PROCRAFT SM1.6-1000 User manual

EN|ENGLISH

1

ELECTRIC NIBBLER

SM1.6-1000

USER MANUAL

ATTENTION!

To ensure safe and reliable functioning of the machine, the nibbler must be

used in a precise accordance to this operating manual. To avoid confusion, we

kindly ask you before starting working with the product carefully read,

understand and apply the given operating manual. You can avoid the

occurrence of accidents and incidents, having got acquainted with methods to

perform the work with machine and following safe working procedures, using

these operating instructions.

GENERAL SAFETY RULES

To ensure safe and reliable operation, grooved scissors should be used in

accordance with instructions. Before you start, you need to read and

understand this manual to the user. You can avoid the occurrence of accidents

and incidents, acquainted with the controls and following safe working

procedures.

WARNING:

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and / or serious personal

injury.

SAVE THESE INSTRUCTIONS

1.Work Area

Keep your work area clean and well it.

Cluttered benches and dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases, or dust. Power tools create sparks which may

ignite the dust or fumes.

Keep bystander children and visitors away while operating a power tool.

Distractions can cause you to lose control.

2.Electrical safety

Power tool plugs must match the outlet. Never modify the plugs in any way.

Do not use any adapter plugs with earthed power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.Do not change the plug in

EN|ENGLISH

2

any way. Double insulation eliminates the need for the three wire grounded

power cord and grounded power supply system.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges

and refrigerators. These is a increased risk of electric shock if your body is

grounded. Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock. Do not abuse the

cord. Never use the cord to carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cord increase the risk of electric shock.

When operating a power tool outside, use an outdoor extension cord marked

“W-A” or “W”. These cords are rated for outdoor use and reduce the risk of

electric shock.

3. Personal safety

Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools

may result in serious personal injury. Dress properly. Do not wear loose

clothing or jewelry. Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or long hair can be caught in

moving parts.

Avoid accidental starting. Be sure switch is off before plugging in. Carrying

tools with your finger on the switch or plugging in tools that have the switch

on invites accidents.

Remove adjusting keys or wrenches before turning the tool on. A wrench or a

key that is left attached to a rotating part of the tool may result in personal

injury.

Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate

conditions. Ordinary eye or sun

glasses are NOT eye protection.

4. Tool use and care

Use clamps or other practical way to secure and support the workpiece to a

stable platform.

Holding the work by hand or against your body is unstable and may lead to

loss of control.

Do not force tool. Use the correct tool for your application. The correct tool will

do the job better and safer at the rate for which it is designed.

EN|ENGLISH

3

Do not use tool if switch does not turn it on or off. Any tool that cannot be

controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly

maintained tools with sharp cutting edges are less likely to bind and are easier

to control.

Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tools operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool, may become hazardous

when used on another tool.

5. Service

Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of

injury. When servicing a tool, use only identical replacement parts. Follow

instructions in the Maintenance section of the manual. Use of unauthorized

parts or failure to follow Maintenance instructions may create a risk of electric

shock or injury..

Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tools operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool, may become hazardous

when used on another tool.

SPECIFIC SAFTETY RULES

DO NOT let comfort or familiarity with product (gained from repeated use )

replace strict adherence to Nibbler safety rules. If you use this tool unsafely or

incorrectly, you can suffer serious personal injury.

1. Always be sure that the tool is switched off and unplugged before

carrying out any work on the tool.

2. Always lead the power supply cord away from the tool towards the rear.

3. Do not touch the blade or the workpiece immediately after operation; they

may be extremely hot and could burn your skin.

EN|ENGLISH

4

4. Hold tool by insulated gripping surfaces when performing and operation

where the cutting tool may contact hidden wiring or its own cord. Contact with

a “live” wire will make exposed metal parts of the tool “live” and shock the

operator.

5. Hold the tool firmly with both hands.

6. Apply the machine to the workpiece only when switched on.

7. Always switch the machine off and wait until it has come to a standstill

before placing it down.

8. Never allow children to use the machine.

9. Some material contains chemicals which may be toxic. Take caution to

prevent dust inhalation and skin contact. Follow material supplier safety data.

This manual will help you understand how to use this tool. Remember

that you are working with power tools and unsafe, so be extremely

careful while working

Specifications

Model

SM1.6-1000

Rated

voltage/Frequency

220 V/50 Hz

Input Power

1000 W

Max cutting capability

For mild still: 1,6 mm

For stainless: 1,2 mm

For Aluminum: 2,5 mm

No Load speed

2000 rpm (+/-10%)

Gross /Net weight

1,9 kg

Minimum cutting radius

0,45 mm

EN|ENGLISH

5

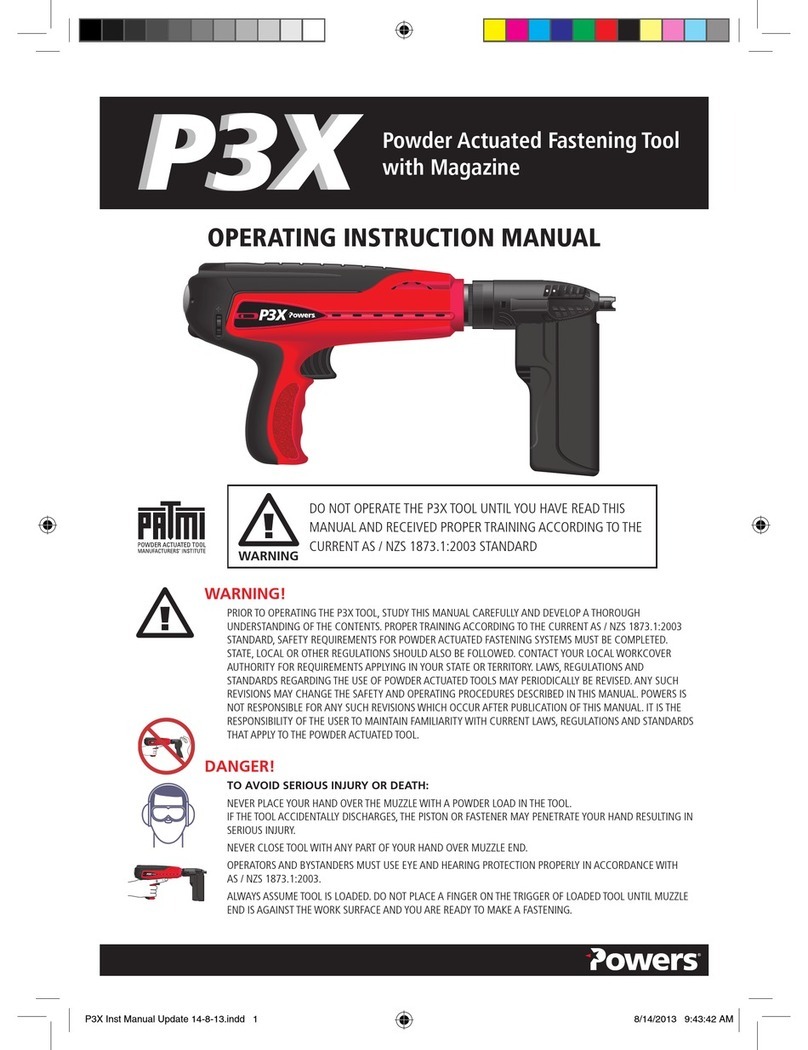

Fig 1

Description

1. screw matrix

2. matrix

3. punch

4. holder matrix

5. plugnut

6. push button

7. cap carbon brush

1. Switch ON and OFF(Fig6)

Fig 2

Caution:

Before plugging it into an outlet, check whether the switch works properly.

Press down the trigger to see whether the back switch is turned onto position

“OFF”.

To switch ON: Push the back of the switch (6) forward, and press down the

front of the switch to lock it.

To switch OFF: Press down the back of the switch to turn it off.

EN|ENGLISH

6

Change the die position(Fig3)

AWaming: Before changing the position of the die cut, make sure that the

switch of the tool is turned off, and the power plug is pulled out.

The position of the die cut can be changed within 0°,90°, 180°, 360 ° according

to the following steps:

1.Loosen the cap nut (5) with the attached wrench.

2.Pull the blanking rod slightly (4) and rotate it to a desired position.

3.Tighten the cap nut to fix the blanking rod at a desired position.

There are 4 fixed positions separately at 90° , at 0° on the right and the left, at

90° and 180° .

Fig 3

Thickness gauge (Fig4)

The recess of the holder matrix (4) is considered as a measuring scale, which

indicates the allowable thickness of the die cut.

Line of cut(Fig4)

The gap on the blanking rod indicates the line of cut. The width of the gap is

the same as the width of cut. Make sure to align the line of cut on the work-

piece with the gap.

Pre-grease

Coat the mobile oil on the line of cut of the work-piece to increase the

efficiency and strengthen the durability. It’s especially important to cut the

aluminum work-piece.

EN|ENGLISH

7

Fig 4

Method of die cut (Fig5)

Hold the electric tool to make the die cut chip at right angles (90° ) to the

work-piece being cut and push the machine slightly according to the cut

direction.

Fig 5

cutouts (Fig6)

Cutouts can be done by first opening a round hole over 21 mm in diameter

which the cutting head can be inserted into.

Fig 6

Cutting the corrugated or trapezoidal sheet metals

EN|ENGLISH

8

When cutting the corrugated or trapezoidal plate, make the punch face the cut

direction whether to cut it at an angle or at right angles. When operating, the

direction of holding the tool must run parallel to the corrugating direction.

What’s more, make the die cutting chip at right angles(90 ° ) to the work-piece

being cut. Shown as the figures 7&Fig 8.

Fig 7

Fig 8

Functional Description

EN|ENGLISH

9

Fig 9

Fig 10

■ Assembly

♦Installing and removing the punch and die ACaution:

Always be sure that the tool is switched off and unplugged before removing or

installing the punch and die.

1. Make sure to replace the punching needle and the punching die set. When

disassembling them, loosen the cap nut with the wrench, disassemble the rod

out of the tool, and then loosen the nut fastening the punching die with a hex

wrench. Disassemble the punching die out of the rod, and then loosen the

screw rod fastening the punching needle with a hex wrench. Pull the punching

needle out of the rod.(Fig9&Fig10)

When assembling the punching needle and the punching die, insert the

punching needle into the clamp to make the hole face the fastening screw rod

and then tighten it. Put the punching die into the blanking rod and tighten the

fix screw cap. Finally, put the blanking rod into the tool to make the punching

needle insert the tool through the hole in it and tighten the screw cap to fix

EN|ENGLISH

10

the blanking rod and the tool. Grease it after finishing the replacement of the

punching needle and the punching die set.(Fig11& Fig12)

Fig 11

Fig12

Replace a carbon brush

Replace and check the carbon brush regularly. When the wearing of a carbon

brush reaches the wearing limit line, It should be replaced. Keep the carbon

brush clean and make t roll freely inside the fixer. Replace the carbon brushes

at the same time. Take down the cover of the carbon brush fixer with a

screwdriver. Take out the worn-out carbon brush . Insert the new one into it

and then tighten the cover of the carbon brush fixer (7).

EN|ENGLISH

11

Fig 13

CAUTION:

Be sure to re-install the knob after inserting new carbon brush.

After replacing brushes, plug in the tool and break in brushes by running tool

with no load for about 10 minutes. Then check the tool while running, when

releasing the switch trigger.

To avoid confusion, we kindly ask you before working with the product

carefully read the conditions of use specified in this operating manual. Please

note tool is used only in domestic purposes. Lifetime warranty on the product

is 12 months. This period is calculated from the date of sale at retail.

Our warranty applies only to defects discovered within the warranty period,

and due to the industrial, technological and structural defects, ie. admitted as

the fault of the manufacturer.

The warranty does not apply to:

А) Product malfunction resulting from:

1. non-compliance with the requirements of the operating manual;

2. mechanical damage caused by external influence or any other reason;

3. misuse of the machine;

4. the impact of adverse weather and external factors on the product, such as

rain, snow, high humidity, heat, aggressive media, electric supply source

parameters, mismatched electrical requirements of the manual;

5. the use of accessories, consumables and spare parts not covered by the

technological structure of the model;

6. ingestion of foreign objects or products clogging the vents a lot of waste,

such as dust, sawdust, shavings, etc.

B) The items, that were subjected to stripping, repair or modification by

unauthorized persons.

EN|ENGLISH

12

C) Failures caused by improper handling or storage of the machine, signs of

which are:

1. the presence of rust on the metal elements of the product;

2. the presence of oxides of the engine manifold;

3. breaks and cuts of the supply cord;

4. chips, scratches, strong abrasions of housing.

D)Malfunctions caused by overloading the product which caused the failure of

the motor or other components and parts.

To definite signs of overload refers:

- deformation or melt plastic parts and assemblies of the machine;

- emergence of scale on the collector of motor or on carbon brushes;

- simultaneous failure of armature and stator;

- darkening or charring of the wire insulation.

Attention! When buying a product require a verification completeness

and serviceability.

Manufacturer reserves the right to change specifications without notice.

Specifications may differ from country to country

Other PROCRAFT Power Tools manuals

Popular Power Tools manuals by other brands

Blue point

Blue point BP301 Operating instructions manual

AVK

AVK AL Series Instruction and maintenance manual

Panasonic

Panasonic EY4541 operating instructions

Sturtevant Richmont

Sturtevant Richmont exacta 2 Quick start instructions

Gage Bilt

Gage Bilt GB703SRVT Installation

KNIPEX

KNIPEX 97 52 63 DG operating instructions