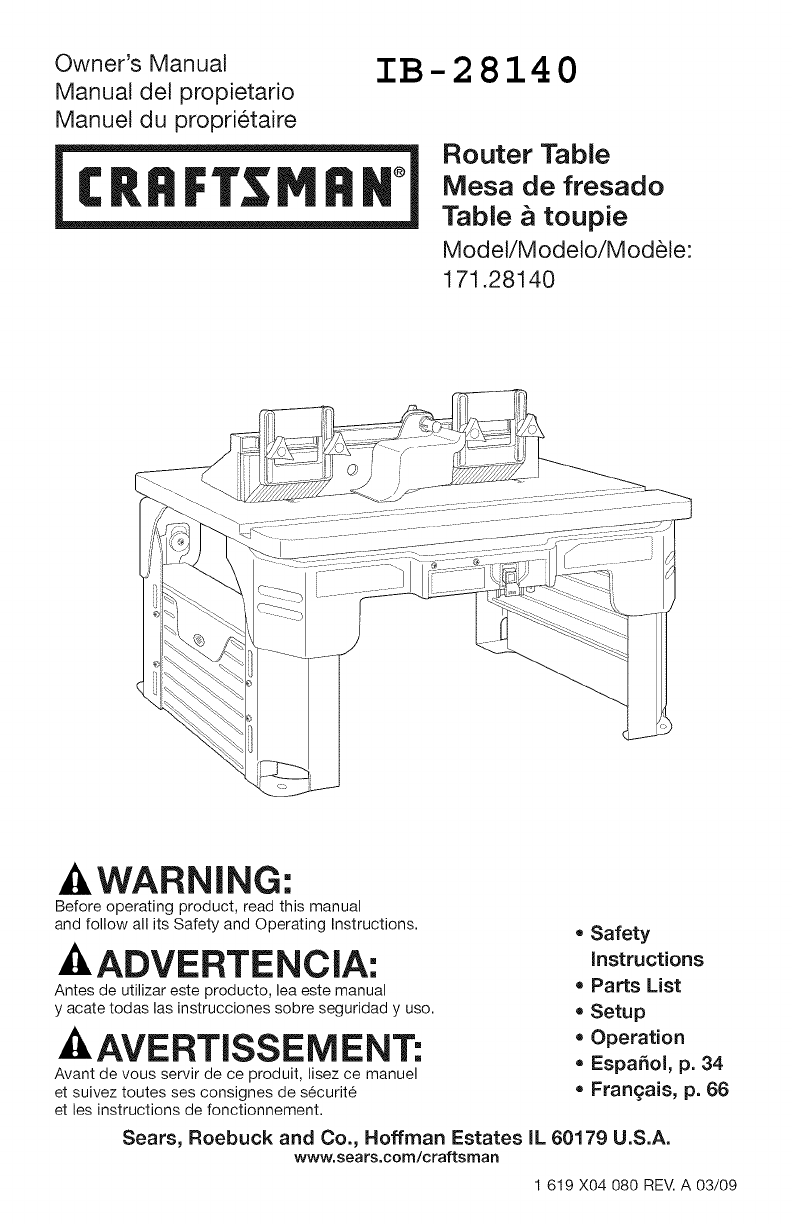

shiftingunexpectedlywhileinuse,resultingin

propertydamageorseriouspersonalinjury.

Disconnecttherouterfromthepower

supply before installing router into the

table, making adjustments, changing

accessories, removing the router from the

table, performing maintenance, or storing

the tool. Such precautionary safety measures

reduce the risk of unintentional tool operation.

Do not plug router motor power cord into

standard wall outlet. Always plug router

cord into the router table switch box. Power

tool switches and controls need to be within

your reach in emergency situations.

Do not permit fingers to touch terminals on

the plug when inserting or removing plug

from the outlet.

Before connecting router or vacuum to

router table switch box, ensure that the

router or vacuum switch is off and that the

router table switch box is unplugged. Such

precautionary safety measures reduce the risk

of unintentional tool operation.

Before using the router table, verify that

the router is securely clamped in the router

table base. While working, periodically

check the router base fastener clamping

tightness. Vibrations from cutting operations

can cause router motor clamps to loosen and

the router motor may fall from the table.

Before starting to work, ensure that the

power cords from the router accessories,

the switch box, and the extension cord do

not and cannot come in contact with the

router or any moving parts of the router.

Such precautionary safety measures reduce

the risk of injury due to loss of control.

Do not use the router table without the

overhead guard or starter pin guard.

Remove all dust, chips, and any other

foreign particles that can affect its

function. Adjust the guard height so that

it clears the router bit and the workpiece.

The guard will aid in keeping hands from

unintended contact with the rotating bit.

Do not use bits that have a cutting

diameter that exceeds the clearance hole

in the tabletop insert plate or insert rings.

Bit could contact insert plate or insert ring,

throwing fragments.

Never use dull or damaged bits. Damaged

bits can snap during use. Dull bits require

more force to push the workpiece, possibly

causing the bit to break or the material to

kick back.

Handle sharp bits with care. Such precau-

tionary safety measures reduce risk of injury.

Do not alter insert ring or insert plate bit

hole. Match the cutting diameter of the

bit to the inner diameter of the insert ring

or insert plate bit hole such that the

difference is no less than 1/16 in. on a side.

Insert rings are meant to reduce the gap

between the cutting diameter of the bit and the

table so that workpieces maintain full support

of the table while routing.

Install bit in accordance with instructions

in the router manual. Securely clamp the

router bit in the collet chuck before making

any cuts. Securing the bit before cutting

reduces the risk of the bit becoming loose

during operation.

Never place your fingers near a spinning

bit or under the guard when the router is

plugged in. Such precautionary safety

measures reduce the risk of injury.

Never hold the workpiece on the outfeed

side of the bit. Pressing the workpiece

against the outfeed side of the fence may

cause material binding and possible kickback,

pulling your hand into the bit.

Guide the workpiece with the fence to

maintain control of the workpiece. Do not

place the workpiece between router bit

and fence while routing the edge. This

placement will cause the material to become

wedged, making kickback possible.

Only use touters for working with wood,

woodlike products, plastic, or laminates.

Do not use router and router table for

cutting or shaping metals. Be sure

workpiece does not contain nails or other

hard objects. Cutting nails may cause loss

of control of the tool or workpiece.

Never start the tool when the bit is

engaged in the material. The bit-cutting edge

may grab the material, causing loss of control

of the workpiece.

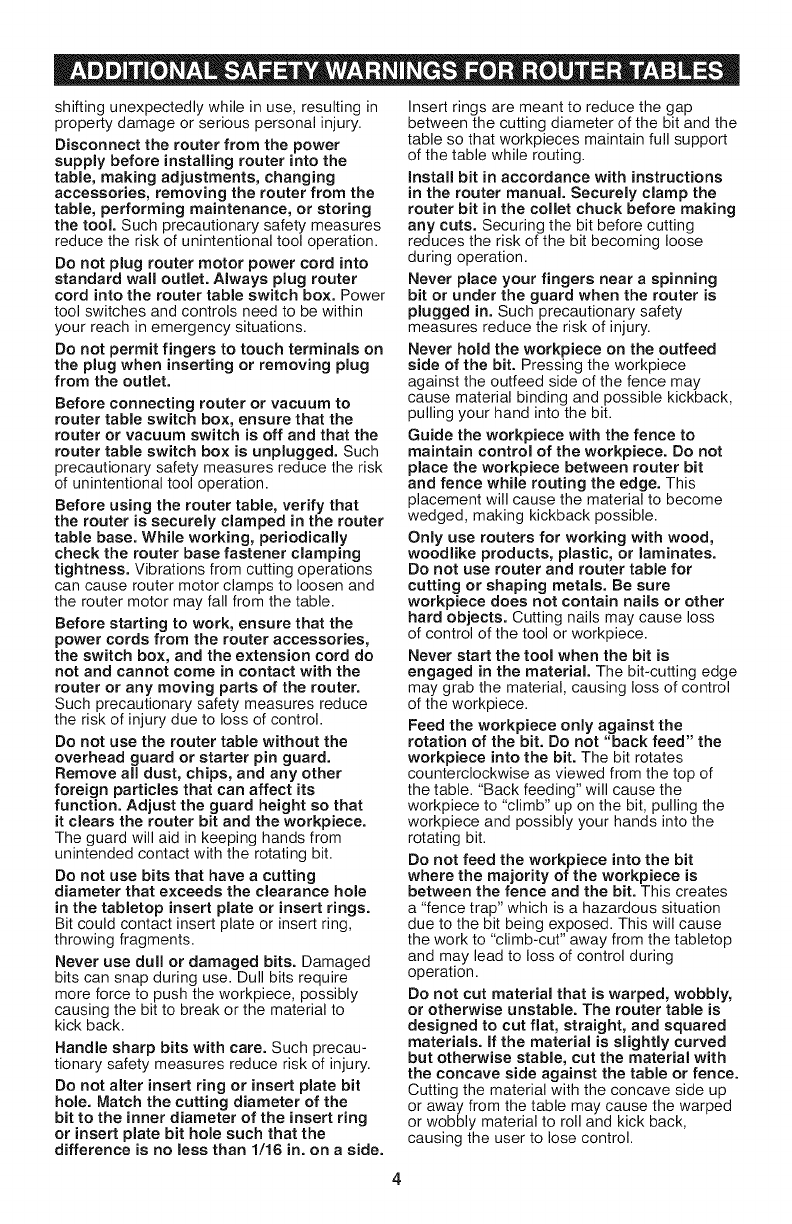

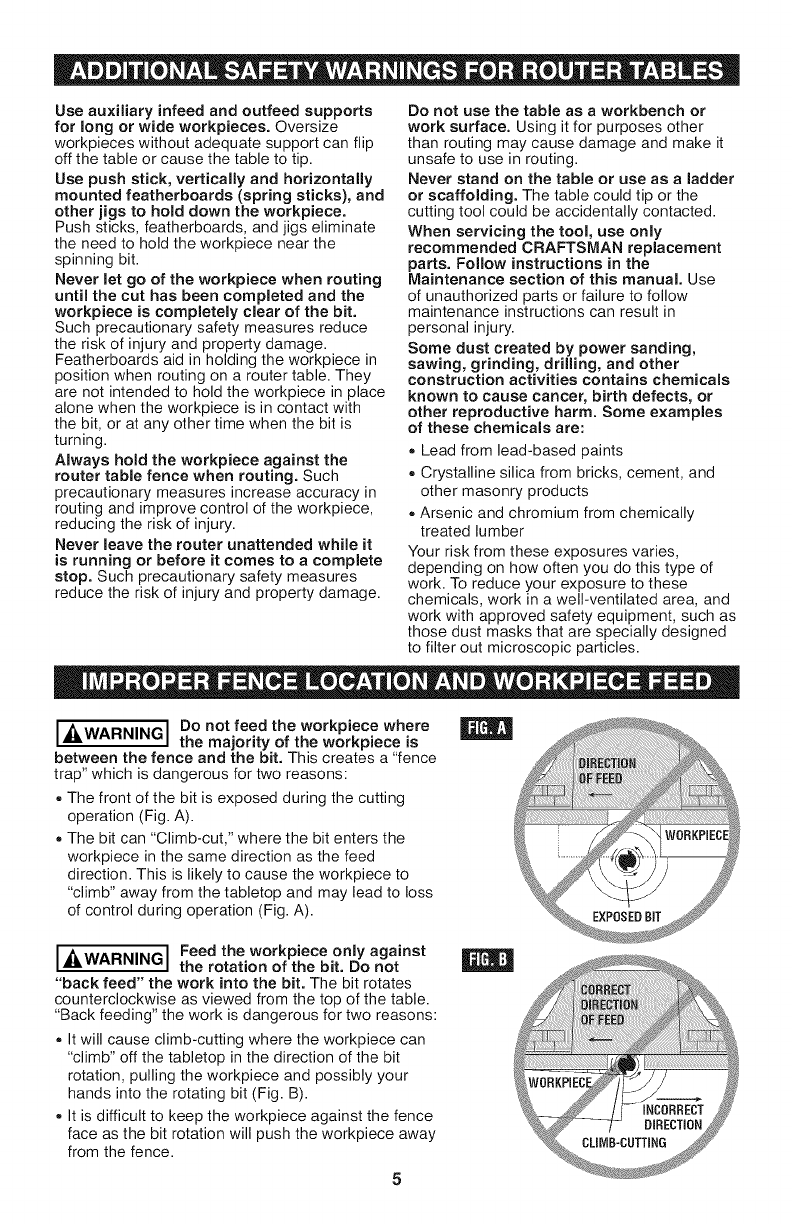

Feed the workpiece only against the

rotation of the bit. Do not "back feed" the

workpiece into the bit. The bit rotates

counterclockwise as viewed from the top of

the table. "Back feeding" will cause the

workpiece to "climb" up on the bit, pulling the

workpiece and possibly your hands into the

rotating bit.

Do not feed the workpiece into the bit

where the majority of the workpiece is

between the fence and the bit. This creates

a "fence trap" which is a hazardous situation

due to the bit being exposed. This will cause

the work to "climb-cut" away from the tabletop

and may lead to loss of control during

operation.

Do not cut material that is warped, wobbly,

or otherwise unstable. The router table is

designed to cut fiat, straight, and squared

materials, if the material is slightly curved

but otherwise stable, cut the material with

the concave side against the table or fence.

Cutting the material with the concave side up

or away from the table may cause the warped

or wobbly material to roll and kick back,

causing the user to lose control.