Produal HDHFL User manual

USER GUIDE

HDHFL

V2.2 (22.08.2014)

1 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 [email protected]i www.produal.com

Information is subject to change without prior notice.

COMMISSIONING

Selecting the transmitter position

The device can be installed in dry surroundings (IP20) by screws on the wall surface or on the standard flush mounting

box. The recommended installation height is 150…180 cm.

The device position should be selected carefully. All the error factors that can affect to the measurements should be

eliminated as well as possible. The following list defines the typical measurement error factors.

direct sun light

occupant proximity

air flow coming from windows or doors

air flow coming from ventilation nozzles

air flow coming from the flush mounting box

differential temperature caused by external wall

NOTE: The wireless network coverage affects also on the transmitter positioning. With the help of FLSER

commissioning tool, you can see the wireless network coverage and select the ideal transmitter positions inside the

network.

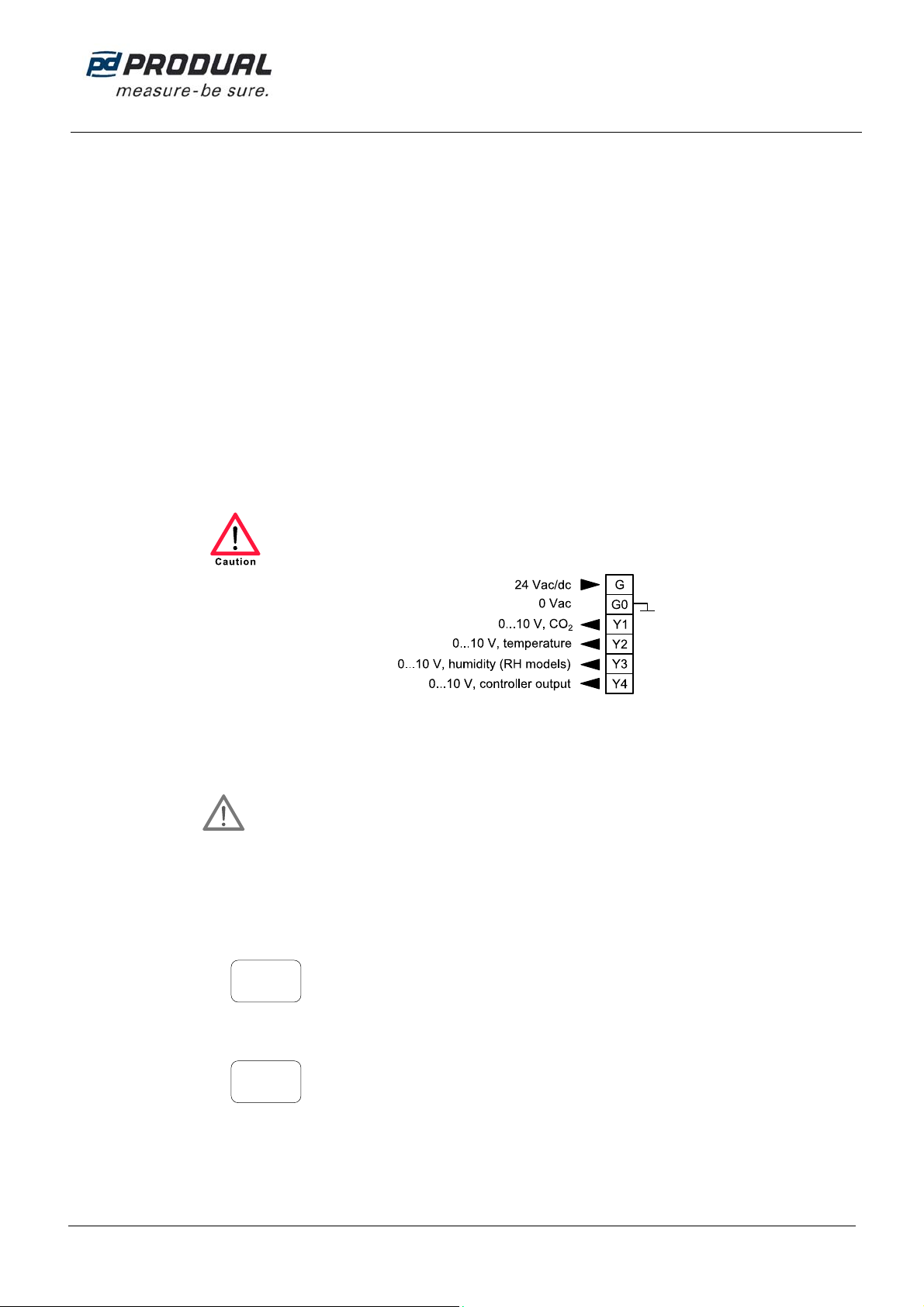

Wiring

Device wiring and commissioning can only be carried out by qualified professionals. Always make the

wirings while the power is switched off.

NOTE: CO2measurement causes a current peak to the supply voltage. This can produce an error to the analogue

outputs when using long and thin cables. It is recommended to increase the wire cross section area in long cable

situations (e.g. by using free pairs) to ensure reliable measurement signal.

Connecting to wireless network

IMPORTANT: The device wireless network settings are made by using either FLSER or ML-SER

commissioning tool. When the wireless settings are made with one tool, the other tool cannot be used to

change or check the wireless settings.

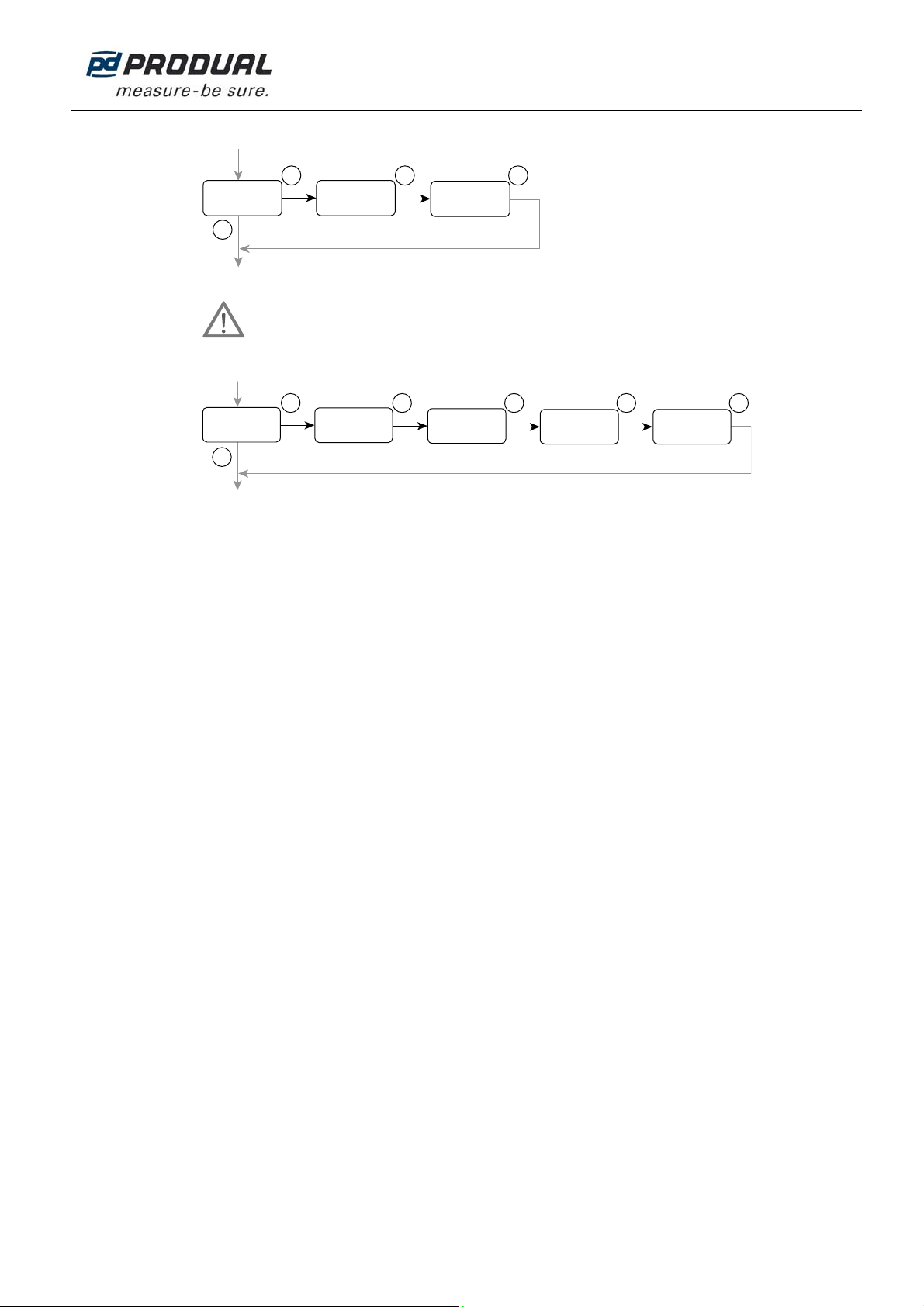

Connecting to wireless network by using FLSER tool

1. Disconnect the transmitter power supply.

2. Set the FLSER tool switch to the MID position.

3. Push the + and - buttons to select the FLTA base station master ID (MID) to which you are connecting the

transmitter.

4. Set the FLSER tool switch to the S-RID position.

5. Push the + and - buttons to select the sensor ID (SID) for the transmitter.

6. Push the OK button.

“Wait” message starts to flash on the FLSER tool display. You have now approximately 30 seconds to complete

the next step.

6

MID=

8

SID=

USER GUIDE

HDHFL

2 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 [email protected]i www.produal.com

Information is subject to change without prior notice.

7. Connect the power supply.

“OK” flashes on the FLSER display. When the flashing stops, the transmitter is ready to start the communication

with the FLTA base station.

8. FLSER tool starts to display the communication signal strengths between the FLSER and transmitter.

The bigger number indicates the strength of the received signal sent by FLSER and the smaller number the

strength of received signal sent by the transmitter.

RSSI = Received Signal Strength Indication:

1…2 = poor

3…5 = satisfactory

6…9 = good

10. Go to the FLTA base station and check that the signal strengths are adequate.

11. Set the FLSER tool switch to the OFF position.

The transmitter starts to communicate with the FLTA base station.

Reading the transmitter information from FLTA base station

The transmitter information can be read from the FLTA base station in three ways:

From the display

Temperature

CO2level

Humidity (only in RH models)

Through the analogue outputs

Via Modbus

INDICATOR LIGHT FUNCTIONS

A. Green indicator light

B. Red indicator light

The indicator lights are on for 0.5 seconds during the device start-up.

The green indicator light flashes when the device sends information to the base station. The red indicator light turns on

when the message transmit to the base station fails 20 consecutive times.

56.0

6 RH%

720

6 LUX

21.0

6 TE°C

8

RSSI 9

USER GUIDE

HDHFL

3 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 [email protected]i www.produal.com

Information is subject to change without prior notice.

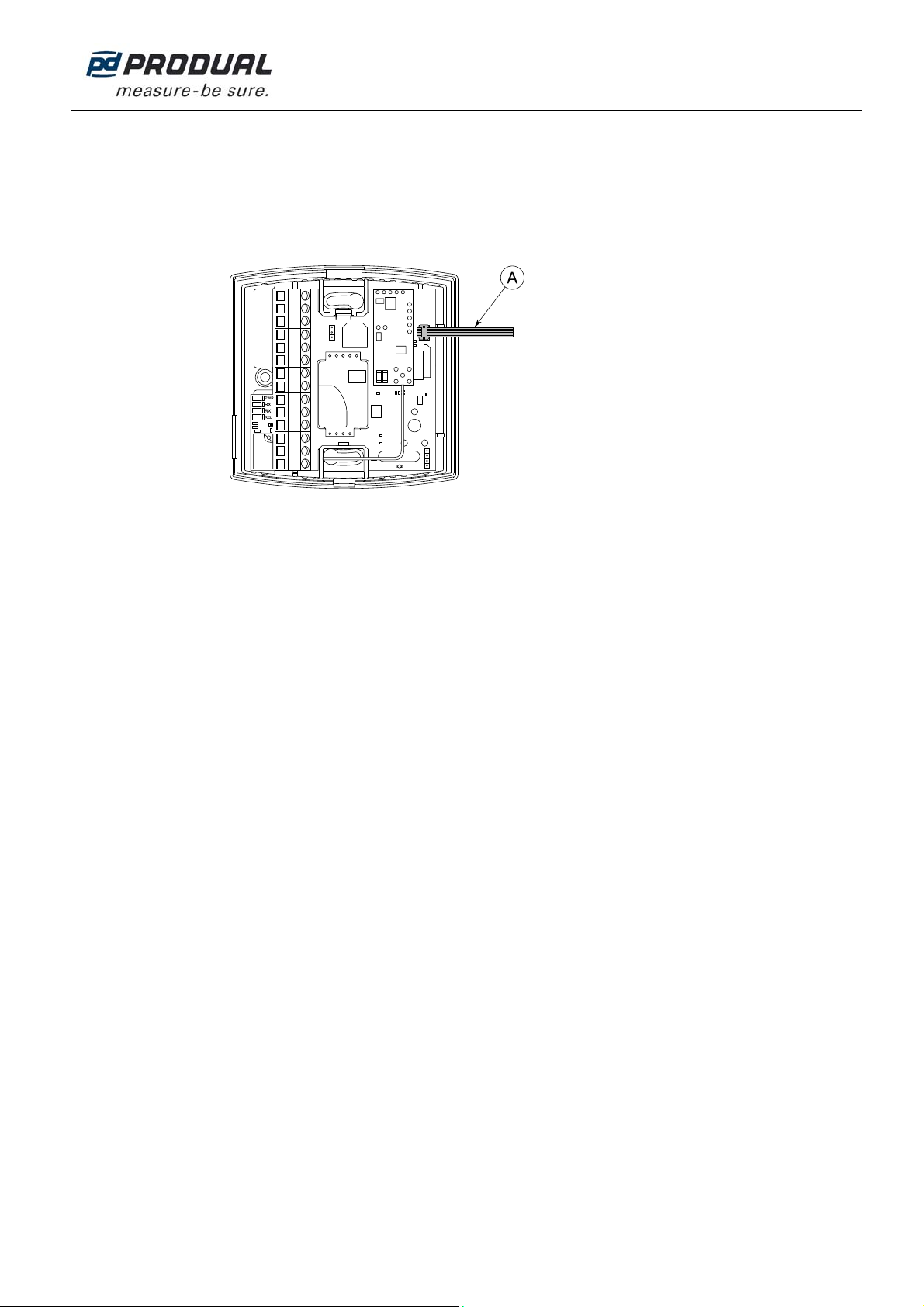

ML-SER TOOL

With the ML-SER tool you can change the device settings, controller and wireless network settings for example.

Connecting ML-SER tool to the device

1. Remove the display / HD-AL3 option.

2. Connect the ML-SER cable to the connector.

A. ML-SER cable

CO2measurement value shows on the ML-SER tool display.

USER GUIDE

HDHFL

4 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 [email protected]i www.produal.com

Information is subject to change without prior notice.

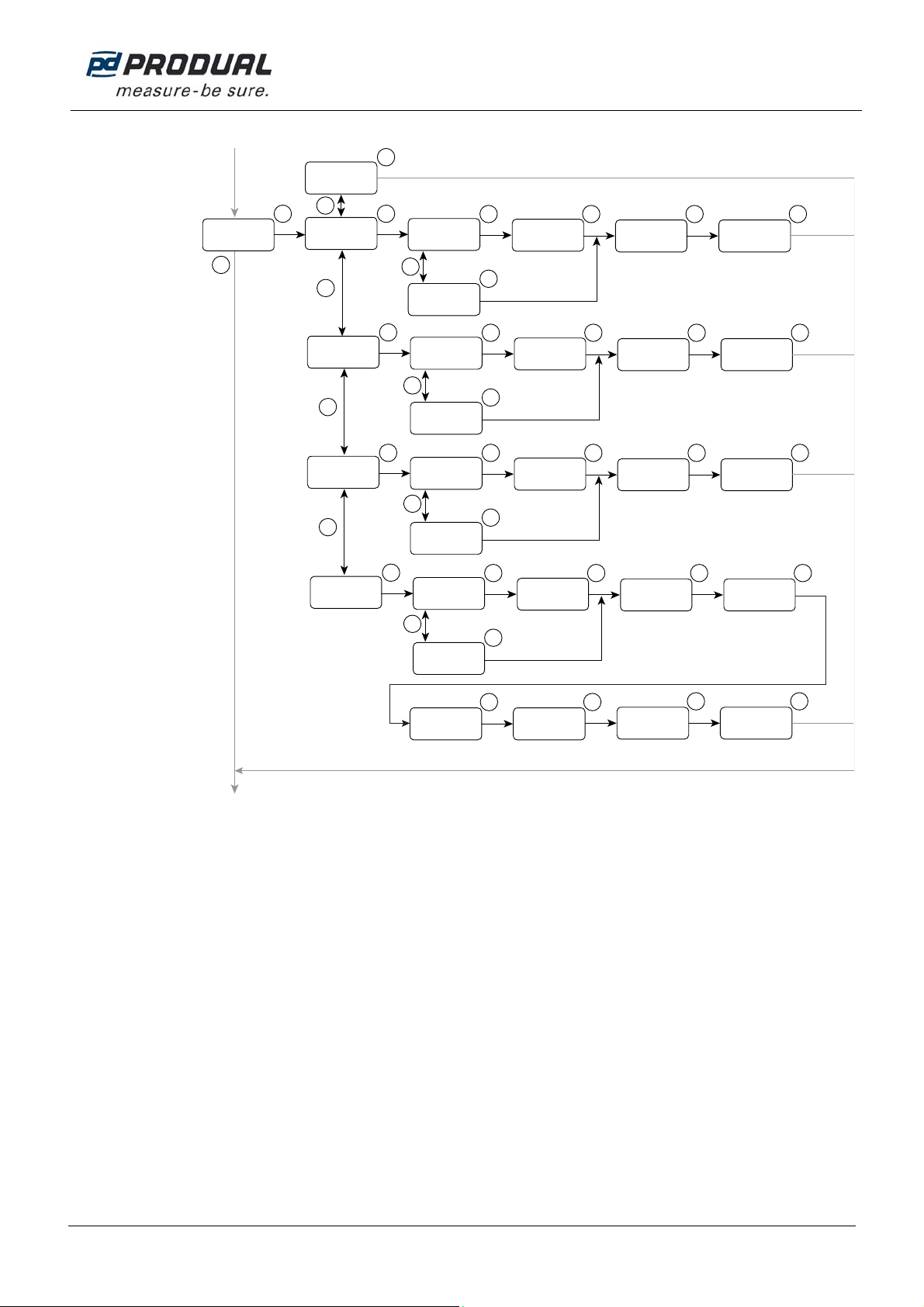

ML-SER menu

ML-SER menu opens by pressing the M button. The values can be changed with the ”+” and ”-” buttons. The menu is

device-specific and the content depends on the device and installed options.

The following menu structure contains the factory settings.

Measurement

Master ID (MID)

[1…63] Sensor ID (SID)

[OFF / 1…99]

CO

2

tuning

[±200 ppm] ABCLogiccalibration

[On / Off] Temperature measurement

tuning [±3,0 °C] Humiditymeasurement

tuning [±5 %RH]

Wireless

settings

menu

Calibration

menu

Controller

menu

AL3

menu

Info

menu

Controlmethod

[PI / P] Integration time

[50...5000 s] CO

2

set point

[400...10000ppm] CO

2

proportionalband

[100...10000]

Integration time

[50...5000 s] °C set point

[18...26 °C] ° C proportionalband

[1,0...32,0]

Integration time

[50...5000 s] %RH set point

[0...100 %] %RH proportional band

[10...100]

Integration time

[50...5000 s] CO

2

set point

[400...10000ppm] CO

2

proportionalband

[100...10000]

°C set point

[18...26 °C] ° C proportional band

[1,0...32,0] %RH setpoint

[0...100 %] %RH proportional band

[10...100]

Yellow indicator light illumination

point[400...10000 ppm] Red indicator lightillumination

point [400...10000 ppm]

Software

version Reset to factory settings

[no / yes]

Controlmethod

[PI / P]

Controlmethod

[PI / P]

Controlmethod

[PI / P]

M

M

M

OK OK OK

OK

M

Modbus ID

OK

+/-

+/-

+/-

CO2ppm

900

WIRELESS 1

MASTERID OFF

SENSOR ID

CALIBRATION

OK OK OK

Modbus ID

0

Offset:CO2ppm On

ABC-Logic 0.0

Offset: °C

OK

0

Offset: %RH

CONTROLLER

OFF

Cont

CO2

Cont

OK OK OK OK

Modbus ID

PI

Controlmode 300

Integr. time s 700

CO2Setpoint

OK

500

CO2Propor.band

P

Controlmode

OK

+/-

+/-

TEMPERATURE

Cont

OK OK OK OK

ModbusID

PI

Controlmode 300

Integr. time s 21.0

°CSetpoint

OK

2.0

°CPropor.band

P

Controlmode

OK

+/-

+/-

HUMIDITY

Cont

OK OK OK OK

ModbusID

PI

Controlmode 300

Integr. time s 50

%RHSetpoint

OK

50

%RHPropor.band

P

Controlmode

OK

+/-

MAXIMUM CTRL

Cont

OK OK OK OK

Modbus ID

PI

Controlmode 300

Integr. time s 700

CO2Setpoint

OK

500

CO2Propor.band

P

Controlmode

OK

OK

21.0

°CSetpoint

OK

2.0

°CPropor.band

OK

50

%RHSetpoint

OK

50

%RHPropor.band

M

OK OK OK

AL3 750

YELLOW 1250

RED

M

OK OK

Modbus ID

INFO 1.1.3

VERSION no

RESET

5 s

OK

OK

USER GUIDE

HDHFL

5 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 [email protected]i www.produal.com

Information is subject to change without prior notice.

Wireless settings menu

Master ID (MID)

[1…63] Sensor ID (SID)

[OFF/ 1…99]

M

OK OK OK

Modbus ID

WIRELESS 1

MASTERID 1

SENSOR ID

Through the wireless settings menu you can set the master ID and sensor ID.

IMPORTANT: The device wireless network settings are made by using either FLSER or ML-SER

commissioning tool. When the wireless settings are made with one tool, the other tool cannot be used to

change or check the wireless settings.

Calibration menu

M

OK

CALIBRATION

OK OK OK

Modbus ID

0

Offset: CO2ppm On

ABC-Logic 0.0

Offset:°C

OK

0

Offset:%RH

CO2tuning

[±200 ppm] ABCLogiccalibration

[On / Off] Temperature measurement

tuning[±3,0 °C] Humidity measurement

tuning[±5 %RH]

All the measurements can be tuned through the calibration menu. The humidity tuning is available only in RH models.

The CO2value can be adjusted by 10 ppm steps.

The temperature value can be adjusted by 0.1 °C steps.

The humidity value can be adjusted by 1 % steps.

ML-SER tool display shows how much the current value is tuned.

USER GUIDE

HDHFL

6 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 [email protected]i www.produal.com

Information is subject to change without prior notice.

Controller menu

Controlmethod

[PI / P] Integration time

[50...5000 s]

CO

2

set point

[400...10000 ppm]

CO

2

proportionalband

[100...10000]

Integration time

[50...5000s] °C set point

[18...26 °C] ° C proportional band

[1.0...32.0]

Integration time

[50...5000s] %RH setpoint

[0...100 %] %RH proportional band

[10...100]

Integration time

[50...5000 s]

CO

2

set point

[400...10000 ppm]

CO

2

proportionalband

[100...10000]

°C set point

[18...26 °C] ° C proportionalband

[1.0...32.0] %RH set point

[0...100 %] %RH proportional band

[10...100]

Controlmethod

[PI / P]

Controlmethod

[PI / P]

Controlmethod

[PI / P]

M

OK

+/-

+/-

+/-

CONTROLLER

OFF

Cont

CO2

Cont

OK OK OK OK

ModbusID

PI

Controlmode 300

Integr.time s 700

CO2Setpoint

OK

500

CO2Propor.band

P

Controlmode

OK

+/-

+/-

TEMPERATURE

Cont

OK OK OK OK

Modbus ID

PI

Controlmode 300

Integr. time s 21.0

°C Setpoint

OK

2.0

°C Propor.band

P

Controlmode

OK

+/-

+/-

HUMIDITY

Cont

OK OK OK OK

Modbus ID

PI

Controlmode 300

Integr. time s 50

%RHSetpoint

OK

50

%RHPropor.band

P

Controlmode

OK

+/-

MAXIMUM CTRL

Cont

OK OK OK OK

Modbus ID

PI

Controlmode 300

Integr. time s 700

CO2Setpoint

OK

500

CO2Propor.band

P

Controlmode

OK

OK

21.0

°C Setpoint

OK

2.0

°C Propor.band

OK

50

%RHSetpoint

OK

50

%RHPropor.band

OK

The control output can be controlled either according to a one measurement value or according to the maximum

selection of all values. Humidity related settings are only available in RH models.

The CO2values can be adjusted by 10 ppm steps.

The temperature values can be adjusted by 0,1 °C steps.

The humidity values can be adjusted by 5 % steps.

USER GUIDE

HDHFL

7 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 [email protected]i www.produal.com

Information is subject to change without prior notice.

In the maximum selection control, the control output signal is formed according to the measurement that causes the

largest control signal value. The following situation is in the example figure:

Carbon dioxide concentration is 800 ppm

Temperature is 21,5 °C

Humidity is 55 %

AL3 menu

M

OK OK OK

AL3 750

YELLOW 1250

RED

Yellow indicator light illumination

point [400...10000 ppm] Red indicator light illumination

point [400...10000 ppm]

AL3 menu is available if HD-AL3 option is installed. The indicator light limits can be changed through the menu. The

hysteresis is 50 ppm.

Info menu

M

ModbusID

INFO 1.1.0

VERSION no

RESET?

OK

OK OK

5s

Software

version Reset to factory settings

[no/ yes]

You can check the device software version and reset the device to factory settings through the Info menu.

NOTE: If the wireless settings are set with the FLSER tool, resetting the factory settings doesn't return the wireless

settings to the factory defaults.

USER GUIDE

HDHFL

8 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 [email protected]i www.produal.com

Information is subject to change without prior notice.

SELECTING THE MEASUREMENT INFORMATION TO BE VIEWED ON THE DISPLAY

The measurement values scroll on the N model display. The wanted value can be locked to view continuously by

pressing the S1 button. You resume to the scrolling view by pressing the S1 button again.

A. S1 button

CALIBRATION

If ABCLogic™ method is not in use, the device should be calibrated every 6-12 months. The recommended calibration

interval is 5 years even if the ABCLogic™ is in use.

ABCLOGICTM self-calibration feature

ABCLogic™ (Automatic Background Calibration Logic) is a patented self-calibration technique. ABCLogic™ method

eliminates the possible long term drift. ABCLogic™ method can be used when the CO2concentration drops at least

two times within a week to the level of approx. 400 ppm. Therefore the ABCLogic™ is effective in spaces that are not

continuously occupied.

ABCLogic™ can be deactivated in continuously occupied spaces.

Deactivating the ABCLogic™

The ABCLogic™ function can be deactivated by using the ML-SER tool.

Table of contents

Popular Measuring Instrument manuals by other brands

Schroeder Industries

Schroeder Industries HY-TRAX Operating and maintenance instructions

Cybertronix

Cybertronix Sentinel EFI-MFZ-50 user manual

Arkon

Arkon AgrimagP user guide

Rion

Rion UN-14 instruction manual

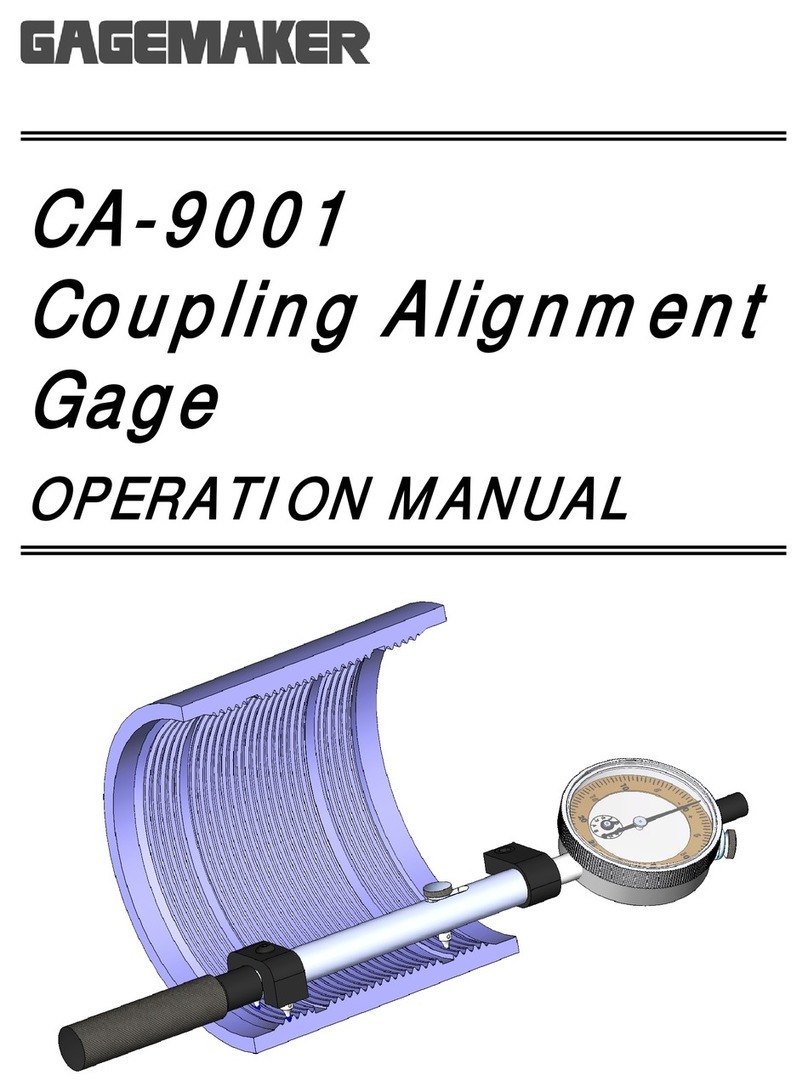

GAGEMAKER

GAGEMAKER CA-9001 Operation manual

Transducer Techniques

Transducer Techniques SSI Operator's manual

Endress+Hauser

Endress+Hauser RID14 Brief operating instructions

AESSEAL

AESSEAL FLOWTRUE FTP-50-145 Installation, operation & maintenance manual

Doza

Doza MKS-15D Snegir user manual

Vaisala

Vaisala HUMICAP HM70 user guide

Endress+Hauser

Endress+Hauser dosimass technical information

Rae

Rae ToxiRAE Pro user guide