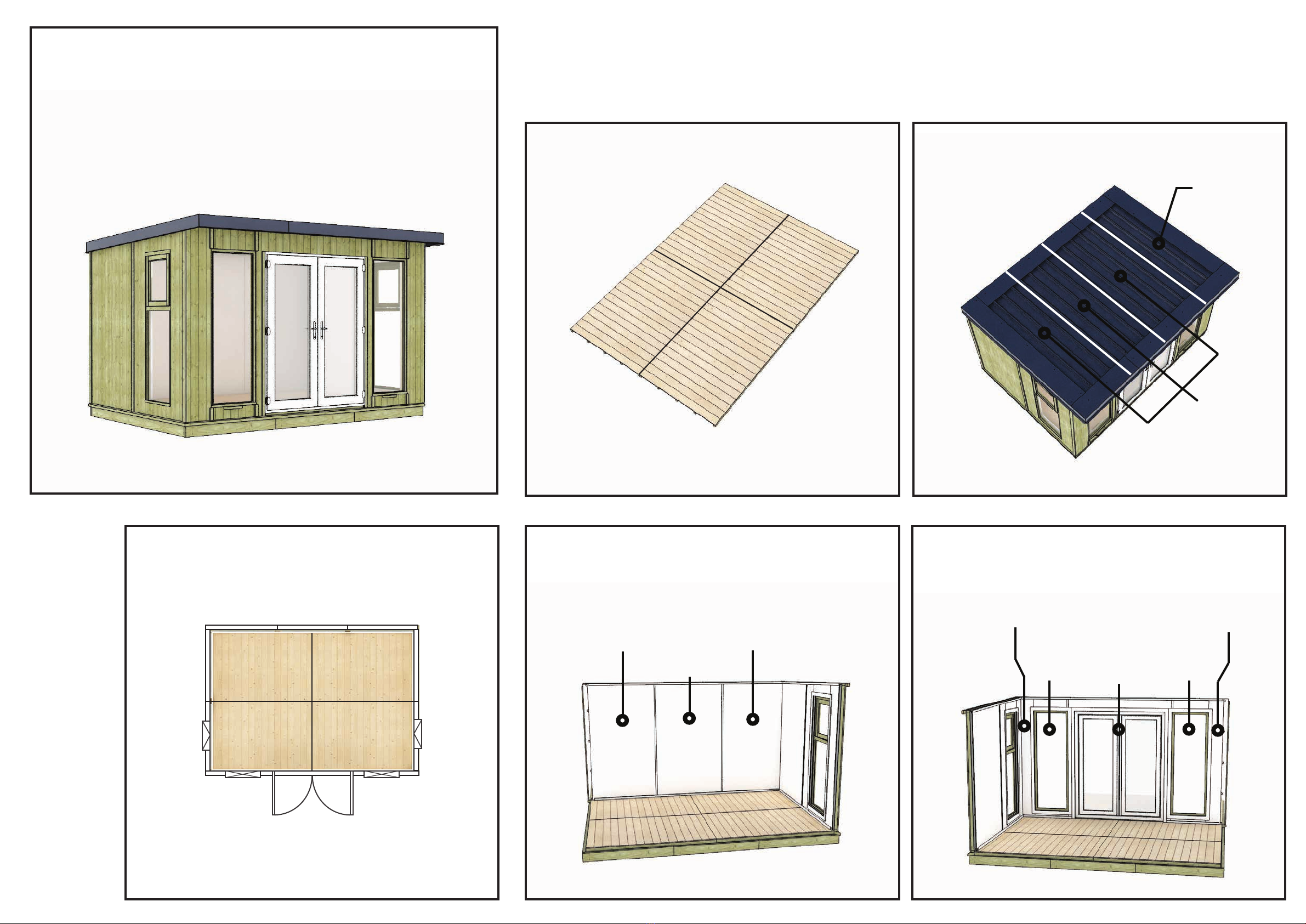

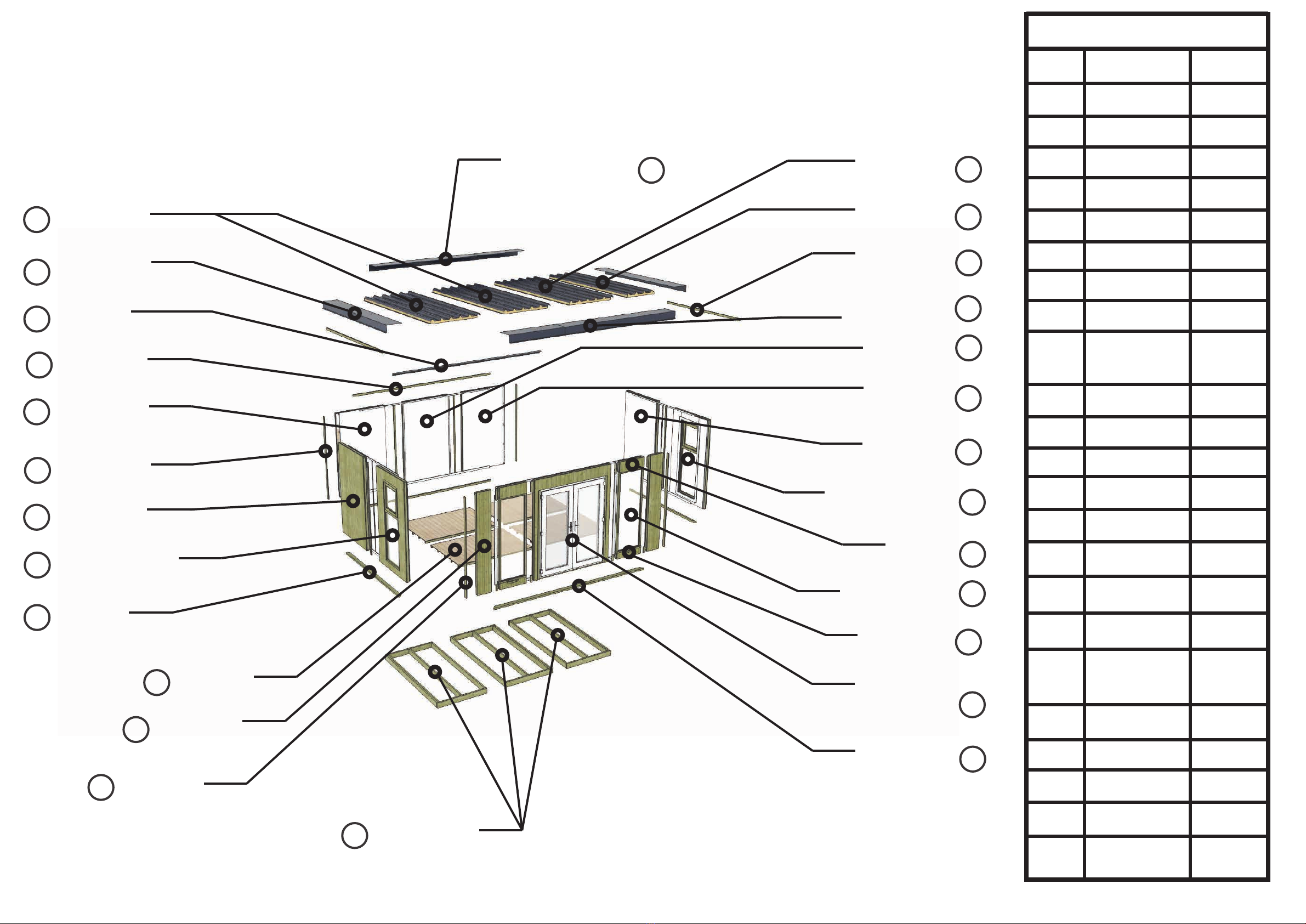

Project Timber Evolution My Den 12x8 Instruction Manual

Other Project Timber Garden House manuals

Project Timber

Project Timber Corner Shed Windowless Instruction Manual

Project Timber

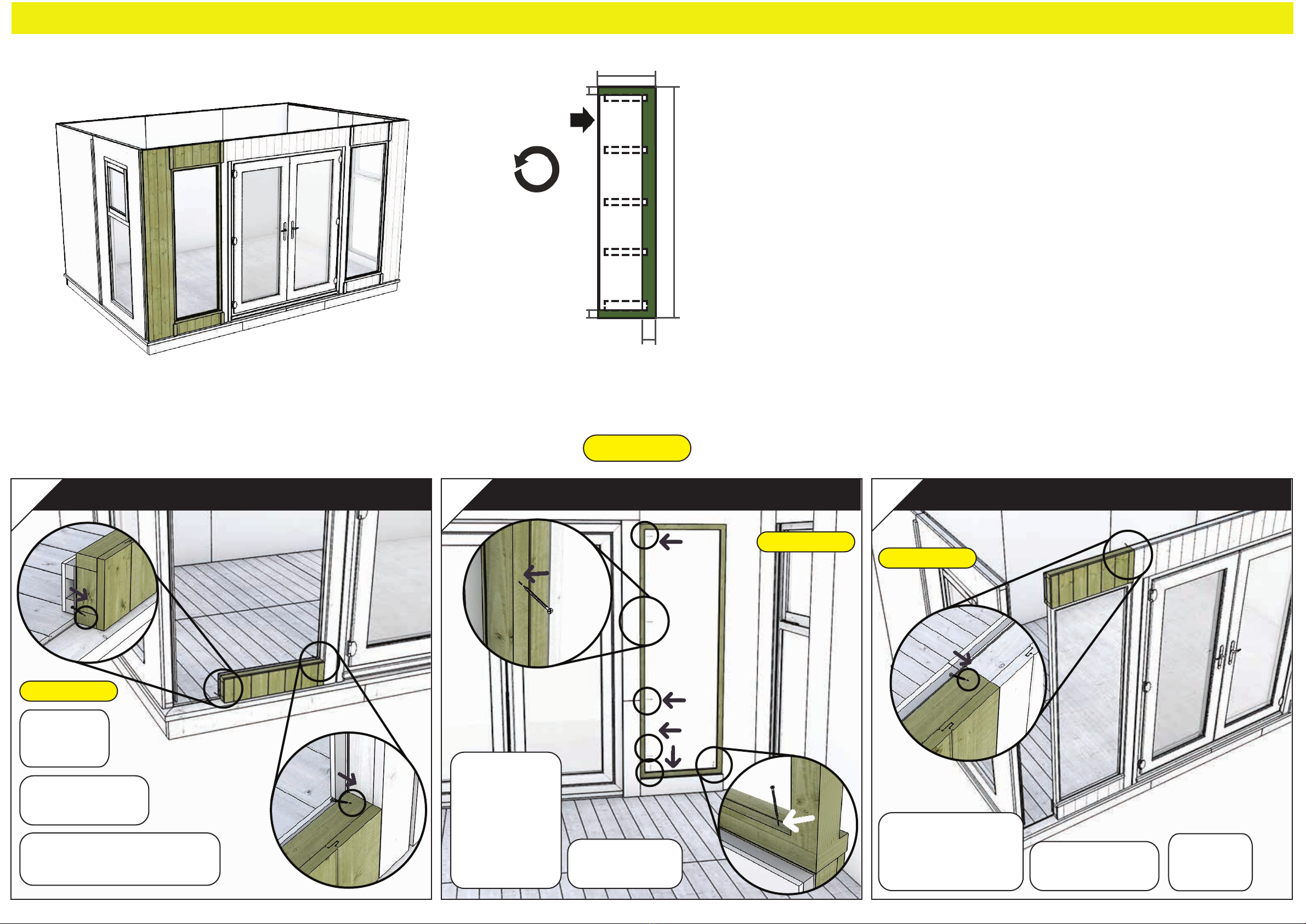

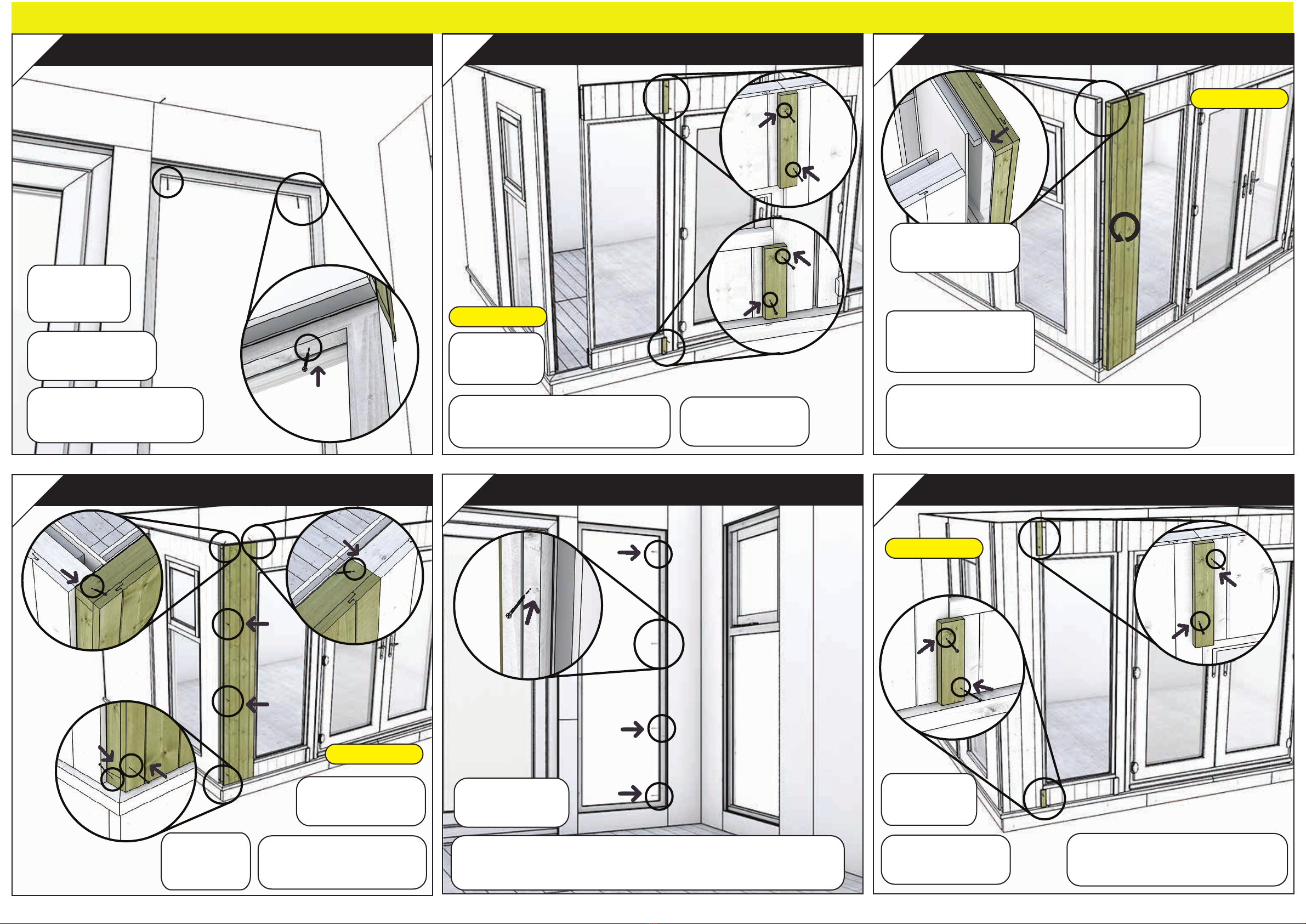

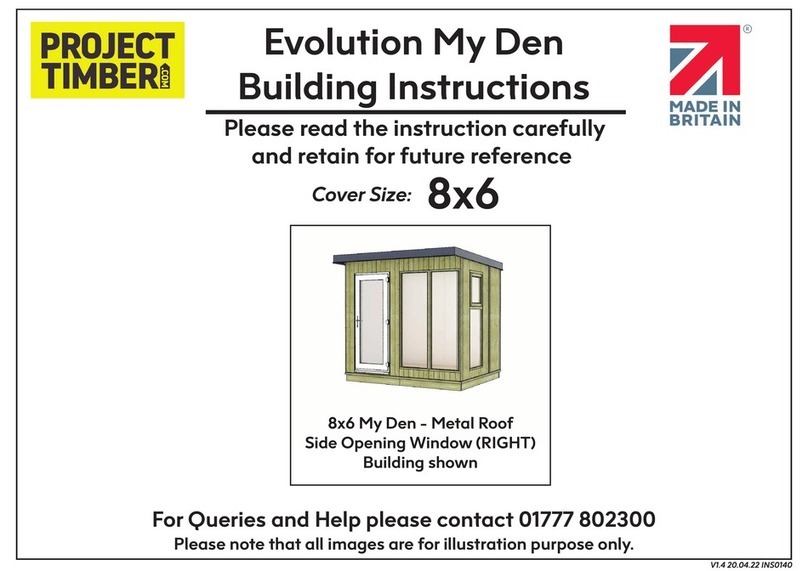

Project Timber Evolution My Den 8x6 Instruction Manual

Project Timber

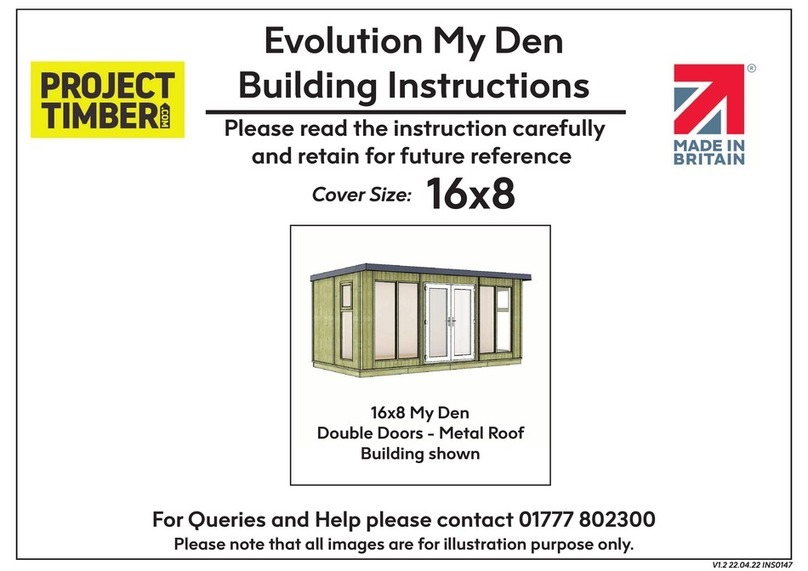

Project Timber Evolution My Den 16x8 Instruction Manual

Project Timber

Project Timber Cannes Summerhouse Instruction Manual

Project Timber

Project Timber 20x6 Hobbyist Windowed Pent Shed Instruction Manual

Project Timber

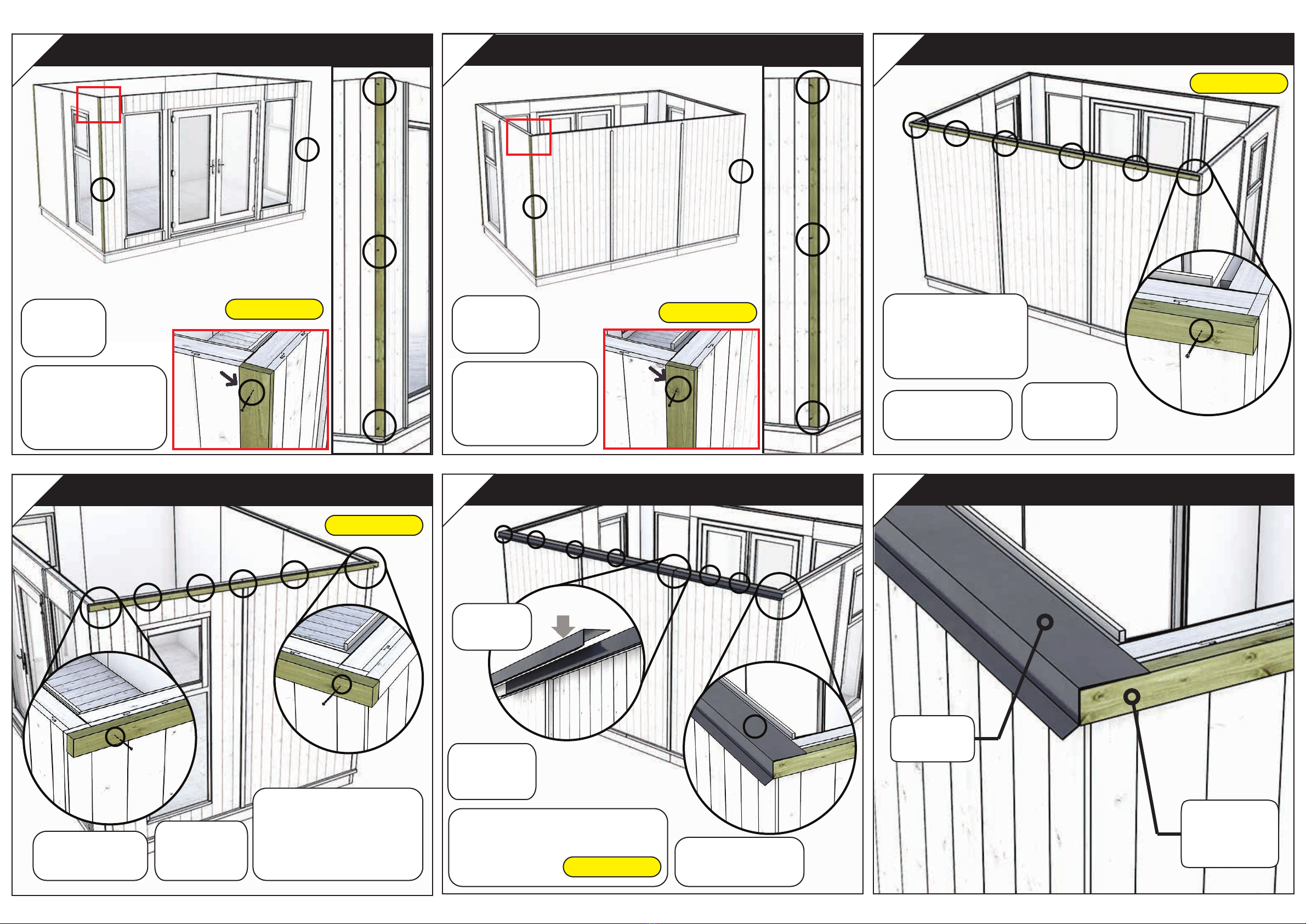

Project Timber My Den Metal Roof Instruction Manual

Project Timber

Project Timber Cannes Summerhouse 12x6 Instruction Manual

Project Timber

Project Timber Corner Shed Instruction Manual

Project Timber

Project Timber Evolution My Den Instruction Manual

Project Timber

Project Timber Evolution My Den Instruction Manual

Popular Garden House manuals by other brands

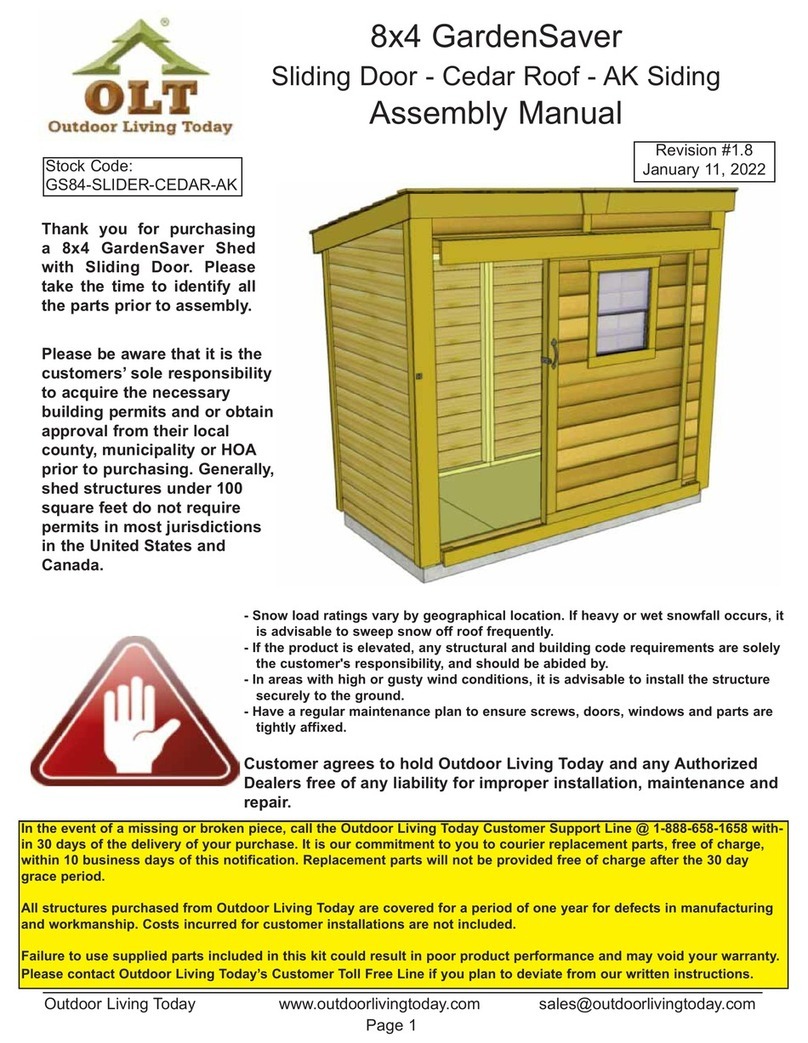

OLT

OLT SunShed Garden Shed SSGS1212-AK-METAL Assembly manual

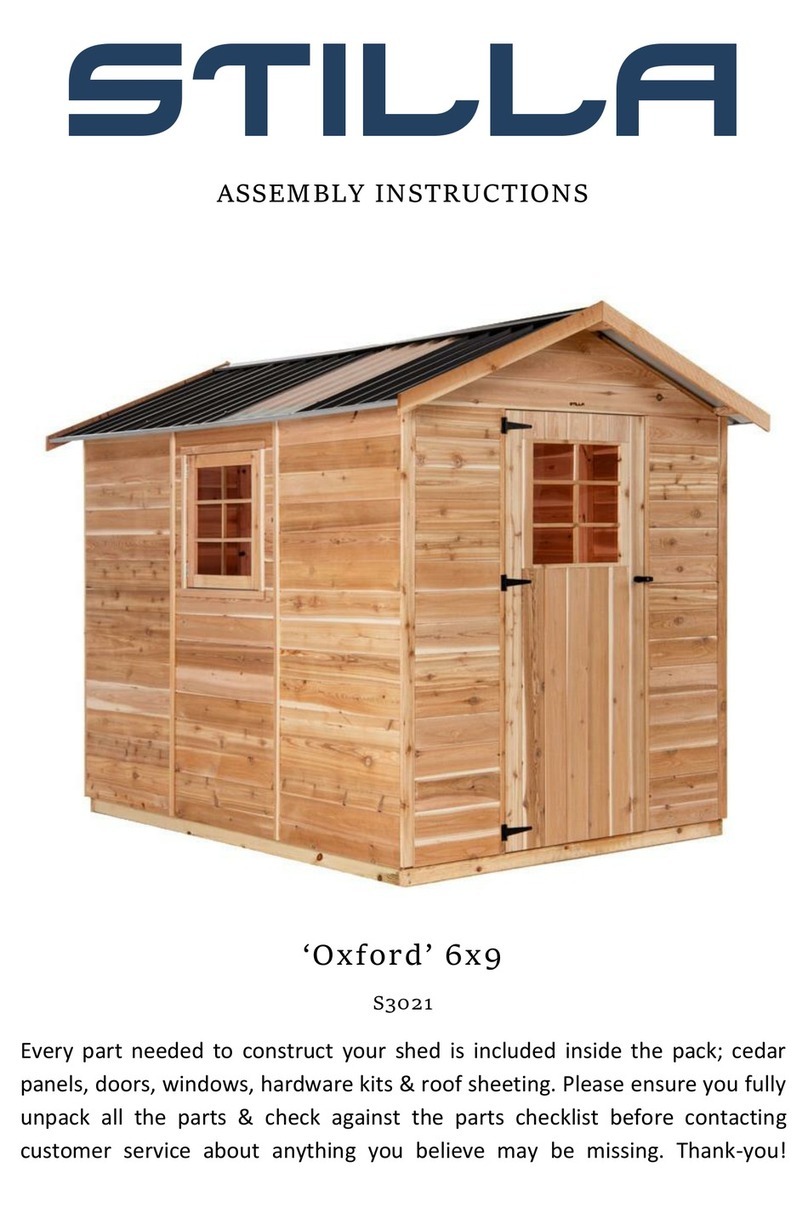

STILLA

STILLA Oxford 6x9 S3021 Assembly instructions

Reynolds Building Systems

Reynolds Building Systems West Virginia 16'x32' Assembly Book

GARDIVAL

GARDIVAL VERSAILLES 250 manual

Luoman

Luoman LILLEVILLA Tyrni Assembly and Maintenance

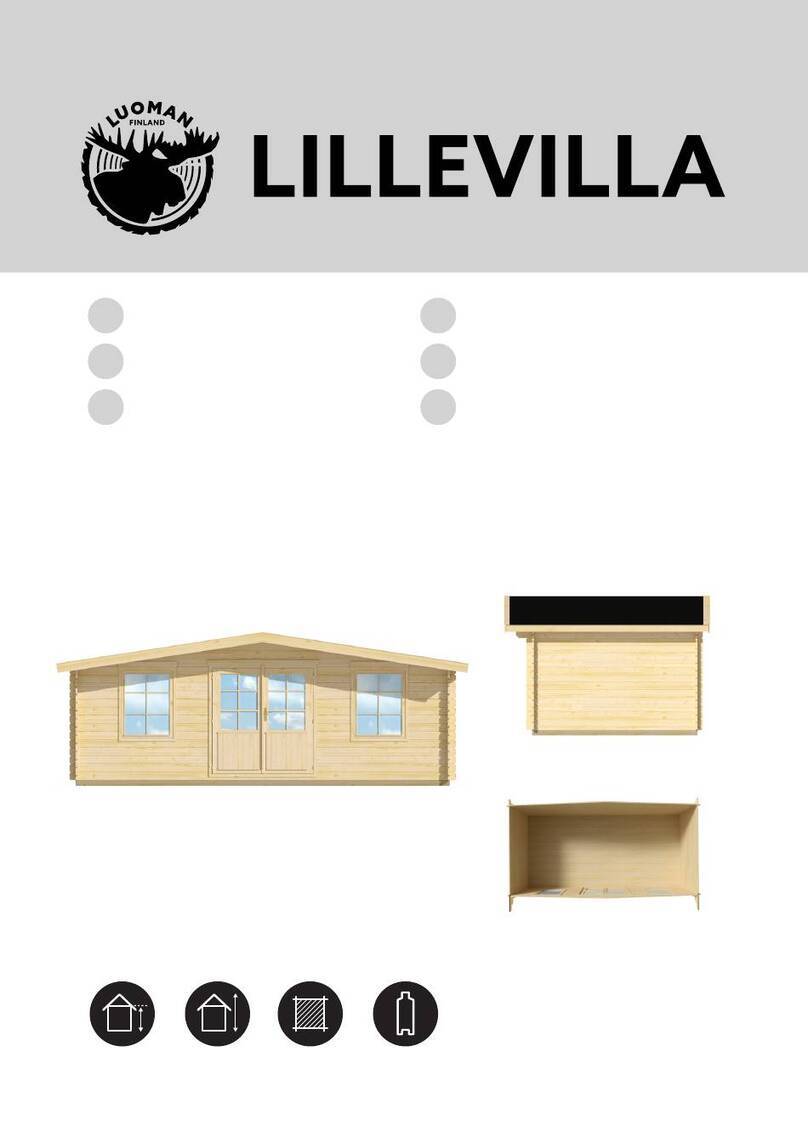

Luoman

Luoman Lillevilla 321 Assembly and Maintenance