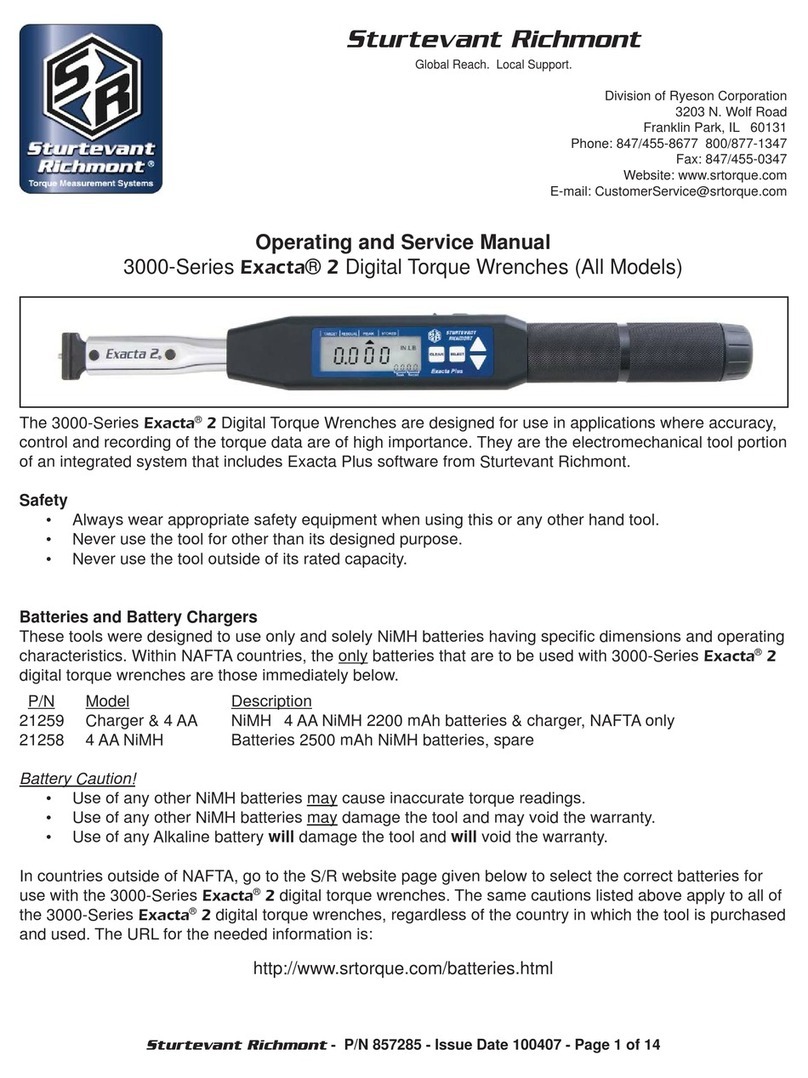

Sturtevant Richmont exacta 2 Programming manual

Sturtevant Richmont - P/N 857282 Issued 100405 - Page 1 of 4

Sturtevant Richmont

Global Reach. Local Support.

3203 N. Wolf Road, Franklin Park, IL 60131

Phones: 847/455-8677 800/877-1347 Fax: 847/455-0347

E-mail: [email protected]

URL: www.srtorque.com

Quick Start Instructions

1100-Series Exacta® 2 Digital Torque Wrench

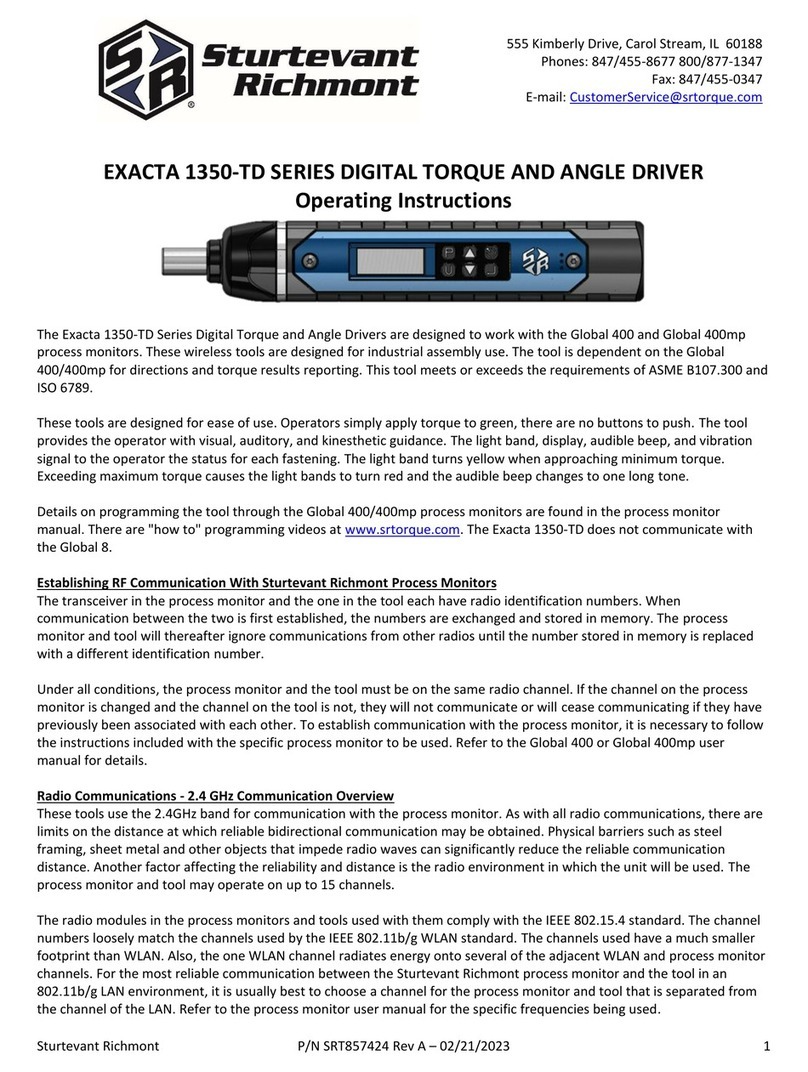

S/R 1100-Series Exacta®2Digital Torque Wrenches are designed to work with the Global 8, Global 8 - Ethernet, RFE

and RFE - Ethernet controllers to provide torque application integration that extends from your shop control system

all the way to the fastener. The details of programming the tool through each controller are found in the controller

manual.

Safety

◘Always wear appropriate personal safety equipment when operating this tool.

◘Never use this tool for any purpose other than that for which it is intended.

◘Never use the tool beyond its’ rated torque capacity.

Caution

• When using this product with an S/R controller and radio communication is lost, the tool will retain the

most recently-downloaded specifications until radio communication is re-established or alternate means

are used to change the specifications.

Battery and Battery Charger Selection

The Exacta®2 digital torque wrench has very specific battery requirements that must be adhered to. Only batteries

meeting these requirements may be used.

•Use of any batteries other than those provided by S/R or meeting the specifications on the Batteries page of our

website (http://www.srtorque.com/batteries.html) may cause the tool to become inaccurate.

•Use of any batteries other than those provided by S/R or meeting the specifications on the Batteries page of our

website (http://www.srtorque.com/batteries.html) may damage the tool.

•Use of any batteries other than those provided by S/R or meeting the specifications on the Batteries page of our

website (http://www.srtorque.com/batteries.html) will void the warranty on the tool.

•Under no circumstances should alkaline batteries, rechargeable or disposable, be used in the tool.

The correct battery and charger pack (NAFTA countries only) for tools in the Exacta®2digital torque wrench line is

S/R part number 21259. This pack includes a 15-minute charger and four (4)AANiMH 2200 mAh batteries.

The correct replacement battery pack (NAFTA countries only) for tools in the Exacta®2digital torque wrench line is

S/R part number 21258. This pack includes four (4)AANiMH 2500 mAh batteries.

Sturtevant Richmont - P/N 857282 Issued 100405 - Page 2 of 4

For countries outside NAFTA, consult the batteries page on our website (http://www.srtorque.com/batteries.html) to

find the correct battery and battery charger for use in your country. Follow the manufacturer links provided and select

the appropriate product for your country and need.

S/R Dovetail and Interchangeable Heads

Those models of the Exacta®2digital torque wrench that are equipped with an S/R dovetail are designed to be used

with S/R interchangeable heads. The dovetail design provides an exceptionally strong and rigid connection.

The Exacta®2 models with the dovetail are calibrated for use with S/R interchangeable heads having a 1 7/16”

Common Centerline Length (CCL). Use of interchangeable heads with a different CCL or head extension(s) will

make the tool inaccurate until and unless it is recalibrated with a head having the same CCL as that which has been

selected for use. Always recalibrate the tool immediately if changing to a head with a different CCL or if a head

extension is to be used.

Ratchets

Some Exacta®2 models have ratcheting square drives instead of the S/R dovetail. These are slide pin ratchets

capable of being set to ratchet in either the clockwise (CW) or counter-clockwise (CCW) direction. To change the

ratcheting direction, remove all torque load from the tool and push the slide pin to the opposite side from that to which

it is currently biased.

The ratchet should be disassembled, cleaned and lubricated periodically. The procedure for performing this function

can be found in the FAQ section of our website. See the Ratchet Replacement procedure (FAQ 7) and simply clean

and replace the original parts instead of installing new parts. If the ratchet is damaged, contact your S/R distributor

and order the correct ratchet renewal kit for your tool, then use the instructions on the website to perform the

replacement.

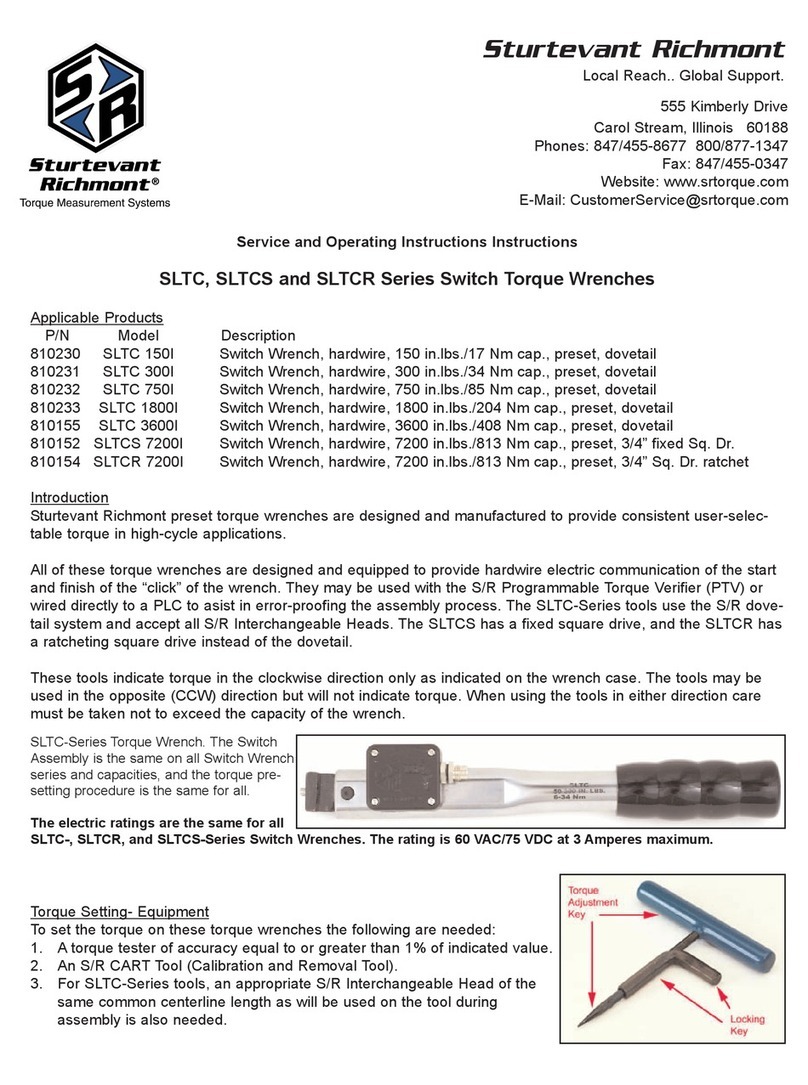

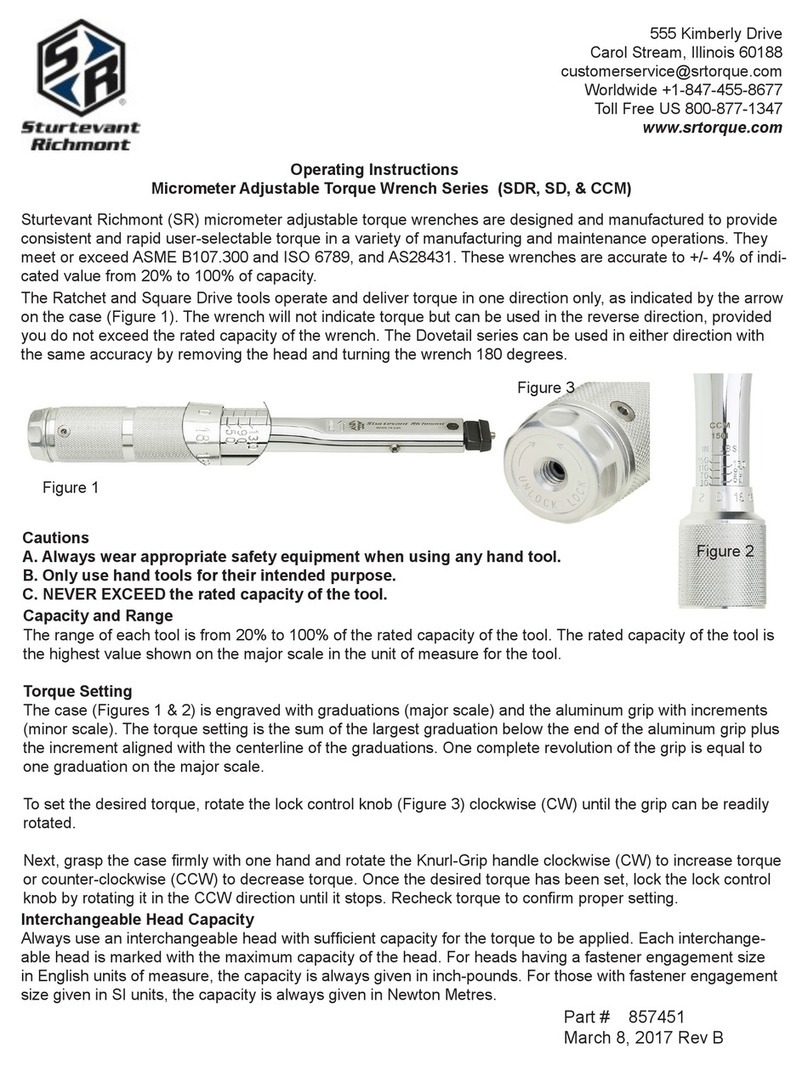

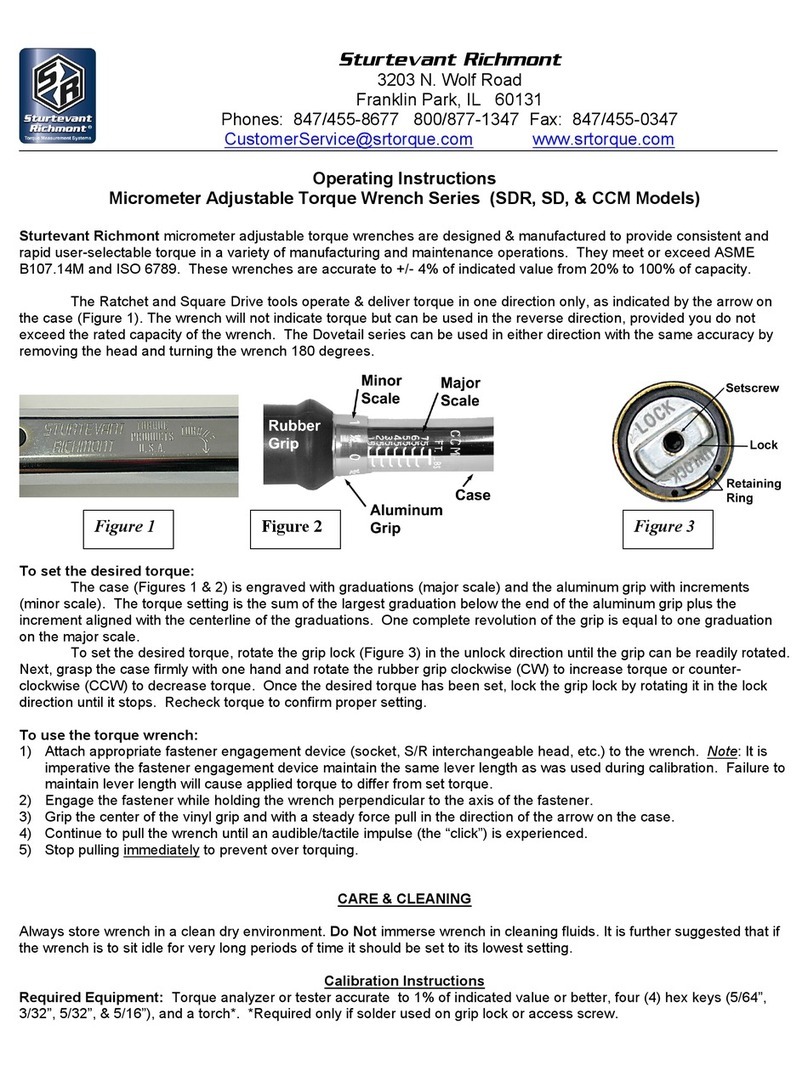

Component Identification

1. Electronics Module

The electronics module houses and protects the circuit boards, display, operating buttons and other electronic

components.

2. Display

The display conveys the visual information needed for use and generated by use.

3. Indicator Labels

These labels, working with indicators on the display, inform the user what mode or function is currently active.

4. Buttons

These buttons (Clear, Select, Up, Down) are used to access program functions and data on the display.

5. Grip

The grip is where the tool should be grasped when in use. The load point on the grip is marked by the plain ring in

the center of the grip.

6. Battery Compartment Cover

The battery compartment cover protects the batteries and associated parts, and permits access for battery

replacement.

Sturtevant Richmont - P/N 857282 Issued 100405 - Page 3 of 4

7. Switch Cover

This rubber cover protects the power switch and the serial port.

8. Serial Port

This is a single-pin serial port for communications.

9. Power Switch

This switch enables and disables electric power from the batteries to the

electronics.

10. Indicators

There are four triangular indicators in a line across the top of the display. These indicators are activated and

deactivated to show what mode or operation is currently active on the tool. To the right of these is a battery icon

(not activated in this photograph) used as a battery level (low battery power) indicator.

11. Unit of MeasureArea

This area of the display shows the

currently active unit of measure,

both during use and during

keyboard programming.

12. Data Record Area

This small four-digit display shows

the currently-active data record in

memory or, when programming, part

of the function information required. When in radio contact, it displays “rAd”.

13. Quality Attribute Area

There are several icons along the bottom of the display to the left of the Data Record area. These include “OK”

and “BAD”, which provide the attribute evaluation of the torque against the programmed specification when the

tool is in use. They also include MAX and MIN

14. CCW Icon

The CCW icon illuminates when the torque is in the counter-clockwise direction.

15. Primary Display Area

The primary display area conveys differing information depending upon the current action of the tool. This may be

numeric information such as torque values or alphabetic information such as is used in some programming and

communication functions.

16. Rear Cover

The radio cover permits access to the electronics when repair is required; it should not be removed except for

repair situations requiring its’ removal.

17. Rear LED Lens

This lens illuminates with the color (Yellow-Orange/Green/Red) in the same manner as the display when the LED

color system is in use. This permits the user to know the status of the tightening even when the tool is used in an

orientation where the display is not immediately visible.

18. Buzzer

This buzzer provides an audible indication of the torque status to augment the visual indicators. When in use, the

buzzer emits a single sound when power to the tool is enabled, a rapid series of beeps when the torque specifi-

cation is attained and while within the specification. It will emit a single longer beep if the torque specification or

torque capacity is exceeded.

Sturtevant Richmont - P/N 857282 Issued 100405 - Page 4 of 4

Battery Installation

To install the batteries in the tool:

1. Move the power switch to the disabled (off) position.

2. Unscrew the battery cover from the rear of the grip.

3. Observe the two labels inside on the battery holder.

4. Install the batteries as shown on the labels and in the

photograph here.

5. Reinstall the battery cover.

Starting Routine

To use the wrench slide the power switch to the Enabled or On position. The tool will begin an internal starting routine

and the display will first show the version of the firmware that resides on the tool then display the model of the tool

(tool capacity in foot-pounds).

Once the starting routine is complete, the tool will then show on the display the information for the status in which it

was most recently set. This includes the mode of operation, unit of measure, current data record number and target

torque setting.

If the tool has been associated with or learned by a controller, the lower right-hand corner of the display will have the

characters “rad” active.

The Controller Association or Learning Process

Each of the controllers these tools can be used with has a different learning process, and the instructions for creating

the association for each is slightly different. There are a couple of common elements in the process:

• The process will start with the tool power disabled (tool turned off)

• The controller will be placed into a “learning” mode or the tool transmitter serial number will be provided to the

controller.

• At the point in the process where the actual association is to be created, the tool power will be enabled (power

turned on).

During this process the controller and tool will establish the communication link, and the controller will notify the

operator or programmer that the association has been made, usually through a sound or LED illumination. Once

this process is complete, the options for tool programming through the controller and tool use with the controller are

available.

Using the Tool Without a Controller

S/R 1100-Series Exacta®2Digital Torque Wrenches can be used without a controller when needed, but the operating

characteristics are significatly different; the tool functions as a standard Exacta®2Digital Torque Wrench. Additional

information on this is available on our website, along with calibration instructions and Exawin 5 software. All of these

are available at no charge; simply register your tool(s) by following the links on the Exacta®2page and follow the

instructions to download all of the available options.

Cleaning, Calibration and Repair

These tools should be cleaned periodically with a soft damp cloth to remove dirt.

Factory calibration (with certification from our ISO 17025 Accredited Laboratory) is available, as is factory repair

if needed. Simply contact your S/R distributor, or contact us directly using the information on the first page of this

document.

Other manuals for exacta 2

2

Table of contents

Other Sturtevant Richmont Power Tools manuals

Sturtevant Richmont

Sturtevant Richmont LTCR Series User manual

Sturtevant Richmont

Sturtevant Richmont SLTC Series Operating instructions

Sturtevant Richmont

Sturtevant Richmont SD Series User manual

Sturtevant Richmont

Sturtevant Richmont SLTC-FM 2.4GHz Series User manual

Sturtevant Richmont

Sturtevant Richmont exacta 2 Service manual

Sturtevant Richmont

Sturtevant Richmont SLTCR-FM 2.4GHz 3000I User manual

Sturtevant Richmont

Sturtevant Richmont EXACTA 1350-TD Series User manual

Sturtevant Richmont

Sturtevant Richmont exacta 2 User manual

Sturtevant Richmont

Sturtevant Richmont DTC User manual

Sturtevant Richmont

Sturtevant Richmont SDR Series User manual