

male

Molex

right

angle

connector

in

its

lo-

Position

connector

with

in

mounting

holes,

Step

5

.

Install

diode

D5

(1N270)

in

its

location

to

the

right

of

Area

B.

Position

D5

so

that

its

dark

band

mark

(cathode)

is

on

the

righthand

side.

Solder

and

trim

leads.

Jr)

Step

6

.

Install

diodes

Dl

,

D2

,

D3

and

D4

(1N4001

or

1N4002)

in

their

locations

above

the

heat

sink.

Position

Dl

,

D3

and

D4

that

their

dark

band

marks

(cathode)

are

at

the

bottom,

and

position

D2

so

that

its

dark

band

is

at

the

top.

Step

7

.

Install

the

ing

locations.

Take

correct

orientation.

three

tantalum

capacitors

in

the

follow-

care

to

observe

proper

values

and

the

LOCATION

VALUE

(ufd)

ORIENTATION

(/)

C21

15

"+"

lead

top

(/)

022

1

"+"

lead

bottom

(/)

023

1

"+"

lead

right

Check

the

capacitors

for

correct

value

and

orientation,

bend

leads

outward

on

solder

(back)

side

of

board,

solder

and

trim.

(/J

Step

8

.

Install

disc

capacitors

in

numerical

order

in

the

indicated

locations.

Insert

leads,

pull

down

snug

to

board,

bend

leads

outward

on

solder

(back)

side

of

board,

solder

and

trim.

NOTE

Disc

capacitor

leads

are

usually

coated

with

wax

during

the

manufacturing

pro

cess.

After

inserting

leads

through

mounting

holes,

remove

capacitor

and

clear

the

holes

of

any

wax.

Reinsert

and

install.

LOCATION

VALUE

(

ufd)

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

TYPE

Disc

Ceramic

Disc

Ceramic

Disc

Ceramic

Disc

Ceramic

Disc

Ceramic

Disc

Ceramic

Disc

Ceramic

Disc

Ceramic

(Continued

on

Page

II-8.

)

II-7

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

)

Step

8

.

(continued)

LOCATION

c9

CIO

rr

en

KT

Ci

2

CI

3

W

C14

cl

5

-W

C16

C17

(--)-

C18

(---)

C19

>(

—

)

C20

>*)

C24

C25

J»

C26

>-)

C27

4-7

028

-4-*)

C29

VALUE

(

ufd

)

TYPE

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

0.1

Disc

Ceramic

(

)

Step

9

.

Install

all

resistors

in

numerical

order

in

the

in

dicated

locations.

Bend

leads

to

fit

distance

between

the

mounting

holes,

insert

leads,

pull

down

snug

to

board,

bend

leads

outward

on

back

(solder)

side

of

board,

solder

and

trim

Refer

to

footnote

at

the

end

of

this

step

before

installing

asterisked

(*)

resistor.

VALUE

(

ohms

)

39,

2

watt

1.5K

(or

2.2K)

1.5K

(or

2.2K)

1.5K

(or

2.2K)

1.5K

(or

2.2K)

1.5K

(or

2.2K)

1.5K

(or

2.2K)

1.5K

(or

2.2K)

1.5K

(or

2.2K)

1.5K

(or

2.2K)

470

1.5K

(or

2.2K)

470

470

*D0

NOT

install

R1

unless

battery

COLOR

CODE

orange-white-black

brown-green-red**

brown-green-red**

brown-green-red**

brown-green-red**

brown-green-red*

*

brown-green-red*

*

brown-green-red**

brown-green-red**

brown-green-red**

yellow-violet-brown

brown-green-red**

yellow-violet-brown

yellow-violet-brown

standby

power

is

to

be

used

**

red-red-red

if

2.2K

ohms

II-8

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

(

)

Step

10

.

Install

Augat

pins

as

follows:

NOTE

You

will

find

it

helpful

to

hold

the

board

between

two

objects

so

that

it

stands

on

one

edge.

Area

C

.

Remove

two

pins

from

one-half

of

the

carrier.

Insert

them

into

the

mounting

holes

from

front

(component)

side

of

board.

Solder

pins

from

back

(solder)

side

of

the

board

so

that

the

solder

"wicks

up"

to

the

front

side.

(This

will

hold

the

pins

firmly

in

place.

)

Insert

a

component

lead

into

one

pin

and

reheat

the

solder.

Using

the

component

lead,

adjust

pin

until

it

is

perpen

dicular

to

board.

Allow

solder

to

cool

while

holding

the

pin

as

steady

as

possible.

Repeat

with

other

pin.

NOTE

If

the

cooled

solder

is

mottled

or

crystallized,

a

"cold

joint"

is

in

dicated,

and

the

solder

should

be

reheated.

Check

both

installations

for

cold

joints

and

solder

bridges

.

Area

B

.

Remove

three

more

pins

from

the

carrier

and

in

stall

them

in

mounting

holes

P,

CLR

and

U.

Install

these

as

you

did

the

Area

C

pins.

Check

for

cold

joints

and

solder

bridges.

Area

A

.

Remove

remaining

three

pins

from

carrier.

In

stall

two

of

them

in

mounting

holes

W

and

0.

Install

the

third

in

mounting

holes

1

or

2

if

desired

(refer

to

Sec

tion

III

of

this

manual).

Install

these

pins

as

you

did

the

Area

C

pins.

Check

for

cold

joints

and

solder

bridges.

NOTE

Only

three

Augat

pins

are

supplied

for

Area

A

since

the

8KRA

runs

at

maximum

speed

and

requires

no

wait

states.

Should you

have

a

pin

avail

able

and

wish

to

install

it

in

the

remaining

mounting

hole,

do

so.

Step

11

.

Install

DIP

Switch

in

its

location

in

the

upper

right

corner

above

the

heat

sink.

Position

it

so

Switch

No.

1

is

at

the

left.

As

you

will

note,

the

DIP

Switch

II-9

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

mounting

area

is

designed

to

accommodate

a

7-position

switch.

If

a

6-position

switch

(12

pins)

is

supplied,

position

it

as

far

to

the

left

as

possible.

(The

two

holes

to

the

right

will

be

unused

in

this

case.)

If

a

7-position

switch

(14

pins)

is

supplied,

remember

that

Switch

No.

7

is

not

used.

Step

12

.

Fill

all

exposed

(not

covered

with

lacquer)

feed-

through

holes

to

the

right

of

IC16,

IC32,

IC48

and

IC64.

Step

13

.

Using

the

#24

bare

wire,

install

jumpers

in

Areas

A,

B

and

C

according

to

your

selection

of

the

options

that

are

described

in

Section

III

of

this

manual.

\(

)

/

Step

14

.

If

you

intend

to

use

the

battery

standby

power

fea-

ture

of

the

8KRA,

fabricate

a

"cable"

to

interconnect

the

8KRA

and

your

standby

supply.

A

mating

connector

for

the

male

Molex

you

installed

in

Step

4

is

provided

for

this

purpose.

Fabri

cation

and

power

supply

details

are

shown

in

Figure

2-3.

Figure

2-3.

Standby

power

supply

and

interconnection.

11-10

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

Step

15

.

Install

RAM

DIP

sockets

and

check

installations.

Install

these

sockets

in

the

indicated

locations

with

their

end

notches

oriented

as

shown

on

the

assembly

drawing.

Take

care

not

to

create

solder

bridges

between

the

pins

and/or

traces.

(Note

that

after

each

row

of

sockets

—

e.g.,

IC1

through

16

and

IC17

through

32

—

is

installed,

you

will

be

testing

for

shorts.)

(/)

Id

through

IC16

.

Install

16-pin

DIP

sockets

in

loca

tions

IC1

through

IC16.

Then

perform

the

"RAM

Area

Test"

described

in

Step

1

of

the

Assembly

Procedure.

Make

the

measurements

at

IC1.

If

any

of

the

tests

fail,

you

cre

ated

a

solder

short

at

one

or

more

points

in

the

row

of

sockets

just

installed.

Find

and

eliminate

the

short(s)

before

proceeding

further.

If

your

installations

pass

the

test,

continue

on

to

the

next

row.

IC17

through

IC32

.

Install

16-pin

DIP

sockets

in

loca

tions

IC17

through

IC32.

Check

this

row

as

you

did

IC1

through

IC16,

but

make

the

measurements

at

IC17

.

IC33

through

IC48

.

Install

16-pin

DIP

sockets

in

loca

tions

IC33

through

IC48.

Check

this

row

as

you

did

IC1

through

IC16

,

but

make

the

measurements

at

IC33.

)

IC49

through

IC64

.

Install

16-pin

DIP

sockets

in

loca

tions

IC49

through

IC64.

Check

this

row

as

you

did

IC1

through

IC16,

but

make

the

measurements

at

IC49.

After

installing

the

sockets

for

IC1

through

IC64

and

check

ing

your

installations

for

freedom

from

shorts,

proceed

to

the

next

step.

Step

16

.

Install

remaining

DIP

sockets.

Install

each

sock

et

in

the

indicated

location

with

its

end

notch

oriented

as

shown

on

the

assembly

drawing.

Take

care

not

to

create

sol

der

shorts

between

the

pins

and/or

traces.

LOCATION

SOCKET

TYPE

IC70

IC72

IC74

IC75

IC77

IC78

IC79

IC67

through

IC69

IC71

IC73

)

IC76

14

pin

14

pin

14

pin

14

pin

14

pin

14

pin

14

pin

16

pin

16

pin

16

pin

16

pin

11-11

PROCESSOR

TECHNOLOGY

CORPORATION

8KRA

STATIC

READ/WRITE

MEMORY

MODULE

SECTION

II

(

)

Step

17

.

Check

regulator

operation.

This

check

is

made

to

prevent

potential

subsequent

damage

to

the

IC

'

s

from

incor

rect

voltages.

(

X

Install

8KRA

in

computer.

(The

use

of

a

Processor

Tech

nology

EXB

Extender

Board

is

recommended.

)

CAUTION

NEVER

INSTALL

OR

REMOVE

CIRCUIT

BOARD

WITH

POWER

ON.

TO

DO

SO

CAN

DAMAGE

THE

BOARD.

Turn

power

on

and

measure

the

voltage

between

ground

and

each

of

the

+5

V

pins

of

the

Molex

connector

(

se^

Figure

2-3

on

Page

11-10).

You

should

measure

+5

V

de

-5%

in

each

case.

£X)

If

either

voltage

is

incorrect,

determine

and

correct

the

cause

before

proceeding.

Especially

check

for

sol

der

shorts

.

If

voltages

are

correct,

turn

power

off,

from

computer,

and

go

on

to

Step

18.

remove

module

(X

Step

18

.

Install

the

following

IC

s

in

the

indicated

loca

tions.

Pay

careful

attention

to

the

proper

orientation.

NOTE

Pin

1

is

PC

Board

IC

NO

JX

IC69

X-7

IC70

XT

ic7i

IC72

f~WC73

IC74

JXTIC75

(X"lC76

5X)

IC77

W

IC78

LX

IC79

indicated

by

a

dot

on

the

and

assembly

drawing.

TYPE

74LS138

743^283

*QT98)or

809

75LS136

74LS283

74LS13

74LS109

(not

supplied)

74LS132

74LS132

8T^8>Br

098

‘

8T93

74LS04

*This

IC,

the

"wait

state

counter",

is

not

required

since

the

8KRA

runs

at

maximum

speed.

IC73

is

consequently

not

supplied

with

your

kit.

For

special

applications,

a

74LS109

can

be

used

in

this

location.

11-12

Table of contents