Produal KRM-X-1 User manual

USER GUIDE

KRM-X-1 & KRM-X-2

V1.0 (07.05.2020)

1 (9)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

5 d

h

3 d

h

5 d

h

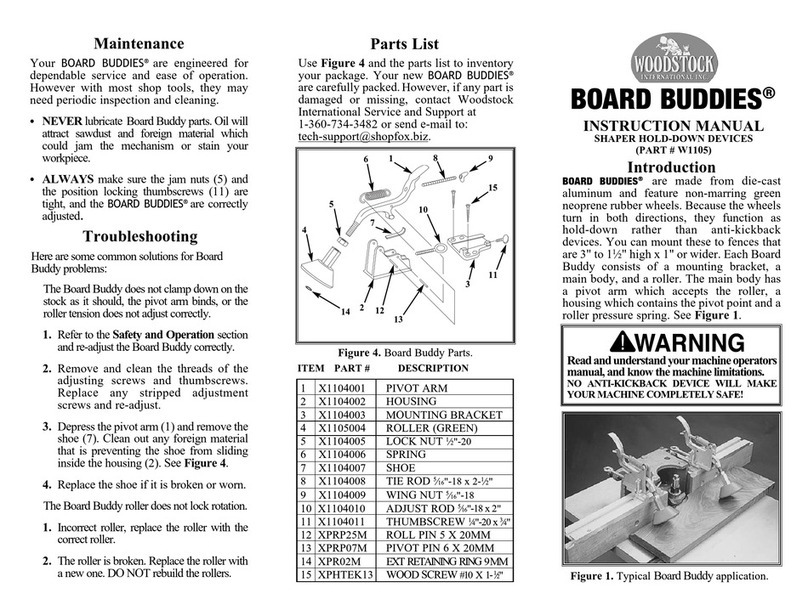

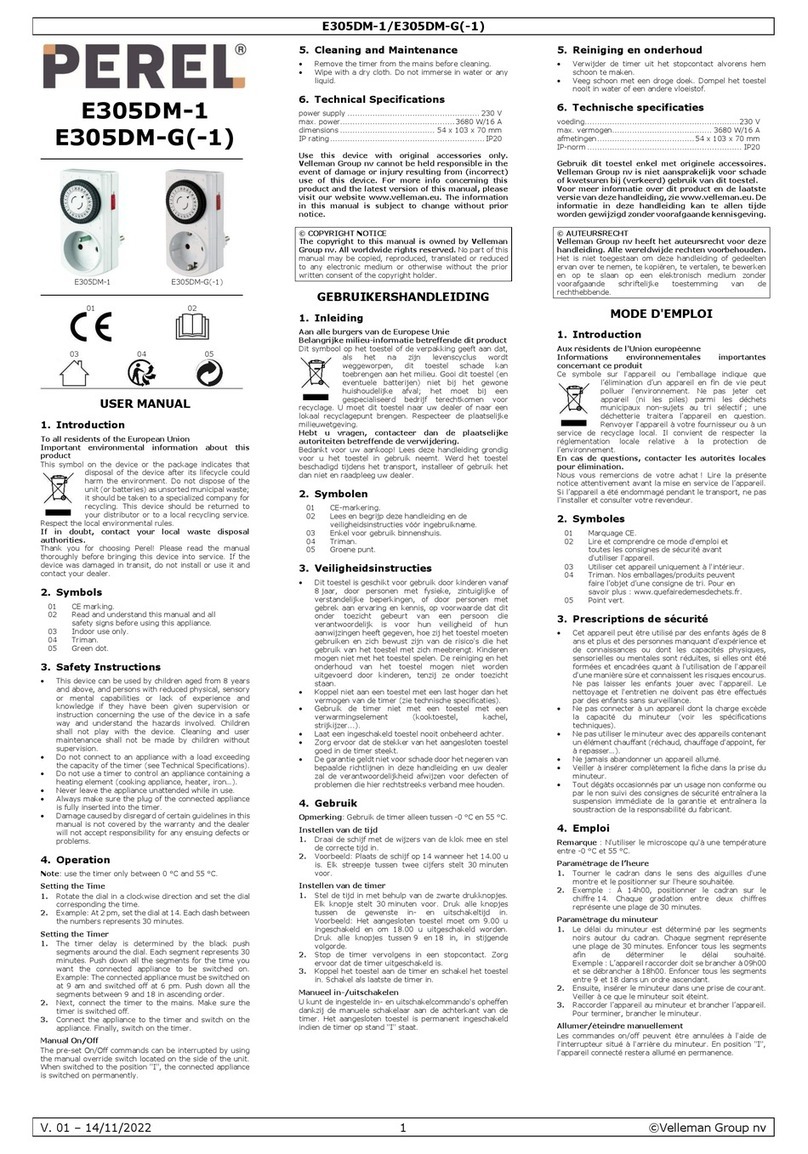

SENSOR CONSTRUCTION

1. Adapter plate with gasket

2. Patented measuring tube

3. End cap

4. Rubber bushing

(only for insulated or circular ducts)

5. Housing base with gasket

6. Electronics

7. Optical smoke detector

8. Housing top with gasket

9. LED red: alarm/reset button

10. LED yellow: failure

11. LED display: sensor contamination in %

12. LED green: in operation

13. LWD blue: airflow below 1 m/s

14. Opening for test gas

15. Air duct

ASSEMBLING

Device assembly, wiring and commissioning can only be carried out by qualified professionals.

Always make the wirings while the power is switched off.

Positioning of the sensor

The KRM-X must be positioned in accordance with the applicable local regulations on ventilation

systems. Reliable smoke detection must be ensured. The air collecting tube may be cut to a length of

160 mm, depending on the cross-section of the ventilation duct. It must not be cut to less than this

minimum length of 160 mm. Using the KS-X mounting bracket, this makes it possible to monitor ducts up

to <100 mm ø. There is no maximum width, height or diameter for air ventilation ducts monitored with the

600 mm long standard air collecting tube under the VdS approval/DIBt certification. The indicated airflow

direction must be observed when installing the tube adapter. The air collecting tube may be mounted

laterally, below or above the air duct – the location makes no difference.

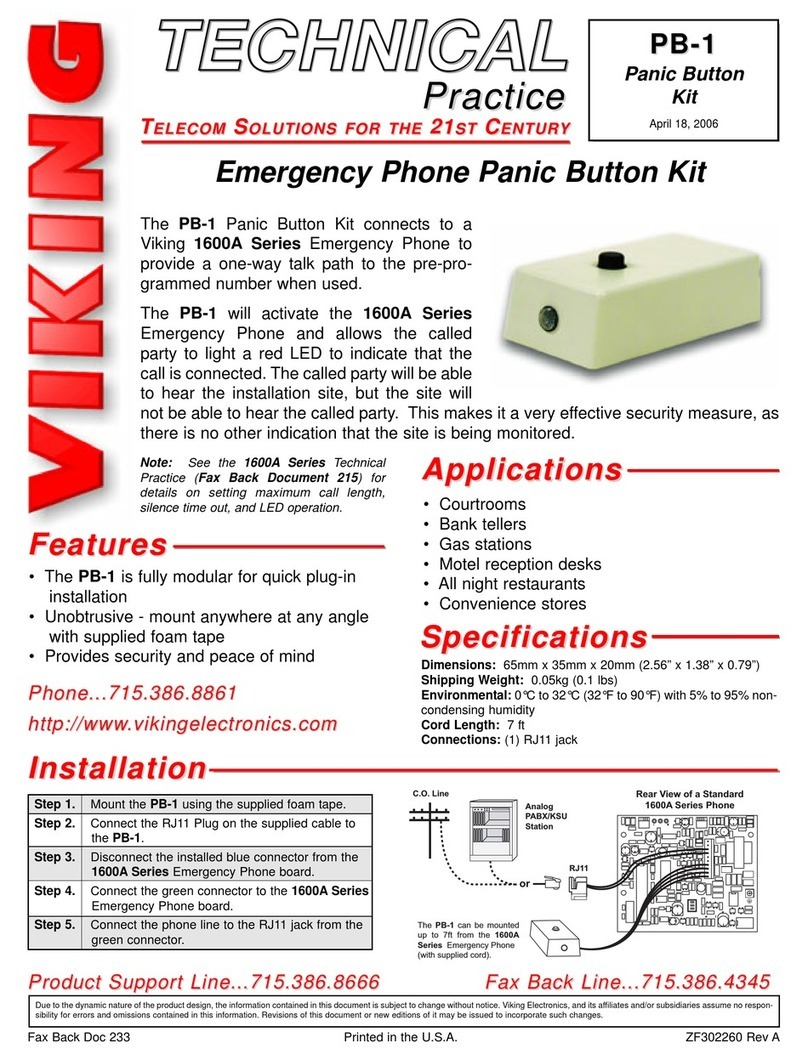

In the ideal case, as far as is structurally possible, install the KRM-X in a location where flow meters etc.

are normally installed, so that there is a laminar airflow along the measuring tube. We recommend

mounting and installing the KRM-X at the same distance from heating, cooling and humidity devices and

in a similar way as flow sensors. The distance of the KRM-X to fittings, valves, filters, etc. should be 3

times the diagonal of the channel cross-section against the flow direction and 5 times with the flow

direction, if this is structurally possible. The KRM-X, including the air collecting tube, may not be installed

along the longitudinal edges of ventilation ducts (corner area). The KRM-X must be installed such that

the air collecting tube is constantly located in the air stream. In horizontal ventilation ducts the KRM-X,

including the air collecting tube, should be installed in the upper third of the ventilation duct or at the top

of the ventilation duct, if this is structurally possible.

Example of positioning after the

change of air duct direction

Air outlet

Example of positioning after air

outlets.

1

15

10

11

12

13

14

USER GUIDE

KRM-X-1 & KRM-X-2

2 (9)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

If the positioning recommendations cannot be followed for structural reasons, the KRM-X should be

mounted such that reliable smoke detection and airflow are nonetheless ensured. The blue airflow LED

serves as an airflow indicator (the LED is off with sufficient flow).

Observe these instructions. All work (such as installation, electrical connection, start-up, operation, and

maintenance) must only be performed by sufficiently qualified tradesmen. The respectively applicable

local rules and regulations (e.g. national building codes, electrical/VDE regulations, etc.) must be

observed. Installers and operating entities are required to sufficiently familiarize themselves before start-

up. Read the product description before operating the equipment. Verify that the product can be used for

the relevant application without restrictions. We are not liable for printing errors and changes after

printing. Appropriate use implies compliance with operating and installation instructions. We are not liable

for losses due to inappropriate use. Unauthorized manipulations or modifications of the device render the

operating permit, the product warranty and warranty claims null and void.

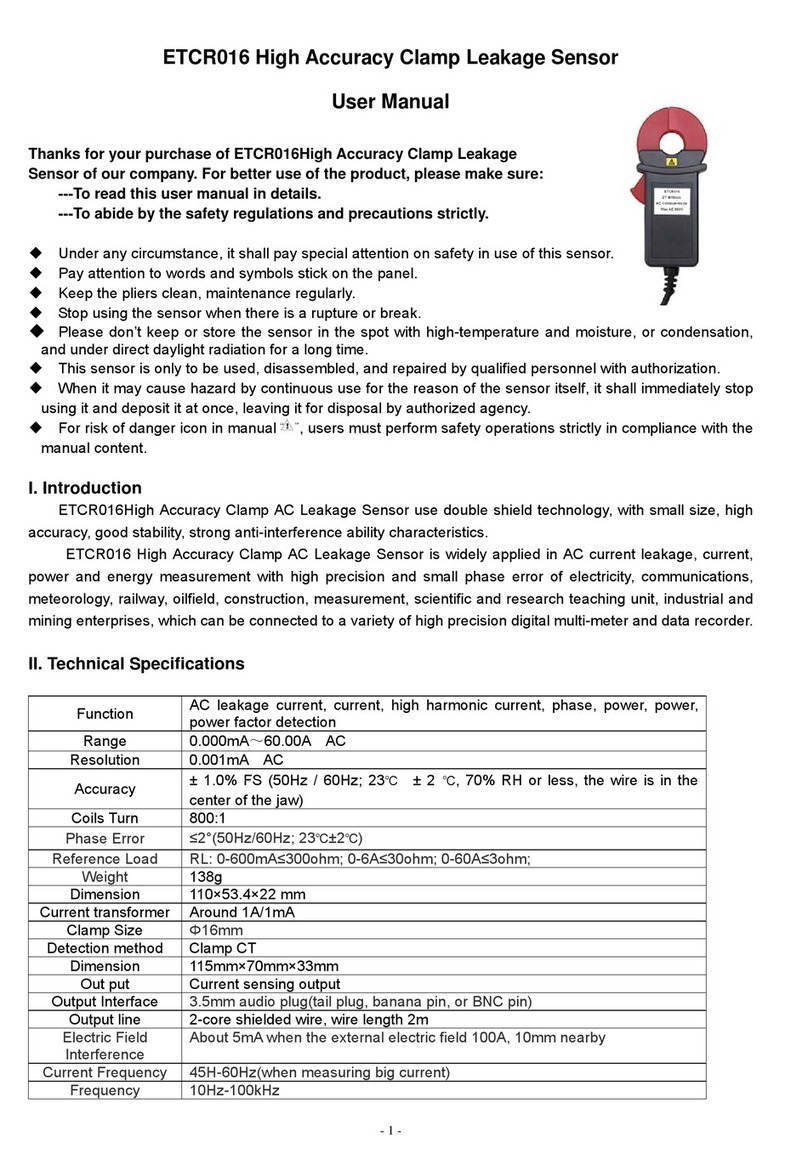

Hydraulic diameter, dh

dh

=2xHxW

H+W

H

W

dh

=D

øD

Round duct Rectangular duct

Example of positioning (recommendation):

MIN 3xd

h

MIN 5xd

h

MIN 3xd

h

MIN 5xd

h

MIN 3xd

h

MIN 5xd

h

MIN 3xd

h

MIN 5xd

h

KRM

KRMKRMKRMKRMKRMKRMKRM

Fan Damper Silencer Heater

KRM

KRM

KRM KRM KRM

KRM

KRM

KRM

MIN 5xd

h

MIN 3xd

h

MIN 5xd

h

MIN 5xd

h

MIN 3xd

h

MIN 3xd

h

MIN 5xd

h

MIN 5xd

h

MIN 3xd

h

Exhaust air

Supply air

Change in air duct

direction

Air duct forking Air duct narrowing / air

duct enlargement

Air duct device

Mounting procedure

1. Drill a hole Ø 43…44 mm in diameter at the intended mounting location.

NOTE: Installation of the measuring tube is possible either from the top, bottom or side of the chan-

nel for all duct cross-sections (for round ducts as well).

2. Determine how long the measuring tube must be. If necessary, shorten the tube. Remove the burr

from the cut tube and put the end plug back on up to the stop collar.

min. 145 mm

Caution: operation without

end plug not allowed

IMPORTANT: Operation without end plug is not allowed. Fit the end plug according to the flow direc-

tion marks.

USER GUIDE

KRM-X-1 & KRM-X-2

3 (9)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

3. Determine the direction of flow and fit the adapter plate (A) so that the line on the adapter plate un-

der the text ”Strömungsrichtung” is parallel to the flow direction. Use four self-tapping screws (not in-

cluded in delivery) for attaching the plate to the duct.

A

4. When installing on a rectangular air duct, fit the plate directly to the tube. When installing on a circu-

lar air duct, use KS-X fitting plate (B) and rubber bushing (C).

C

B

C

5. When installing on the air ducts with insulation, use the rubber bushing and insert it into opening in

the air duct. Install the fitting plate (B). Insert the assembled adapter plate (A) into the measuring

tube by sliding the measuring tube through the bushing and screw the adapter plate onto the fitting

plate (B) using 4 self-tapping screws. Then the insulation (D) can be installed.

BD

C

A

Rubber

bushing, inner

outer

USER GUIDE

KRM-X-1 & KRM-X-2

4 (9)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

6. When installing sensor outdoors or in cold environment, use WDG type housing. Housing prevents

the warm air in the smoke detector duct from condensing. The interior of the housing is insulated

with foam rubber.

7. Attach the housing bottom part (G) with the electronics and sensor to the adapter plate (A).

The housing (G+F) can be attached at increments of 90°. The direction of the housing has no effect

on the measurement result. You can align the housing with the sensor optimally.

The cover screw tightening torque is 1.2 Nm.

F

G

A

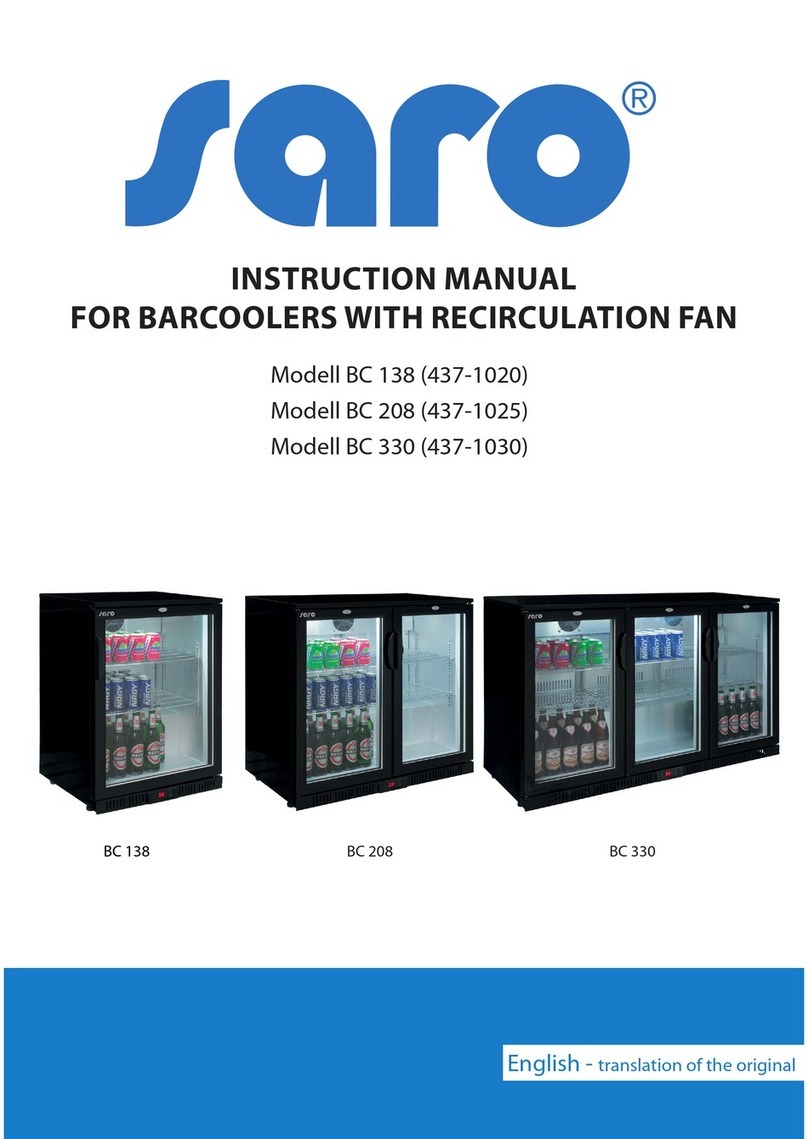

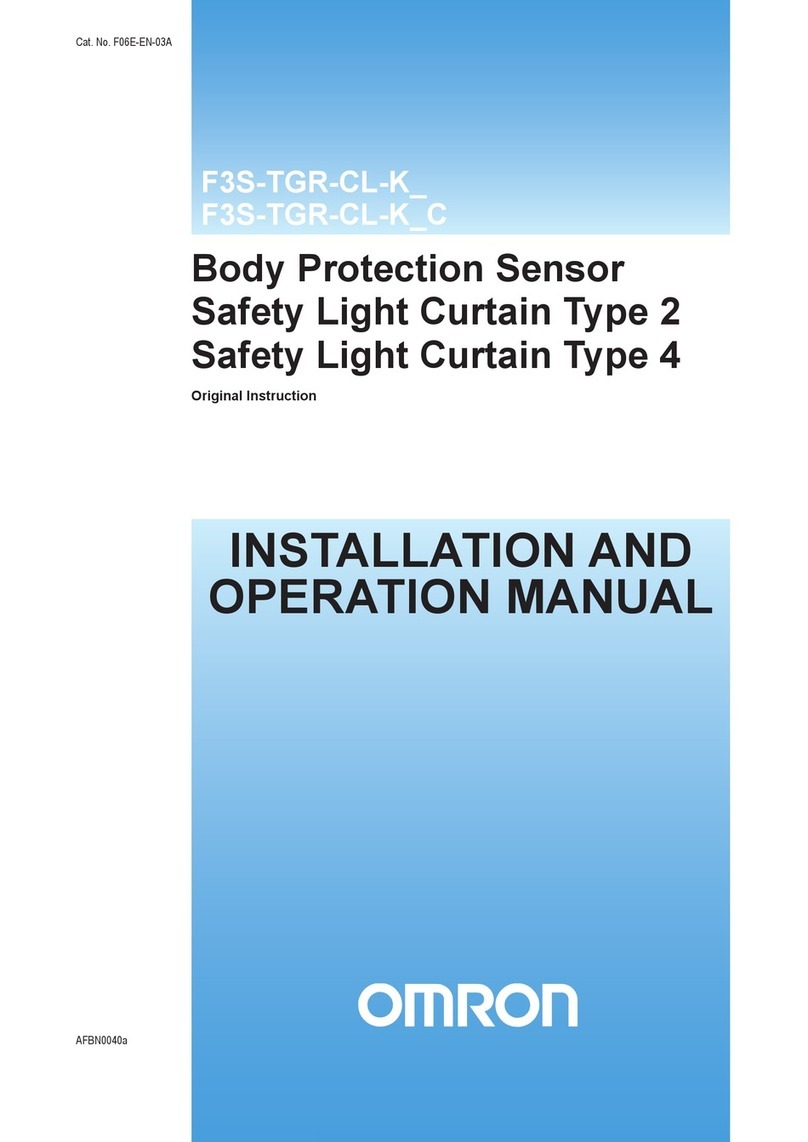

8. Wire the unit according to the applicable wiring diagram.

Power supply

230 Vac

Test/Reset

(NC contact)

9

10

11

12

13

14

15

green

16

17

yellow

blue

Smoke alarm

Smoke alarm

Service signal

Contamination

red

Test/Reset

3

4

Power supply

230 Vac

1

2

Power supply

24 Vac/dc

Test/Reset

(NC contact)

9

10

11

12

13

14

15

green

16

17

yellow

blue

Smoke alarm

Smoke alarm

Service signal

Contamination

red

Test/Reset

3

4

Power supply

24 Vac/dc

1

2

5

6

7

8

Bus B

Bus B

Bus A

Bus A

RS485

(for information)

MOD / BAC models

KRM-X-1 KRM-X-2, KRM-X-2-MOD, KRM-X-2-BAC

•The cable jacket for field wire connecting must be done as near as possible to the terminal

block. For wires longer than 10 mm, the wire must be fixed by a cable clip near the terminal

block or insulated in pairs with a suitably protective tube.

•Test/reset (terminal 9 +10): if bridge circuit is removed, a floating NC contact must be

connected.

•The floating switching contacts (terminals 11 – 17) should be assigned as uniformly as possible

to an installation category according to EN 60730-1. These switching contacts are only to be

used for 230 Vac or 24 Vac/dc. Combinations are not permitted unless at least one contact

USER GUIDE

KRM-X-1 & KRM-X-2

5 (9)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

between the potentials remains unassigned. A mixed connection of safety extra-low voltage

(SELV) and low voltage are not allowed. The assembly may only be operated on one mains

phase. Disconnection / electrical protection equipment must be provided by the customer with a

suitable fuse.

Programming the bus address and bus speed for the KRM-2-MOD / KRM-2-BAC

1. Press buttons T3+T4 on the circuit board (to the right,

next to the display) at the same time, so that the

display changes from contamination level to show the

bus address (the display will flash).

The device returns automatically to previous state after

3 seconds without a button being pressed.

2. Press the T3 or T4 button to set address (1 – 99)

3. Confirm the address with simultaneously pressing of T3

and T4. The value is saved when two underscores

appear on the display (“_ _”).

4. Set the bus speed.

The available speeds are:

01 = 9600 bit/s (default)

02 = 19800 bit/s

03 = 38400 bit/s

04 = 76800 bit/s

5. Confirm the bus speed with simultaneously pressing of

T3 and T4. The value is saved when two underscores

appear on the display (“_ _”).

NOTE: The current value is also

saved after 6 seconds without a

button being pressed.

TESTING THE SENSOR

1. Press the alarm / reset button (9) to perform a simple initial functional test. All LEDs must light up

and all relays drop out. The units connected to the relays are activated! The display (11) indicates

the current degree of sensor contamination. On releasing the button, all LEDs go out except for LED

(12), which shows the supply voltage, and the relays pull in.

11

9 9

14 14

12

2. Open the test hole cover (14).

3. Insert the test spray‘s tube fully into the test opening and release as much test gas as needed until

the smoke sensor activates. Do not spray too much, otherwise the smoke sensor may display a

higher degree of contamination at the next start / reset.

The alarm / reset button lights up, the relays drop out. The electronics are on alert and locked.

4. Press the Alarm reset button for 2 second to reset the alarm. At the time of the reset, the sensor

must be free of smoke and test gas.

5. If there is still test gas in the chamber, the device will indicate a higher contamination level. In this

case, wait a while and then perform a reset by disconnecting the voltage or perform an external

reset. If necessary, remove the housing cover and blow out the smoke from the detector.

USER GUIDE

KRM-X-1 & KRM-X-2

6 (9)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

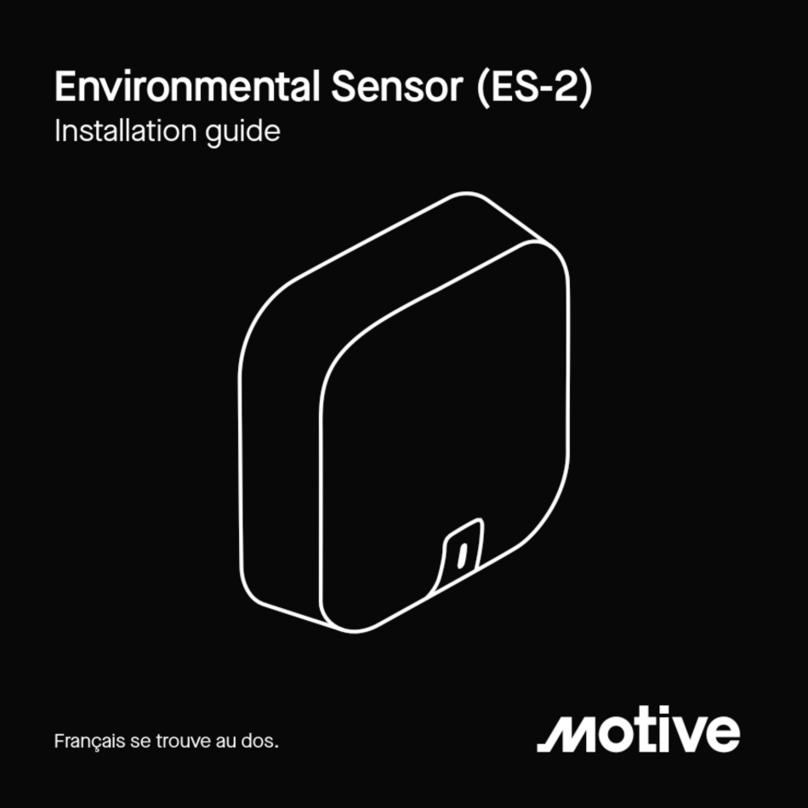

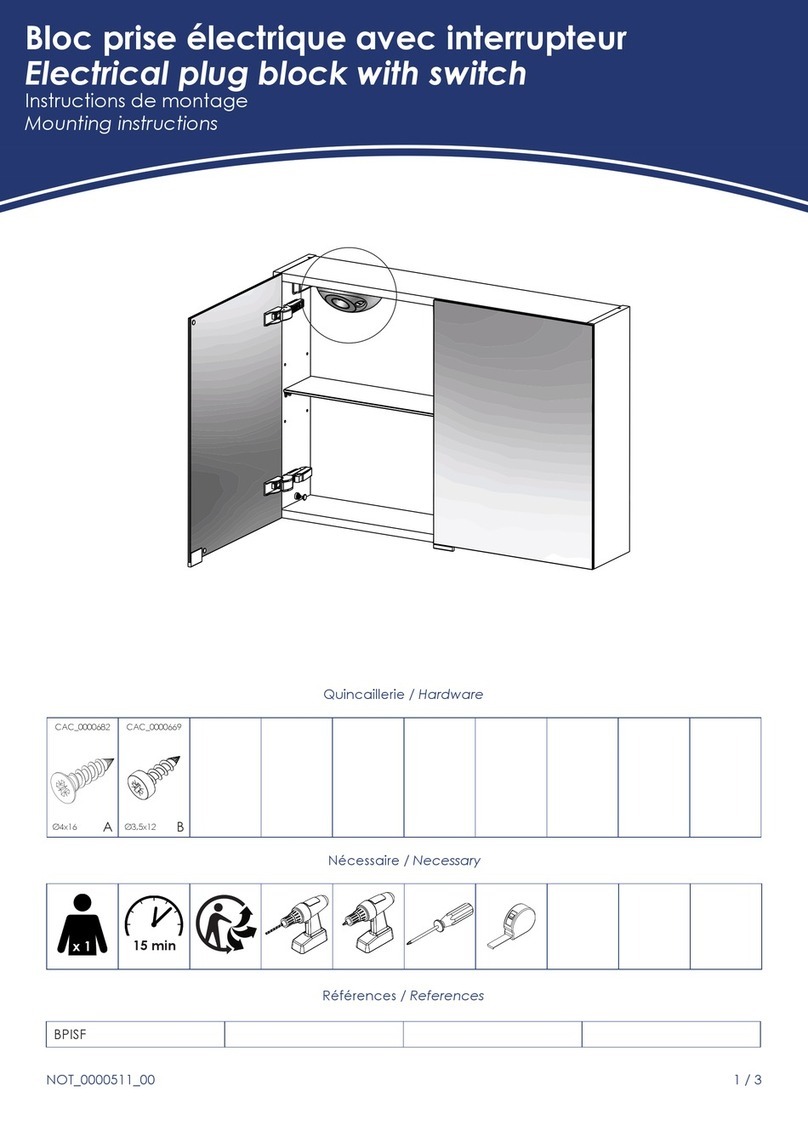

DISPLAY AND OPERATION

A. Smoke alarm (red).

B. Failure (yellow).

C. Alarm (red) and alarm/reset button.

Failure reset: briefly press button and release.

Alarm reset: Press button for at least 2 seconds until

the red light goes out.

D. Display indicator (contamination in % or status).

E. Power supply (green).

F. Air flow (blue) lights up when there is insufficient air

flow

Display Meaning Explanation

Start /

calibration

Shortly after starting the software version is displayed (4 digits), e. g.

00 then 20 = Software 0020. The BACnet versions are indicated with

“bA”. At startup or after a power failure, this is followed by a rotating

segment display.

Contamination in

%

Flashes starting at 70 % (contamination relay drops out). At 99 %, the

alarm light illuminates.

Failure e.g. Missing smoke detector, disrupted communication with the

smoke detector, processor failure.

Failure (B) and alarm (A) lights light up at the same time

Troubleshooting: change the detector and confirm by pressing the

alarm / reset button (C).

+

all lights on

the circuit

board light

up

Confirmation of

reset / new start

Occurs when alarm/reset button (C) is pressed for more than 8

seconds, or if bridge circuit/ terminal 9/10 is open (missing bridge

circuit or remote reset). Display goes out after releasing the

alarm/reset button or closing the bridge circuit between terminal 9 +

10.

00 – 99

flashing

Bus address Only appears with MOD/BAC versions after pressing the address

buttons T3/T4 directly on the circuit board.

Indicator

lights

Meaning Explanation

Alarm / reset

(red)

Smoke alarm or

failure

Reset after failure:

Briefly press alarm / reset button. KRM-X immediately restarts.

Reset after alarm:

Press and hold the alarm/reset button for at least 2 seconds until the

red alarm light in the button goes out. KRM-X will start again after

releasing the button. If the alarm/reset light continues to flash while

the button is pressed, the smoke detector is still filled with test

gas/test spray/smoke and cannot be reset. In that case, blow out the

smoke from the detector or wait.

A

B

C

A

D

E

F

USER GUIDE

KRM-X-1 & KRM-X-2

7 (9)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

Indicator

lights

Meaning Explanation

Failure

(yellow)

Defective circuit

board or missing

smoke alarm

Check / replace circuit board or smoke detector.

Smoke

alarm (2 x

red)

Smoke alarm or

contamination

99 %

Red LEDs directly on the smoke detector. LEDs permanently on until

reset has taken place.

Power

(green)

Supply voltage

is connected

Green light illuminates if supply voltage is connected.

Air flow

(blue)

Air flow is too

low

Blue light illuminates when air flow is too low. Check smoke detector

position in the duct, check sampling tube for contamination / clean if

necessary.

Behaviour of the alarm relay and fault relay and displays, plus reset options

Valid with

software

0020

Smoke alarm Device failure / missing detector

Alarm relay,

connectors

11/12/13

Drops out Drops out

Alarm relay,

connectors

14/15

Drops out Drops out

Alarm / Reset

light Lights up Lights up

Failure light Does not light up Lights up

Alarm reset or

failure reset

Disconnect power or press alarm

button or reset via terminal 9/10.

Detector chamber must have been

cleared.

Disconnect power or press alarm button or

reset via terminal 9/10. Detector chamber must

have been cleared and fault rectified.

MAINTENANCE AND REPAIR

The smoke detector must be tested at least once a year in order to ensure that it performs reliably over

long time periods. Without maintenance the sensor will become soiled sooner or later, depending on

environmental conditions, and will eventually trigger an alarm, i.e. a false alarm.

NOTE: The sensor will give a specific maintenance requirement signal at a contamination level of 70 %

(display flashes, relay contamination drops out). The smoke detector is equipped with a 2-digit digital

contamination indicator, allowing maintenance according to demand. The smoke detector must be

replaced at a contamination level 70 % or higher. The contact provided for this “contamination” signal

should be connected to the automation station.

Maintenance and repair procedure

Before starting maintenance work, it must be clarified with the staff whether the unit needs to remain

responsive to smoke while work is in progress. If a brief shutdown cannot be tolerated for operational

reasons, measures must be taken to prevent a shutdown. If necessary, a bridge can be placed over the

alarm contact for this purpose. After completion of maintenance work, any such bridge must be removed,

and a complete functional test of all system components must be carried out. Any defects found must be

rectified immediately.

Before opening the housing, turn off all supply voltages – The housing may only be opened by

a qualified electrician. Supply and switching voltages must be observed.

USER GUIDE

KRM-X-1 & KRM-X-2

8 (9)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

1. Remove the cover.

2. Turn the white sensor element anticlockwise about 20° to remove it.

The detector must be replaced by a new detector if it has reached the contamination limit (>70 %) or

if the prescribed standard replacement period has expired, whichever is earlier.

3. Clean the cover, measuring tube and the inner housing.

4. Check the electrical connections, tightening the terminals if needed.

5. Make visual inspection and clean the electrical circuit board if needed, as well as the inner housing.

Check all seals.

6. Assemble all parts.

The cover screw tightening torque is 1.2 Nm.

7. Test system by triggering the smoke detector with test spray.

9

14

8. Check with the operator about the function of the downstream systems and components, such as:

•Turning off of fans.

•Closing of flaps.

•Notification to the building automation system.

•When checking network failure and recovery, does the sensor return to its normal function and

does it unlock again from the state ”smoke alarm” and return to its normal function when there is

no longer any present? Does the detector return to the alarm state and lock up if the smoke

alarm persists?

•The detector can be released by pressing the reset button or briefly disconnecting the voltage.

MODBUS

Modbus properties

Protocol

RS-485 Modbus RTU

Bus speed

9600/19200/38400/76800 bit/s

Data bits

8

Parity

even

Start bits

1

Stop bits

1

Polling

> 100 ms

USER GUIDE

KRM-X-1 & KRM-X-2

9 (9)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

Modbus function codes

Decimal

Hexadecimal

Function

3

0x03

Read Holding Registers

Modbus registers

Holding

register

Parameter description Data type Values Range

0 Device status. U16 1 - 2 - 3 - 4 - 5 -

6

1 = Normal function

2 = Starting

3 = Fault

4 = Alarm

5 = Alarm and fault

6 = 99 % contamina-

tion

1

Smoke detector value. If the value is over

255, there is smoke in the detector. The value

is only informative.

U16 0...65535 0...65535

2

Contamination value.

U16

0...100

0...100 %

3 Air flow status U16 0 - 1

0 = Inadequate air

flow

1 = Adequate air flow

4

NTC temperature value. The value can be

used to determine the ambient temperature.

The value is combination of the ambient

temperature and self-heating of the circuit

board. See the following table for the

temperature values according to the Modbus

register values.

U16 0...65535 0...65535

Register

value

Temp [°C]

Register

value

Temp [°C]

Register

value

Temp [°C]

Register

value

Temp [°C]

75

50,2

147

33,3

298

17,1

615

2,0

79

48,8

155

32,0

314

16,0

647

1,0

83

47,5

159

31,4

326

15,2

681

0,0

87

46,3

167

30,3

342

14,2

716

-1,0

91

45,2

175

29,2

350

13,7

754

-2,0

95

44,1

183

28,1

362

12,9

794

-3,0

99

43,0

191

27,1

378

12,0

839

-4,0

103

42,0

199

26,2

396

11,0

881

-5,0

107

41,1

207

25,3

417

10,0

933

-6,0

111

40,2

218

24,1

437

9,0

979

-7,0

115

39,3

226

23,3

458

8,0

1033

-8,0

119

38,4

234

22,5

482

7,0

1090

-9,0

123

37,6

250

21,0

505

6,0

1150

-10,0

127

36,8

262

20,0

530

5,0

135

35,3

274

19,0

558

4,0

143

34,0

286

18,0

586

3,0

This manual suits for next models

1

Table of contents

Other Produal Accessories manuals