Procomp ZX2108 User manual

ZX2108

Revised

12.01.14

PRO COMP SUSPENSION

This document contains very important information that includes warranty information and instructions for

resolving problems you may encounter. Please keep it in the vehicle as a permanent record.

ZX2108

GM 1500 4WD & 2WD 2014-UP PRO RUNNER SS™ 0-1.75” Lift

Latest Revision

Date:

12.01.2014

400 W. Artesia Blvd.

Compton, CA 90220

Fax: (310) 747-3912

Ph: 1-800-776-0767

Website: www.procompusa.com

ZX2108

Revised

12.01.14

Introduction:

2

This installation requires a professional mechanic!

We recommend that you have access to a factory service manual to assist in the disassembly and reassembly of your

vehicle. It contains a wealth of detailed information.

Prior to installation, carefully inspect the vehicle’s steering and driveline systems paying close attention to the tie rod

ends, ball joints, wheel bearing preload, pitman and idler arms. Additionally, check steering-to-frame and suspension-

to-frame attaching points for stress cracks. The overall vehicle must be in excellent working condition. Repair or re-

place all worn or damaged parts!

Read the instructions carefully and study the illustrations before attempting installation! You may save yourself a lot of

extra work.

Check the parts and hardware against the parts list to assure that your kit is complete. Separating parts according to the

areas where they will be used and placing the hardware with the brackets before you begin will save installation time.

Check the special equipment list and ensure the availability of these tools.

Secure and properly block vehicle prior to beginning installation.

ALWAYS wear safety glasses when using power tools or working under the vehicle!

Foot pound torque readings are listed on the Torque Specifications chart at the end of the instructions. These are to be

used unless specifically directed otherwise. Apply thread lockretaining compound where specified.

IT IS ADVISABLE THAT YOU HAVE HELP AVAILABLE WHEN INSTALLING THIS KIT. SOME COM-

PONENTS ARE HEAVY AND AWKWARD. AN ADDITIONAL SET OF HANDS IS GOOD INSURANCE

AGAINST INJURY!

Please note that while every effort is made to ensure that the installation of your Pro Comp lift kit is a positive ex-

perience, variations in construction and assembly in the vehicle manufacturing process will virtually ensure that

some parts may seem difficult to install. Additionally, the current trend in manufacturing of vehicles results in a

frame that is highly flexible and may shift slightly on disassembly prior to installation. The use of pry bars and ta-

pered punches for alignment is considered normal and usually does not indicate a faulty product. However, if you

are uncertain about some aspect of the installation process, please feel free to call our tech support department at

the number listed on the cover page. We do not recommend that you modify the Pro Comp parts in any way as this

will void any warranty expressed or implied by the Pro Comp Suspension company.

Pro Comp Suspension products are gas-filled and are highly pressurized. Never place any Pro Comp Suspension prod-

uct in a vise or use a clamp on any Pro Comp Suspension product. Never apply heat near any Pro Comp Suspension

product, and never attempt to open or repair any Pro Comp Suspension, in order to prevent serious bodily injury or

death. Any attempt to misuse, misapply, modify or tamper any Pro Comp Suspension product voids any warranty and

may result in serious bodily injury or death.

DO NOT use impact tools for loosening or tightening fasteners. This may destroy the bolt threads.

Suspension springs are PRELOADED! The suspension spring must be compressed with the assistance of an appropri-

ate strut vise and spring compressor. The top mount must not be removed until the preload pressure is no longer pre-

sent and the spring can be moved by hand, or serious bodily injury or death may result.

After installing any Pro Comp Suspension product, the caster and camber must be checked and/or adjusted to comply

with the vehicle manufacturers specifications. Also, the (load dependent) brake compensator and the anti-lock brake

system must be checked and/or reset to comply with the vehicle manufacturers specifications. Also the headlight aim

must be checked and adjusted.

Reuse the original equipment components only if they are in good condition.

Otherwise replace them with new components. Never remove the slight film of oil on the piston rod and seal.

All mounting fasteners for struts must be securely tightened before tension is placed on the suspension system. Make

sure that the bump stop and dust cover are correctly and properly fastened.

When replacing other brands, Pro Comp Suspension shock absorbers should always be installed as a set. Installation of

shock absorbers, struts and cartridges requires special tools and expert knowledge. Accordingly, installation of all Pro

Comp Suspension products must be performed by a qualified suspension specialist.

All Pro Comp Suspension products must only be used for the specific, intended application as indicated in the applica-

tion guide. Any use of any Pro Comp Suspension product other than for it’s intended use may result in serious

bodily injury or death.

ZX2108

Revised

12.01.14

Part # Description Qty. Illus. Page

3

Box 1-PN ZX2108

PRO COMP SUPPLIED PARTS: (per shock)

OE22362 SHOCK W/ CIRCLIP 1 - -

P-1705 HARDWARE PACK: ZX SHOCK

130600264 MULTI POSITION SPRING SEAT 1 - -

1374000172 JOUNCE BUMPER 1 - -

113900036 M12 LOCK NUT 1 - -

129400024 SPRING SEAT COLLAR 1 - -

103300060 BUMPSTOP CAP ASSY 1 - -

106200018 CLIP 2 - -

ORIGINAL PARTS TO BE REUSED:

UPPER MOUNT (with Isolator and Dust Cover) 1 - -

COIL SPRING 1 - -

BUMPSTOP 1 - -

Rear Shock Options: ZX2020 0-1.5” Rear Lift or ZX2001 4” Rear Lift

51029B/ K1158B 2014 GM1500 4WD 4” W/ STEEL OE KNUCKLE

51030B/ K1159B 2014 GM1500 4WD 4” W/ ALUM OE KNUCKLE

51014B/ K1154B 2014 GM1500 4WD 6” W/ STEEL OE KNUCKLE

51015B/ K1155B 2014 GM1500 4WD 6” W/ ALUM OE KNUCKLE

51031B/ K1160B 2015 TAHOE 6”

Also, check out our outstanding selection of Pro Comp tires to

compliment your new installation!

Optional EquipmentAvailable from your Pro Comp Distributor!

ZX2108

Revised

12.01.14

Assembly Instructions:

4

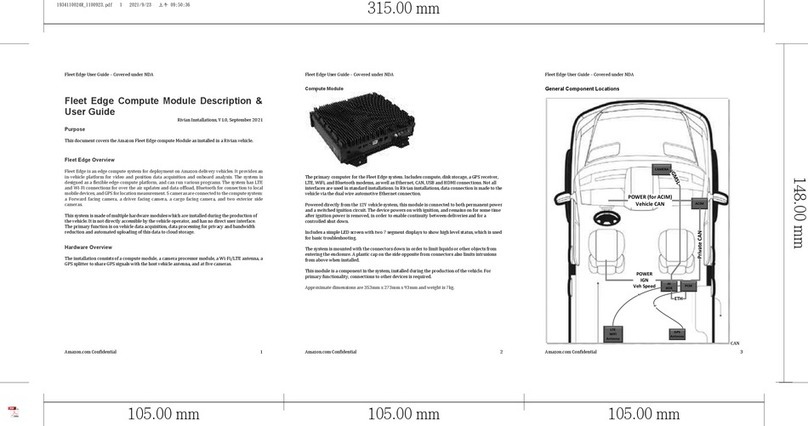

OE Upper

Mount

PC Bump

Stop

OE Coil

Spring

Pro Comp

Spring Seat

Lifted Position

(shown)

Spring Seat

Collar

Pro Comp

Multi Position

Spring Seat:

Lifted Vehicle

Position

Pro Comp

Multi Position

Spring Seat:

Stock Vehicle

Position

ILL. 1

Circlip

on shock

PC Bump Stop

Cap Assembly

1. Ensure that your work space is of adequate

size and the work surface is level. Set the

emergency brake. Place your floor jack under

the front axle and raise vehicle. Place jack

stands under the frame rails behind the front

wheel wells and lower the frame onto the

stands. Remove the jack and place blocks

both in front of and behind the rear wheels.

Remove the wheels. CAUTION: The coil is

under extreme pressure and severe bodily in-

jury may occur if the coil spring is disassem-

bled without using a coil spring compressor.

2. Unbolt and remove the OE strut assembly

from the vehicle. NOTE: The position of the

upper studs relative to the lower mount.

3. Compress the coil spring on the strut assem-

bly with a suitable coil spring compressor so

that the coil spring can be rotated by hand.

Remove the upper strut isolator retaining nut.

NOTE: Do not use an impact gun to remove

the retaining nut. It will damage the strut

shaft. NOTE: Save the OE retainers and

bushing for reuse.

4. Install the supplied PC SPRING SEAT COL-

LAR onto the new strut body with the collar

sitting over the circlip. IMPORTANT!: Be

sure the spring seat holder fits squarely over

the circlip on the strut body.

5. Install the MULTI POSITION SPRING

SEAT on to the new strut body and into

place. It will slide over and sit on the previ-

ously installed PC SPRING SEAT COLLAR.

NOTE: Ill. 1 shows stock and lifted posi-

tion orientations. (Shown not fully seated

for illustration purposes.)

6. Install the PC BUMP STOP CAP ASSEM-

BLY over the strut rod, tapping it down until

fully seated. NOTE: Use caution not to dam-

age the strut rod while seating the assembly.

ILL. 2

ZX2108

Revised

12.01.14

7. Reinstall the OE BUMPSTOP. If degraded, a

replacement has been provided.

8. Reinstall the compressed OE COIL SPRING

onto the strut assembly using the reference

marks as a guide.

9. Install the OE UPPER STRUT MOUNT over

the piston rod end onto the top of the coil

spring using the previously removed OE re-

tainers and bushings on the top and bottom.

Align the coil spring with the rubber isolator

in the upper mount. NOTE: Rotate the upper

mount so that the studs are in their original

position relative to the lower mount.

10. Secure the upper strut mount using the sup-

plied M12 NUT. Torque the upper strut

mount retaining nut to 19 ft./lbs.

11. Decompress the coil spring on the strut as-

sembly.

NOTE: Make sure that the spring is

seated correctly into the upper and lower strut

mounts.

12. Fit the strut assembly into the stock mounting

locations. Fasten using the previously re-

moved OE hardware on the top mount.

13. Install the OE bolts through the lower strut

mount and a-arm.

14. Torque the upper and lower OE strut mount-

ing hardware to manufacturers specifications.

15. Reinstall the front wheels and lower the vehi-

cle to the ground. Torque the front lug nuts

to manufacturers specifications.

16. Check the front wheel alignment. If neces-

sary, align the vehicle to manufacturers speci-

fications.

5

Assembly Instructions:

Finished Assembly

ILL. 3

ZX2108

Revised

12.01.14

The PRO COMP PROMISE WARRANTY

At Pro Comp, we know you have many choices when selecting products to personalize your vehicle. You should demand

nothing but the highest quality available and have total confidence that the products you selected are the best in the industry.

It is for these reasons that Pro Comp Suspension products are backed by the best warranty in the industry...the Pro Comp

Promise!

Pro Comp promises that its products will last a lifetime or we will replace it free of charge. It’s that simple! Because of our

commitment to quality and manufacturing excellence, we are able to stand behind our products. FOREVER.

It is Pro Comp’s Promise that if one of our suspension products breaks not due to misuse, neglect or vandalism, we will re-

place it. Whether you are the original purchaser or not, you can be assured that we will make it right. The Pro Comp Promise

covers all suspension products including shocks and steering stabilizers. Buy Pro Comp Suspension today and enjoy it for

the rest of your life!

That’s our Pro Comp Promise!

Notice to Owner, Operator, Dealer and Installer:

Vehicles that have been enhanced for off-road performance often have unique handling characteristics due to the higher

center of gravity and larger tires. This vehicle may handle, react and stop differently than many passenger cars or unmodi-

fied vehicles, both on and off–road. You must drive your vehicle safely! Extreme care should always be taken to prevent ve-

hicle rollover or loss of control, which can result in serious injury or even death. Always avoid sudden sharp turns or abrupt

maneuvers and allow more time and distance for braking! Pro Comp reminds you to fasten your seat belts at all times and

reduce speed! We will gladly answer any questions concerning the design, function, maintenance and correct use of our

products.

Please make sure that the Dealer / Installer explains and delivers all warning notices, warranty forms and instruction sheets

included with Pro Comp product.

Warranty and Return Policy:

Pro Comp warranties its full line of products to be free from defects in workmanship and materials for the life of the product.

Pro Comp’s obligation under this warranty is limited to repair or replacement, at Pro Comp’s option, of the defective product.

Any and all costs of removal, installation, freight or incidental or consequential damages are expressly excluded from this

warranty. Pro Comp is not responsible for damages and / or warranty of other vehicle parts related or non-related to the in-

stallation of Pro Comp product. A consumer who makes the decision to modify his vehicle with aftermarket components of

any kind will assume all risk and responsibility for potential damages incurred as a result of their chosen modifications. War-

ranty coverage does not include consumer opinions regardingride comfort, fitment and design. Warranty claims can be

made directly with Pro Comp or at any factory authorized Pro Comp dealer.

IMPORTANT! To validate the warranty on this purchase please be sure to mail in the warranty card.

Claims not covered under warranty

* Parts subject to normal wear; this includes bushings, bump stops, ball joints, tie rodends and heim joints.

* Finish after 90 days.

* Damage caused as a result of not following recommendations or requirements called out in the installation manuals.

Pro Comp MX Series coil-over shocks are considered a serviceable shock with a one-year warranty against leakage only.

Rebuild service and replacement parts will be available and sold separately by Pro Comp. Contact Pro Comp for specific

service charges. Pro Comp accepts no responsibility for any altered product, improper installation, lack of or improper main-

tenance or improper use of our products.

E-Mail: info@procompusa.com

Website: www.procompusa.com

Fax: (310) 747-3912

Ph: 1-800-776-0767 HERE: __________________

WARRANTY REGISTRATION

NUMBER

PLACE

This manual suits for next models

2

Table of contents

Other Procomp Automobile Accessories manuals