ProGear E-FREE TRIKE User manual

NOTE: This manual may be subject to updates or changes. Up to date manuals are available through our website at www.progearbikes.com.au

Only be to assembled by a skilled bicycle mechanic

Read all instructions carefully before using this product. Retain this owner’s manual for future

reference.

E-FREE TRIKE OWNER’S

MANUAL

2

TABLE OF CONTENTS

1. IMPORTANT SAFETY INSTRUCTIONS 3

2. BATTERY CARE AND SAFETY 4

3. PARTS LIST 6

4. ASSEMBLY INSTRUCTIONS 8

5. COMPONENTS 17

6. ELECTRONICS 20

3

1. IMPORTANT SAFETY INSTRUCTIONS

Failure to obey all of the warnings and instructions contained in this manual may result in serious injury, or

permanent damage to your bike.

Always wear a properly fitted and fastened helmet when riding. This is required by law in most

states and is an important safely precaution. Failure to wear an approved safely helmet can result in

severe injury or death.

Check your helmet for proper fit and damage before each ride.

Always obey all traffic laws.

The purchaser, owner, and/or riders of this cargo bike are directly responsible for knowing and

obeying all local, state and federal laws regarding the riding and use of this cargo bike

Always ride cautiously, maintaining complete control and a reasonable speed (<20km/h).

The rider should hold the handlebars and stop before get on or off

Sitting securely when riding.

Slow down the speed to 10km/h or less before turning the corner, in order to avoid rolling over

This bike is not suitable for stunt riding, jumping, competition, or racing.

Always check that brakes and throttle are functioning properly before each ride.

Only one rider at a time.

Carrying more than 4 objects in the basket may interfere with your control of the cargo bike, and can

result in loss of control.

Do not ride at night or in conditions when visibility is impaired, unless you install head lamps and tail

lamps that make you visible to all pedestrians and vehicles.

Wet weather significantly detracts from brake performance. Always allow a longer distance for

safely stopping in the rain, or on a wet or icy road surface.

This product should not be used by minors without adult supervision.

Do not modify the bike

Do not tow or pull with the cargo bike. Do not allow the cargo bike to be towed or pulled.

Keep fingers away from moving parts and chain.

Always park in right place.

Avoid high speed sharp turns, as your cargo bike may tip over.

Make sure that there is an enough braking distance when with cargo.

Must use rear brake every time when braking.

Some localities require that the owner or rider equip their bike with a horn, bell, or other sound

making device to use for warning others of your approach.

Check handlebar and seat adjustments before riding.

Check all axle, motor mounting, and drive system mounting nuts.

Check your tires for cuts, exposed casing, casing cords, and proper inflation before each ride.

This bike is not recommended for competition, stunt, any aggressive or off-road riding.

Ensure you wear safe footwear and keep loose articles of clothing clear of moving parts on your E-

Bike while riding.

4

2. BATTERY CARE AND SAFETY

Do not disassemble the battery pack and modify the unit or your warranty will be void and you will

be responsible for the modification.

Make sure that the battery pack has been fully charged before first use, and remove the charger

after fully charging. Turn the main battery switch off while charging or not using.

Check that all electrical connections and mechanical parts are securely locked and fastened before

use.

The performance and mileage of the unit will be varied with the battery condition, temperature,

terrain, wind speed, tire pressure, rider weight and the maintenance.

Always handle the battery pack with care and do not drop it.

Do not connect the terminals of battery pack with any foreign object.

1. Battery Charging

Battery should be charged timely after riding the power assist vehicle. Lithium battery of the Company should

be charged with designated charger. Connect the output plug to the charger and then connect the charger

to 240V alternating current power supply. Battery can be used after charging 6-7 hours until the charging

indicator light turn from red to green.

2. Battery Discharging

Riding process of the power assist vehicle is the process of battery discharging. Users are not permitted to

over discharging the battery. Over discharging may cause severe damage to battery life. When instrument

displays that the battery is under voltage, the controller will stop power supplying at any time.

3. Battery Storage & Additional Charging

Reserve of electricity will somewhat lose when storing or during the transportation process. Battery should

be additional charged before use. Charging method is as above.

4. Battery Use, Maintenance & Attention

4-1 Never put battery close to heat source of high temperature;

4-2 Charging environment is better to be below 37℃;

4-3 Avoid charging under direct sunlight;

4-4 Resolutely use designated charger to charge the battery;

4-5 Short circuit is not allowed at battery charge port;

4-6 Never put battery in wet places or in water;

4-7 Never randomly dismantle the battery or do any unauthorized modification;

4-8 Never impose external forces on the battery or drop it from high places;

4.9 When battery is not in use, it should be fully charged and stored in a dry and cool place. Places within

1m around the battery should be free of inflammables and is insulating. Battery should be kept away from

heavy load and children. Complete additional charging should be conducted every 2 months.

5. Special Warning:

a) Never clean the vehicle with hydraulic monitor which may cause damage to electrical components

due to water intake.

5

b) If the product smokes or burns when damaged by external forces, put it out with dry-chemical fire

extinguisher or sandy soil.

c) Although the lithium battery is environmental friendly product, it also contains various kinds of

chemical substances. When it is broken due to aging, it may pollute the environment. Therefore,

please discard it as useless within 36 months since the date of purchase, and give it to skilled

company for professional treatment.

6. Disclaimers

a) no responsibility for any damages caused by nonconforming the requirements in application

instruction manual

b) no responsibility for any damages caused by any unauthorized modification

c) no responsibility for any damages caused by force majeure

6

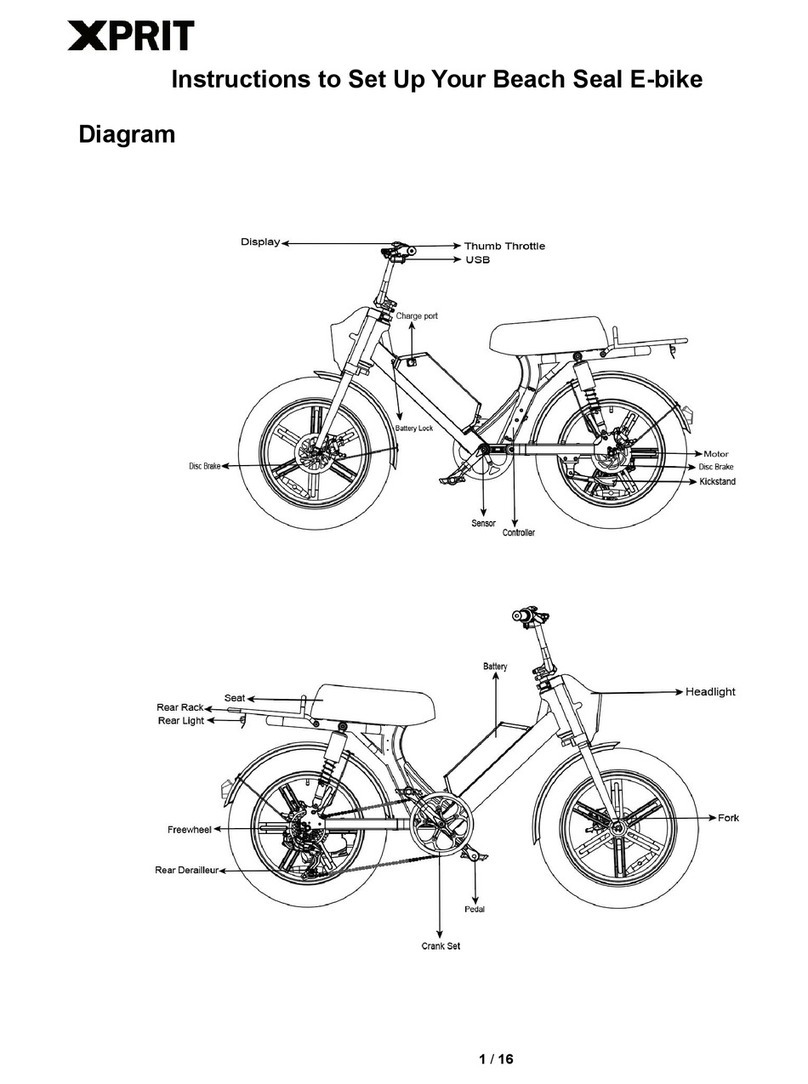

3. PARTS LIST

PART

DESCRIPTION

1

Handlebar

2

LCD Display Panel

3

Brake Lever

4

Gear Shift

5

Disc Brake

6

Gear Freewheel

7

Rear Derailleur

1

2

3

4

5

6

7

7

PART

DESCRIPTION

8

Front Frame

9

V-Brake

10

Front Fork

11

Front Wheel Set with Motor

12

Chain Cover & Chain

13

Chain Wheel and Cranks

14

Pedal

15

Real Wheel Set

16

Wheel Reflector

17

Basket

18

Rear LED Light

19

Li-battery

20

Seat Post Clamps

21

Seat Post

22

Saddle

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

8

4. ASSEMBLY INSTRUCTIONS

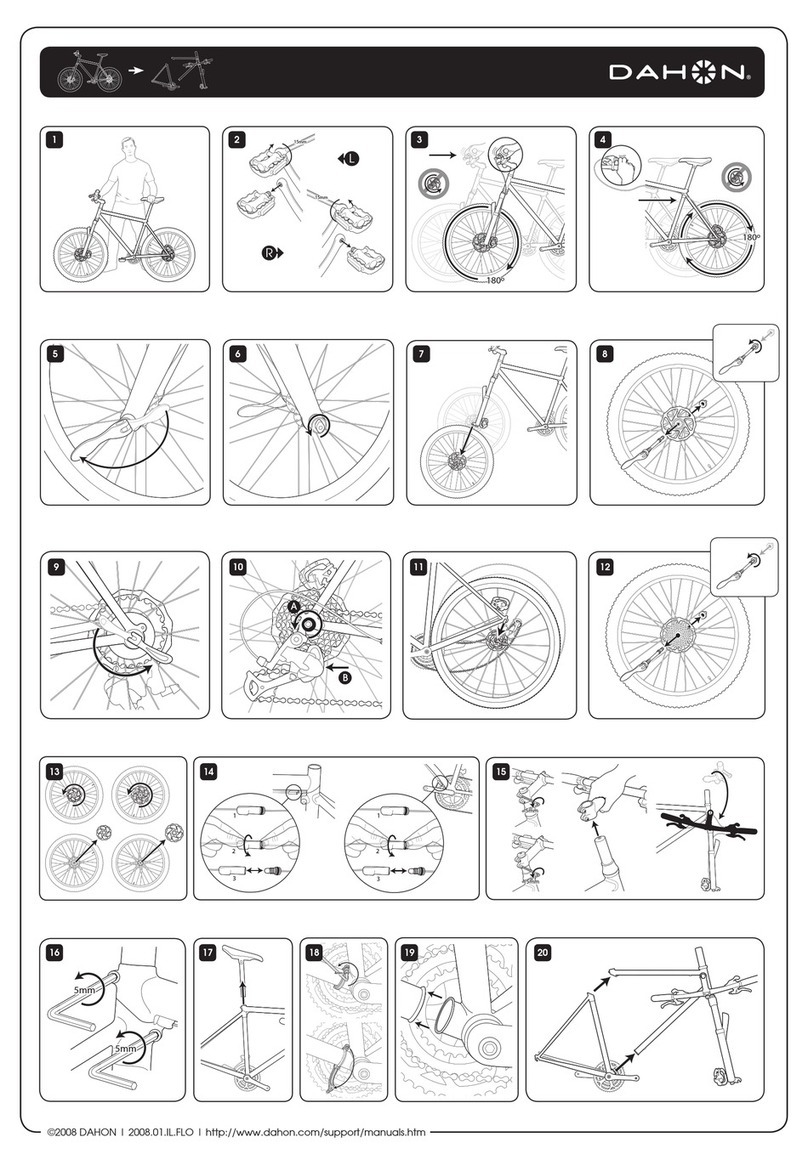

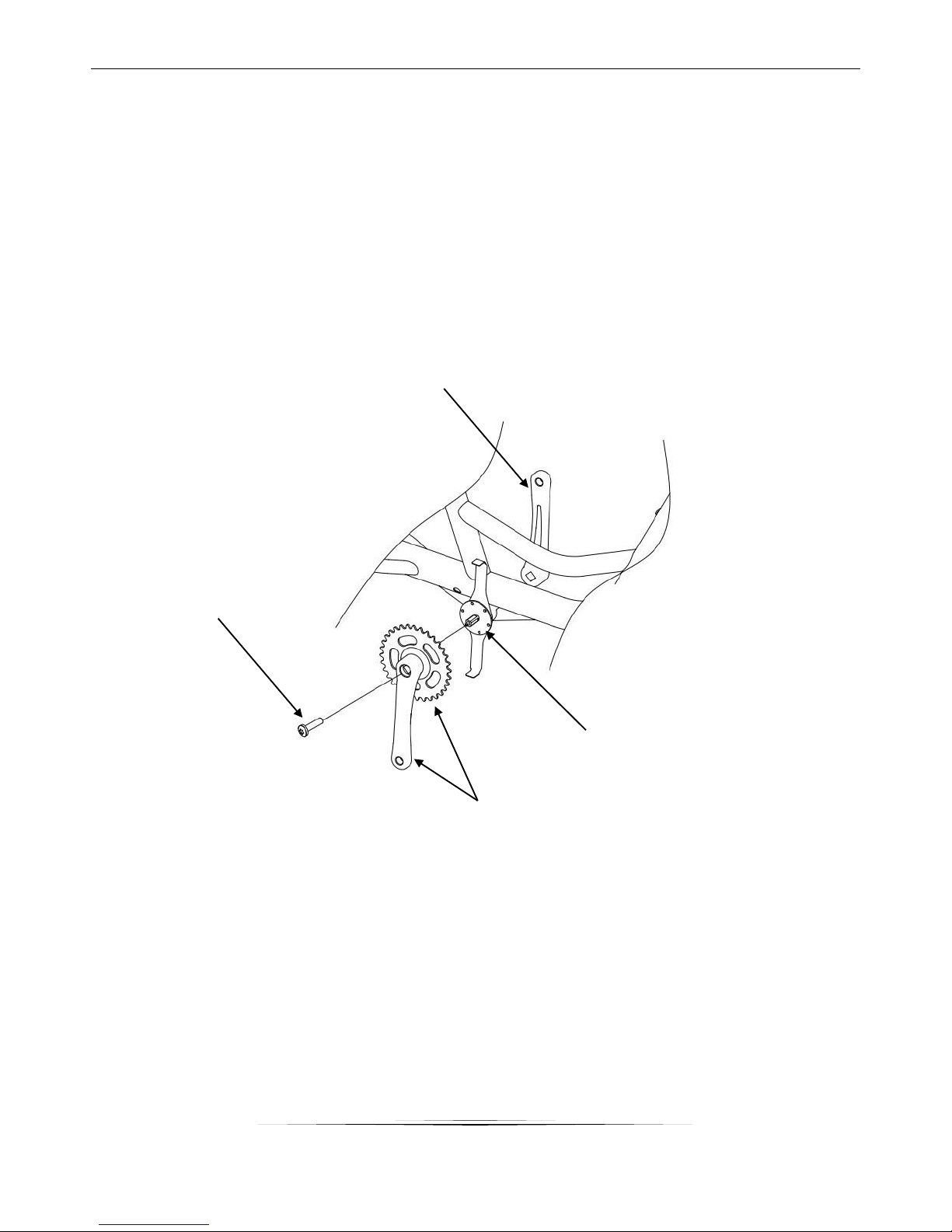

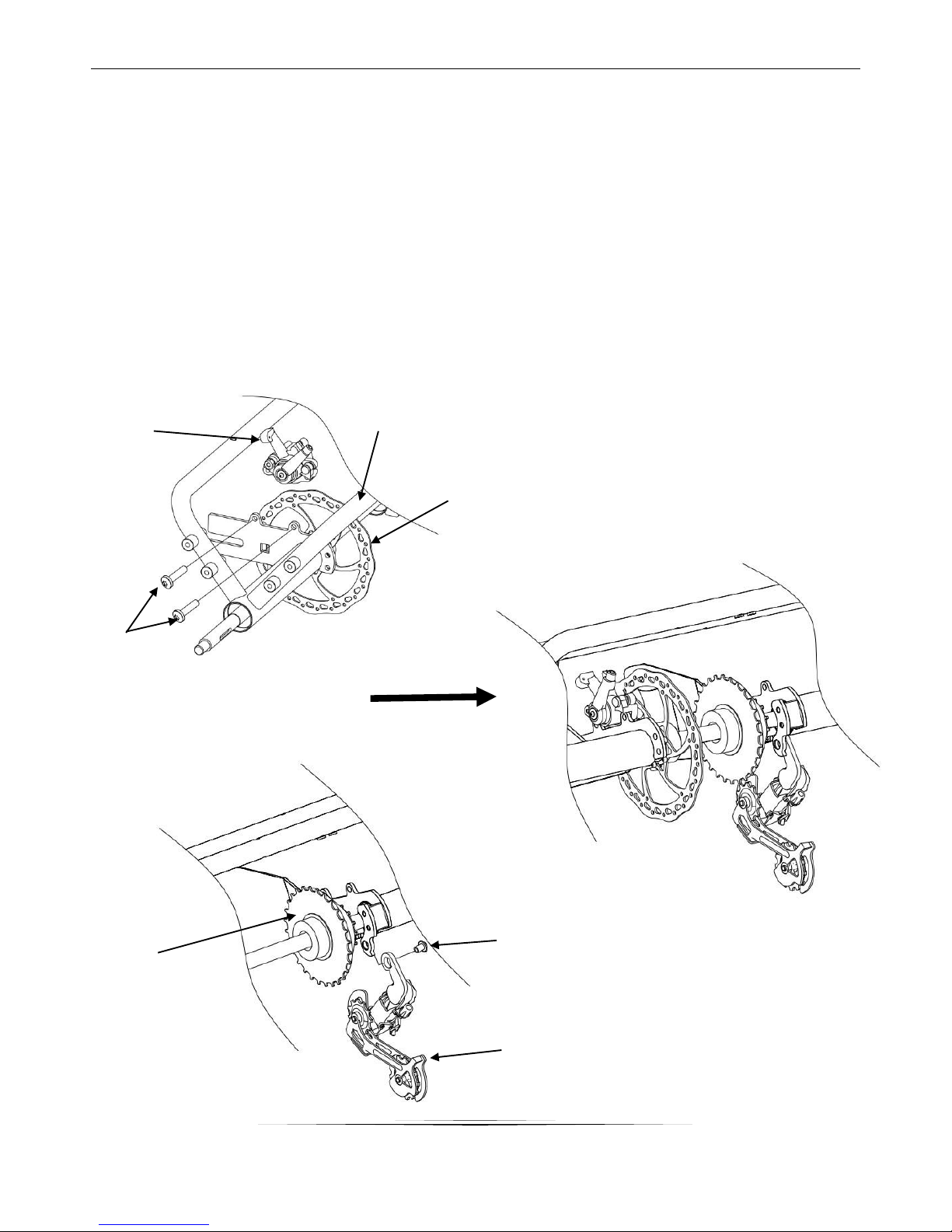

STEP 1 – Chain Wheel and Crank Assembly

a) Attach electromagnetism sensor piece into the middle axle. Ensure the sensor piece is assembled

towards the correct riding

b) direction.

c) Assemble the chain wheel and crank to middle axle and secure with fixing bolts.

Crank

Fixing bolts

Chain wheel and crank

Electromagnetism

Sensor piece

Figure 1

9

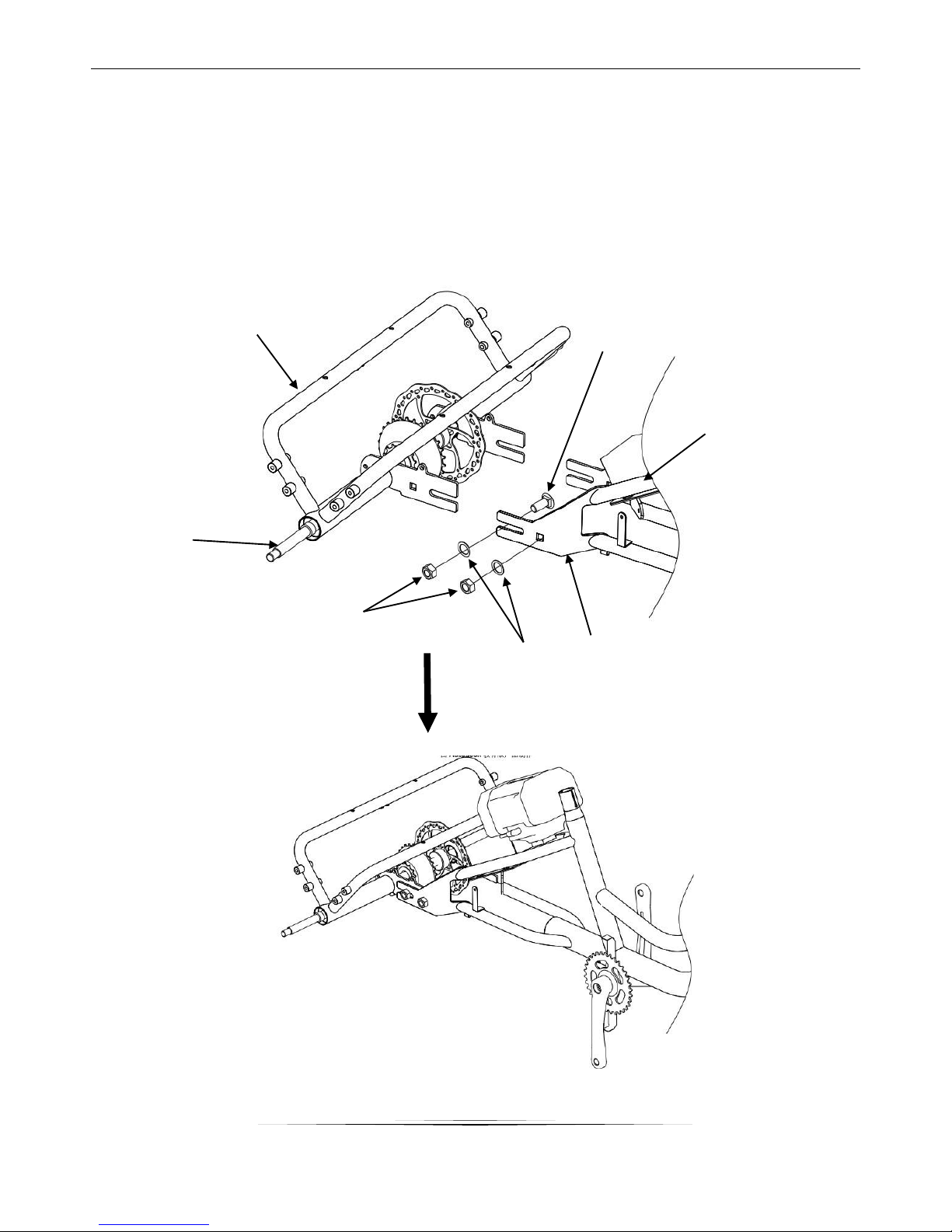

STEP 2:

a) Refer to Fig.2: Connect the front frame and rear frame with:

- Square neck bolts

- Nuts

- Washers

Figure 2

Rear frame

Front frame

Transmission

Axle

Front frame

Bracket

Nut

Washer

Square neck bolt

Figure 3

10

STEP 3:

a) Refer to Fig. 4 & 5: Assemble the disc brake and rear derailleur onto the rear frame.

b) Assemble disc brake disc on the rear axle first.

c) When bolting on the disc brake caliper ensure there is even clearance between both sides of the

disc pads and the disc.

d) Check the rear derailleur adjustment on attached sheet.

Figure 4

Figure 5

Figure 6

Assembled Image

Disc Brake

Caliper

Rear frame

Disc brake disc

Screw

Gear freewheel

Derailleur

Screw

11

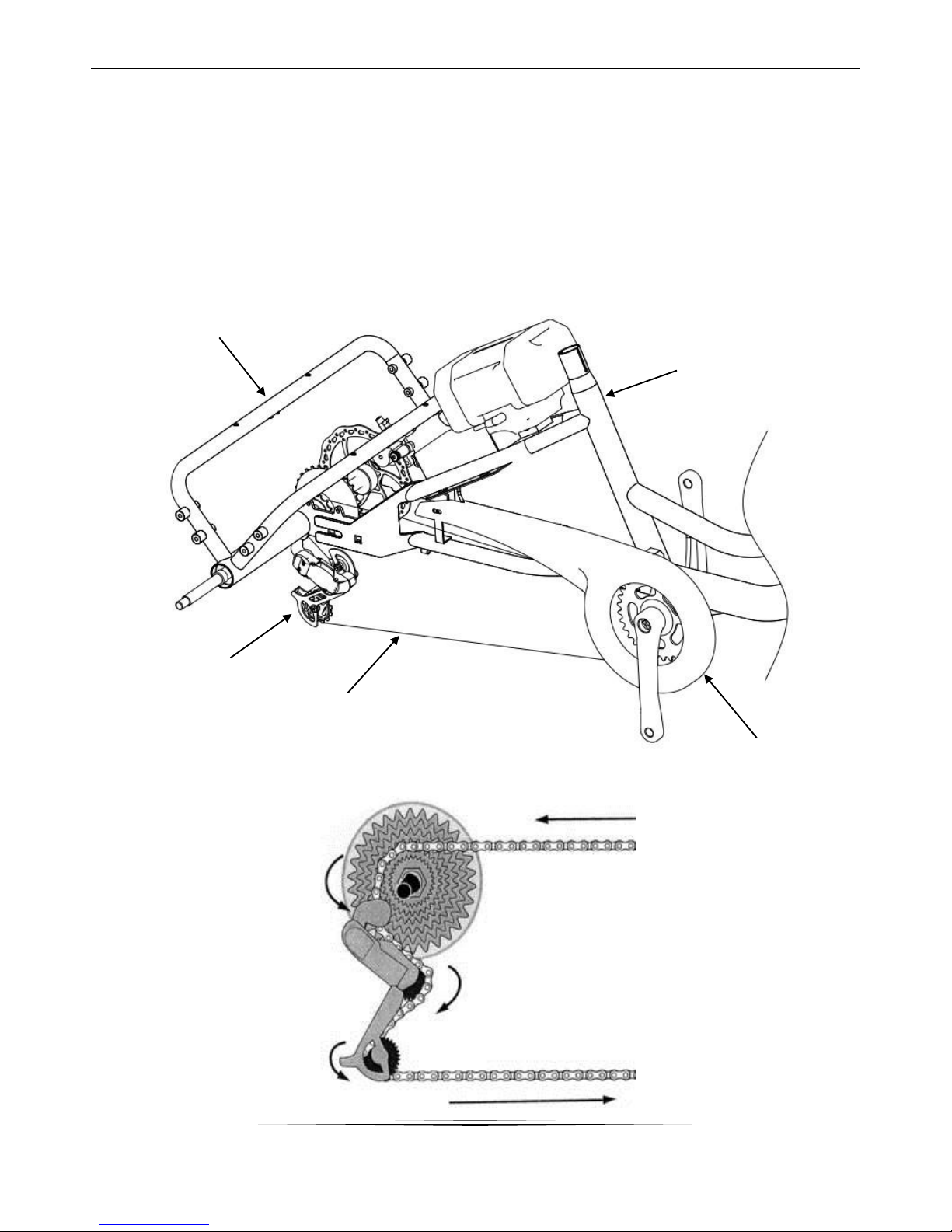

STEP 4: Chain and Chain Cover Assembly

a) Refer to Fig. 7 and Fig. 8: Assemble the chain (Gear adjustment see Attachment 1 and 2) and

secure the chain cover to frame with screws

b) A chain breaking tool will be required to re-rivet the chain once fed through the gear system (no

joining link in this chain)

Derailleur

Chain

Rear frame

Front Frame

Chain cover

Figure 7

Figure 8

12

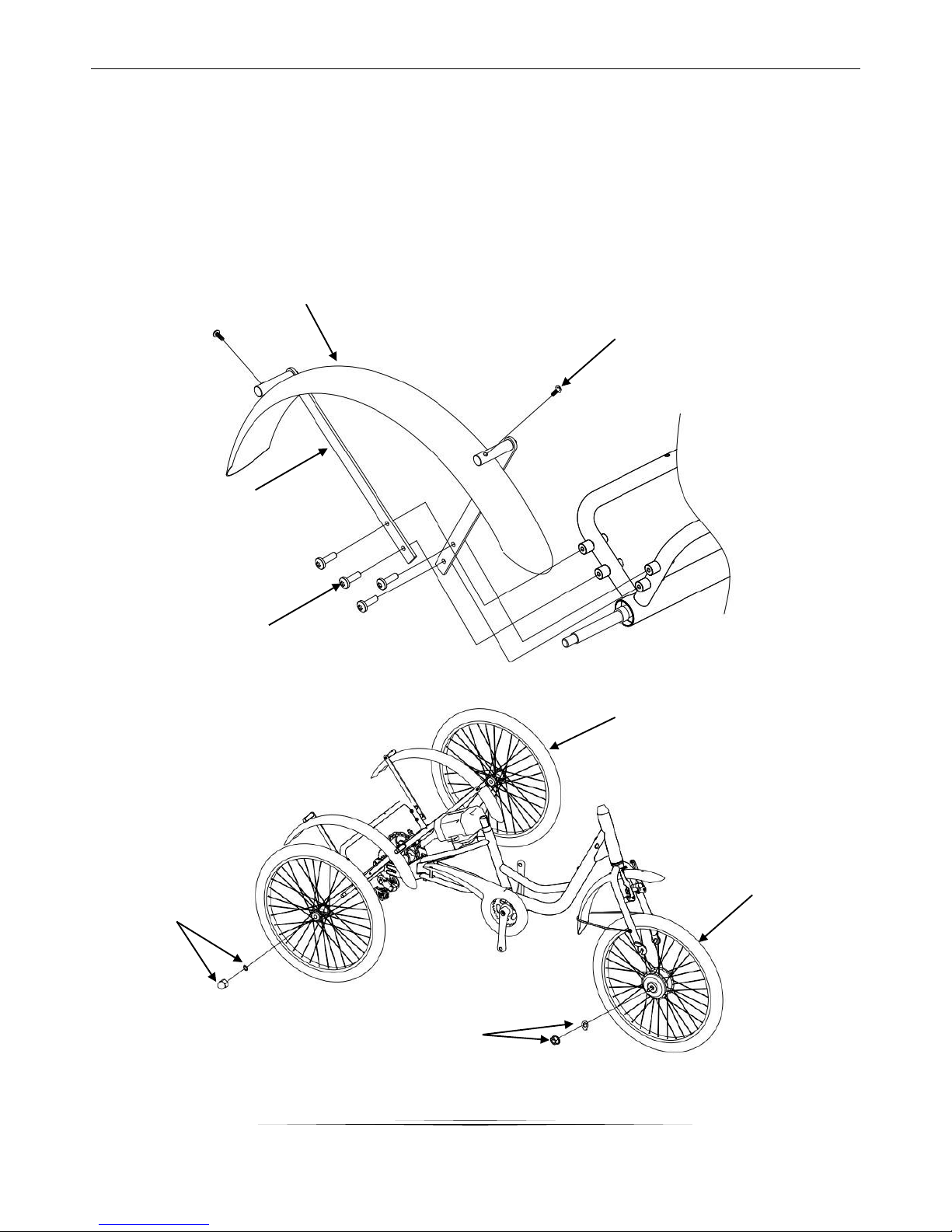

STEP 5: Fender and Front Chain and Chain Cover Assembly

a) Refer to Fig. 9: Secure the front and rear fenders to the correct position on frame with screws.

(Assembly of fender is optional)

b) Refer to Fig. 10: Attach the front and rear wheelset with nuts and washers. (Note: Cable of the front

wheel motor should be on left side)

Figure 9

Figure 10

Rear fender

Screw for fixing

attaching fender

Screw for fender stay

Fender stay

Rear wheelset

Front wheelset

with motor

Locking nut

and washer

Cap nut and

washer

13

Handlebar stem

Gear Cable

Brake cable

Brake lever

Handlebar

Figure 11

STEP 6: Handlebar and brake cable adjustment

a) Refer to Fig. 11: Insert the handlebar stem

into head tube of front frame

b) Adjust head stem height and tighten step

bolt.

c) Adjust the handle bar angle and secure into

place.

d) Adjust the front and rear brake cables to

ensure brake cables are fitted correctly.

(For gear adjustment see attachment 1 and

2).

STEP 7: Basket Assembly

e) Refer to Fig. 12: Attach the basket to the

rear frame with:

- Basket layer

- Screw

- Nuts

Figure 12

Screw & nut

Basket Layer

Basket

Stem bolt

14

STEP 8: Fender and Front Chain and Chain Cover Assembly

a) Attach saddle to seat post clamp and tighten slightly.

b) Insert the seat post into the seat tube and tighten bolts (Note: Safety line should be covered)

c) Adjust seat angle and retighten seat clamp

Figure 12

Saddle

Seat Post

Seat Post

Clamp

Seat Tube

15

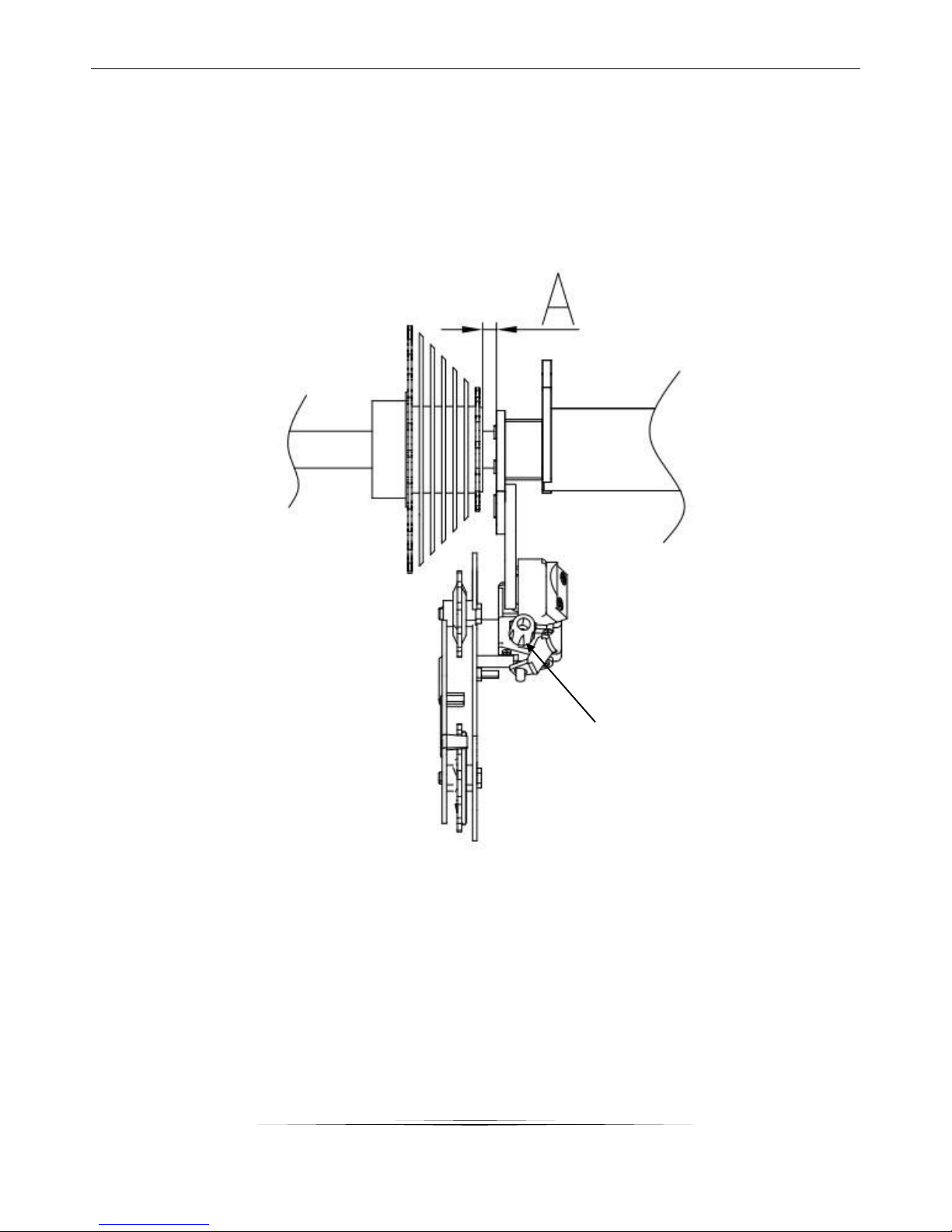

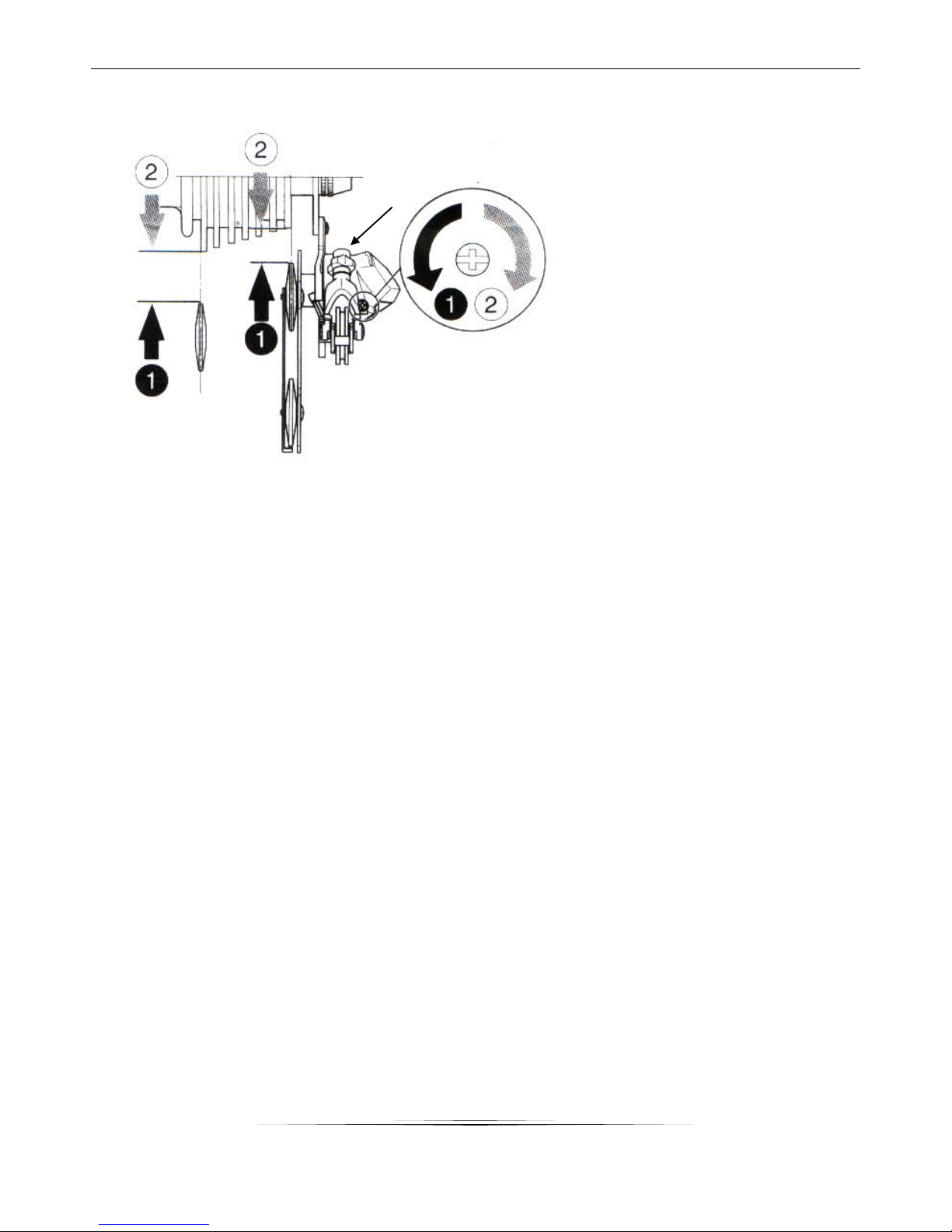

Attachment 1

Refer to Fig. 13: Adjust the position of freewheel to make sure the distance between gear freewheel and

derailleur is equal to 5~6mm.

Feed the inner gear cable through the derailleur ferral and secure with lock nut.

Figure 13

Derailleur Ferral

16

Attachment 2

Figure 14

4

Cable Tension: 5 – 7 N.M

Pull

Figure 15

Refer to Fig.15:

a) Turn the top (marked H) adjustment screw to so that the guide roller is below the outer line of the

smallest sprocket when looking from the rear.

b) Turn the low (marked L) adjustment screw so that the guide pulley moves to a position directly

below the largest sprocket. Ensure it does not over shift.

Note: these screws are stop screws only so the derailleur does not over shift.

Adjust the screw

towards below

Guide Roller

17

Figure 16

Refer to Fig. 16:

Adjust the tightness of inner cable to

ensure the derailleur shifts smoothly.

If the cable is too loose:

The derailleur will not upshift to the

larger sprockets

If the cable is too tight:

The derailleur will not downshift to

the smaller sprockets

18

5. COMPONENTS

Disc-Brake Adjustment

The city bike uses the Australian style of the brake system. The right brake lever is for the front wheels while

the left for rear wheel.

Important:

Brake pad wear limit: replace the brake pads before the friction material has been worn down to less than

2.5 mm.

1. Open the brake lever and place the nipple end of the short brake cable into the lever, then close the lever.

Secure the ferrule against the lever using the cable adjusting barrel.

2. Depress the brake lever about 10 times as far as the grip to check that everything is operating correctly

and that the shoe clearance is correct before riding the bike.

19

Tires

Bicycle tires are available in many designs and specifications, ranging from general-purpose designs to tires

designed to perform best under very specific weather or terrain conditions. If, once you’ve gained

experience with your new bike, you feel that a different tire might better suit your riding needs, your

dealer can help you select the most appropriate design.

The size, pressure rating, and on some high-performance tires the specific recommended use, are marked

on the sidewall of the tire .The part of this information which is most important to you is Tire Pressure.

WARNING: Never inflate a tire beyond the maximum pressure marked on the tire’s sidewall. Exceeding

the recommended maximum pressure may blow the tire off the rim, which could cause damage to the

bike and injury to the rider and bystanders.

The best and safest way to inflate a bicycle tire to the correct pressure is with a bicycle pump which has a

built-in pressure gauge.

Tire pressure is given either as maximum pressure or as a pressure range. How a tire performs under

different terrain or weather conditions depends largely on tire pressure. Inflating the tire to near its

maximum recommended pressure gives the lowest rolling resistance; but also produces the harshest ride.

High pressures work best on smooth, dry pavement. Very low pressures, at the bottom of the

recommended pressure range, give the best performance on smooth, slick terrain such as hard-packed

clay, and on deep, loose surfaces such as deep, dry sand.

Tire pressure that is too low for your weight and the riding conditions can cause a puncture of the tube by

allowing the tire to deform sufficiently to pinch the inner tube between the rim and the riding surface.

Tire Valves

The tire valve allows air to enter the tire’s inner tube under pressure, but doesn’t let it back out unless you

want it to. There are primarily two kinds of bicycle tube valves used in Australia: the Schraeder Valve and

the Presta Valve. The bicycle pump you use must have the fitting appropriate to the valve stems on your

tire.

The tires use a Schraeder valve, which is like the valve on a car tire. To inflate a Schraeder valve tube,

remove the valve cap and push the air hose or pump fitting onto the end of the valve stem. To let air out of

a Schraeder valve, depress the pin in the end of the valve stem with the end of a key or other appropriate

object.

1. Check whether rim is deflected or loosened and whether spoke is loosened or broken before riding. If any

unusual condition, ask professional technician for adjustment or change.

2. Please change the tyre if cover tyre grain is worn and torn.

3. Please guarantee proper PSI. When inflating, please take nominal value of cover tyre as reference. Never

inflate over the pressure or under the pressure.

Caution: Please make sure the contact area of tyre and ground should not be less than 10cm while riding.

20

Change of Pedals

Left pedal and right pedal should be clarified when changing. Pedal spindle is usually engraved with “R” and

“L”.

Tool: 15mm open end wrench

When changing Right side, clockwise rotation is to lock and anticlockwise rotation is to disassemble.

When changing Left side, clockwise rotation is to disassemble and anticlockwise rotation is to lock.

Tightening torque should be more than 18N.m

Table of contents

Other ProGear Bicycle manuals