Professional Picture Frame Equipment Onyx 90 User manual

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Know Your Onyx 90 Media Cutter

Professional Picture Frame Equipment

441 South Whitted Street

Hendersonville, North Carolina 28739

Vol318

Owner’s Manual

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Page 2

Congratulations and thank you! You have just purchased what we believe is the best

wall mounted media cutter in the world. The Onyx 90 will provide you with a lifetime

ofdependableservicewithonlyminimalmaintenance.

We know you are anxious to begin using it. But before you do anything, please take

the necessary time to read and understand this manual. It will answer a lot of your

questionsand avoid possible problems.

Table of Contents

1.0 SafetyPrecautions&Recommendations Page 3

2.0 Registration&Warranty Page 3

3.0 KnowYourMachine Page 3

4.0 Installation of the Onyx 90 Page 5

5.0 CuttingTool Holders Page 9

6.0 Using theOnyx 90 Page 10

7.0 RoutineMaintenance Page 13

8.0 Adjustments Page 13

9.0 Troubleshooting Page 17

Every Onyx 90 machine is made using computer controlled (CNC) machiney here in North

Carolina. Every machine is assembled from the parts made here and assembled on a wall by

experienced assembly technicians.

It is adjusted and set up for cutting glass, mat board and acrylic. There is a form that comes

with each machine showing it was checked and approved by a supervisor.

Please DO NOTADJUST the machine.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

1. Safety Precautions & Recommendations

WhenusingtheOnyx90, basicsafetyprecautions shouldalwaysbe followedtoeliminate theriskof damageorinjury to

personsormaterials. Wearsafetyglasses,glovesandprotectiveclothing. Usecaution when using,transporting,

storingordisposing ofdangerousobjects,such ascuttingtools,glass, etc. Makesurethemachine is mountedsecurely.

Manysituations exist thatwecan not predict,butit iscriticalthatyour Onyx90isattached securelyandsolidlyto the

wall.Keepthe machine and theworkareaaround the machineclean. Neverplaceyourhand or fingersbehindthe

mediaclamp. For what it is worth – be safe!

2.0 Registration & Warranty

YourOnyx 90hasa5yearmanufacturer’s warranty from the date of purchase. Please takeamomenttocompleteand

mailtheenclosed warranty card. Proofofpurchasemust be submittedwiththe warranty card.

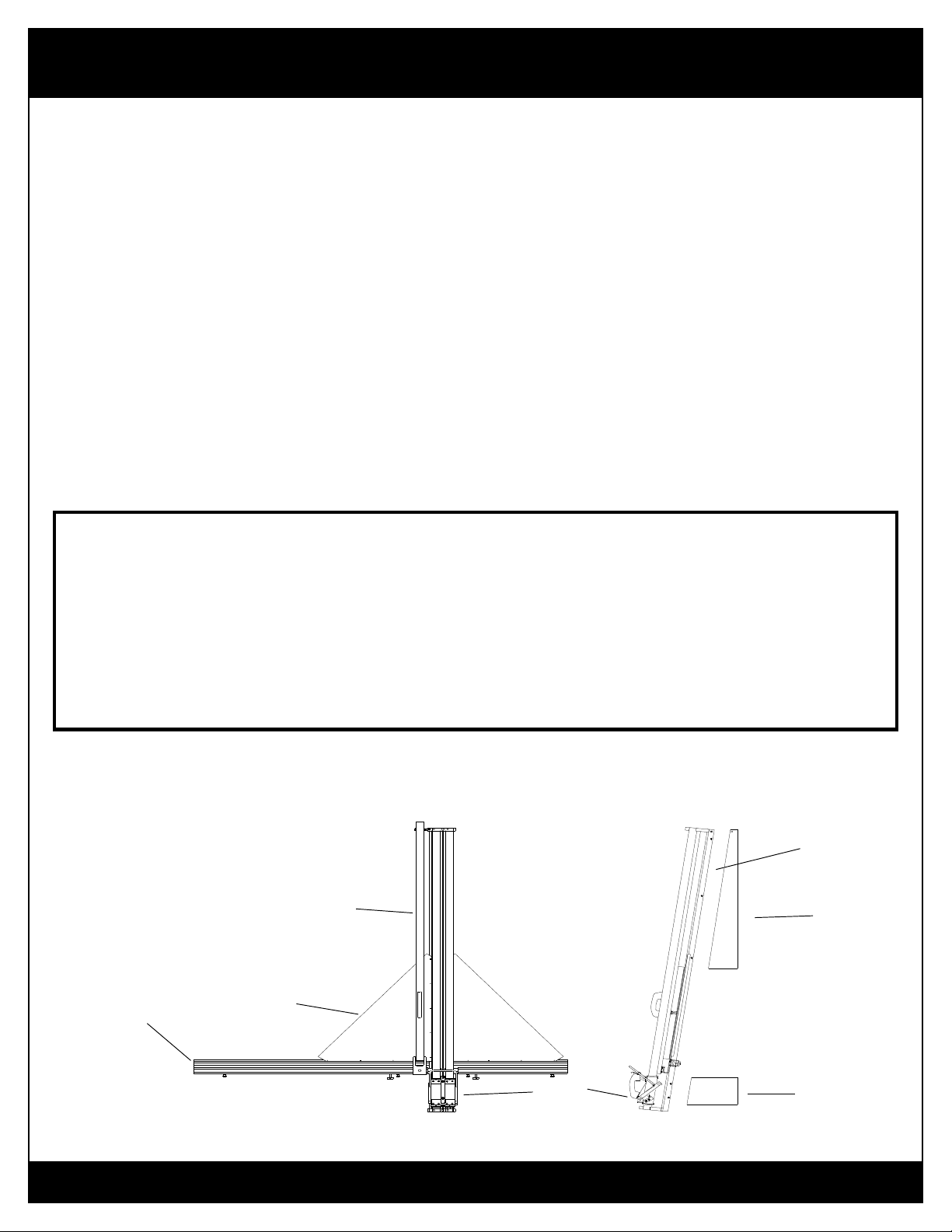

Verticalaxis

extrusion

Top hanging

bracket

Bottom hanging

bracket

Cutting

Cart

Lefthorizontal

extrusion Left stainless

steel gusset

plate

Mediaclamp

assembly

Page 3

3.0 Know Your Machine

Diagram of Parts

Professional Picture Frame Equipment warrants the Onyx 90 to be free from defects in workmanship and parts for 5

years from the date of purchase. Professional Picture Frame Equipment warrants it will repair or replace any defec-

tive parts. The Onyx 90 must be subjected to normal use and service. A return merchandise authorization (RMA) must

be requested from Professional Picture Frame Equipment before returning. The transportation to and from the factory

is the customer’s responsibility. This warranty is in lieu of all other agreements. Professional Picture Frame Equipment

is not liable for any damages or losses, incidental or consequential, direct or indirect, arising out of the use of this

product.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Bearing-tubes and

cart-assembly unit

Horizontal mounting

brackets

Bottom hanging

bracket

Top hanging

bracket

Media clamp

assembly

Left stainless

steel gusset

plate

Right stainless

steel gusset

plate

Lefthorizontal

extrusion Right horizontal

extrusion

Page 4

List of Parts That Were Shipped

Owner’sManual

Box(large cardboardshippingbox)

MediaClampAssembly

Bearing-tubesandCartAssemblywithattachedVerticalAxisExtrusionunit

LeftHorizontalExtrusion

RightHorizontalExtrusion

StainlessSteel Gusset Plates(2)

VerticalWallMountingBrackets(2)

HorizontalWallMountingBrackets(2)

Hardware Packets (4)

GlassCuttingToolHolder

MatBoardCuttingToolHolder

PlasticCuttingToolHolder

ProductionStop

SpareMatCutting Blades

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Builder’s

square

Page 5

Matcuttingtool Glass cutting tool Acryliccuttingtool

BlackHandle Red Handle Blue Handle

4.0 Installation

Toolsyouwillneedto collect beforebeginning installation

An assistant

Ladder

Level,preferably atleast3 ftlong

Electricdrill/screwdriver witheithera1/4”masonrydrillbit or1/8”woodbit

Hammer

Phillipsheadscrewdriver,large

Tape measure

Straightedge,36” orlonger

Builder’s square

Pencil

Step-By-Step Instructions

Thesewritteninstructions areprovidedhere. TheOwner’s Manual andvideoare also availableontheInternet. http://

www.youtube.com/watch?feature=player_detailpage&v=ZmZyR4oX7sM

1. Determineon whattypeof wallyouwill beinstallingyour machine-wood,drywall,steelormasonry? Follow

appropriateinstructions.

2.Determine your personalworkingheight (seebelow).

Cutting Bed Elevation Chart

Generallyspeaking,mostframers determinethe cuttingbed height(theheightthatyourmediarestson)oftheirmachine

asinfluenced by twofactors:employee’s workheight,andthe weightandsizeof thematerialstobe placedontothe

cuttingbed of theOnyx 90.For exampleifyouare tall,thenmounting the machinehighermay bebetterforyou. If you

processalot of largesized glass,acrylicor other sheetmaterials,youmay find alowercuttingbed height better. Al-

waysthinkofsafetywhenliftingandprocessingyourmaterials.Fromthefollowingchart,choosethecuttingbedheight

suitedfor youandyour employees. Onceyouhavedeterminedyour cuttingbedheight, thischartwill indicatethe

measurementof the topholeof the tophangingbracket.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Page 6

33 inches above the floor 93 inches above the floor

32 inches above the floor 92 inches above the floor

31 inches above the floor 91 inches above the floor

30 inches above the floor 90 inches above the floor

29 inches above the floor 89 inches above the floor

28 inches above the floor 88 inches above the floor

27 inches above the floor 87 inches above the floor

26 inches above the floor 86 inches above the floor

25 inches above the floor 85 inches above the floor

Note: If you have an 8' ceiling, the maximum cutting bed height will be 31” from the floor.

Installation on a Wood Wall

It is very helpful to watch the “How To Install” video

http://www.youtube.com/watch?v=ZmZyR4oX7sM&feature=player_detailpage

1.Removeprotectivepolyethylenefilmfromallstainlesssteel parts.

2.Locatea vertical stud on thewall.

3.Using alevel,draw averticalline 94”inlength onthewalltothefloor.

4.Drill a 1/8”pilothole on theline91” from thefloor. (Seeabovechart to determineyourpersonal working height.)

5.Usingthe top hanging bracketasatemplate, center the topholeofthetop hanging bracket overthedrilledhole on

theline.Tracetwocircles for thetwolower holes.

6.Remove the bracket/templateanddrillthe twolower1/8”pilot holes

7.Placethetophangingbracketover the holes and using the screws and washers from the bracket hardware package,

mountthe tophangingbracket inallthreeplaces.

8. Measure 29 1/4” downfrom the bottom of the top hanging bracket and place a mark on the vertical line.

9. Placethetopofthebottomhangingbracketonthatmeasurementline– the one you just marked at 29 1/4”.

10.Usingthe bottomhangingbracketas a template,centerthe two holesinthe bottom hangingbracketoverthevertical

line.

11.Tracethetwoholeswith a pencil.

12.Remove the bottomhangingbracket/ templateanddrill the two1/8”pilot holes.

13.Placethebottom hanging bracket over the holes andusingthescrewsand washersfrom the bracket hardware

package,mount the bottomhangingbracket tothewall.

14.Checkto verify thatthetopand bottom hanging bracketsareinline with eachotherandplumb.

Cutting Bed Elevation Chart

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Page 7

1.Locatethebearing tubes and cart assembly withattachedverticalaxisassembly. Placeit on the topbracketand

insertthesafetyscrew and nut . The screw is ¼-20X1½”long.Thisisveryimportantfor safety.

2. Liftandsituate theverticalaxisextrusion withthebearingtubes andcartassemblyso thattheflangeson the backof

theverticalaxis extrusion straddle thetopandbottom brackets. See aboveimage.

3. Lightlytighten thefivescrews ontheverticalaxisextrusion tothetwo verticalwallbrackets. Therewillbeafurther

adjustmentlater.

4. Locatethe left horizontalextrusion– it ismarked.

5. Attachthelefthorizontal extrusiontotheleftmountingbracket.Note: theleft andrighthorizontalmountingbrackets

areidentical.

6. Placetheleft horizontal extrusion ontotheverticalaxisextrusion. Use two ¼-20 X2”hexheadscrews, washers

andlocking nutstoattach thelefthorizontalextrusionto thesquaretube ontheverticalaxisextrusion.

7. Attachthe leftstainless steelgussetplatetothelefthorizontal extrusionandtheverticalaxisextrusionusing thenine

(smallflat head) #4 x40flathead stainlesssteelscrewsand nuts. Attachtheleft horizontal mountingbracketto the

wall. Makesurethe bracket is perpendicular tothewall.

8. Placetheright horizontal extrusion ontotheverticalaxis extrusion. Use two ¼-20X2”hex head screws, washers

andlocking nutstoattach thelefthorizontalextrusionto thesquaretube ontheverticalaxisextrusion.

9. Attachthe rightstainless steelgussetplatetotherighthorizontal extrusionandtheverticalaxisextrusionusing nine#4

x40flat head stainlesssteelscrewsand nuts.

10. Attachthe righthorizontalextrusionwall mountingbracketto thewall. Again,make surethebracket isperpendicu-

larto thewall.

Mounting the Vertical Axis Extrusion

Installation on a Masonry Wall

It is very helpful to watch the “How To Install” video

http://www.youtube.com/watch?v=ZmZyR4oX7sM&feature=player_detailpage

1.Use a1/4”masonry drillbitto drillallholes intothewall.

2.Insert blueplasticanchorsintodrilled holesinthewall.

3.Followallotherinstructionsforawoodwallinstallation.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Important

In orderfor the machinetoworkproperly, thecuttingbedsmust be inline. Stand along thesideofthe

Onyx90and look downthecuttingbeds where the leftandrightcutting beds areattachedtothevertical

axisextrusion.Thecuttingbeds must not be bowedeither towardsthe wall orbowed awayfrom thewall.

Everythingmustbeinline. Thisnext adjustment will ensure that.

1. Loosenthefour1/4”x20x 2”screws and nuts located on the back of the vertical axis extrusion. Thefourscrews

arelocatedin the square tube attached totheverticalaxisextrusion. Do not remove thescrews-justloosen them

makingsurethat the safetyscrew& nut areinplace.

2.Loosenthe 5mountingscrewson theverticalaxisextrusion andloosenthe4 screws onthehorizontal wall brackets.

3. Usinga straightedgeplacedagainst thefrontofthe leftandright horizontalextrusions,push orpullas necessaryto

straightenand removeanygapbetweenthe straightedgeand thehorizontalextrusions.

4. Whilemaintainingthepushing/pullingaction,haveanassistant tightenthe fourscrews locatedinthesquaretubeon

theback ofthevertical axisextrusion.

Mounting the Media Clamp Assembly

1.Locatethe¼-20 tapped hole in thetopmountingbracketofthe bearing-tubes and cart assemblyunit.

2.Insertthe¼-20x23/4”screwofthetop mat clamp assembly into the tapped hole in the top mounting bracket of

thebearing-tubesandcart-assembly unit. Tightenthe ¼-20 x23/4”screwinto the hole and jamthenuttosecure.

3.Attachthebottomofthe mediaclampassembly to theT-nutintheleft horizontalextrusionusing¼-20 x1”screw

andlockwasher.

4.Adjustthe mediaclampassemblyso that itisthesame distance from theverticalaxisextrusion at thetopandbot-

tom.When thedistancesarethesame, tighten the screw to theT-nut.

5.Youhave completedtheassemblyand mountingofyournew Onyx90MediaCutter.

6.Doublechecktomake sure all screws and nuts are tight.

Squaring the Cutting Beds

Page 8

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Page 9

5.0 Cutting Tool Holders

Awordabout safety – razorblades,plasticcutting tools and glasswheelscanall cut you.

Be careful whenhandlingthem. ALWAYSWEARSAFETYGLASSES.

Acrylic Cutting Tool Holder (with blue handle)

Plasticsupto 1/4” thickcanbe scored andfracturedonyour Onyx 90machine. Theplasticcutting tool holderutilizesa

double-endedcarbide insert toscoreyour plasticmedia. Thiscarbideinsert providesanextremely durable tool,lasting

manythousandsof cuts. Warning: thiscarbideinsert is very hardandsubjecttobreakage if dropped.

Replacementcuttingblades-PPFE-311

Toremovecarbideinsert,

1.Removethe slottedmachinescrewlocated in thecenterof theinsert withasmallscrewdriver.The carbide inserthas

twoends.The carbideinsertiscaptured via amachinedslot and cannotbecomemisaligned.

Glass Cutting Tool Holder (with red handle)

TheOnyx 90’sglasscutting toolincorporatesasix-positionturret whichcontains sixsolidcarbideglasscutting wheels.

Thisturretis numbered 1through6,giving you meanstokeeptrack of thenewandused carbide wheelsintheturret.

Replacementsixwheelturret - PPFE-7001

Attention:Ifthe turret retainingscrewis loosenedmorethan½ turn,thecarbide wheelsmayfalloff theaxlesand

becomelost. Whenreplacingorremoving the turret, always place a pieceofnewspaperorkraftpaperon your work

surfacebeforeyou begin. In caseawheelfalls off, itwillbeeasy to locate it.

To change to a new wheel (Old Style Tool Holder):

1. Loosentheturret retaining screw ½turnandindex the

turretto thenextposition.

2.Alignthenew wheelsothecenter of thewheelis

alignedwith the holemarkon thefaceof the toolholder.

Itis veryimportantthat theapex(highest point)ofthe

glasswheel is theonlypart oftheholderthat isincontact

withtheglass.

3.Tightenthescrew.

To change to a new wheel (New Style Tool Holder):

1.Loosen thesmallmetal turretretainingscrew ontheside

ofthetool holder ½ turn.

2.Loosenthe screwwiththeplastic turning knobonthe

backofthetoolholder.

3.Turntheturretto thenextavailable glasswheel.

4.Tightenthe screwwiththeplasticturning knob.

5.Then, tightentheturretretaining screwonthe sideofthe

toolholder.

ImportantTip

Toachievethemaximumutilizationfromyourcarbideglasscuttingwheels,thewheels

mustbekept welloiled.WD-40isagoodlubricantfor this purpose. Before each use

oneshould squirt theactivewheel witha“shot” of oil. Werecommendyou use asmall

plasticcontainer withawell oil-soakedclothinthe plasticcontainer. When thetoolis

notin use,placethetool inthecontainer withthewheelsdown againstthecloth. This

willensurethemaximumlife andbestresultsfromyourcarbideglasscuttingwheels.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Page10

Mat Board Cutting Tool Holder (with black handle)

Thistoolholder is used forcuttingmatboard, foam board, gatorboard,sentra,travicel, cardboardas well as many

othermedia.

Changing and Adjusting Blade Depth

Attention:Usecaution during this processsothat

yourhanddoesnotcomein contact with the

razorblade.

ChangingtheBlade

1. Loosenthe2screwsonthesideofthematboardcuttingtoolholder

2. Discardtheoldbladesafely.

3. Placeanewblade in the mat cuttingtoolholderandtightenthe 2 screws.

4. Notethereis small set screw to support the back of the blade (small arrow).

Replacement Blades

TheOnyx90 uses economical blades – Part Pro-42592

6.0 Using Your Onyx 90

Changing from one type of tool holder to another

Onceyouhave practiced afewtimes,we are sureyouwillagree that theOnyx90’stoolinterlock system allowsyou

veryfast toolchange.

To insert a tool holder into the machine

1. Holdthetoolholderby the handle and place the tool ontothegroovesinthepivotarm.

2. Noticethaton the toolholderthereis a locking rollpinlocatedon the bottomfrontofthe tool holders. Thislocking

pinmust engageorfitintoa matchinggrooveonthepivot arm.

3. Slidethebottom of the tool holderpinintothegrooved pivot arm, pull backanddownonthe spring loaded handle.

Itwilllockinplace.

To remove a tool holder from the machine

1.Liftup on the toolhandleandremove the tool.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Page11

UsingtheOnyx90 CuttingTools

Cutting Glass

Attention: Rememberto weareyeprotection, glovesandprotectiveclothingwhenhandlingglass.

1. Ifyou use themediaclamp assembly whencuttingglass, place ontheglass very carefully. Manypeopledon’tuse

themediaclampforcuttingglass.

2. Placeyourglass on the leftsideofyour Onyx 90 machine.

3. Placetheglass cutting toolholderonthe pivot arm.

4. Thelargerpiece of glass shouldbeontheleft side of thecutandthesmaller piece of glassshouldbeonthe right side

ofthecut.

5. Useeither therightor leftmeasuringscale onthehorizontal axisextrusionsas necessary.

6. Placeyourleft hand on theglass-applyholding pressure.

7. Withyourrighthand,pull backthehandle.

8. Raise the cutting cart to the topedgeof the glass.

9. Lowerthehandleandplace the glass cutting wheel on the topedgeoftheglass.

Youcan nowtakeadvantageofonethe Onyx 90’sbest features.Youcan vary theamountofpressure

neededtomake an efficientscorejustby adding more orlesspressure. Noglobal machine adjustmentis

necessary.

10. With one slow,smooth,continuous motion, pulldownthe cutting cartpastthebottom edge oftheglass.

11. Youhavejust“scored”the glass. Onlyscoreglassonetime.

12. With your lefthand,applyslight pressureonthebottom leftedgeofthe glassnearthescore.Withyourright thumb,

apply increasingpressureon the bottom right edge of glassnearthescoreuntiltheglass separates.

13. Thebreakwilloccur at the bottom of the score line and run up to the top of the scoreline. The break chases the

score. Youmaydevelopyourownbest technique.

Cutting Mat Board

TheOnyx90 will cut up to 5/8”deep. Whencuttingmaterialsthat deep, a sharp bladeandsuccessivecutsin same

groovearenecessary. The media clamp can not be used on thicknesses greaterthat1/4”. Theuseofthemediaclamp

isnot mandatory,butonthin media,itwillreduce thechanceofmedia buckling.Where itisdeemednecessary tohavea

finecutedge,a slip sheet under the cutsheetmaybedesired.

1.Placethe mat board cutting toolholderonthepivot arm.

2.Slidethe media to becutontotheleft cutting bed oftheOnyx90.Use the right orleftmeasuringscaleas necessary.

3.Pull backthehandleon thecuttingcart untilitlocks.

Youcan nowtakeadvantageofonethe Onyx 90’sbest features.Youcan vary theamountofpressure

neededtomake an efficientscorejustby adding more orlesspressure. Noglobal machine adjustmentis

necessary.

4.Withone slow,smooth,continuous motion,pulldownthe cuttingcartpastthe bottomedgeofthe media.

5.Releasethe mediaclamp.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Plasticfracture

swingarmhandle

Page12

Cutting Plastic

Onyx90 willcutor“fracture”sensitive plasticupto1/4”thick. This includes acrylic,polycarbonate,“Plexiglas”etc.

1.Placethe plastic cuttingtool holderonthe pivot arm.

2.Slidethe media to becutontotheleft cutting bed oftheOnyx90.Use the right orleftmeasuringscaleas necessary.

3.Engagethemediaclampbylifting,pushingforward andlowering theclampintoposition.

4.Pull backthehandle ofthecuttingcart untilitlocks.

5.Raisethe cuttingcarttothe upper edgeofthe fracture sensitiveplasticmedia.

6.Release thehandleusing thethumbrelease.

You can now takeadvantageofoneoftheOnyx 90’sbest features.You can vary the amount ofpressure

neededtomake efficientscoresjustby adding moreorless pressure. Noglobalmachineadjustment is

necessary.

7.Withone slow,smooth,continuous motion,pulldownthe cuttingcartpastthe bottomedgeofthe media.

Note: youwill hearagouging soundofthe material.

8.Repeatthis procedure twoorthreetimes, depending upondensityofmaterial being scored.

9.To fracture or “crack” the plastic, raise the cuttingcarttothetopedgeofthe plastic.

10.Push in ontheplasticfracture swingarm handle. Atthesame time, alignthewhite rollers withthetop edge ofthe

fracturesensitiveplastic.Whileapplyingincreasingpressuretotheplasticfracture,swingthearmhandleuntilyouhear

theplastic snap.

11. Continuetohold thepressureon theplasticfracture swingarmhandlewhilepulling downthecutting cartpastthe

bottomofthefracture sensitiveplastic inoneslow,smooth continuousmotion.

12.Releasethe mediaclamp.

13.Removetheplasticfrom the Onyx 90 and separate thetwoplasticpieces.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Page13

Using the Media Clamp

Themedia clamp requiresonlyone handtooperate. Simplylift uptheclamp from itsrestposition andmoveittowards

themedia tobeclamped. Gravitywill pulltheclamp downwardandsecurely lockyourwork againstthestainlesssteel

gussetplate. The clampisreleased byliftingup thehandleand returningtheclamptotheresting position.Themedia

clamphas arubberblanket thatwillhold yourmediavery securely. Ifyoucut largesize(1/2”thick) material,youmay

wantto purchasethe optionalhorizontalmediaclamp.

UsingtheProductionStop

Theproduction stop isusedwhen you aremakingseveral consecutivecutsofthe samedimension. Theproductionstop

canbe placedoneither theleftorrighthorizontal extrusion.

1.Simply loosen theplasticlocking knobandinsert theT-nutand

productionstopinto thechannellocatedat thefrontofeither the leftor

righthorizontal extrusion.

2.Rotate theplasticarmuntilitisagainst themeasuringscale.

7.0 Routine Maintenance

1.Brush alldebrisfrom boththeleft andrightcutting beds.

2.Make sure allnutsand boltsremaintight.

3.Donot oil the machine. Use awaxbasedfurniturepolish such as Pledgetoclean.

8.0Adustments-should they become necessary – but not likely

SquaringtheMachine -making the cutting beds perpendicular to the vertical axis extrusion

Your Onyx 90 was squared at the factory and should not require you to make any adjustments.

Ifforsome reason youfinditnecessary to make thisadjustment,hereare the steps:

Tools Needed: Anassistant

builder’ssquare

2 - 7/16” open-end wrench

2 - 9/16” open-end wrench

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

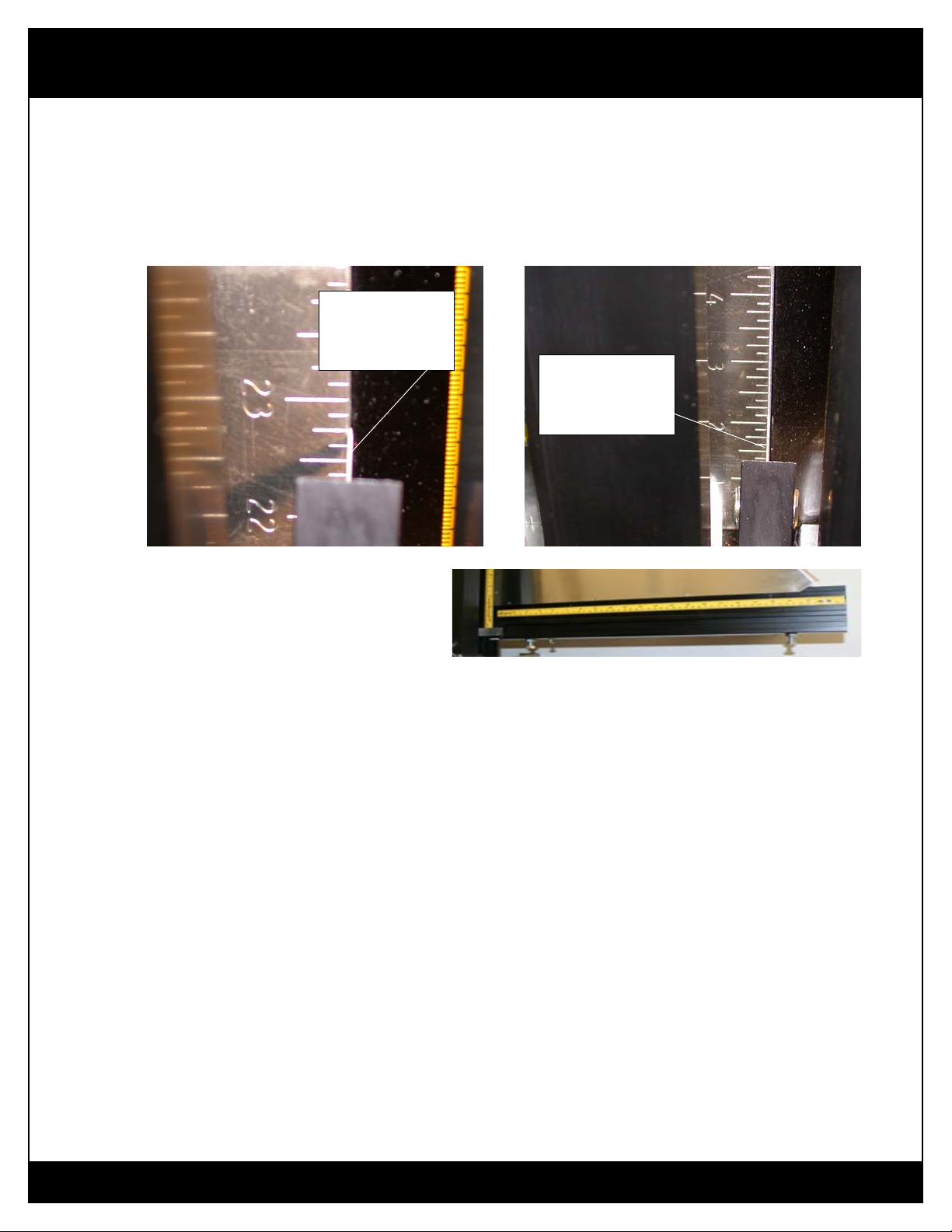

Mat cutting blade

resting against

builder’s square

Mat cutting blade

resting against

builder’s square

Page14

Step 1

Thereare twoboltseachonthe rightandlefthorizontalextrusion thatpreventthecuttingbeds frommovingif someone

putsaheavy weight on theendsofthe cutting beds -safetyfeature.

Loosen the jamnutsand bolts beforemakingany adjustmentstoeitherthe leftortheright cuttingbed.

Step 2-SquaringtheLeft Cutting Bed

1.Laythe builder’ssquare on theleftcuttingbed.

2.Put the matcuttingtool in the toolholder. The horizontalportionofthe builder’s square shouldberesting on theleft

cuttingbed.The vertical portionofthe builder’s squareshouldberesting -justtouching thematcuttingrazor blade.

Withoutmovingthebuilder’ssquare,raise the cuttingcartto thetopofthe verticalportionof thebuilder’s square.The

distancefromthe blade to thebuilder’s square mustbethesameat the topandbottomthroughoutthe cutting cart’s

travel.

3.Ifthere is a gap atthetopof the builder’ssquare/blade intersection, then youmustloosenthe jam nut on theleftside

ofthelefthorizontalextrusion. Tightenthe3/8”boltslightlyuntilthegapdisappears.Tightenthejamnut.

4.Ifthereis a gap at thebottomofthebuilder’s square/blade intersection,thenyoumustsquare the left cutting bedthe

otherdirection. Loosen thejamnutonthe leftsideoftheleft horizontalextrusion.Youmustloosen the3/8”boltslightly.

Thiswillchange thegap.Thegapmustbe thesameatthe topandbottomof thebuilder’s squarethroughoutthecutting

cart’s travel.Recheck.

5.Once thegapisthe same,tightenthe jamnut. Youhavecompletedsquaring thelefthorizontalcutting bed.

Step 3- SquaringtheRightCuttingBed

1.Placethe builder’s squareontheleft cutting bed andslidethebuilder’ssquare over totherightcutting bed. There

shouldbeno gapunderthebuilder’s square ontherightcutting bed.

2.Ifthere is agapunderthebuilder’s square ontherightcutting bed, loosenthetwojam nuts undertherighthorizontal

extrusion.Adjustthetwo3/8” boltstomake thesurfaceof therightcuttingbed flushwiththe bottomofthe builder’s

square. Thebuilder’ssquareshouldslidefromleft-to-rightand right-to-leftwithouthittingeithercutting bed.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

3.If thebuilder’s squarehitstheleft orrightcutting bed,youwill need toadjustthe elevationofthe innermostbolton

theright cutting bed. Adjustthe3/8” bolt asneededso thatthebuilder’s square willtravelfrom left-to-right andright-

to-leftwithouthittingeithercuttingbed.

4.Tightenbothofthe rightcuttingbed jamnuts.Recheck.

Setp4-Finish Squaring theCutting Beds

1.Tightenthe 1/4 x20screws.

2.Bringthejam nutsuptothebottomofthehorizontalextrusion andlightlytightenthejamnuts.

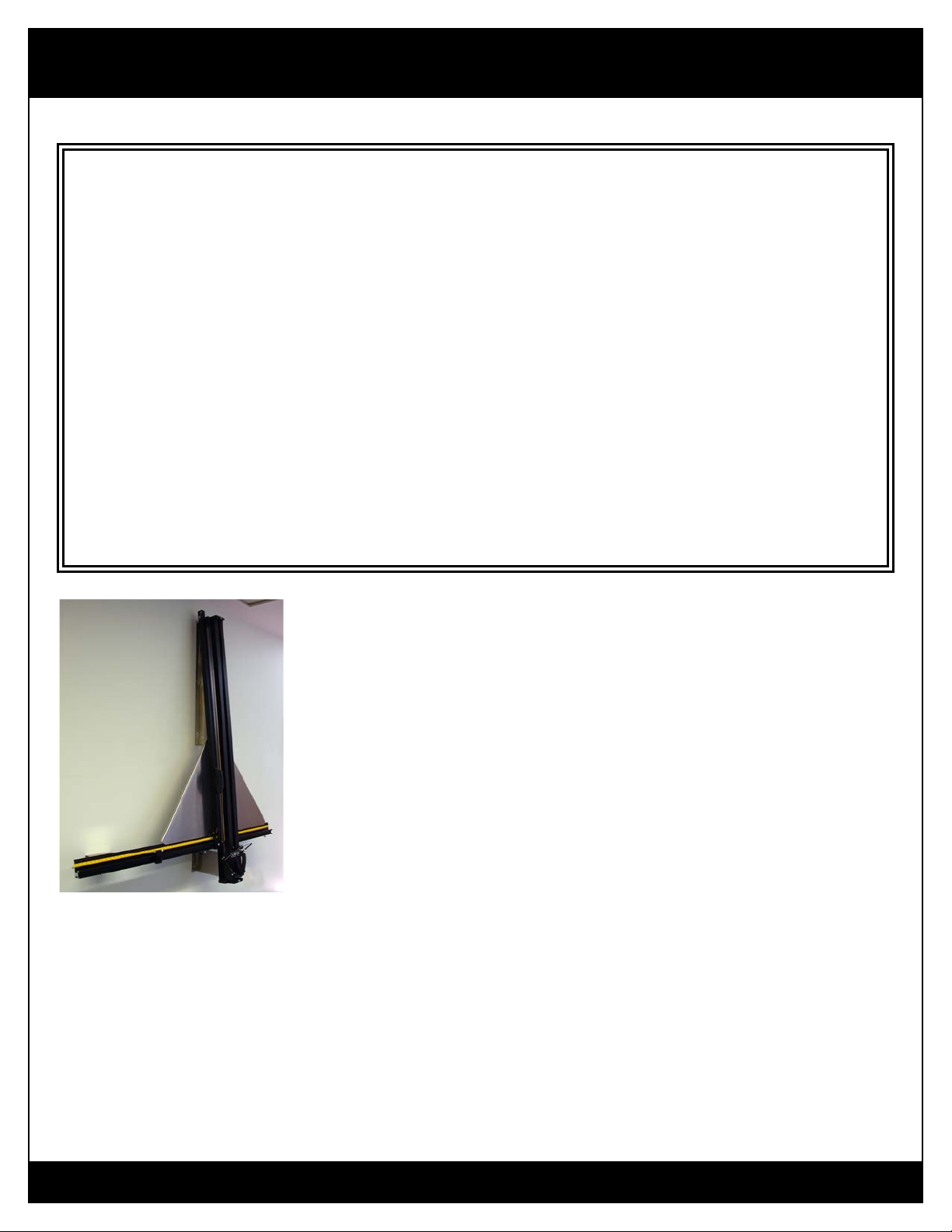

Calibration of the Measuring Tape Scales

Thehorizontaland verticalmeasuringtapescales have beensetatthe factory. Wehavesecuredthe measuring tape

scalesusinga smallscrewandnut applied attheoutside ends ofthemeasuringtape scales.Ifforsome reason youfindit

necessarytomakethis adjustment, here are the steps.

1.Position themeasuringtapescalewhere youfeelit shouldbebyslidingit intheextrusion.

2.Oncein position, re-tightenthescrewand nut.

Global Adjustment of the Cutting Spring Pressure

Thisadjustmenthas been set atthefactory. If for somereasonyoufind it necessary tomakethisadjustment,here are

thesteps:

1.Remove allcuttingtool holdersfromthe cart.

2.Thespring tension adjustmentnutislocatedbetween the bearingtubesonthe very bottom ofthecart. Thisadjust-

mentisbest done ifthebottomof the cuttingcartiselevated. Youshould have anassistantsecurelyhold the cartatthat

elevation. Donottry to holditandadjust by yourself.

3.Usinga7/16” nut driver or deep-wellsocket,reachbehindthe cart from the righthandsideandslide the tool onto

thespring tensionadjustmentnut.If moretension isdesired, tightenthespringtensionadjustment nut. Iflesstensionis

desired,loosenthespring tensionadjustment nut. Thisnut hasaninternalnylonlockingringtokeepitfrommoving.

4.Once youmove it,thenutwillstay inthatpositionuntilyoumoveit again.

5.Inserttheglass tool into the cutting cartandtrythenew pressure. Adjust as required.

Page15

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Springtension

adjustingnut

Page16

Adjustment for Depth of Cut

Thisadjustmenthas been set atthefactory. If for somereasonyoufind it necessary tomakethisadjustment,here are

thesteps:

1.Lookat the handlelocatedonthe cutting cart.Noticea lower handleretainingscrewand an upperhandleretaining

screw. Thesetwoscrewsarecounter-boredintothehandleandattachthehandletothecuttingcart. Just above the

upperhandle retaining screw, youwillseea thirdcomboheadscrew

orallen setscrew. Thisthird screwisthe “adjustmentlocking

screw.”

2.Loosen theadjustmentlocking screwuntil youcaninsert alarge

phillipsheadscrewdriverintotheslot ofthe upperhandle retaining

screw.

3.Insert the glasscuttingtool onto toolpivotarm.

4.Release thehandlewiththe thumbreleaseand allowtheglass

cuttingtool tobottom.

5.Withthe handle inthereleasedorbottomed position, rotate the

upperhandleretaining screw clockwisetodecrease thedepth.

6.Rotatethe upper handleretainingscrew counter clock

wisetoincrease the depth. After you have made the

adjustmenttothe cuttingdepth,besure topushthehandle in

sothatitis resting on the newadjustedstopdistance.

7.Recheckand tighten the adjust-

mentlockingscrew.

Newversionuses allen headset

screw.

Upper handle

retaining screw

Lower handle

retaining screw

Adjustment

locking screw

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Page17

9.0 Troubleshooting

When cutting glass, the glass cutter jumps or skips.

Causes: Dirtyglass Clean glass

Wornglasswheel

Rotate to new wheel

Too littlepressure

Adjust by applying slight pressure with hand

Oil the active wheel

Shardsof glassimparingproper rotationofglasswheel

Blast with aerosol such as WD-40

When cutting glass, chipping or flaking occurs.

Cause: Too much pressure

Oil the active wheel. You may be applying too much pressure on the handle.

Pull back on the handle during cut.

Too much pressure will shorten wheel life.

Never score twice.

When cutting plastic, it skips and/or chatters.

Causes: Scoringtoo fast

Slow down the stroke speed

Scoringtool broken

Rotate cutter if you have not done so previously

Toomuchpressure

Reduce pressure slightly on handle

Notusingmediaclamp

Use media clamp

ImportantTip

Toachievethemaximumutilizationfromyourcarbideglasscuttingwheels,thewheels

mustbekept welloiled.WD-40isagoodlubricantfor this purpose. Before each use

oneshould squirt theactivewheel witha“shot” of oil. Werecommendyou use asmall

plasticcontainer withawell oil-soakedclothinthe plasticcontainer. When thetoolis

notin use,placethetool inthecontainer withthewheelsdown againstthecloth. This

willensurethemaximumlife andbestresultsfromyourcarbideglasscuttingwheels.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Page18

When cutting mat board, the mat board buckles.

Causes: Matboardnotclamped

Use media clamp

Bladetoodull

Change to new blade

The cut edge of mat board is frayed.

Causes: Dullmatcuttingblade

Change to new blade

Noslip sheet undermediabeing cut

Use slip sheet

When I make my cuts, the dimensions are incorrect.,

Cause: Themeasuringscaleisoff

Recalibrate the measuring scale

The cut edge is not square - not a 90 degree cut.

Causes: Debrisbetween the mediaandcutting bed

Remove debris

Cuttingbed isnot perpendiculartoverticalextrusion.

Square the cutting bed -Not likely-

You are very important to us. Our success depends on your

satisfaction. If you are having any problems or have any

comments, please call us at 828-388-5782.

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-388-5782

Onyx 90 Product Registration CardOnyx 90 Product Registration Card

Onyx 90 Product Registration CardOnyx 90 Product Registration Card

Onyx 90 Product Registration Card

Registering your Onyx 90 media cutter is essential to ensure that you validate your warranty and receive all the

benefits of product ownership.

Date of Purchase ______________________________________________________________________

First Name ___________________________________________________________________________

Last Name ____________________________________________________________________________

Street Address _________________________________________________________________________

Street Address _________________________________________________________________________

City, State, Zip _________________________________________________________________________

Email Address _________________________________________________________________________

Phone Number _________________________________________________________________________

Serial Number __________________________________________________________________________

Mail to Professional Picture Frame Equipment

441 South Whitted Street

Hendersonville, NC 28739

Fastest tool change in the industry Cuts mat board, gator board, glass and acrylic

Anodizedaluminumandstainlesssteel Built to lasta lifetime

Oilimpregnatedbronzebushings FedEx/UPSshippable

Ultrahighmolecularweight polyethylene bearings Five yearwarranty

Productionstopincluded Stainlesssteelwallmounting brackets

Cuttingdepth5/8inches Carbideplastic cutter

Built-inmatboardandacrylicclamp Made in the USA

Page19

Other manuals for Onyx 90

1

Table of contents

Other Professional Picture Frame Equipment Cutter manuals