Profibus T1H-PBC User manual

T1H-PBC

PROFIBUSTM I/O

system overview

If you are using a PROFIBUS™ controller

network, the Terminator I/O sub-system

will help further reduce the cost of your

overall application. The T1H-PBC module

allows the micro-modular Terminator I/O

sub-system to be linked with a PROFIBUS

master controller. PROFIBUS is a control

bus that provides a common method

to connect automation equipment with

devices on a single network. This standard

communications media is referred to as

PROFIBUS and significantly reduces hard-

wiring costs. PROFIBUS provides specifica-

tions for information exchanged between

nodes, such as controller data associated

with low- level device and configuration

parameters individually related to system

operations.

PROFIBUS allows 32 stations per segment.

Segments vary in length depending on

the desired transmission speed. The

maximum speed is achieved on a segment

100 meters (327 feet) in length. Our

PROFIBUS-DP Slave represents a single

station. Repeaters also count as stations

and are used to extend the network to

greater distances. Our PROFIBUS module

supports baud rates of 9.6 Kbaud to 12

Mbaud depending on the network length.

Here’s how it works:

The T1H-PBC module is a PROFIBUS

slave, which can be plugged into

the network interface position of the

Terminator I/O micro-modular family of

I/O bases. This module reports all the

identification data, diagnostic information,

and parameters that control the module

operation. The T1H-PBC module scans

and reports all discrete and analog I/O

data to a PROFIBUS master. The exter-

nally-powered AC Terminator I/O base

units contain a 24VDC power supply for

simple wiring of sensors and actuators

into the Terminator I/O modules, and for

controlling them with a PROFIBUS master.

Using our PROFIBUS I/O sub-system

will increase installation flexibility as well

as save on wiring costs. The T1H-PBC

module supports all Terminator discrete

and analog I/O modules.

The T1H-PBC also offers the following

features:

• Cost-effective: With a single network for

devices, hardwiring costs are reduced.

• Easy connectivity: Low-cost installation is

easy to implement and maintain.

•Diagnostics: The PROFIBUS slave offers

advanced error diagnostics not commonly

available in traditional systems.

• High baud rates: Response time is 10 ms

per device

• LED Indicators: These provide quick indi-

cation of Terminator power and operating

mode.

Profibus Base Controller

MODULE STATUS

LINK ACTIVE

LINK GOOD

ERROR

P

R

O

F

I

B

U

S

P

O

R

T

PROFIBUS™ Slave

Specifications

Module Type PROFIBUS Network Interface Module

Max. Expansion 126 stations, 32 stations per segment, 9 repeaters in a row

Max. I/O Points per Controller

244 Input Bytes (analog or discrete)

244 Output Bytes (analog or discrete)

as specified by the PROFIBUS DP Specification

Communications RS-485 PROFIBUS, PROFIBUS-DP.

Baud rate selectable from 9.6 Kbaud to 12 Mbaud.

Module Connectors PROFIBUS 9-pin D-shell, RJ-12 serial (for firmware update only)

Internal Power Consumption 530mA maximum at 5VDC (supplied by base power supply)

Operating Environment 0ºC to 60ºC (32ºF to 140ºF), 5% to 95% humidity

(non-condensing)

Manufacturer Host Automation Products, L.L.C.

Please Note:

1. Terminator I/O PROFIBUS slave network interface mod-

ule T1H-PBC is a PTO-certified PROFIBUS-compliant

slave I/O interface product.

See www.profibus.com for more information.

2 For use with Think & Do Software, we recommend the

SST PROFIBUS PCI Master Card, part number

5136-PFB-PCI. (AutomationDirect does not provide this

interface).

See www.mysst.com for more information.

tFED-61 Universal Field I/O

.

ERNI ERbic

connectors

for

PROFIBUS

networks

Connectors are

available for the PROFIBUS Base

Controller. They are available in

standard node and standard termi-

nation styles with vertical cable entry

for Terminator I/O.

Horizontal entry

cable

Vertical

entry cable

Contact A Contact B

Shield tied

Bar Contact A Contact B

MODULE STATUS

LINK ACTIVE

LINK GOOD

ERROR

H

Termination

Female

Male

Node

5

4

3

2

1

9

8

7

6

5

4

3

2

1

9

8

7

6

PROFIBUS Slave

Recommended Cables

Siemens 6XV1 830 0AH10

Belden 3079A

ERNI ERbic Connectors

Part

Number Price Description Device

103658

PROFIBUS

certified standard

node

vertical connector.

9-pin male D-sub

Terminator I/O

T1H-PBC or any

PROFIBUS ISA/

PCI Personal

Computer

Master/Slave

Card

103659

PROFIBUS

certified standard

termination

vertical connector

9-pin male D-sub

Terminator I/O

T1H-PBC or any

PROFIBUS ISA/

PCI Personal

Computer

Master/Slave

Card

Terminator I/O Modules Supported

Discrete Types Analog Types

8-point DC Input 8-channel Current Input

8-point AC Input 8-channel Voltage Input

16-point DC Input 8-channel Current Output

16-point AC Input 8-channel Voltage Output

8-point DC Output 16-channel Current Input

8-point AC Output 16-channel Voltage Input

16-point DC Output 16-channel Current Output

16-point AC Output 16-channel Voltage Output

8-point Relay Output

16-point Relay Output

Baud

Max.

Segment

Length

Max.

Expansion

Feet Meters Feet Meters

9.6 Kbps 3278 1000 32786 10000

19.2 Kbps 3278 1000 32786 10000

93.75 Kbps 3278 1000 32786 10000

187.5 Kbps 3278 1000 32786 10000

500 Kbps 1311 400 13114 4000

1.5 Mbps 655 200 6557 2000

3 Mbps 327 100 3270 1000

6 Mbps 327 100 3270 1000

12 Mbps 327 100 3270 1000

www.lamonde.com-fieldIO Universal Field I/O tFED-62

.

It is important to understand the installa-

tion requirements for your Terminator I/O

system. This will ensure that the Terminator

I/O products work within their environ-

mental and electrical limits.

Plan for safety

This catalog should never be used as a

replacement for the technical data sheet

that comes with the products or the

T1K-INST-M Installation and

I/O Manual (available online at

.) The tech -

nical data sheet contains information that

must be followed. The system installation

should comply with all appropriate elec-

trical codes and standards.

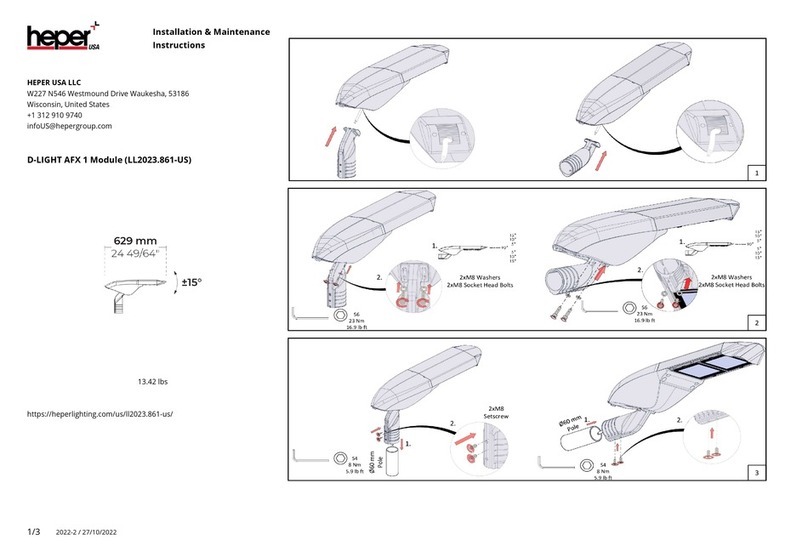

Unit dimensions and

mounting orientation

Use the following diagrams to decide

if the Terminator I/O system can be

installed in your application. Terminator

I/O units should be mounted horizon-

tally. To ensure proper airflow for cooling

purposes, units should not be mounted

upside-down. It is important to check the

Terminator I/O dimensions against the

conditions required for your application.

For example, it is recommended to leave

2” depth for ease of access and cable

clearance. However, your distance may

be greater or less. Also, check the instal-

lation guidelines for the recommended

cabinet clearances.

48mm

(1.89in)

80mm

(3.15in)

80mm

(3.15in)

48mm

(1.89in)

80mm

(3.15in)

48mm

(1.89in)

89mm

(3.5in)

80mm

(3.15in)

83.3mm

(3.28in)

Power Supply Network Interface Module Half-size I/O Module

with Base

System DepthFull-size I/O Module

with Base

Dimensions and Installation

See the Enclosures

section for an enclosure that may

be suitable for your application

Terminator I/O Environmental Specifications

Ambient Operating Temperature 32°F to 131°F (0°C to 55°C)

Storage Temperature -4°F to 158°F (-20°C to 70°C)

Ambient Humidity 5% to 95% (Non-condensing)

Atmosphere No corrosive gases. The level of environmental

pollution = 2 (UL 840)

Vibration Resistance MIL STD 810C, Method 514.2

Shock Resistance MIL STD 810C, Method 516.2

Voltage Withstand (Dielectric) 1500VAC, 1 minute

Insulation Resistance 500 VDC, 10 Mq

Noise Immunity

NEMA ICS3-304

Impulse noise 1µs, 1000V

FCC class A

RFI (144MHz, 430MHz 10W, 10cm)

Agency Approvals UL, CE, FCC class A, NEC Class 1 Division 2

tFED-53 Universal Field I/O

.

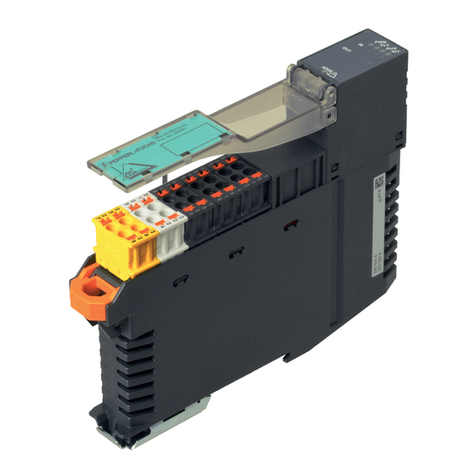

I/O Module Installation

Grip the locking handle, as shown, and pull gently to

eject the I/O module from its base. The module will slide

out for easy replacement. This procedure does not apply

to network interface modules or power supplies, which

have integral bases.

Hot-swappable

I/O modules

You can remove I/O

modules under power,

but exercise caution while

doing so. Do not touch the

terminals with your hands

or any conductive material.

Always remove power when

possible.

Removing I/O modules

is a snap

I/O module installation

Terminator I/O modules feature separate

terminal bases for easy installation.

To install I/O modules:

1. Slide the module into its terminal base

(until it clicks into position)

2. Hook upper DIN rail tabs over the top of DIN

rail, and press the assembly firmly onto the

DIN rail.

3. Slide the module along the DIN rail until it

engages with the adjacent module.

DN-ASB-1

angled mounting

bracket

Optional angled support bracket

raises and tilts the mounting rail for

easier access and wiring. Use with

35mm DIN rail. See the Connection

Systems in this catalog for details.

Great for mounting

in upper locations

Great for mounting

in lower locations

1

2

3

www.lamonde.com-fieldIO Universal Field I/O tFED-54

.

Calculating the power budget

To calculate the power budget, read the

available power (current rating) from the

Power Supply Specifications table and

subtract the power consumed by each

module to the right of the power supply.

Do not include modules to the right of an

additional power supply.

Power supplies

The Terminator I/O product line offers

two power supply options: AC or DC.

The power supplies are always positioned

to the left of the modules to which they

supply power. Consult the system configu-

ration examples and the power budgeting

example for more information on posi-

tioning power supplies.

This power supply powers these three I/O

modules

This power supply powers the network interface module and

the next two I/O modules

Power Supplies and Power Requirements

Power requirements

Power supply

specifications

Power Supply

Specifications

T1K-01AC

T1K-01DC

Input Voltage Range 110/220 VAC 12/24 VDC

Input Frequency 50/60 Hz N/A

Maximum Power 50VA 30W

Max. Inrush Current 20A 10A

Insulation

Resistance > 10Mq@ 500 VDC

Voltage Withstand 1 min. @ 1500VAC between

primary, secondary and field

ground

5VDC

PWR

Voltage 5.25 VDC 5.25 VDC

Current Rating

2000 mA max

(see current

option note

below)

2000 mA max

Ripple 5% max. 5% max.

24VDC

PWR

Voltage 24VDC N/A

Current Rating

300mA max.

(see current

option note

below)

N/A

Ripple 10% max. N/A

Fuse 1 (primary), not replaceable

Replacement

Terminal Block

(Phoenix Contact)

MVSTBW

2.5/4-ST-5.08

BK

MVSTBW

2.5/6-ST-5.08

BK

Note: 500mA @ 24VDC can be achieved by lowering the

5VDC from 2000mA to 1500mA.

Power Budget Example

Module 5VDC 24VDC

T1K-01AC +2000mA +300mA

T1H-EBC100 -300mA -0mA

T1K-16ND3 -70mA -0mA

T1K-16TD2 -200mA -0mA

T1F-08AD-1 -75mA -50mA

Remaining +1355mA +250mA

Module 5VDC 24VDC

Analog Input Modules

T1F-08AD-1 75 50*

T1F-08AD-2 75 50*

T1F-16AD-1 75 50*

T1F-16AD-2 75 50*

T1F-16RTD 150 0

T1F-16TMST 150 0

T1F-14THM 60 70*

Analog Output Modules

T1F-08DA-1 75 150*

T1F-08DA-2 75 150*

T1F-16DA-1 75 150*

T1F-16DA-2 75 150*

Combination Analog Modules

T1F-8AD4DA-1 75 60*

T1F-8AD4DA-2 75 70*

* Use either internal or external source

for 24VDC

Module 5VDC 24VDC

DC Output Modules

T1H-08TDS 200 0

T1K-08TD1 100 200*

T1K-16TD1 200 400*

T1K-08TD2-1 200 0

T1K-16TD2-1 200 0

AC Output Modules

T1K-08TA 250 0

T1K-16TA 450 0

T1K-08TAS 300 0

Relay Output Modules

T1K-08TR 350 0

T1K-16TR 700 0

T1K-08TRS 400 0

Specialty Modules

T1H-CTRIO 400 0

* Use either internal or external source

for 24VDC

Module 5VDC 24VDC

Interface Modules

T1H-EBC100 300 0

T1H-PBC 530 0

T1K-DEVNETS 250 45

T1K-MODBUS 300 0

DC Input Modules

T1K-08ND3 35 0

T1K-16ND3 70 0

AC Input Modules

T1K-08NA-1 35 0

T1K-16NA-1 70 0

Adding additional

power supplies

Each power supply furnishes power only to

the network interface and I/O modules to

its right. Inserting a second power supply

closes the power loop for the power

supply to the left, while also powering

the modules to its right. Perform a power

budget calculation for each power supply

in the system.

tFED-55 Universal Field I/O

.

Expansion I/O Configurations

T1K-10CBL

T1K-10CBL-1*

Right side to left side

expansion cable

Using T1K-10CBL expansion cable

and T1K-05CBL-RR expansion cable

Expansion cables T1K-05CBL-LL

T1K-05CBL-LL-1*

Left side to left side

expansion cable

Using two T1K-10CBL expansion cables

Using T1K-05CBL-RR expansion cable

and T1K-05CBL-LL expansion cable

Using T1K-05CBL-RR expansion cable

The T1K-10CBL(-1) connects the right

side of an I/O base to the left side of

the next I/O base. A maximum of two

T1K-10CBL(-1) cables can be used per

expansion system.

The T1K-05CBL-LL(-1) connects the left

side of an I/O base to the left side of the

next I/O base. Only one T1K-05CBL-LL

(-1) cable can be used per expan-

sion system and must be used with a

T1K-05CBL-RR cable. This cable cannot

be connected to the left side of the network

interface base.

Some of the examples below show

the T1K-05CBL-RR expansion

cable. This cable is no longer

available.

Refer to the examples if you already

have these cables. If you are

purchasing new cables, we recom-

mend the T1K-10CBL(-1) cables.

The T1K-05CBL-RR connects the

right side of an I/O base to the right

side of the next I/O base. A maximum

of one T1K-05CBL-RR cable can be

used per expansion system. Note:

When this cable is used, the expan-

sion I/O assignments are from right

to left (reversed).

*Note: The (-1) versions of the expansion cables pass 24VDC through on an isolated wire. (All cables pass the 5VDC base

power.) Any local expansion DC input module configured for “internal power” (current sourcing) must either have a power supply

preceding it on the same base or, have a (-1) version cable pass 24VDC from a power supply on the preceeding base.

T1K-10CBL

T1K-05CBL-RR

(Retired Product)

T1K-05CBL-RR

(Retired Product)

T1K-05CBL-RR

(Retired Product)

T1K-05CBL-LL

In the system below, power supplies can be used anywhere.

Power supplies can be used anywhere in the first two bases,

but not in the last expansion base.

A power supply can be

used on either base.

Power supplies can be used anywhere in the first and third

bases, but not in the second base.

T1K-10CBL(-1)

Power supplies can be used anywhere in the first base, but not

in the second base.

I/O Addressing

I/O Addressing

I/O Addressing

I/O Addressing

T1K-10CBL(-1)

Do not connect a

T1K-05CBL-LL(-1)

to the left side of the

network interface base.

Cable length = 1.0m Cable length = 0.5m

T1K-05CBL-RR RETIRED

Right side to right side

expansion cable is no longer

available

www.lamonde.com-fieldIO Universal Field I/O tFED-56

.

Terminal base

specifications

Terminator I/O terminal bases are available

in screw clamp and spring clamp versions for

both half-size and full-size modules. Hot stamp

silkscreen labeling is used for numbering I/O

points, commons, and all power terminals.

Screw clamp, half-size

Screw clamp, full-size

2 and 3-wire DC input devices

using bussed 24VDC power

Use externally supplied 24VDC

power or 24VDC auxiliary power

from T1K-01AC

Spring clamp, full-size

Spring clamp, half-size

T1K-08B

T1K-16B T1K-16B-1

T1K-08B-1

Field Device Wiring and Power Options

Do not jumper modules together

to create a 24VDC bus when

using the “hot swap” feature.

See Note below.

Terminal Base Specifications

Terminal Type Screw type Spring clamp

Recommended

Torque

1.77–3.54 lb·in

(0.2–0.4 N·m) N/A

Wire Gauge

Solid:

25–12 AWG

Stranded:

26–12 AWG

Solid:

25–14 AWG

Stranded:

26–14 AWG

Field device wiring options

Power your DC input devices from the

integrated 24VDC power supply bus.

T1K-08ND3 and T1K-16ND3 DC input

modules include jumpers for selecting the

internal 24VDC power supply available

for 2- and 3-wire field devices. Clearly

labeled triple stack terminals make it easy

to wire 2- and 3-wire devices ensuring

clean wiring with only one wire per

termination.

External user supplied 24VDC power, or

auxiliary 24VDC terminals from T1K-01AC,

can be easily applied directly to one end of

the terminal rows and jumpered across each

base in the system.

This is a convenient solution for powering

analog I/O and discrete DC output

devices whose modules do not have direct

access to the internal bussed 24VDC. If

current consumption increases, simply

add additional T1K-01AC power supplies

into the system.

Hot-swap feature

The hot-swap feature allows Terminator

I/O modules to be replaced while system

power is on. Be careful not to touch the

terminals with your hands or other conduc-

tive material to avoid the risk of personal

injury or equipment damage. Always

remove power if it is equally convenient to

do so.

Note: Before hot-swapping analog or

DC output modules in a Terminator I/O

system, make sure that each of the analog

and DC output module’s 24VDC and 0

VDC base terminals are wired directly to

the external power supply individually. If

the external 24VDC and 0 VDC is jump-

ered from base to base in a daisy chain

fashion, and an analog or DC output

module is removed from its base, the risk

of disconnecting the external 24VDC and

0 VDC to the subsequent I/O modules

exists.

tFED-57 Universal Field I/O

.

Table of contents