Proma A-5120 Operating instructions

Installation & Owners Manual

Proma Dental Light

!

120V 60HZ

1A

1 AMP FUSES

INPUT VOLTAGE:

CURRENT:

111153

P/N 93155

CONFORMS TO

UL STD 60601-1

CERTIFIED TO

CAN/CSA STD C22.2 No. 601.1

WARNING:

REPLACE FUSE AS MARKED

RISK OF FIRE - CLASS 1

S/N PLT A5000001

A-5120 Ceiling Mounted Light

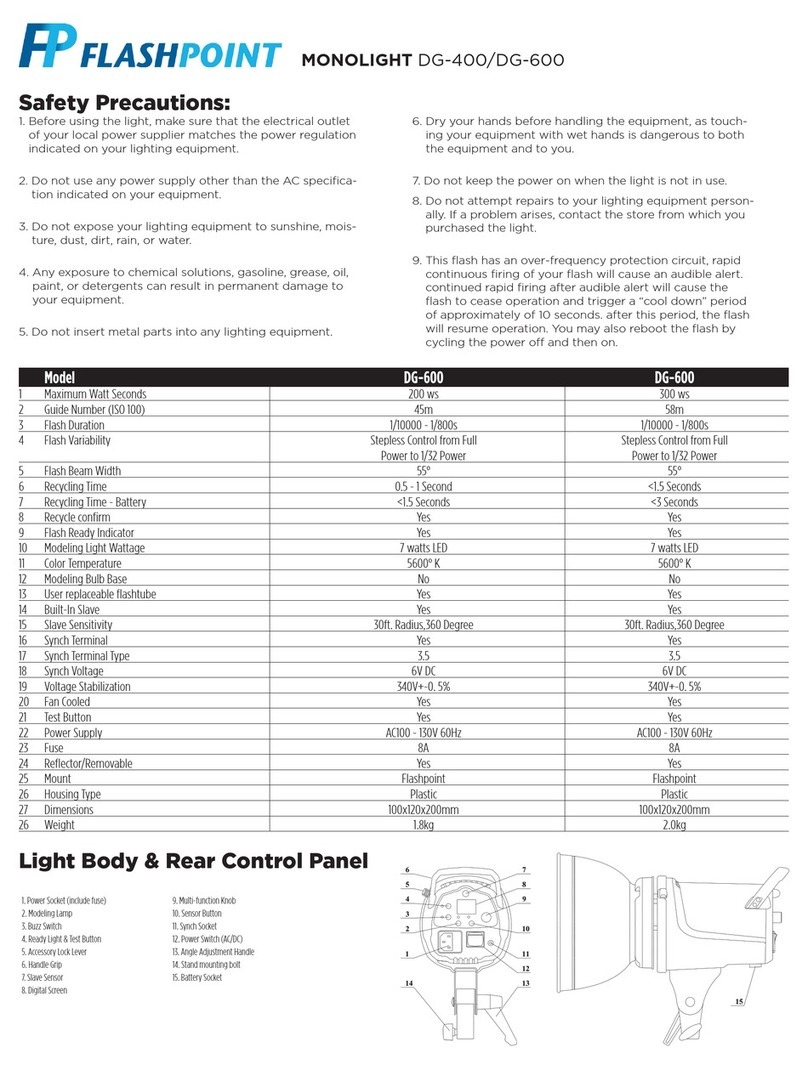

Specications...................................... 2

Operating Conditions.......................... 2

Storage & Shipping Conditions........... 2

Classications..................................... 2

Technical Support................................2

Installation Overview........................... 2

Pre-Installation Notes..........................2

Recommended Service Tools

Electrical Connections and Supply

Cautions on Installation and Use

Installation........................................... 3

Cleaning Instructions...........................4

Wiring Diagram & Warranty................. 4

Flex Arm Counterbalance

Adjustment.......................................... 5

On / Off Switch Lever

Installation........................................... 5

Drill Template.......................................6

Table of Content Serial Numbers

Please locate and write down the Serial

Numbers on the A-5120 Dental Light

and Transformer. Having this informa-

tion available will aid in the identication

of your dental light and transformer.

Dental Light Serial Number

Transformer Serial Number

The Proma label is located in two loca-

tions on the dental light system. The

dental light serial number is located on

the light arm and the Transformer serial

number is located on top of the trans-

former housing

The serial number is located along the

left edge of the label

Bulb Replacement

Note: A replacement bulb is included.

Please locate it and store in a conve-

nient place. Order replacement Light

Bulb Proma #93146

WARNING!

Turn the light off and allow cooling be-

fore removing the shield. Failure to do

so can cause injury by burning. Always

handle bulbs with tissue paper, do not

allow skin to contact the bulb, as it will

shorten the life.

Remove the shield by gently squeezing

the ends and pull it toward you

Remove the bulb by wrapping in tissue

and gently pulling forward

The replacement bulb should be

pushed in gently. The lamp pins must

be securely in the lamp socket

Replace the shield by squeezing the

sides and gently pushing it into the

housing. You will hear a “Click” when

the shield seats properly.

WARNING!

Failure to properly seat the shield

could allow it to fall off and cause injury

Turn on the light and check the focus

by shinning the light on a surface 27”

away. The light pattern should be even

with dened edges over an area of 4”

x 6”. If necessary, rotate the focus

adjustment.

Focus Adjustment Screw

730 E. Kingshill Place • Carson, CA 90746

Phone 310.327.0035 • Fax 310.327.4601

Document 9050736 rev C 06/07

Compliance with Local Building

Codes is the Responsibility of the

Dealer and the Contractor

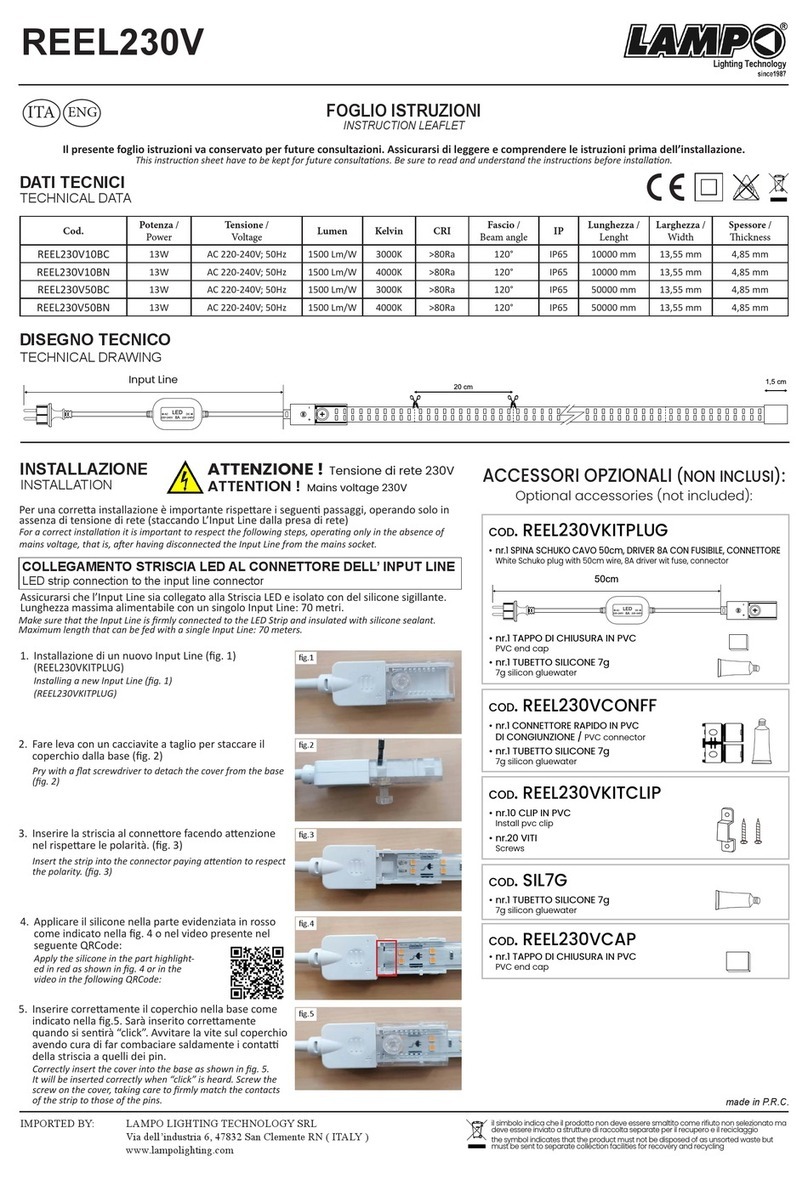

Specications

Electrical Input:

Voltage 120 V~

Phase 1

Frequency 60 Hz

Power 150 W

Electrical Output:

Voltage 13-19 V~

Current 3.4-5 Amps

Operating Conditions

Ambient

Temperature +10 C to +40 C

Humidity 30% to 75%

Atmospheric

Pressure Range 700 hPa to

1060 hPa

Storage & Shipping

Ambient

Temperature - 40 C to +70 C

Humidity 10 to 95 RH

(Non-condensing)

Atmospheric

Pressure Range 7 to 15 psi

(50 to 106 Kpa)

Classications

Classication

of Equipment Class I

Degree of Protec-

tion against harmful

ingress of water

Mode of Operation Intermittent

Ordinary

Technical Support

For Technical support and repair assis-

tance, contact your local Proma dealer

Check Product Contents

Immediately upon receipt, open the

box, examine for damage and com-

pare contents to the packing slip. If

not as ordered, please notify your

dealer. If hidden shipping damage

is identied, immediately contact the

shipping service. Contact Proma to

arrange for replacement goods.

Read all Cautions / Warnings on

Labels and in this Manual

Check the product for all caution and

warning labels and read them. Re-

view this manual for all cautions and

warnings prior to installation.

Check Installation Site and

Access

Before installation, check room di-

mensions, locate required tools and

establish clear access to the site.

SHUT OFF ELECTRICAL POWER

to the appropriate outlet.

Installation Overview

Prepare Electrical Connections

Conrm the electrical connections

to be used. Locate all switches and

circuit breakers involved.

Test and Adjust Product after

Installation

It is important to complete any instal-

lation by verifying all connections

and controls are functioning properly

before allowing the device to be used

for patient treatment.

Train Personnel on Operating

Equipment

Educate staff on the product’s proper

use, cleaning and disinfection. Identi-

fy parts that may require replacement

(i.e. lamps, lens covers and fuses).

1.

2.

3.

4.

5.

6.

Recommended

Service Tools

• Allen Wrench Set

• Bubble Level

• Tape Measure

• Phillips Screw Drivers

Electrical Connections

and Supply

Note: a licensed electrician must per-

form all wiring. Due to varying city elec-

trical codes, the dealer should ensure

installation will meet local requirements.

Proma cannot be responsible for an

installation that does not meet local

electrical codes. Installer must meet the

following additional requirements:

115 Volts AC (minimum) electrical

power

Use wiring with insulation rated for 90º

C minimum. Ensure all wiring is prop-

erly grounded. Protect circuit with circuit

breaker

CAUTION

Possible re hazard when used with

oxygen administering equipment other

than the nasal mask or length bed

tent type. Oxygen tent should not ex-

tend below mattress support level.

To ensure proper grounding, plug unit

into “Hospital Only” or “Hospital Grade”

outlet.

Transformer Cover to be removed by

Qualied Service Personnel Only

DANGER!

Risk of explosion if used in the pres-

ence of ammable anesthetics!

Risk of Fire. Replace fuse as marked

2

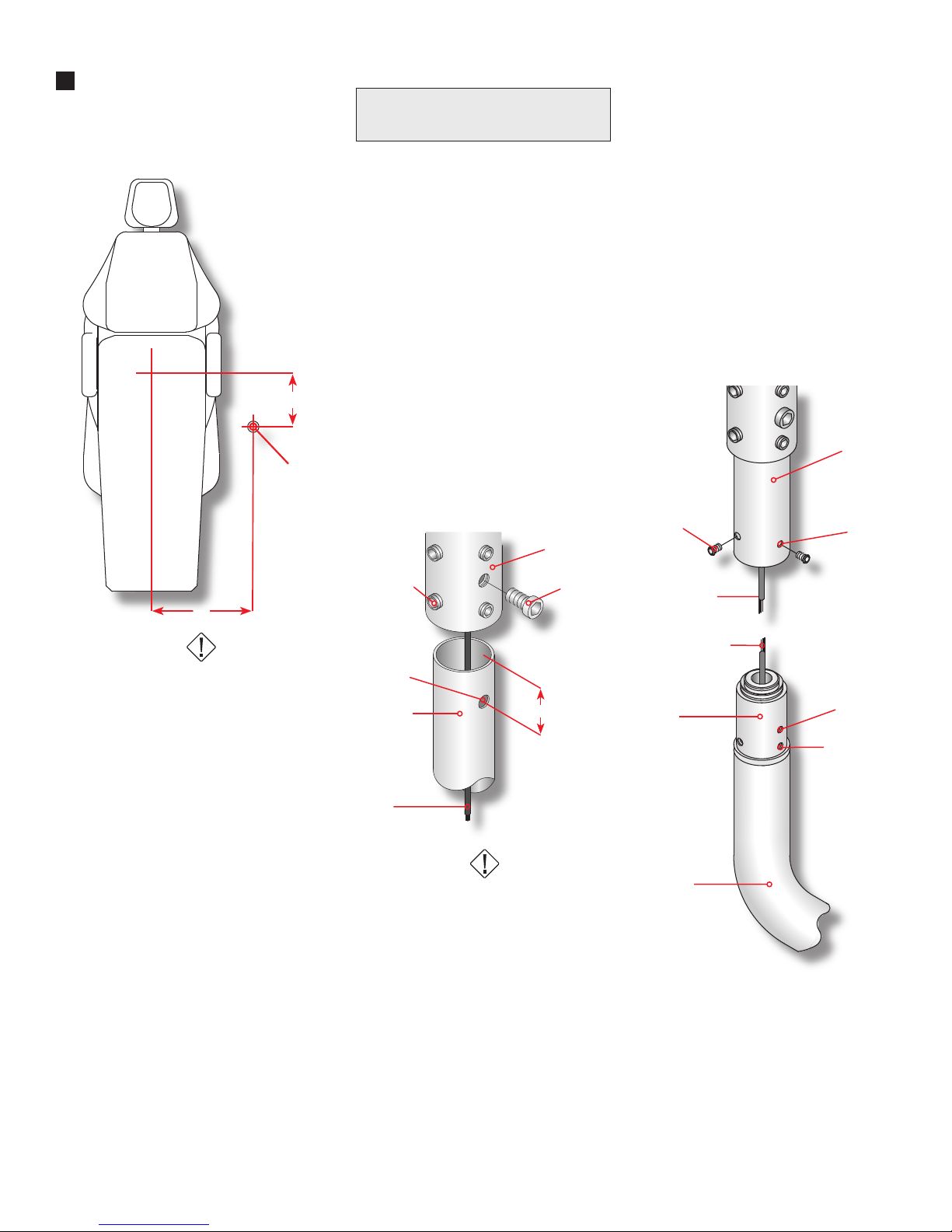

12”

18”

Drop Post

Support Hub

5/16” Bolt

5/16” - 18

Set Screw

Drop Post

Pigtail

11/32”

Diameter

1 5/8”

Figure 2

10-32 x 1/4”

Button Head

Drop Post

Clearance

Holes (3)

Pigtail - Low

Voltage Cable

Spade Terminals

Swivel

Rigid Arm

Figure 3

Rotation

Stop Screw

Tapped Holes

(3)

3

Figure 1

Installation Notes

1.

2.

3.

4.

5.

6.

7.

Follow recommended dimensions

on Figure 1 to determine the position

for the support plate.

HAZARD

Check ceiling structure and deter-

mine that it will support a minimum

of 200 pounds. Failure to fasten ceil-

ing securely to a structurally sound

and appropriately designed structure

could result in a hazard of potential

injury to patient or users caused by

the light falling.

Note: It is the responsibility of a

licensed mechanical structural engi-

neer to verify that each site is safe to

mount such device.

Using drill template provided on

page 6, mark mounting hole centers.

Mount the support plate to ceiling

using three (3) 3/8” diameter lag

screws.

Note: The ceiling light is designed to

accommodate up to 11’ ceiling. The

drop post is pre-cut to suit your ceil-

ing height.

Ceiling Height 8’ 9’ 10’ 11’

Drop Post Length 9” 21” 33” 45”

Proma discourages the use of

ceiling exceeding 11 foot heights.

Proma suggests the use of a cabinet

mounted or wall mounted light.

Note: The drop post has an 11/32”

(.343) diameter hole on the center-

line, 1-5/8” inches from one end.

This is a clearance hole for the 5/16”

bolt that secures the post to the sup-

port hub.

Route the pigtail from the transform-

er through the drop post containing

the 11/32” diameter hole. Next, insert

the post into the support hub.

Note: Align the hole on the drop post

with the 5/16” socket cap bolt. Tight-

en the 5/16” bolt and let the drop

post rest on the bolt. See Figure 2

HAZARD

Failure to install the 5/16” bolt as de-

scribed may allow the light to fall and

could result in personal injuries.

Tighten the eight (8) 5/16” – 18 set

screws on support hub. Assure that

post is level front to back and side

to side.

Slide the ceiling cover and collar

onto the drop post. Once cover is

on post and resting on the ceiling,

tighten two (2) set screws on collar.

Connect the terminals from the rigid

arm to the pigtail terminals from the

low voltage cable being careful to

match the colors.

Insert the swivel (part of the rigid

arm) into the drop post. With the

rotation stop set screw, located in

the swivel, towards the foot of the

chair, align the three (3) holes on the

drop post with three tapped holes on

the swivel and secure with the three

(3) 10-32 x 1/4” button head screws

provided. See Figure 3.

Test Light

Turn the light switch located immedi-

ately behind the light head. This is a

three position switch. Center is Off,

Left is the normal operating intensity

and Right is maximum intensity for

color matching.

8.

Cleaning Instructions

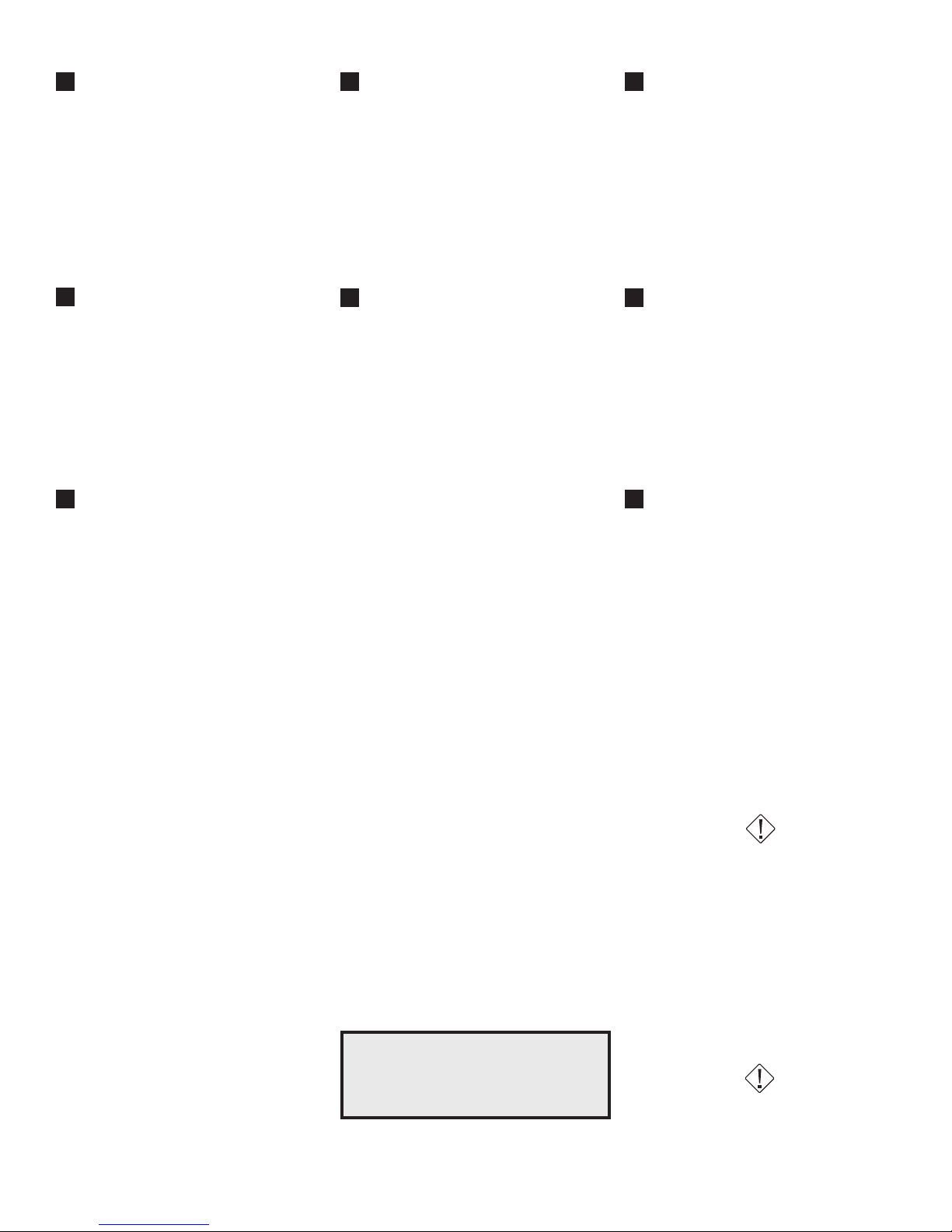

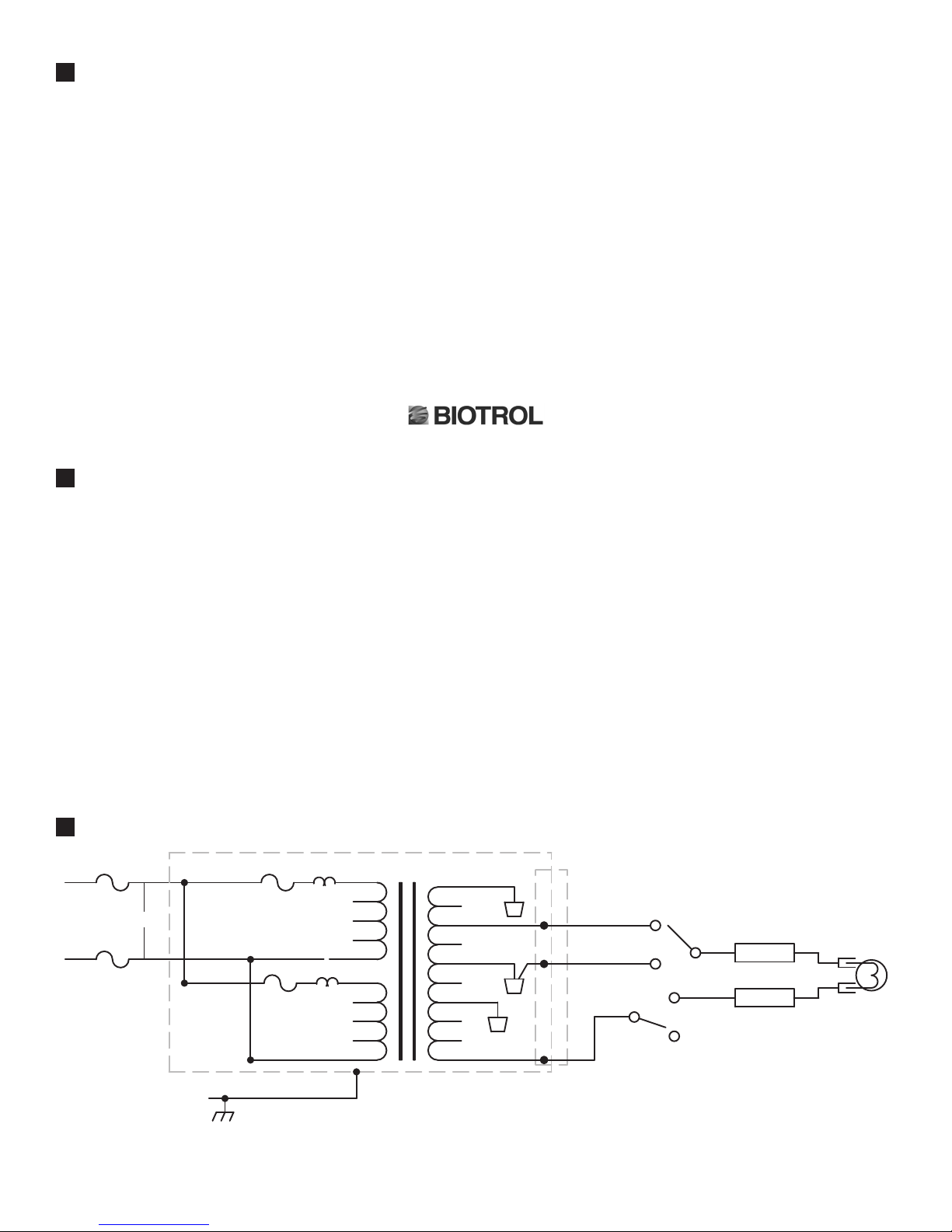

Wiring Diagram

BRW

2A

2A

BLK

LIGHT

BLUE

WHT

120 VAC

BLK

BLK / RED

F1

F2

GRN / YEL

TL1

TL2

BLK / WHT

PUR (19V)

BRN (17V)

BLU (15V)

ORG (13V)

WHT/ RED

RED

WHT

BLK

BLK

WHT WHT

WHT

120 V~APPLICATION

4

WHT

Warranty

Use Disposable Plastic Films and

Foils

Proma encourages the use of dispos-

able lms and foils on the handles

and surfaces commonly touched with

gloved hands. This can reduce the

need for chemical surface disinfection

and extend life span and appearance of

these surfaces.

Do Not Soak Plastic Parts

The useful life of many plastics may be

greatly shortened by soaking in disin-

fectant solution for extended periods

of time.

Cleaning Your Proma Light

Clean and disinfect the unit at begin-

ning and end of each workday.

The outside surfaces may be cleaned

with a moist (not dripping) soft towel

soaked in any mild soap and water so-

lution. Wipe and dry with a soft towel.

Do not use abrasive cleaners or rough

paper towels which may scratch the

molded surfaces. After cleaning, wipe

surfaces with gauze sponge moistened

(not dripping) in disinfectant.

Proma approves the use of mild soap

and water solution, applied with a soft

cloth.

Proma recommends Birex®SE manu-

factured by Biotrol International

Proma warrants its products against defects in materials and / or workmanship for ve (5) years from the date of shipment

from the factory. No other warranties are expressed or implied. No employee, representative or dealer is authorized to

change this warranty in any way, or grant any other warranty dealing with this product. Proma’s sole obligation under this

warranty is limited to repair, replace, or modify the defective part or product if, in its judgment, this is advisable. Labor and

other costs for removal and reinstallation are not included in this warranty. The buyer shall have no other remedy. (All spe-

cial, incidental, and consequential damages are excluded.) Written notice of breach of warranty must be given to Proma

within the warranty period. The warranty does not cover damages resulting from improper installation or maintenance, ac-

cident or misuse. Warranty is void if product is not installed by an authorized Proma dealer. NO OTHER WARRANTIES

AS TO MERCHANTABILITY, FITNESS FOR USE OR OTHERWISE ARE MADE. This warranty gives specic legal right,

and there may also be other rights which vary from state to state. (Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above exclusion may not apply.)

Proma will provide service advice and instructions as required for repair or replacement of this product.

Call 1.310.327.0035 for service.

1

2

3

3

Adjustment Nut

Counterbalance

2

Lever- Limit Switch

Adjust Screw

Limit Switch

4

4

Friction

Screws

1 On/Off Switch Lever Installation

Remove the white-rounded lever from the plastic bag that

contains the spare fuses and spare bulb. Install the lever

onto the On /O ff switch by pressing it over the teardrop

shape toggle until it bottoms-out. The lever is designed to

t onto the toggle with a minimum amount of force.

WARNING

Be careful not to over press the lever as you may dam-

age the switch.

Flex Arm Counterbalanced Adjustment

On / Off Switch Lever Adjustment

On / Off Switch

Rounded Lever

Light Head

Flex Arm

5

Counterbalanced Spring Tension Adjustment

If light head drifts or springs back up, the spring tension

needs to be counterbalanced. To get access to the ten-

sion nut and adjust the spring, remove the plastic bottom

cover by pulling down on the head end of arm. Pass a

at head screwdriver through the slot on the inside of the

extrusion. Rotate counterclockwise the splined nut for a

stiffer spring and clockwise for a looser spring.

Friction Adjustment

Remove plastic bottom cover by pulling down on the

head end of the arm. Use a 9/64” Allen wrench to tighten

or loosen the two friction screws. If arm is drifting, tighten

screws. If arm movement is too stiff, loosen the screws.

Always turn both screws the same amount.

Note: The bottom cover snaps back into place without

the use of any tools.

Auto On/Off Microswitch Adjustment

Remove plastic bottom cover by pulling down on the

head end of arm. Use a 3/32” Allen wrench to loosen

the set screw (marked “Adjust screw”). Move the screw

towards the light head to lower the position that the light

turns Off / On. Move the screw the opposite direction to

raise the On/Off position.

6

Drilling Template

7-1/2”

(7.50”)

8-21/32”

(8.65”)

Note: Print this page on scale of 1: 1

Do Not reduce page size

Center Mark Hole Location on

Ceiling using this Template

Table of contents

Popular Lighting Equipment manuals by other brands

Blizzard Lighting

Blizzard Lighting Puck CSI Xtreme user manual

Philips

Philips Light System Manager manual

Elumen8

Elumen8 Virtuoso 600 Profile RGBAL user manual

Stairville

Stairville Tri Flat PAR Profile 18x3W RGB 25 user manual

BRUSTOR

BRUSTOR PROSTOR E-BIKE LIFT 12V Mounting instruction

ALPHA LITE

ALPHA LITE DL Series User manual book