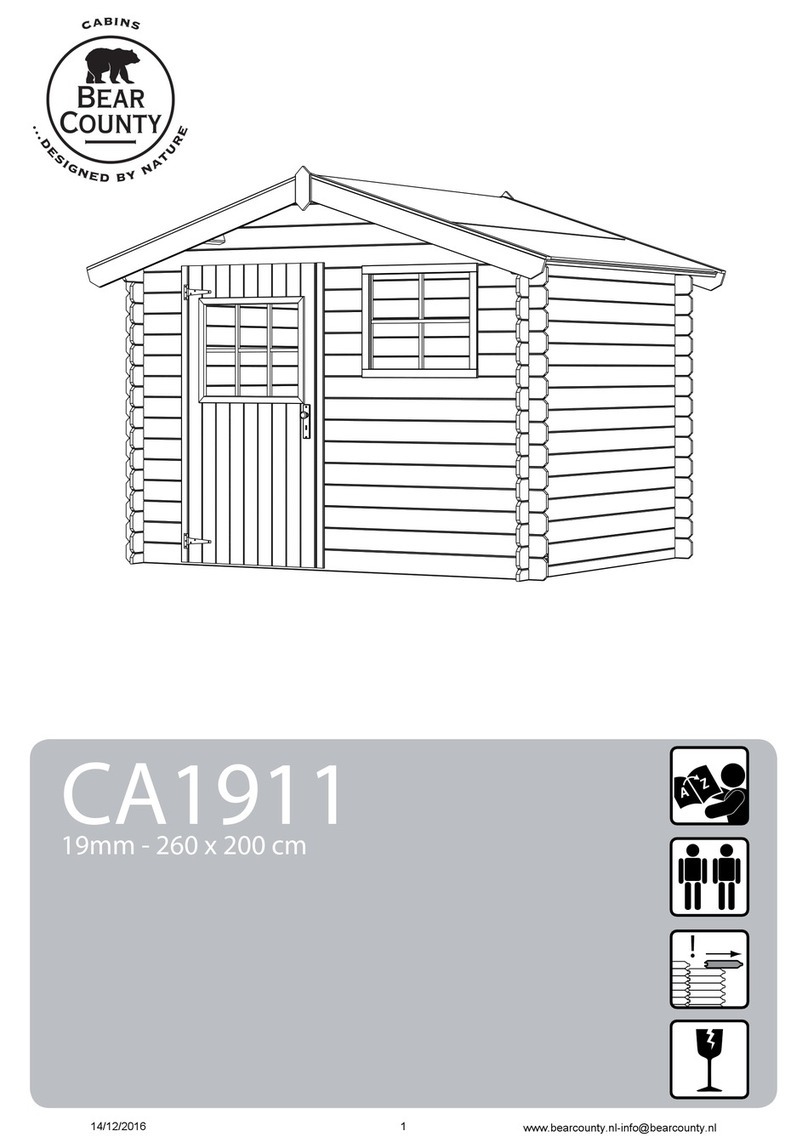

Project Timber Evolution My Den Instruction Manual

Other manuals for Evolution My Den

1

Other Project Timber Garden House manuals

Project Timber

Project Timber Corner Shed Instruction Manual

Project Timber

Project Timber 20x6 Hobbyist Windowed Pent Shed Instruction Manual

Project Timber

Project Timber Hobbyist Instruction Manual

Project Timber

Project Timber Cannes Summerhouse Instruction Manual

Project Timber

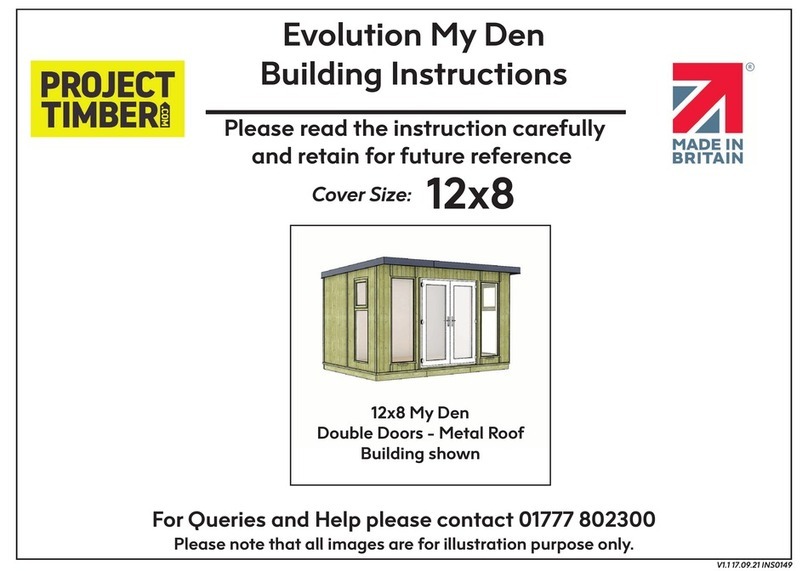

Project Timber Evolution My Den 12x8 Instruction Manual

Project Timber

Project Timber Evolution My Den Instruction Manual

Project Timber

Project Timber My Den Metal Roof Instruction Manual

Project Timber

Project Timber Cannes Summerhouse 12x6 Instruction Manual

Project Timber

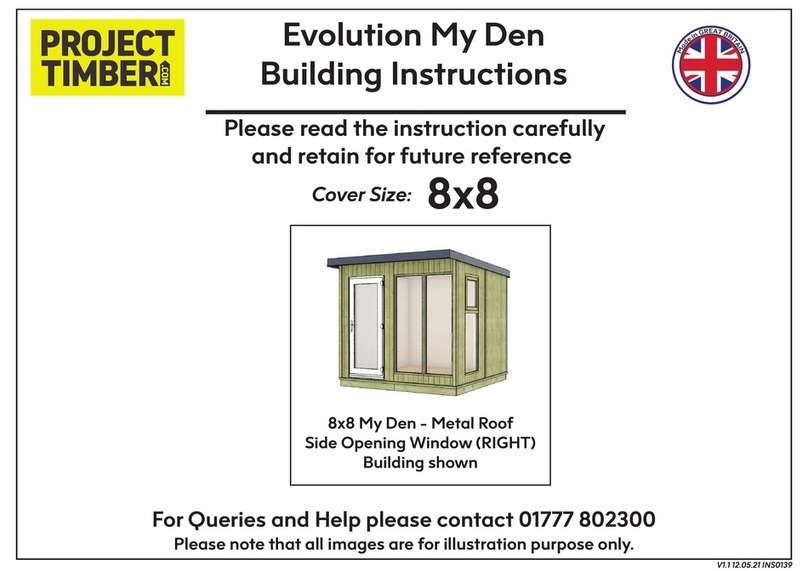

Project Timber Evolution My Den 8x6 Instruction Manual

Project Timber

Project Timber Evolution My Den 16x8 Instruction Manual

Popular Garden House manuals by other brands

Palmako

Palmako Veronica 4 installation manual

Palmako

Palmako FR34-3832-4 installation manual

OLT

OLT Studio Garden Shed STU128-FJ-Metal Assembly manual

Sunjoy

Sunjoy A102014100 Assembly instruction

Lemeks

Lemeks Palmako FR44-5123 Assembly, installation and maintenance manual

Palmako

Palmako FR28-7030-1 Assembly, installation and maintenance manual