Spedo 2600 User manual

1 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

1 Spedo 2600 Pinless Forms Cutter Operator Manual

Spedo 2600 Pinless Forms Cutter

Operator Manual

Issue 5

Part Number SP 007 005

Spedo UK Limited

76 Woolmer Way

Bordon

ampshire

GU35 9QF

ENGLAND

Telephone: +44 (0) 1420 487 447

Fax: +44 (0) 1420 477 827

Web: www.spedouk.com

2 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

2 Spedo 2600 Pinless Cutter Operator Manual

Spedo 2600 Pinless Forms Cutter

History Sheet

Manual Issue Date Changes Incorporated

1

March

2012

First dition

2

January 2013

Change of Address

3

July 2013

Correcti

on of Specifications

4

May 2015

Addition of new functions

5

May 2015

Changed Format

3 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

3 Spedo 2600 Pinless Cutter Operator Manual

Spedo 2600 Pinless Forms Cutter

Publisher

Published by Spedo U Limited

76 Woolmer Way

Bordon

Hampshire

GU35 9QF

ENGLAND

Copyright

Spedo U Limited 2012

All Rights Reserved.

No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written permission of Spedo U Limited.

Unpack

Unpack the equipment and examine it thoroughly to ascertain whether any damage

has occurred in transit. Report immediately any such damage to the agent or

manufacturer. Retain the packing should further transportation be necessary.

All oods

All goods manufactured by the Company are guaranteed to the extent hereafter

mentioned against defects arising from faulty material or workmanship subject to

the goods not having suffered maltreatment or interference. The Company's liability

under this guarantee is limited to replacing any part or parts found defective within

a period as laid down in Company instructions after the date of delivery or

installation.

Other oods

If goods not of the Company's manufacture are ordered, the guarantee of that

company is to be accepted

.

Descriptive Matter

Descriptive matter, illustrations, dimensions and weights issued by the Company are

typical and shall not be held as binding

.

Patterns and Designs

The Company reserves the right to alter patterns and designs without notice

.

First Published

March 2012

We have taken every care in the preparation of this manual. If there are any

inaccuracies, ambiguities or omissions, Spedo U Limited and its consultants and

distributors cannot accept responsibility for any loss or damage these errors may

cause

.

4 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

4 Spedo 2600 Pinless Cutter Operator Manual

Spedo 2600 Pinless Forms Cutter

Safety Measures

This instruction manual contains certain WARNING and CAUTION notices which must be

followed by the user to ensure safe operation and to retain the equipment in a SAFE condition.

All users of the equipment described in this manual MUST have received adequate training in its

use and application in order to ensure SAFE AND PROPER USE.

Any adjustment, maintenance or repair of the opened apparatus under voltage shall be carried

out only by a skilled person who is AWARE OF THE HAZARD INVOLVED.

5 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

5 Spedo 2600 Pinless Cutter Operator Manual

Spedo 2600 Pinless Forms Cutter

Table of Contents

History Sheet ................................................................................................................... 2

Copyright ......................................................................................................................... 3

Safety Measures .............................................................................................................. 4

Table of Contents ............................................................................................................ 5

ENERAL DESCRIPTION SECTION 1

INTRODUCTION .......................................................................................................... 7

TECHNICAL DATA ........................................................................................................ 8

DESCRIPTION OF OPERATION .................................................................................... 9

Spedo 2600 Forms Cutter ...................................................................................... 9

Operation with Web Control Units ...................................................................... 10

Operation with a Printer or Unwinder ................................................................ 10

Operation with a 9400 ......................................................................................... 11

MODES OF CUT ......................................................................................................... 12

Introduction ......................................................................................................... 12

Setting the Form Depth ....................................................................................... 14

Setting the Strip Depth in Dual Cut Mode ........................................................... 18

APPENDIX A1 Optional Accessories ......................................................................... 19

APPENDIX A2 Residual Current Device .................................................................... 20

COMMISSIONIN THE SYSTEM SECTION 2

INTRODUCTION ........................................................................................................ 21

UNPAC .................................................................................................................... 21

ACCESSORIES ............................................................................................................ 21

SITE CONSIDERATIONS ............................................................................................. 21

INSTALLATION .......................................................................................................... 21

Connecting the Mains (Power) Lead ................................................................... 21

Installation Checks ............................................................................................... 22

OPERATIN INSTRUCTIONS SECTION 3

SUMMARY OF CONTROLS ........................................................................................ 24

Paper Transport deck .......................................................................................... 24

Control Panel ....................................................................................................... 24

OPERATING PROCEDURE .......................................................................................... 25

Summary of Controls - Pushbuttons ............................................................... 25

Paper Loading ...................................................................................................... 26

Operation from the Control Panel ....................................................................... 26

Preliminary Manual Cut Operation ................................................................. 27

Start Continuous Operation ............................................................................ 27

Stop Continuous Operation ............................................................................ 27

Emergency Stop Operation ............................................................................. 27

Paper Run-out ................................................................................................. 28

Loading the Paper Web .................................................................................. 29

6 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

6 Spedo 2600 Pinless Cutter Operator Manual

Lowering and Adjusting the Pressure Wheel.................................................. 30

Setting Side Trimmers ..................................................................................... 32

Setting Centre Cutter ...................................................................................... 33

OPERATOR PANEL INSTRUCTIONS ........................................................................... 25

Mode Selection .................................................................................................... 34

Creating a Job ...................................................................................................... 35

Editing a Job ......................................................................................................... 36

Optical Mark Recognition (OMR) Operation ....................................................... 37

Enabling / Disabling the OMR Sensor .................................................................. 39

Adjusting the OMR Sensor .................................................................................. 41

Counter / Batch Mode Operation ....................................................................... 42

Maximum Speed Operation ................................................................................ 44

User Menu Settings ............................................................................................. 45

Maintenance and Engineers Mode ..................................................................... 47

Changing the Blade Setup ................................................................................... 48

Parts Catalogue .................................................................................................... 49

OPERATIONAL MAINTENANCE SECTION 4

WARNINGS ............................................................................................................... 50

CLEANING ................................................................................................................. 50

LUBRICATION ............................................................................................................ 51

7 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

7 Spedo 2600 Pinless Cutter Operator Manual

ENERAL DESCRIPTION SECTION 1

INTRODUCTION

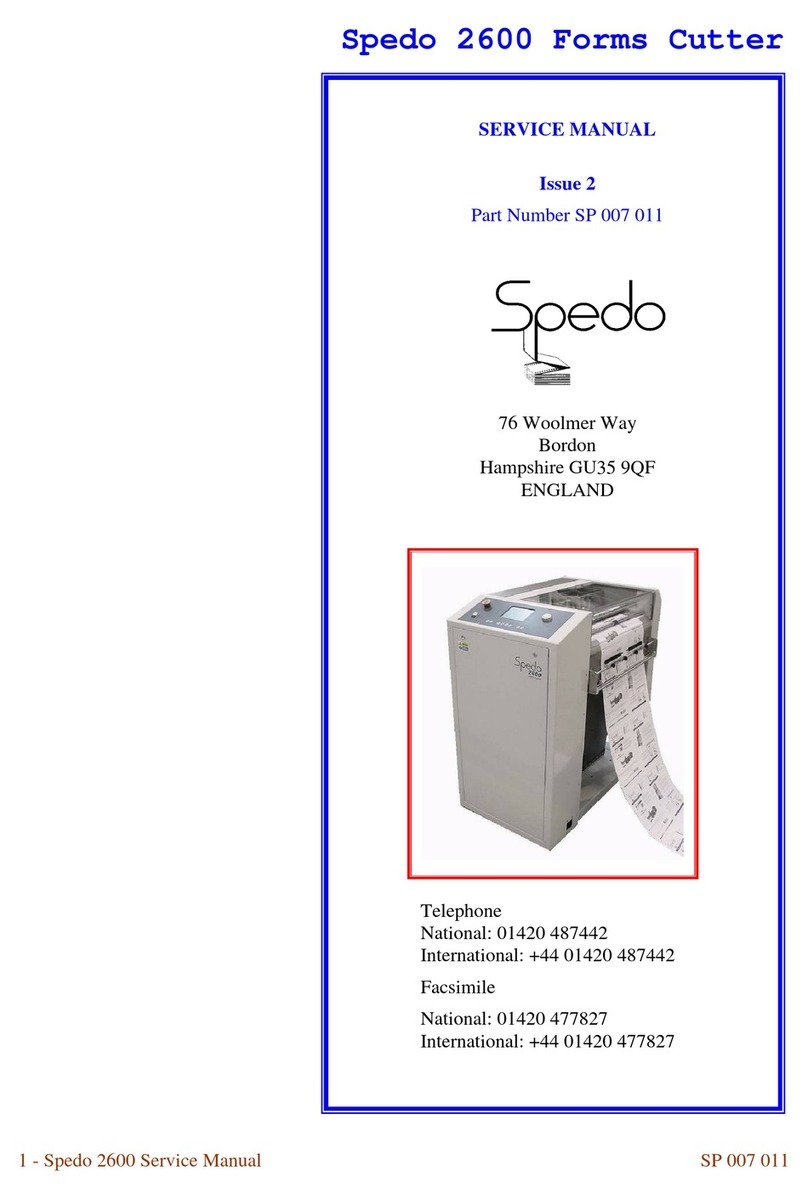

The Spedo 2600 Pinless Forms Cutter is designed to produce cut sheets from continuous paper

webs. In addition, the machine can also optionally trim away either or both margins and

optionally centre cut the paper web.

Fig . Spedo 2600 Pinless Forms Cutter

A normal cross-cut is made at the leading edge of the paper web. However, the machine is also

capable of operating in double cross-cut mode, when it is required to cut before and after the

leading edge to shorten the overall length of the form.

The depth of form to be cut, depth of strip and feed are all measured in terms of line increments,

either as a 6 lines per inch, 8 lines per inch, 10 lines per inch, 12 lines per inch or 16 lines per inch.

In double cut mode, a second cross-cut is made at any interval of between 1 to 9 lines after the

first cut as set by the digital coding switch.

8 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

8 Spedo 2600 Pinless Cutter Operator Manual

TECHNICAL DATA

Basic Design:

The standard machine comprises the operator’s panel, 2 tractor

units with width adjustment by hand wheel, LH & RH edge (margin)

trimmers, noise absorbing protective cover, & paper guides.

EMC Conformity:

The electrical equipment incorporated in this machine with EMC

Directive (89/336/EEC amended by 91/236/EEC and 92/31/EEC),

TUV Rheinland Certification & CE Certification.

Finish:

Spedo white main frame with graphite grey operator panel.

Modes of Cut:

Normal single cut, double (strip) cut or Twin-cut operation.

Paper Weight:

Single Web: 40 g/m

2

to 300 g/m

2

.

Performance:

Form Depth S/Cut 1/6 Strip Cut Twin cut

14 inch 22,320 14,880

12 inch 24,480 15,840 19,680

11 inch 25,920 16,440

10 inch 27,480 17,040

8 inch 31,080 18,360

7 inch 32,760 19,080

6 inch 35,400 20,040

4 inch 42,000 21,120

3 inch 42,120 21.240

Line Feed Increments:

1/6 in, 1/8 in, 1/10 in, 1/12 in, 1/16 in or millimetres

Form Width:

145 mm - 482 mm (5 ¾ - 19inches)

Form Depth:

64mm – 700mm (2 ½ inch – 27 ½ inch)

Strip Cut:

1mm – 38mm (1/32 inch – 1 ½ inch)*

*Subject to stock weight and production speed.

9 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

9 Spedo 2600 Pinless Cutter Operator Manual

Width of Continuous Web:

510 mm (20inches)

Feed Speed:

Rotary control, continuously adjustable.

Counter Type:

Integrated multifunction batch counter.

Power Requirements:

Voltage: 230 V +/-10%

Frequency: 50 Hz to 60 Hz.

Power Consumption: 690 W (approx).

Noise Emissions:

69dB

Dimensions:

Length: 575 mm.

Width: 980 mm.

Height: 1070 mm.

Weight:

140 kg (approx).

Options

Options are listed in Appendix A1 to this section.

DESCRIPTION OF OPERATION

Spedo 2600 Pinless Forms Cutter

Paper is fed into the machine under the paper tension brush, over the in-feed plate, along the paper

supports onto two paper guide units. Once the paper guide units have been adjusted for width and

thickness (weight) of paper web, the web is `jogged' forward and backwards by the operator until it has

been aligned with the edge of the paper guide unit flaps.

At this stage, if the carrier sides (margins) are to be cut off, LH and RH trimmers can be engaged, their

precise position being set by aligning their cut marks with the carrier perforations. In addition, a centre

cutter can be engaged and aligned by the operator at this point, if required.

The machine is capable of operating in conjunction with an ancillary unit (e.g. a web control, printer or

labeller) and successful co-operation between the two units depends on the loop of paper that forms

between the two machines. The presence of paper feeding into the machine is detected by a paper run

out switch located on the in-feed plate. If the paper runs out, the machine automatically stops.

10 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

10 Spedo 2600 Pinless Cutter Operator Manual

Operation with Web Control Devices.

It is possible to run the 2600 Pinless Forms Cutter In-Line with a variety of input devices. Depending on the

speed and application of the input device the correct interface unit can be configured using the examples

below.

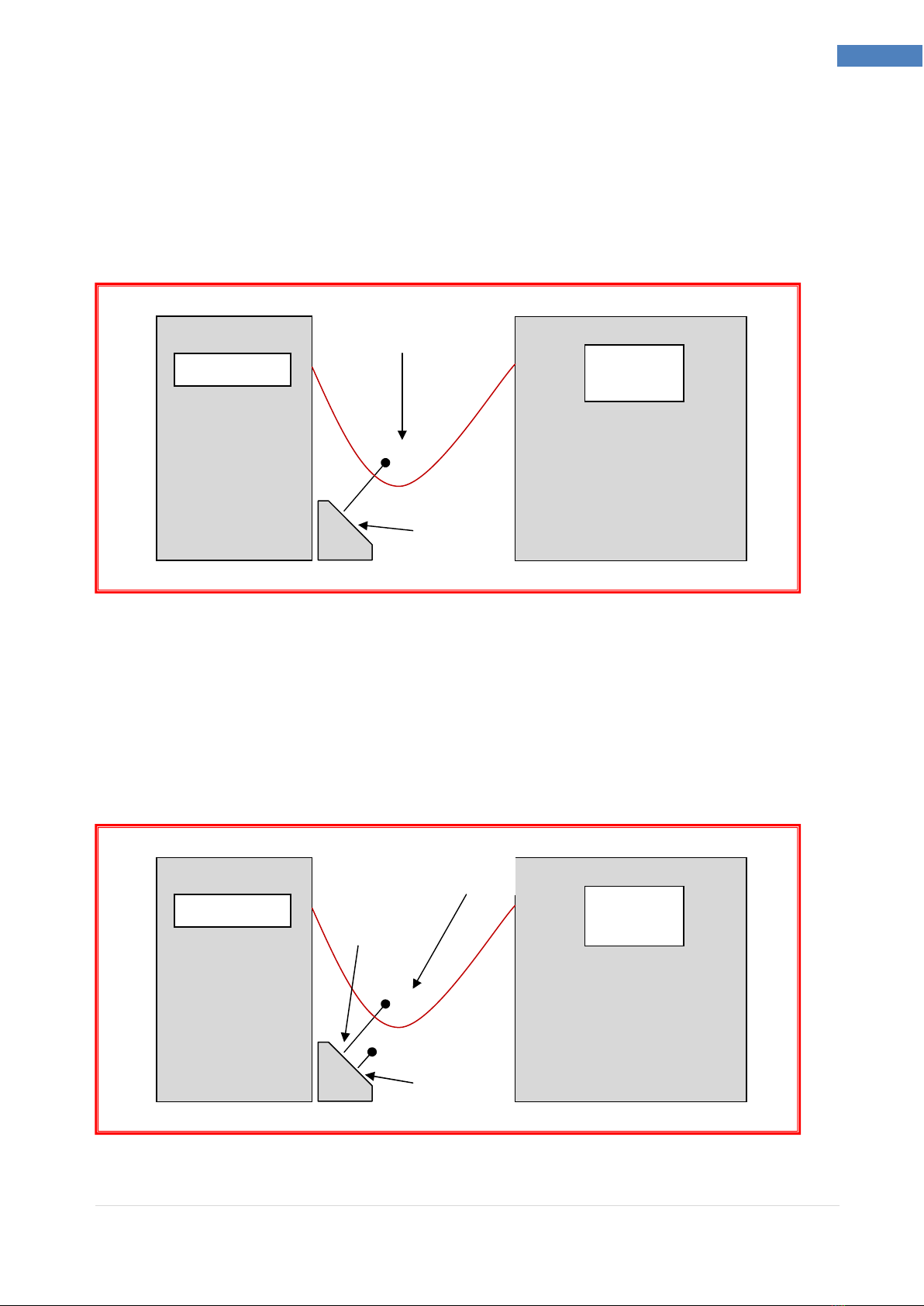

Spedo 2230 Optical Loop Switch.

Fig1.2

Operation with a Printer or Unwinder

When the machine is being supplied from a printer or unwinder which has no means of controlling its out-

feed, it will be necessary to control the paper loop height by positioning either a Spedo Optical Loop

Switch Unit or an Optical Loop Interface Unit between the machine and the printer or unwinder as shown

in Figs 1.2 & 1.3.

Spedo 2231 Optical Loop Interface.

Fig .3

2600 Cutter

Printer or

Unwinder

2600 Cutter

Printer or

Unwinder

P

APER

L

OOP

S

ENSING

A

REA

C

UTTER

S

TOP

S

ENSOR

P

APER

L

OOP

S

ENSING

A

REA

P

RINTER

S

TOP

S

ENSOR

C

UTTER

S

TOP

S

ENSOR

11 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

11 Spedo 2600 Pinless Cutter Operator Manual

Spedo 9400 Web Control Unit.

The Spedo 9400 Web Buffer is an interface unit designed to allow the Spedo 2600 pinless forms cutter to

be run in line with high speed continuous forms printers and unwinders.

The 9400 is able to pause both the cutter and the printer or unwinder as needed, as well as being able to

speed up and slow down to match the speed of the input device.

Fig .4

2600 Cutter Printer or

Unwinder

9400 Web

Buffer

U

LTRASONIC SENSOR

DETECTS WEB EIG T

TO CONTROL INPUT

12 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

12 Spedo 2600 Pinless Cutter Operator Manual

MODES OF CUT

Introduction

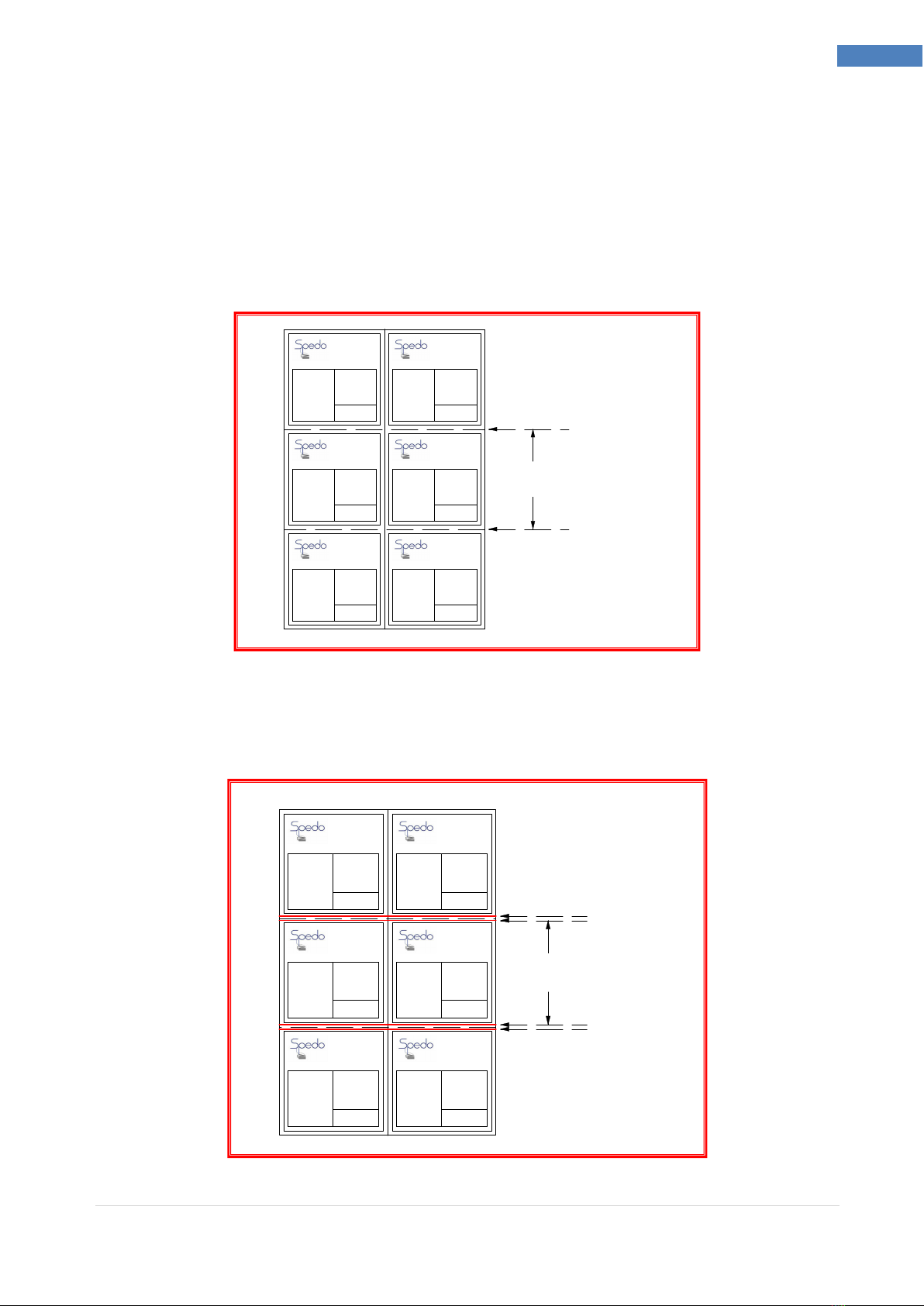

Forms can be cut either by a single cut or by a dual (double) cut as configured by the digital coding switch.

The terminology used in the following explanation relates to Fig 1.5.

Single cut mode is used when it is required to make the cut at the leading edge of the paper web as

shown. The value of form depth is set on the digital code switch on the control panel.

Modes of Cut – Single Cut

Dual cut mode is used when the cut form depth required is smaller than the depth of the original stock

size as shown below, this results in a strip being cut away between forms. In this mode, the value of the

form depth and the strip depth is set in on the digital code switch on the control panel.

Modes of Cut – Dual Cut

FORM

DEPT

SINGLE

CUT ERE

SINGLE

CUT ERE

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

FORM

DEPT

DUAL

CUT ERE

DUAL

CUT ERE

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

13 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

13 Spedo 2600 Pinless Cutter Operator Manual

14 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

14 Spedo 2600 Pinless Cutter Operator Manual

Setting the Form Depth

The principle of setting form depth is by line count. The machine motor is geared such that 1 revolution of

the drive roller moves the paper web forward exactly 6 inches.

For single cut mode, the Strip Depth switch is always set to 0 and can be ignored during the following

explanation.

In order to allow the operator to set various form depth values (6, 12, 18 inches etc..) by line increment,

the machine is fitted with a line increment feature that allows the cut to be made at line positions. The

incremental values can be selected at the Increment switch and are as follows:

1/6 in = 6 lines per inch

1/8 in = 8 lines per inch

1/10in = 10 lines per inch

1/12 in = 12 lines per inch

1/16 in = 16 lines per inch

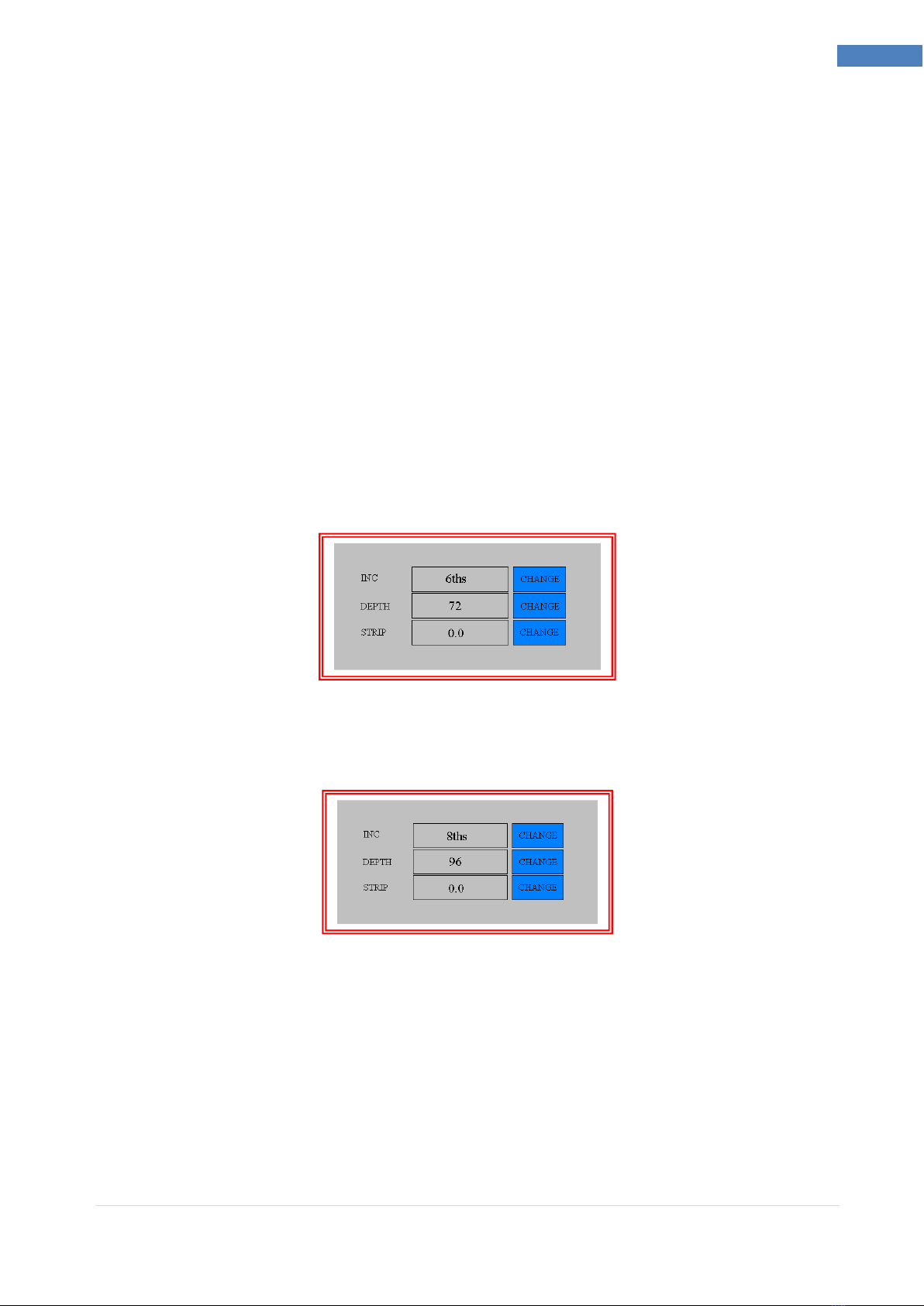

From the above table, it can be seen that if you wished to cut to a form depth of 12 inches, if you selected

a line increment of 1/6 in, this would be 6 lines x 12 inches = 72 lines.

So you would dial up 072 on the Form Depth switch. The machine would then cut at each 72 line point.

Similarly, if you selected 1/8 in line increment, this would be 8 lines x 12 inches = 96 lines.

So you would dial up 096 on the Form Depth switch and the machine would then cut at each 96 line point

and still maintain the 12-inch form depth.

15 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

15 Spedo 2600 Pinless Cutter Operator Manual

Example 1. If you wished to cut a form of depth 11

1

/

4

inches from a continuous paper web, the line

increment set-in must be a multiple of the denominator of the fractional value (in this example it is 4). 4 is

a multiple of 8, 12 or 16, so either of these incremental values can be set to give a round number of total

lines per form depth:

With 1/8 in selected = 8 lines per inch,

8 x 11 = 88

8/4 = 2 lines

88 + 2 = 90 lines.

The values set on the digital code switches would be 8 090.

With 1/12 in selected = 12 lines per inch,

12 x 11 = 132 lines

12/4 = 3

132 + 3 = 135 lines

The values set on the digital code switches would be 12 135.

With 1/16 in selected = 16 lines per inch,

16 x 11 = 176 lines

16/4 = 4

176 + 4 = 180 lines

The values set on the digital code switches would be 16 180.

16 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

16 Spedo 2600 Pinless Cutter Operator Manual

Example 2. If you wished to cut a form of depth 10 1/2 inches from a continuous paper web, the line

increment set-in must be a multiple of the denominator of the fractional value (in this example it is 2).

2 is a multiple of 6, 8, 12 or 16, so either of these incremental values can be set to give a round number of

total lines per form depth:

With 1/6 in selected = 6 lines per inch,

6 x 10 = 60 lines

6/2 = 3

60 + 3 = 63 lines

The values set on the digital code switches would be 6 063.

With 1/8 in selected = 8 lines per inch,

8 x 10 = 80 lines

8/2 = 4

80 + 4 = 84 lines.

The values set on the digital code switches would be 8 084.

With 1/10 in selected = 10 lines per inch,

10 x 10 = 100 lines

10/2 = 5

100 + 5 = 105 lines.

The values set on the digital code switches would be 10 105.

With 1/12 in selected = 12 lines per inch,

12 x 10 = 120

12/2 = 6

120 + 6 = 126 lines.

17 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

17 Spedo 2600 Pinless Cutter Operator Manual

The values set on the digital code switches would be 12 126.

With 1/16 in selected = 16 lines per inch,

16 x 10 = 160 lines

16/2 = 8

160 + 8 = 168 lines.

The values set on the digital code switches would be 16 168.

Example 3. If you wished to cut a form of depth 7

1

/

5

inches from a 12-inch continuous paper web, the line

increment set-in must be a multiple of the denominator of the fractional value (in this example it is 5).

5 is a multiple of 10, so only an incremental value of 10 can be set to give a round number of total lines

per form depth:

With 1/10 in selected = 10 lines per inch,

10 x 7 = 70 lines

10/5 = 2

70 + 2 = 72 lines.

The values set on the digital code switches would be 10 072.

18 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

18 Spedo 2600 Pinless Cutter Operator Manual

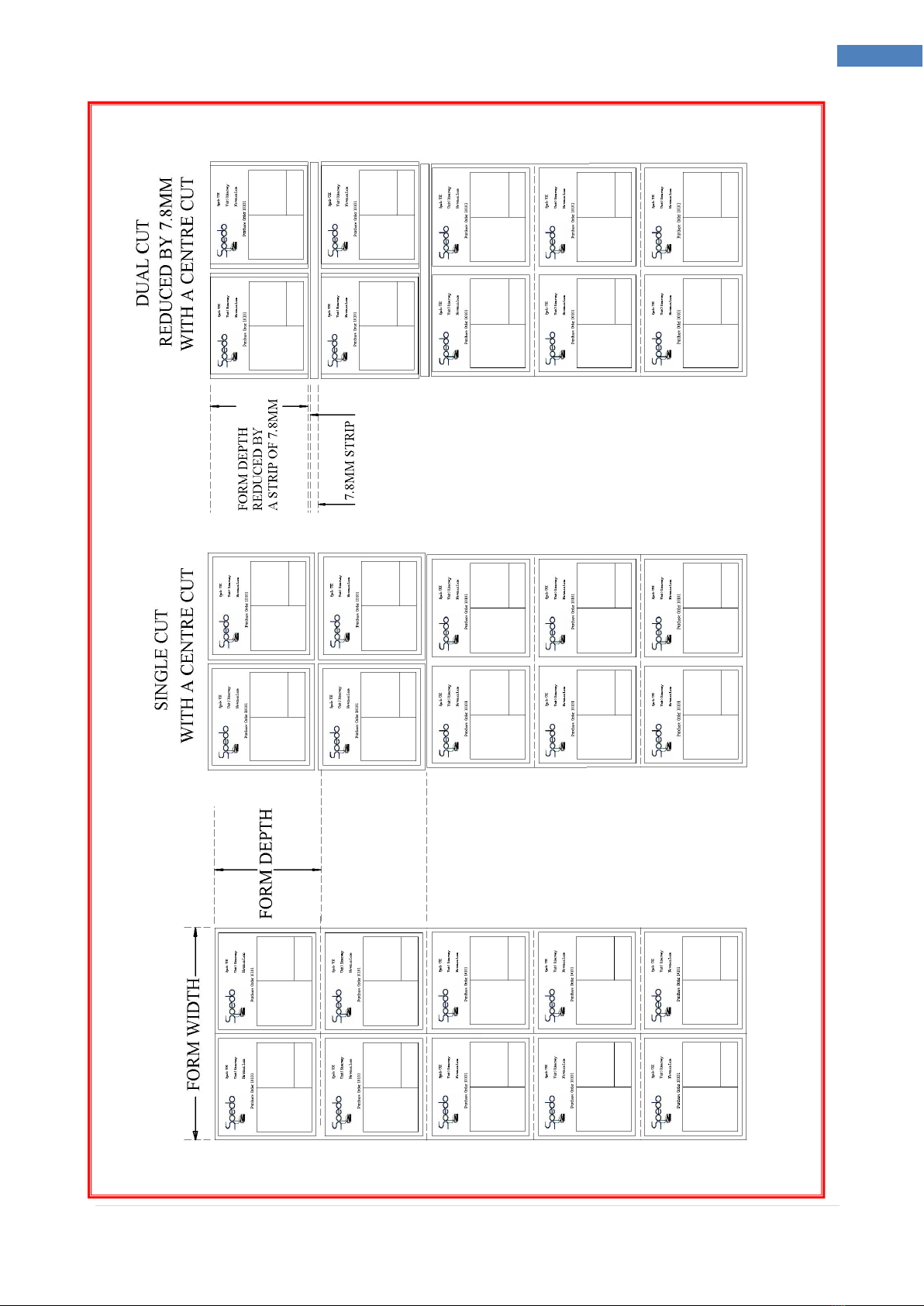

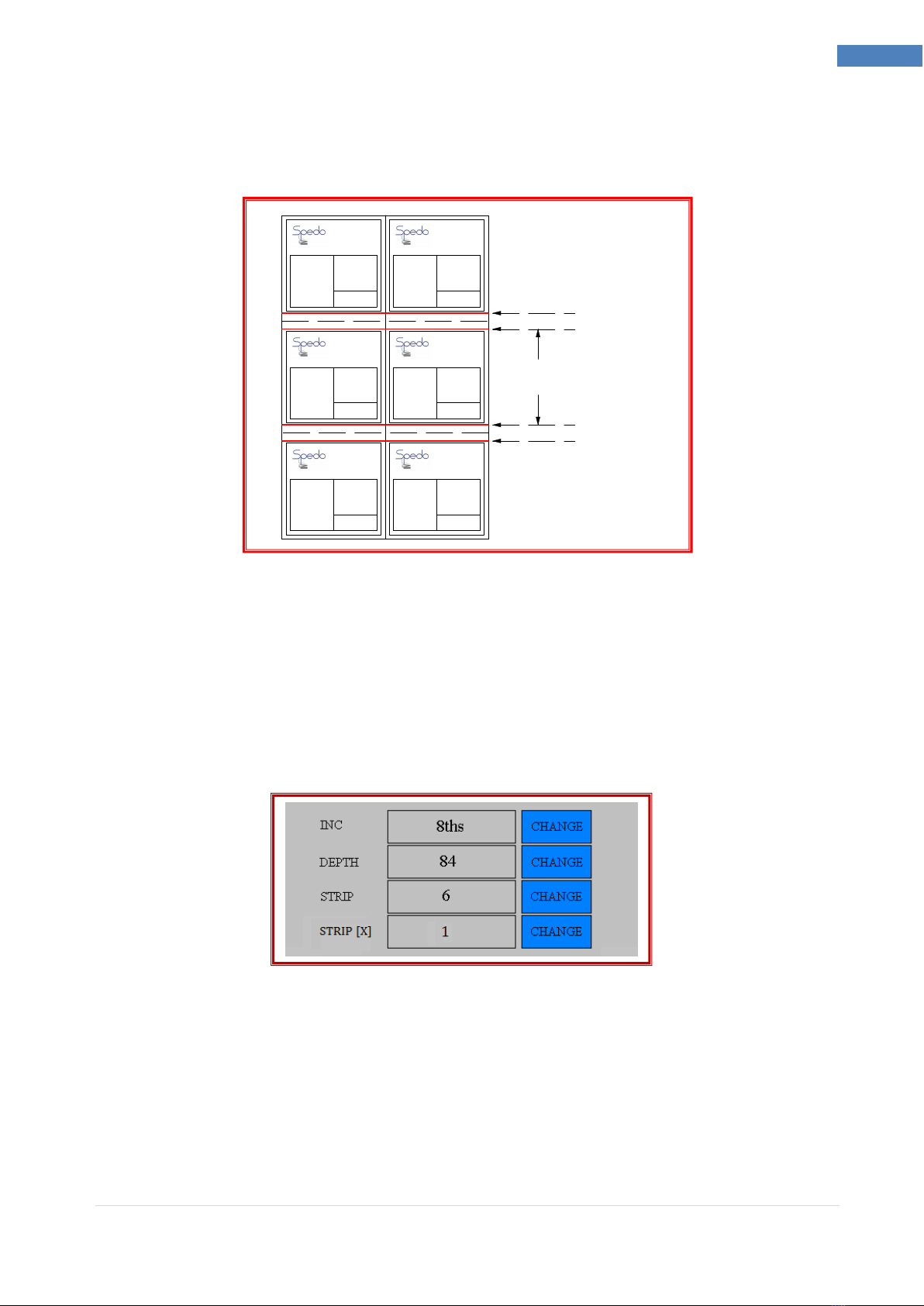

Setting the Strip Depth in Dual Cut Mode

When in dual cut mode, the machine makes a cut immediately before and after a perforation, resulting in

a strip being cut out. The strip depth value is set in terms of line increment on the Strip Depth switch.

Consider Example 1 again. A form depth of 11

1

/

4

is to be cut from a 12-inch web:

12 - 11

1

/

4

=

3

/

4

.

This means that a 3/4 inch strip must be cut out between forms. A

3

/

4

inch depth at a line increment of 1/8

in works out as|:

8/4 = 2

2 x 3 = 6 lines.

With the value 6 set on the Strip Depth switch, 6 must be deducted from the original value of 90 set in for

a single cut, so that 84 is now set-in on the Form Depth switch.

The Strip Depth switch can be set in the range 0 to 9 (lines) and these will relate to the line increment

setting selected.

The cut positions can now be `fine tuned' by the using the JOG pushbuttons to determine how many lines

before and after the perforation line the cuts are made ( i.e., 3 lines before and 3 lines after, or 1 line

before and 5 lines after, etc.)

Multiple strips can also be performed by increasing the STRIP[X] multiplier function.

11 1/4 "

FORM DEPT

3/4 " STRIP

3/4 " STRIP

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

Spedo UK

Unit 5 Riverwey

Newman Lane

Alton, ampshire

GU34 2QL

Purchase Order 10101

19 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

19 Spedo 2600 Pinless Cutter Operator Manual

OPTIONAL ACCESSORIES APPENDIX A1

Double Cross-Cut Blade

This is a cross-cutting device for removing the cross perforation from the paper web, without any

loss of time or performance. The strip depth can be changed from 1/6

th

to 7.8mm.depending on

the size of blade to be fitted. The strip is cleanly separated from the forms on each motion of the

blades by blown air. The movable lower blade can be tilted off for single cut operation, if

required. In this mode, the Strip Depth switch on the control panel will be removed.

Optical Loop Switch Unit 2230

This unit is designed to control the height of the paper loop which forms between an out-feeding

printer or collator and the associated in-feeding Spedo Forms Cutter.

Optical Loop Interface Unit 2232

This unit is designed to control the height of the paper loop that forms between an out-feeding

printer or collator and the associated in-feeding Spedo Forms Cutter. It also detects the overflow

of paper out-feeding from the printer or collator that occurs if the Forms Cutter stops accepting

paper infeed.

Web Control Unit 9400

This unit is a high speed web buffer used to accurately control the paper web into the forms

cutter. The web buffer allows the operator to stop and start the entire print line automatically,

thus improving productivity.

Side Strip Chopper

This is used for shredding the cut-off side strip which is collected in a metal tray.

Anti-Static Kit

This is supplied with mounting accessories to remove static built up from the laser printing

process.

Centre Cutters

Additional Centre Cutter Assemblies can be fitted, providing additional longitudinal cuts along the

paper web.

Additional Accessories

Stack Tray & Paper Stops

20 | S p e d o 2 6 0 0 O p e r a t o r M a n u a l S p e d o U K L t d

20 Spedo 2600 Pinless Cutter Operator Manual

RESIDUAL CURRENT DEVICE APPENDIX A2

USE OF RESIDUAL CURRENT DEVICE (RCD)

As part of its highly reliable cutting mechanism, the Spedo 2600 Pinless Forms Cutter uses

brushless AC servomotors. These servomotors use a high frequency switching current. If it is

necessary to use a Residual Current Device with your system, it must be a unit that has been

specified for inverter use.

Spedo U recommends that only RCDs provided by Spedo U are used. Spedo U will not accept

any responsibility for a system failure if an RCD from another supplier is used.

Two versions are available:

Part No. SP005 376 Residual Current Device, c/w Cord Set.

Part No. SP005 377 Residual Current Device, Wall Mounted.

Other manuals for 2600

1

Table of contents

Other Spedo Cutter manuals