Professional Picture Frame Equipment Onyx 90 User manual

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

Know Your Onyx 90 Media Cutter

Professional Picture Frame Equipment

1237 Shipp Street

Hendersonville, North Carolina 28791

Vol.411

Owner’s Manual

Page number 1

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

Congratulations

and thank you! You have just purchased the best wall mounted media cutter in the

world. The Onyx 90 will provide you with many years of dependable service with

only minimal maintenance.

We know you are anxious to begin using it. But before you do anything, please

take the necessary time to read and understand this manual. It will answer a lot of

your questions and avoid possible problems.

Table of Contents

1.0 Safety Precautions & Recommendations...................Page 3

2.0 Registration & Warranty.............................................Page 3

3.0 KnowYour Machine...................................................Page 3

4.0 Installation of the Onyx 90.........................................Page 5

5.0 Cutting Tool Holders..................................................Page 9

6.0 Using the Onyx 90......................................................Page 9

7.0 Routine Maintenance..................................................Page 13

8.0 Adjustments................................................................Page 13

9.0 Troubleshooting..........................................................Page 17

Page number 2

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

1.0 Safety Precautions & Recommendations

WhenusingtheOnyx90,basicsafetyprecautionsshouldalwaysbefollowedto

eliminatetheriskofdamageorinjurytopersonsormaterials.

Wearsafetyglasses,glovesandprotectiveclothing.

Use caution when using, transporting, storing or disposing of dangerous objects, such as

cuttingtools,glass,etc.

Makesurethemachineismountedsecurely. Many situations exist that we can not predict,

butitiscriticalthatyourOnyx90isattachedsecurelyandsolidlytothewall.

Keepthemachineand the work areaaroundthemachine clean.

Neverplaceyourhandorfingersbehindthemediaclamp.

For what it is worth – be safe!

2.0 Registration & Warranty

Your Onyx 90 hasa 5 year manufacturer’swarranty from thedateof purchase. Please

takeamoment to completeandmail the enclosedwarrantycard. Proof of purchasemustbe

submittedwiththewarrantycard.

Professional Picture Frame Equipment warrants the Onyx 90 to be free from defects in workmanship and parts for 2 years from date of purchase.

Professional Picture Frame Equipment warrants it will repair or replace any defective parts. The Onyx 90 must be subjected to normal use and

service. A return merchandise authorization (RMA) must be requested from Professional Picture Frame Equipment before returning.

This warranty is in lieu of all other agreements. Professional Picture Frame Equipment is not liable for any damages or losses, incidental or consequen-

tial, direct or indirect, arising out of the use of this product.

3.0 Know Your Machine

3.1 Diagram of Parts Vertical axis

Top hanging

Bottom hanging

Cutting

Left

horizontial Left stainless

steel gusset

Mediaclamp

Page number 3

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

3.2 List of Parts That Were Shipped

Box 1 (Large cardboard shipping box)

Media Clamp Assembly

Bearing-tubes and CartAssembly Unit

Left Horizontal Extrusion

Vertical Axis Extrusion

OwnersManual

StainlessSteelGussetPlates(2)

RightHorizontalExtrusion

VerticalWallMountingBrackets(2)

HorizontalWallMountingBrackets(2)

HardwarePackets (4)

ToolingPackage

GlassCuttingToolHolder

MatBoardCuttingTool Holder

PlasticCuttingToolHolder

ProductionStop

SpareMatCuttingBlades

Bearings-tubes and

cart-assembly unit

Horizontal mounting

brackets

Bottom hanging

bracket

Top hanging

bracket

Media clamp

assembly

Left stainless

steel gusset

plate

Right stainless

steel gusset

plate

Left horizontial

extrusion Right horizontial

extrusion

Page number 4

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

4.0 Installation

4.1 Tools you will need to collect before beginning

An assistant

Ladder

Level, preferably at least 3 ft long

Electric drill/screwdriver with either ¼ masonry drill bit or 1/8” wood bit

Hammer

Phillips head screwdriver, large

Tape measure

Straightedge, 36” or longer

Builder’s square

Pencil

4.2 Step-By-Step Instructions

These written instructions are provided as well as a DVD video which requires Windows

MediaPlayer. Thevideo and thisOwnersManual are also availableonthe Internet.

First: Determineon whattype ofwall youwill beinstalling yourmachine -wood or masonry?

Followappropriateinstructions.

Second: Determine your personal working height.

4.3 Cutting Bed Elevation Chart

Generally speaking, most framers determine the cutting bed height (the height that your

media rests on) of their machine as influenced by two factors: employee’s work height,

and the weight and size of the materials to be placed onto the cutting bed of the Onyx

90. For example, if you are tall, then mounting the machine higher may be better for

you. If youprocess a lot of large sized glass, acrylic, or other sheet materials, you may

finda lowercuttingbedheightbetter. Always thinkofsafetywhenlifting andprocessingyour

materials.

Builders

square

Page number 5

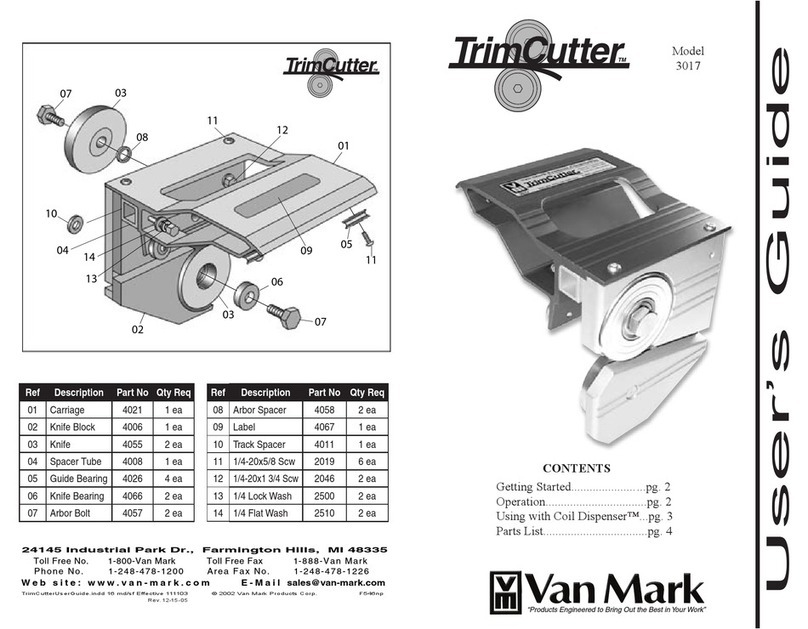

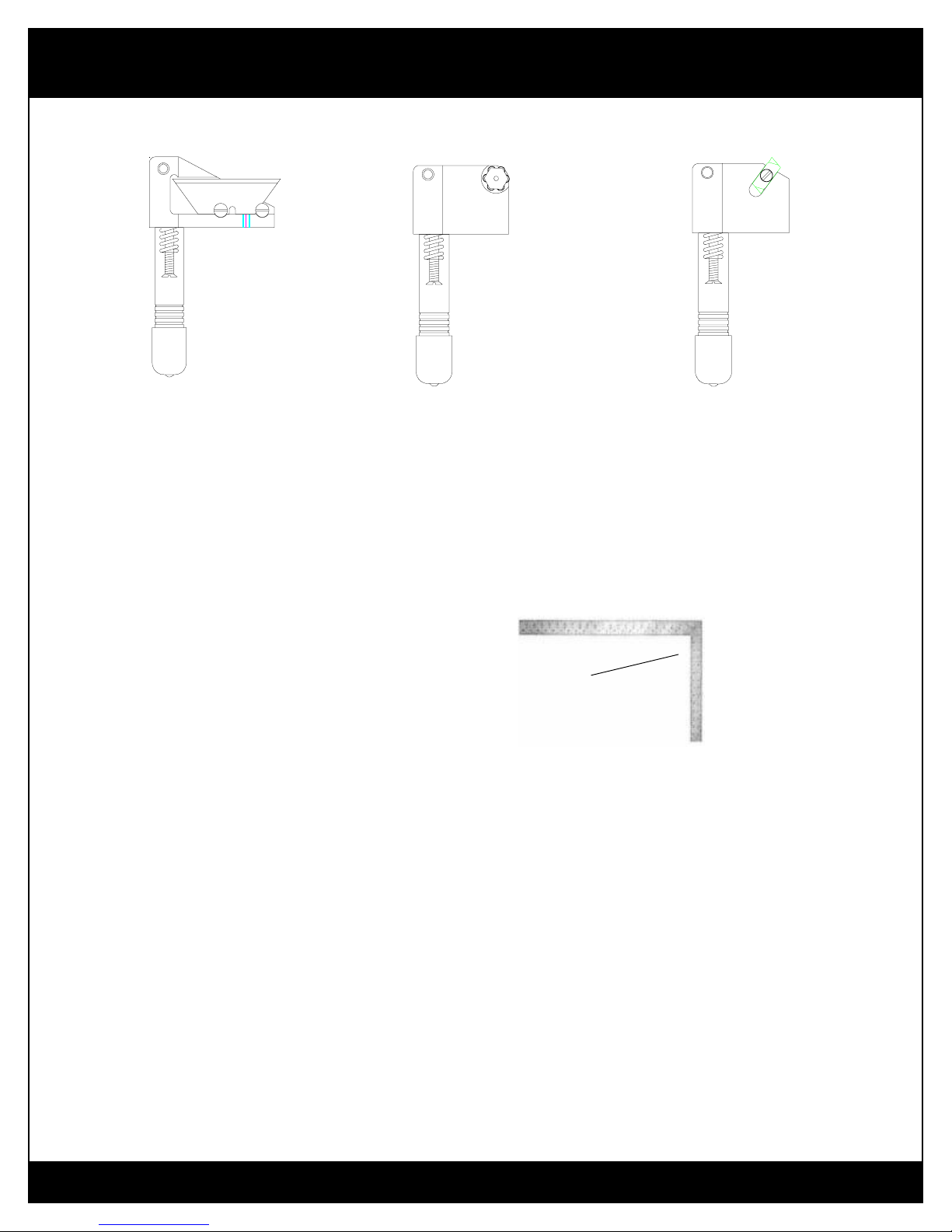

Matcutting tool Glasscutting tool Acryliccuttingtool

Black Handle Red Handle Blue Handle

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

Fromthefollowingchart,youchoosethecuttingbedheightsuitedforyou. Onceyouhavedetermined

yourcutting bed height, thischartwillindicatethemeasurementofthe top hole ofthetophangingbracket.

The following measurements are measured vertically, from the floor up.

Cutting Bed Height Top hole of the top hanging bracket

33 inches above the floor 93 inches above the floor

32 inches above the floor 92 inches above the floor

31 inches above the floor 91 inches above the floor

30 inches above the floor 90 inches above the floor

29 inches above the floor 89 inches above the floor

28 inches above the floor 88 inches above the floor

27 inches above the floor 87 inches above the floor

26 inches above the floor 86 inches above the floor

25 inches above the floor 85 inches above the floor

Note: If you have an 8' ceiling, the maximum cutting bed height will be 31” from the floor.

4.4 Installation on a Masonry Wall

1. Use a 1/4” masonry drill bit to drill all holes into the wall.

2. Insert blue plastic anchors into a drilled holes in the wall.

3. Follow all other instructions for a wood wall installation.

4.5 Installation on a Wood Wall

4.5.1 Mounting the Vertical Mounting Brackets

1. Remove protective polyethylene film from all the stainless steel parts.

2. Locate a vertical stud on the wall.

3.Using a level, draw a vertical line 94”inlengthonthewalltothefloor.

4.Drilla1/8”pilot hole on theline91”fromthefloor. (See above chart todetermine

yourpersonalworkingheight.)

5.Usingthetophanging bracket as atemplate,centerthetophole of the tophanging

bracketoverthedrilledhole on the line.Tracetwo circlesforthetwolowerholes.

6.Removethebracket/templateanddrillthetwolower1/8”pilotholes

7.Placethe top hangingbracketover the holesandusing the screwsand washersfrom

Page number 6

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

thebracket hardware package,mountthe top hangingbracket in allthreeplaces.

8. Measure 29 1/4” down from the bottom of the top hanging bracket and place a

mark on the vertical line.

9. Place the top of the bottom hanging bracket on that measurement line – the one you

just marked at 29 1/4”.

10. Using the bottom hanging bracket as a template, center the two holes in the bottom

hanging bracket over the vertical line.

11. Trace the two holes with a pencil.

12. Remove the bottom hanging bracket / template, and drill the two 1/8” pilot holes.

13. Place the bottom hanging bracket over the holes and using the screws and washers

from the bracket hardware package, mount the bottom hanging bracket to the wall.

14. Check to verify that the top and bottom hanging brackets are in line with each other

and plumb.

4.5.2 MountingtheVerticalAxisExtrusion

1. Placethevertical axis extrusionwiththe two flanges onthetop bracket andinsertthe

safety screwand nut.The screwis ¼-20X 1½” long.

2. Liftandsituatetheverticalaxisextrusionsothat

theflangesonthebackoftheverticalaxisextru

sion straddlethe top and bottom brackets.

3. Lightlytightenthefivescrewsontheverticalaxis

extrusion.Therewill beafurtheradjustmentlater.

4. Retrievethe left horizontal extrusion – it is marked.

5. Attachthelefthorizontalextrusiontotheleftmounting

bracket.Left andrighthorizontalmountingbracketsare identical.

6. Placethelefthorizontal extrusion onto theverticalaxisextrusion. Use two ¼-20 X

2”hex head screws, washersandlocking nuts tomaketheattachment.

7. Attachtheleftstainlesssteelgussetplatetothelefthorizontalextrusionandthe

verticalaxisextrusionusingthenine#4x40flatheadstainlesssteelscrewsandnuts.

8. Attachthelefthorizontalmounting bracket to thewall.Makesurethebracket is

perpendicularto thewall.

9. Placetherighthorizontalextrusion onto the verticalaxisextrusion. Usetwo¼-20X

2”hexheadscrews, washers and lockingnutstomake the attachment.

10. Attach therightstainlesssteelgusset plate to the righthorizontalextrusionandthe

verticalaxis extrusion using nine #4 x 40 flatheadstainlesssteelscrewsandnuts.

11. Attachtherighthorizontalextrusionwallmountingbrackettothewall.Again,make

surethe bracket is perpendiculartothe wall.

Page number 7

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

4.5.3 CuttingBedAdjustment

Inorderforthemachinetowork properly, the cutting bedsmustbeinline.When you stand

alongthesideoftheOnyx90,look down the cutting beds,

wherethe left and right cutting beds attach tothevertical

axisextrusion,thecuttingbedsmustnotbebowed either

towardsthe wall or bowed awayfromthe wall. Every

thingmustbeinline. Thisnextadjustmentwilldothat.

1. Loosen the fourbottom-most screws locatedonthe back

oftheverticalaxisextrusion.

2. Using a straightedge placedagainstthefrontoftheleftand

righthorizontal extrusions, push orpullasnecessarytostraightenandremove any gap between

thestraightedgeandthehorizontalextrusions.

3. Whilemaintainingthepushing/pullingaction,haveanassistanttightenthefourbottom-most

screwslocatedonthebackofthe vertical axis extrusion.

4.5.4 Mountingthe Bearing-tubesand Cart-assemblyUnit

1. Placethebearing-tubesandcart-assemblyunitontotheverticalaxis

extrusion. Thetop andbottomofthisunit willfitpreciselyonto

the machinedsurfacesoftheverticalaxisextrusion.

2. Attachthebearing-tubesandcart-assembly unit with thefour5/16-

18”X 3/4” hexscrews and washersprovided.

4.5.5 Mountingthe MediaClampAssembly

1. Locatethe ¼-20 tappedhole inthe top mounting bracketof the bearing-tubesand cartassem-

bly unit.

2. Insert the ¼-20 x 23/4” screwof the top mat clampassembly into the tapped holein thetop

mounting bracket of the bearing-tubesand cart-assemblyunit. Tightenthe ¼-20 x 2 3/4”

screwinto the holeand jamthe nut tosecure.

3. Attachthe bottomofthemediaclamp assemblytotheT-nutinthelefthorizontal extrusionusing

¼-20 x 1” screw and lock washer.

4. Adjust the mediaclampassemblysothatit is thesamedistancefromthevertical axis extrusion

at thetop and bottom.When the distancesare the same,tighten the screwto the T-nut.

5. You have competed theassembly and mountingof your newOnyx 90 MediaCutter.

6. Double check tomakesureall screws and nutsaretight.

Page number 8

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

5.0 CuttingToolHolders

Awordaboutsafety– razor blades, plastic cuttingtoolsandglasswheelscan all

cutyou –becarefulwhenhandling them.

5.1 Acrylic Cutting Tool Holder (with blue handle)

Plasticsup to 1/4”thickcan be scoredand fractured onyourOnyx 90 machine. The

plasticcutting tool holder utilizes a double-ended carbide inserttoscoreyourplastic

media. Thiscarbide insertprovidesanextremelydurable tool,lastingmanythousands

ofcuts. Warning- this carbideinsert is veryhard and subject tobreakage if dropped.

5.1.1 To remove carbide insert, remove the slotted machine screw located in the center

ofthe insertwithasmallscrewdriver.

5.1.2 Thecarbide insert has two ends. Rotateend forend (if you haven’t doneso

previously)andreplacethecarbideinsertin tool holder.Thecarbide insertiscap

turedvia a machined slot and can not becomemisaligned.

5.1.3 Re-inserttheslottedmachinescrew and tighten.

5.2 Glass Cutting Tool Holder (with red handle)

TheOnyx 90’sglasscuttingtoolincorporatesa six-positionturretwhichcontains

six solid carbide glass cutting wheels. This turret is numbered 1 through 6,

givingyoumeansto keep track ofthenewand used carbide wheelsintheturret.

5.2.1 To change toanew wheel, simply loosentheturret retaining screw ½turnand

indextheturrettothenextposition.

5.2.2 Alignthenewwheel so the centerofthewheel is aligned withthecrossmark on

thefaceofthe tool holder.

5.2.3 Tighten thescrew.

Attention: If the turret retaining screw is loosened more than ½ turn, the carbide

wheels may fall off the axles and become lost.

5.3 Mat Board Cutting Tool Holder (with black handle)

Thistoolholderis used for cuttingmatboard,foam board, gator board,sentra,travicel,

cardboardaswell as many othermedia.

Page number 9

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

5.4 Changing and Adjusting Blade Depth

Attention:Use cautionduring thisprocess sothat yourhanddoes notcome incontact withthe

razorblade.

5.4.1 Changing the Blade

1. Loosen the adjustable set screw on the side of the mat board cutting tool holder

2. Discard the old blade safely.

3. Placeanew blade inthemat board cuttingtoolholder and tightentheset screw

withthe ¼”allenwrenchprovided.

5.4.2 Adjusting blade depth

Thereisa phillips headsetscrew and jamnutlocated on thebackof the mat

board cutting tool holderwhichmaintainsproperbladecuttingdepth. This

depthisadjustedat the factory andmayneverrequireadjustment.

5.5 Replacement Blades

TheOnyx 90 uses economical blades– Part#PPFE-0024.

5.6 Changing from one kind of tool holder to another

Onceyouhave practiced afewtimes, we aresureyou will agreethatthe Onyx 90’stool

interlocksystem allowsyouveryfasttool change.

5.6.1 To insert atoolholder into the machine

1. Holdthe tool holderby the handleand place thetool onto the

groovedpivot arm.

2. Noticeon the toolholder there isa locking pinlocated on the

bottomfront of the toolholder.This locking pinmustengageorfit

intoa matching groove onthepivotarm.

3. Slidethebottomofthe tool holder pinsintothegroovedpivotarm, pull

backanddownonthe spring loaded handle,itwilllockinplace.

5.6.2 To remove atoolholderfrom the machine, liftuponthe tool handle andremovethe

tool.

6.0 Using theOnyx90CuttingTools

6.1 Cutting Glass

Attention: Rememberto weareyeprotection,glovesandprotectiveclothing whenhandlingglass.

Page number 10

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

Do not use the media clamp assembly when cutting glass. That clamp is

only used when cutting mat board and plastic.

6.1.1 PlaceyourglassontheleftsideofyourOnyx90machine.

6.1.2 Place the glass cutting tool holder on the pivot arm.

6.1.3 The larger piece of glass should be on the left side of the cut and the smaller

piece of glass should be on the right side of the cut.

6.1.4 Use either the right or left measuring scale on the horizontal axis extrusions

as necessary.

6.1.5 Place your left hand on the glass - apply holding pressure.

6.1.6 Pull back the handle.

6.1.7 Raise the cutting cart to the top edge of the glass.

6.1.8 Lower the handle and place the glass cutting wheel on the top edge of the

glass.

6.1.9 You can now take advantage of one of the Onyx 90’s best features. You can

vary the amount of pressure needed to make an efficient score just by adding

more or less pressure. No global machine adjustment is necessary.

6.1.10 With one slow, smooth, continuous motion, pull down the cutting cart past

the bottom edge of the glass.

6.1.11 You have just “scored” the glass. Only score glass one time.

6.1.12 After scoring, do not move the glass.

6.1.13 With your left thumb, apply slight pressure on the bottom left edge of the

glass near the score. With your right thumb, apply increasing pressure on

the bottom right edge of glass near the score until the glass separates. The

break will occur at the bottom of the score line and run up to the top of the

score line. The break chases the score.

6.1.14 Never apply pressure to the center or the top of the glass because the break

may not follow the score.

6.2 Cutting Mat Board

6.2.1 The Onyx 90 will cut to up 5/8” deep. When cutting materials that deep, a

sharp blade and successive cuts are necessary. The media clamp can not be

used on thicknesses greater that 1/4”.

6.2.2 The use of the media clamp is not mandatory, but on thin media, it will

reducethe chanceofmediabuckling.

6.2.3 Where it is deemed necessary to have a fine cut edge, a slip sheet under the

cutsheetmay be desired.

6.2.4 Placethematboardcuttingtoolholder on the pivot arm.

6.2.5 Slidethemedia to be cutontothe left cuttingbedofthe Onyx 90.

6.2.6 Usethe right or left measuring scale as necessary.

Page number 11

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

6.2.7 Engagethemediaclampbylifting,pushingforwardandloweringtheclamp

intoposition.

6.2.8 Pullbackthe handle on thecuttingcartuntilitlocks.

6.2.9 Raisethecutting cart abovethemedia to becut.

6.2.10 Releasethe handleusingthethumbrelease.

6.2.11 Youcannow take advantageof one ofthe Onyx 90’sbest features.You can

varytheamountofpressureneededtomakeefficientcutsjustbyadding

moreor less pressure. Noglobalmachineadjustmentisnecessary.

6.2.12 With oneslow,smooth, continuousmotion,pulldownthecutting cart past

thebottomedgeofthe media.

6.2.13 Releasethe mediaclamp.

6.3 Cutting Plastic

6.3.1 Onyx90 willcutfracturesensitiveplasticupto 1/4”thick. Thisincludes

acrylic,polycarbonate,Plexiglasetc.

6.3.2 Placethe plastic cutting tool holder on the pivotarm.

6.3.3 Slidethemedia to be cutontothe left cuttingbedofthe Onyx 90.

6.3.4 Usethe right or left measuring scale as necessary.

6.3.5 Engagethemediaclampbylifting,pushingforwardandloweringtheclamp

intoposition.

6.3.6 Pullback thehandleofthecuttingcartuntil itlocks.

6.3.7 Raisethecuttingcarttotheupperedgeofthefracturesensitiveplastmedia.

6.3.8 Releasethehandleusingthethumbrelease.

6.3.9 Youcannow take advantageof one of theOnyx 90’s best features.Youcan

varytheamountofpressureneededto make efficient scores just byadding

moreorlesspressure. Noglobalmachineadjustment is necessary.

6.3.10 Withoneslow,smooth,continuousmotion,pulldownthecutting

cartpast the bottomedgeof the media.

6.3.11 Note: youwillhearagougingsoundofthematerial.

6.3.12 Repeatthisproceduretwoor three times, dependingupondensityof

materialbeingscored.

6.3.13 To fracture “or crack” the plastic,raise the cuttingcart to the top

edgeoftheplastic.

6.3.14 Pushinontheplasticfractureswing arm handle. At the same time, align

thewhite rollers with thetopedgeofthefracturedsensitiveplastic.

6.3.15 Applyincreasing pressure to theplasticfractureswingarmhandleuntil

youheartheplasticsnap. Continue to holdthepressureontheplastic

fractureswingarmhandlewhilepullingdownthecuttingcartpast

bottomof the fractured sensitiveplasticinoneslow,smooth

continuousmotion.

6.3.16 Releasethe mediaclamp.

6.3.17 Removetheplasticfromthe Onyx90 and separate thetwoplastic

pieces.

Plasticfracture

swingarmhandle

Pagenumber 12

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

6.4 Using the Media Clamp

6.4.1 Themediaclamprequiresonlyonehandtooperate. Simplyliftuptheclamp from its rest

positionandmoveittowards the media tobeclamped.

6.4.2 Gravitywill pulltheclampdownwardandsecurelylock yourworkagainstthestainless steel

gussetplate.

6.4.3 Theclamp is released byliftingupthehandle and returning the clamptotheresting position.

6.4.4 Themedia clamp has a substance that will holdyourmediaverysecurely.

6.5 UsingtheProductionStop

Theproductionstopisusedwhenyouaremakingseveralconsecutivecutsofthesamedimension. The

production stopcanbeplacedoneithertheleftorrighthorizontalextrusion.

6.5.1 SimplyloosentheplasticlockingknobandinserttheT-nutand production stop into the

channellocated atthefrontofeither theleftorrighthorizontal extrusion.

6.5.2 Rotatethewhiteplasticarmuntilitisagainst

themeasuringscale.

7.0 RoutineMaintenance

7.1 Brushall debrisfromboththeleftandright

cuttingbeds.

7.2 Make sure all nutsandboltsremaintight.

7.3 Donot oilthemachine.

8.0 Adustments-should theybecome necessary –not likely.

8.1 Squaring the Machine / making the cutting beds perpendicular to the

vertical axis extrusion.

Your Onyx 90 was squared at the factory and should not require you to make any adjustments.

If forsomereasonyou find it necessarytomakethis adjustment, here arethesteps:

Tools Needed: An assistant, builder’s square, 7/16”open-end wrench, 9/16” open-endwrench

8.1.1 Brushall chips of glassanddebrisfromthecuttingbeds.

8.1.2 Thereare two plasticknobs thatare used tomake sure thatthe cuttingbeds do not

moveifsomeoneputs a heavy weightontheends of the cuttingbeds. Theseareused

forsafety. Loosen thejamnutsandplasticknobsbeforemakinganysquaringadjustments.

Pagenumber 13

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

8.1.3 Laythebuilder’s square onthe leftcuttingbed.Putthematcuttingtool in the tool holder. The

horizontalportion ofthebuilder’ssquareshouldberesting ontheleftcuttingbed.Thevertical

portionof the builder’ssquareshouldberesting-justtouching themat cutting blade. Without

movingthebuilder’s square, raise the cuttingcart to thetop of thevertical portion ofthe

builder’s square. Thedistancefrom the blade tothebuilder’s square mustbethe same at the

topandbottomthroughout the cutting cart’stravel. Ifthereis a gap atthetopof the builder’s

square/bladeintersection, thenyoumustloosenthejamnut ontheleftsideoftheleft horizontal

extrusion. Tighten the3/8”boltslightlyuntilthegap disappears.Tighten thejamnut.

8.1.4 Ifthere is agap at thebottom of thebuilders square/blade intersection,then you must

squaretheleftcuttingbed the other direction. Loosenthejamnutonthe left side ofthe

lefthorizontalextrusion.Youmustloosen the3/8”boltslightly.Thiswillchangethegap.The

gapmustbethe same at thetopandbottom of the builder’ssquare throughoutthecutting

cart’stravel.Tightenthejamnut

Youhavecompletedsquaring theleft horizontalcuttingbed.

8.1.5 Tosquarethe right cutting bed, place the builder’s square on the left cutting bedandslidethe

builder’ssquareovertothe right cutting bed. There shouldbenogapunder the builder’s

squareontherightcuttingbed. Ifthere is a gap under thebuilder’ssquareontherightcutting

bed,loosenthetwojamnutsontherighthorizontalextrusion.Adjustthetwo3/8”boltsto

makethesurfaceoftherightcuttingbedflushwiththebottomofthebuilder’s square. The

builder’s squareshouldslidefromleft-to-rightandright-to-left withouthittingeithercutting

beds. Ifthebuilder’ssquarehitstheleft or right cutting bed, youwillneedtoadjustthe

elevationoftheinnermostbolt on the rightcuttingbed. Adjustthe3/8”bolt as needed sothat

thebuilder’ssquarewilltravelfromleft-to-rightandright-to-leftwithouthittingeithercutting

bed.Tightenboththerightcuttingbedjam nuts.

Mat cutting blade

resting aganist

builder’s square

Mat cutting blade

resting aganist

builder’s square

Page number 14

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

8.1.6 Fingertighten the plastic knobs until you feel resistance,thenloosenthetwoplasticknobs¼

turn. Bringthe jamnutsuptothe bottomofthehorizontalextrusion andlightlytightenthejam

nuts. Over-tighteningofeithertheplastic knobs or thejamnutscanbowthe cutting bed and

takethecutting bed outofsquare.

8.2 Calibration of the Measuring Tape Scales

Thehorizontalandverticalmeasuringtapescales have been set at thefactory. If for somereason youfind

itnecessaryto make this adjustment,hereare the steps.

8.2.1 Wehavesecuredthemeasuring tape scales using asmallscrewandnut applied at the outside

endsofthemeasuringtapescales.

8.2.2 Usingasmallscrewdriver, loosen the screw and nut.

8.2.3 Positionthe measuringtapescalewhereyoufeelit shouldbebyslidingitinthe extrusion

8.2.4 Onceinposition,re-tightenthescrewandnut.

8.3 Global Adjustment of the Cutting Spring Pressure

8.3.1 Thisadjustmenthas been set atthefactory. Ifforsome reason youfinditnecessary to make

thisadjustment,herearethesteps:

8.3.2. Removeallcuttingtoolholdersfromthecuttingcart.

8.3.3. Thespringtensionadjustmentnutislocatedbetweenthebearingtubesonthe very bottom of

thecuttingcart. Thisadjustmentisbest done if the bottom ofthe cuttingcartiselevated. You

shouldhaveanassistant securely hold thecartatthat elevation. Do not trytoholdit and

adjustbyyourself.

8.3.4. Usinga7/16”nut driver or deep-wellsocket,reachbehind the cart fromtherighthand side

andslide the tool onto the spring tension adjustmentnut.

8.3.5. Ifmoretensionisdesired,tightenthespringtensionadjustmentnut. If less tension is desired,

loosenthe springtensionadjustmentnut. Thisnut hasaninternalnylonlocking ringtokeepit

frommoving. So onceyoumoveit,the nutwillstayinthat positionuntilyoumoveit again.

8.3.6. Inserttheglass tool into thecuttingcart and trythenewpressure. Adjust as required.

Page number 15

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

8.4 Adjustment for Depth of Cut

Thisadjustmenthasbeenset at the factory. Ifforsome reason you find itnecessarytomakethis adjustment,

hereare the steps:

8.4.1 Lookatthehandlelocated on thecutting cart.Noticealowerhandleretaining screw and an

upperhandleretaining screw. These two screws arecounter-boredinto thehandleand attach

thehandleto the cutting cart. Justabovethe

upperhandle retaining screw,youwill see a

thirdscrew. Thisthirdscrewis

the“adjustmentlockingscrew.”

8.4.2 Loosentheadjustmentlocking

screwuntil you can inserta

largephillipsheadscrewdriverinto

theslotoftheupper handle

retainingscrew.

8.4.3 Insertthe glasscuttingtoolonto

toolpivot arm.

8.4.4 Releasethe handle with the thumb release and allowtheglasscuttingtooltobottom.

8.4.5 Withthehandleinthe released or bottomed

position,rotate the upper handle retaining screw

clockwiseto decrease thedepth. Rotatethe

upperhandle retaining screw counter clockwise

toincreasethe depth.

Afteryou have made the adjustment to the

cutting depth,besure to pushthehandle in so

thatitisresting on the newadjustedstop

distance.

8.4.6 Tightentheadjustmentlockingscrew.

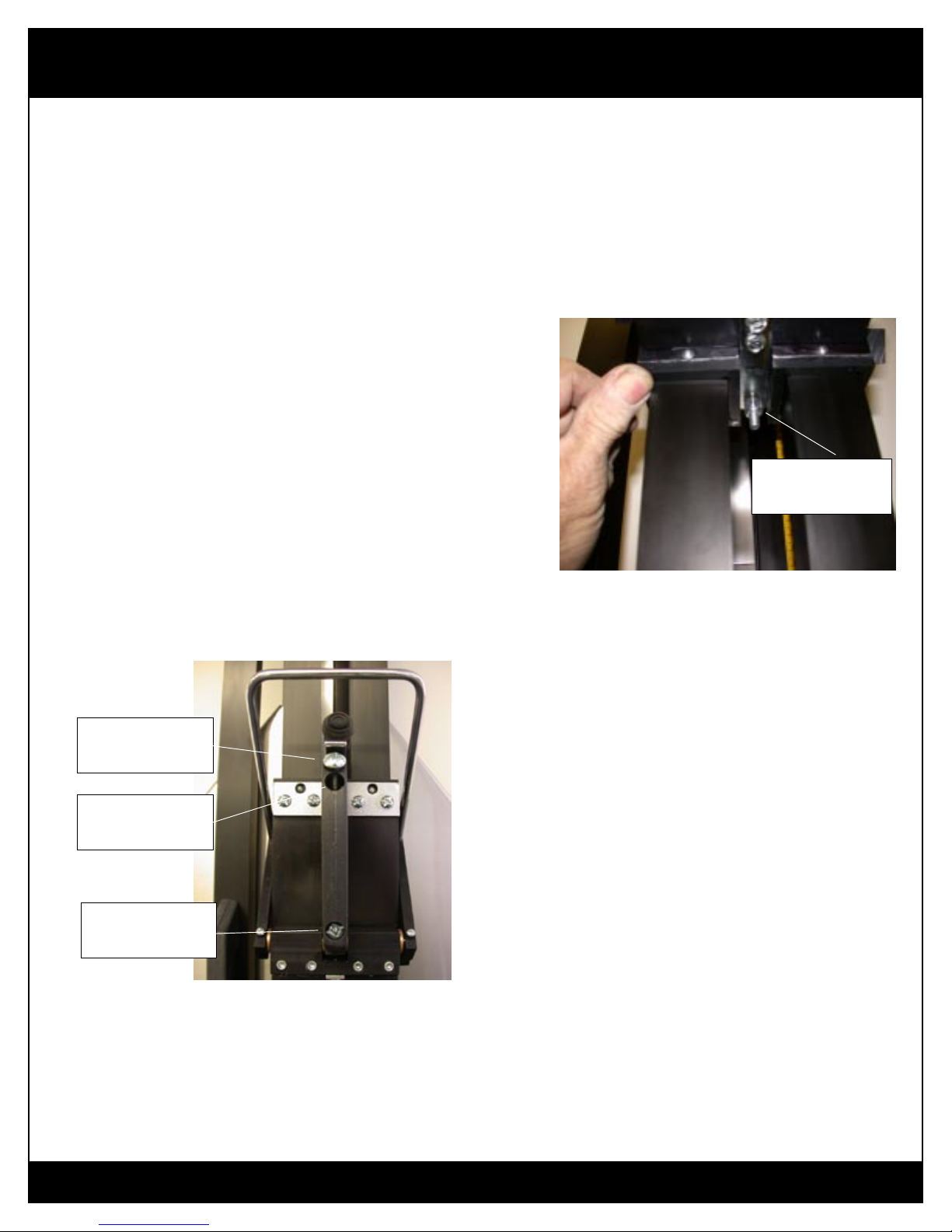

Springtension

adjustingnut

Upper handle

retaing screw

Lower handle

retaing screw

Adjustment

locking screw

Page number 16

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

9.0 Troubleshooting

9.1 When cutting glass, the glass cutter jumps or skips.

Causes: Dirtyglass

Clean glass

Wornglasswheel

Rotate to new wheel

Toolittlepressure

Adjust by applying slight pressure with hand

Make global adjustment -not likely-

Theglass cutting wheel rotates on an axle. There

maybeshardsofglassbetweentheglasscutting

wheelandthewheelaxle.Thisdebris can cause the

glasscuttingwheeltonotrotatefreely.

Lubricate axle and glass wheel area.

9.2 When cutting glass, chipping or flaking occurs.

Causes: Too much pressure

You may be applying too much pressure on the handle.

Pull back on the handle during cut.

Too much pressure will shorten wheel life.

Never score twice.

9.3 When cutting plastic, it skips and or chatters.

Causes: Scoringtoofast

Slow down the stroke speed

Scoringtoolbroken

Rotate cutter if you have not done so previously

Too much pressure

Reduce pressure slightly on handle

Notusingmediaclamp

Use media clamp

9.4 When cutting mat board, the mat board buckles.

Causes: Matboard not clamped

Use media clamp

Bladetoodull

Change to new blade

Page number 17

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

9.5 The cut edge of mat board is frayed

Causes: Dullmatcuttingblade

Change to new blade

Noslipsheetundermediabeingcut

Use slip sheet

9.6 When I make my cuts, the dimensions are incorrect

Cause: Themeasuringscaleisoff

Recalibrate the measuring scale – See Section 8.2

9.7 The cut edge is not square - not a 90 degree cut.

Causes: Debris between the media and cutting bed

Remove debris

Cutting bed is not perpendicular to vertical extrusion.

square the cutting bed -Not likely-

You are very important to us. Our success depends on your

satisfaction. If you are having any problems or have any

comments, please call us at 828-707-5848.

Page number 18

Onyx 90 Media Cutter

The World’s Best Media Cutter 828-707-5848

Onyx 90 Product Registration CardOnyx 90 Product Registration Card

Onyx 90 Product Registration CardOnyx 90 Product Registration Card

Onyx 90 Product Registration Card

Registering your Onyx 90 media cutter is essential to ensure that you validate your warranty and receive all the

benefits of product ownership.

Date of Purchase ______________________________________________________________________

First Name ___________________________________________________________________________

Last Name ____________________________________________________________________________

Street Address _________________________________________________________________________

Street Address _________________________________________________________________________

City, State, Zip _________________________________________________________________________

Email Address _________________________________________________________________________

Phone Number _________________________________________________________________________

Serial Number __________________________________________________________________________

Mail to Professional Picture Frame Equipment

1237 Shipp Street

Hendersonville, NC 28791

Fastest tool change in the industry Cuts mat board, gator board, glass and acrylic

Anodizedaluminumand stainlesssteel Built to lasta life-time

Oil impregnated bronze bushings Ultra high molecular weight polyethylene

FedEx / UPS shippable Stainless steel wall mounting brackets

Production stop included Two year warranty

Cutting depth 5/8 + inches Made in USA

Built-inmatboardandacrylicclamp Carbideplasticcutter

Page number 19

Other manuals for Onyx 90

1

Table of contents

Other Professional Picture Frame Equipment Cutter manuals

Popular Cutter manuals by other brands

Fletcher-Terry

Fletcher-Terry F05221 operating instructions

Clarke

Clarke ETC6 Operating & maintenance instructions

Glomar

Glomar EPG-5-PRO instruction manual

Holmatro

Holmatro SMC 4006 Maintenance instructions

BERGSPORT-STEINLE

BERGSPORT-STEINLE 22CASV6-E Operation manual

Bosch

Bosch PTC 470 Original instructions