2

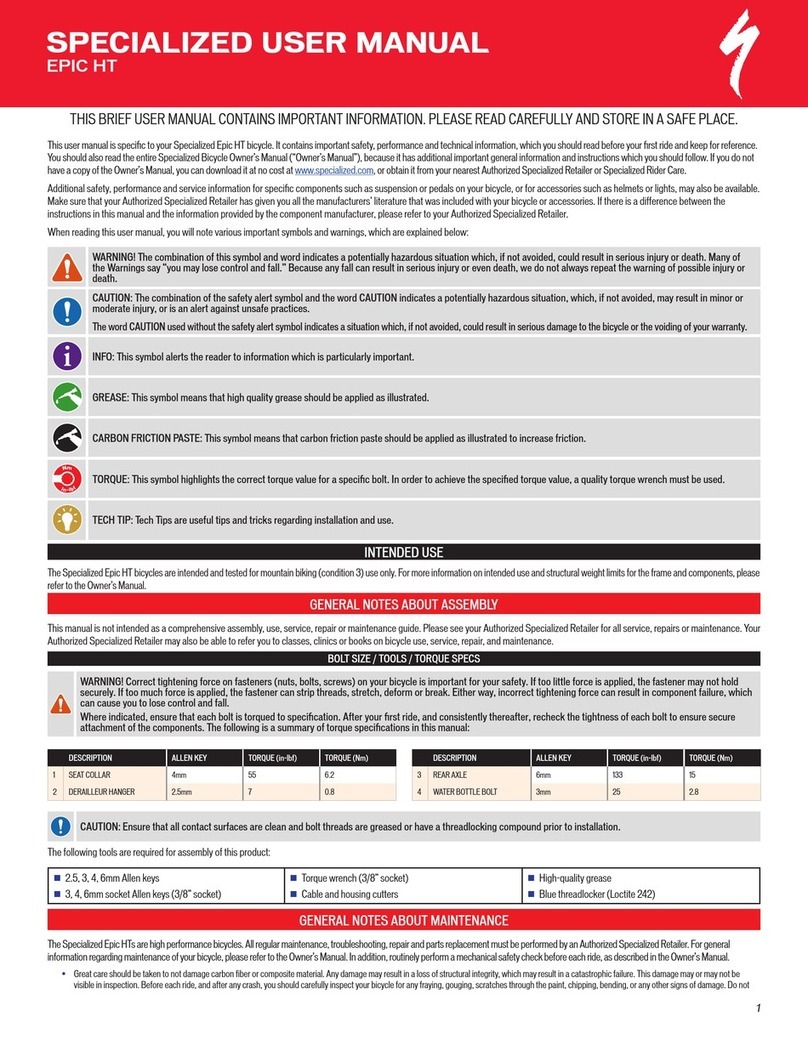

2. GENERAL NOTES ABOUT ASSEMBLY

This manual is not intended as a comprehensive assembly, use, service, repair or maintenance

guide. Please see your Authorized Specialized Retailer for all service, repairs or maintenance.

Your Authorized Specialized Retailer may also be able to refer you to classes, clinics or books

on bicycle use, service, repair, and maintenance.

Tire sizes vary significantly from brand to brand. CEN standards require a minimum of 6mm

of clearance between the frame/fork and the tires. When choosing a wheel and tire combo,

factor in enough clearance for the conditions, setup and wheel flex.

The Aethos frames use a 68mm standard BSA threaded design. Grease the threads. Install

and torque according to the bottom bracket manufacturer’s instructions.

Before installing the bottom bracket and crank, make sure all housings and wires are

routed through the frame.

The Aethos frame is available in two frame configurations, 12R (S-Works

models) and 10R (all other models).

The 12R frames are compatible with electronic shifting systems only. A custom

backing plate is required to mount the front derailleur hanger. Information

specific to 12R frames is covered in section 5.1 (highlighted in BLUE).

The 10R frames are compatible with electronic or mechanical shifting

systems. Information specific to mechanical shifting system installation is

covered in section 5.3 (highlighted in ORANGE).

WARNING! Never modify your frame or components in any way. Do not sand,

drill, file, or remove parts. Do not install incompatible forks or components.

An improperly modified frame, fork, or component, can cause you to lose

control and fall.

In order to successfully build the Aethos bicycle, it is very important to follow

the order of operations as outlined in this manual. Modifying the order of

assembly will result in a longer build process.

Assembly of the front end of the bicycle is easiest with the rider’s fit already

determined (the steerer tube doesn’t need to be cut at this time, it can stick

out the top of the stem), prior to routing all the housings and wires through the

frame and fork.

To determine fit, it is recommended to use a fit tool. If this is not possible,

perform a basic assembly of the wheels, drivetrain and front end components,

without the brakes and housings. Once the fit is complete, all the components

will have to be removed in order to route the housings and wires.

WARNING! Due to the high degree of complexity of the Aethos, proper assembly

requires a high degree of mechanical expertise, skill, training and specialty tools.

Therefore, it is essential that the assembly, maintenance and troubleshooting be

performed by an Authorized Specialized Retailer.

WARNING! Many components on the Aethos, including, but not limited to, the

handlebars and the stem, are proprietary to the Aethos. Only use originally

supplied components and hardware at all times. Use of other components or

hardware will compromise the integrity and strength of the assembly. Aethos

specific components should only be used on the Aethos and not on other

bicycles, even if they fit. Failure to follow this warning could result in serious

injury or death.

CAUTION: Do not face the bottom bracket shell! This can prevent proper

installation of the crank. Your Specialized frame does not require any bottom

bracket shell pre-installation preparation, as all surfaces have been precisely

machined to specific tolerances at the factory for proper interface with a

compatible crankset. Please refer to the manufacturer instructions for crank

and bottom bracket installation.

CAUTION: Always use a bottom bracket equipped with a sleeve between the

two cups. Running a bottom bracket without the sleeve can result in housings

and/or wires contacting the bottom bracket spindle, which can result in wear.