ProMaxX Rocky II User manual

.

User Guide

Rocky II™ User Guide

LIMITED LIFETIME WARRANTY

The ProMaxx® ProPlate™ included in this repair kit is a high-quality precision tool designed and manufactured in the USA and is backed by a

LIMITED LIFETIME warranty. ProMaxx® warrants this product to the original purchaser for its useful life against deficiencies in material and

workmanship. This LIMITED LIFETIME WARRANTY does not cover normal wear and tear, and if it is used incorrectly, abused, altered or

repaired. Deficient products will be replaced or repaired. For more information about ProMAXX® and our line of engineered performance tools

and machine tooling, visit www.promaxxtool.com.

www.promaxxtool.com

(Rocky D/II 3/17) Copyright ProMAXX® tools. All rights reserved. 9/28/2017

Congratul

replacem

e

engines.

debris pri

o

above usi

n

(see abo

v

depth of t

h

PENETR

A

manually

t

edge is m

seconds.

the angul

a

Retract th

the life an

ProPlate

™

eight to t

e

from this

o

approxim

a

and repla

c

blade and

for five to

immediat

e

from the

e

against th

carefully

a

EXCEED

torque lim

ProMAX

X

ProBushi

n

SSSC266

blow the

d

clean the

support a

t

NOTE: P

r

head incr

e

GENUIN

E

MAX: SS

S

SSSC266

and PPG

5

one ProF

a

PROMA

X

REPEAT

A

OPTIMU

M

ations on your

e

nt of broken

e

Used properly

,

o

r to mounting

ng the include

d

v

e) precision-m

h

e bit. Place

o

A

TING OIL/SP

t

urning the ch

u

aintained. Wh

This initial pro

a

r surface of t

h

e bit and clea

n

d cutting actio

n

™

manually as

e

n second inter

v

o

peration. Re

p

a

tely ¼” from

c

c

e the SSSC1

2

insert the proj

ten seconds.

T

e

success of e

x

e

nd of the extr

a

e cylinder hea

d

a

pply torque, fi

r

80 IN-LBS OF

itations stated

X

® offers and r

e

n

g™ PPB188II

6

and PPB266I

I

d

ebris clean a

n

remaining thre

t

724-941-094

1

r

oMAXX® doe

s

e

asing comple

x

E

PROMAXX®

S

C125 @900

R

6

@200. NOTE

5

250 ProGard

™

a

st™ fastener

i

X

X TOOLING I

S

A

BLE RESUL

T

M

PERFORM

A

SAFETY PR

O

GLASSES/G

O

purchase of t

h

e

xhaust manifo

,

this device c

a

the ProMAXX

®

d

ProFast™ P

P

achined toolin

g

o

ne drop of Pr

o

R

AY OR OTH

E

u

ck until the Pr

o

ile applying lig

cess is critical

h

e damaged st

u

n

the debris fro

m

n

of the tooling

described pre

v

v

als and while

p

eat this step f

o

c

ontacting the

b

2

5 ProDrill™

w

ecting pin of t

h

T

his operation

x

tracting the d

a

a

ctor. Tap the

d

. While holdin

r

st in the clock

w

TORQUE. R

e

above. If the

e

commends (h

(see above) f

o

I

ProBushing

™

n

d follow with t

h

ads free of all

d

1

for recomme

n

s

no

t

recomme

x

ity to extract.

PARTS. Tool

i

R

PM, SSSC18

8

: Some air rat

c

™

at www.pro

m

i

n any open h

o

S

SPECIALLY

T

S USING YO

U

A

NCE AND EX

T

O

CEDURE: A

L

O

GGLE AND

P

h

enew ProMA

X

l

d mounting st

u

a

n significantly

®

ProPlate™.

P

F008 precisio

g

bit into an ai

r

o

Lube™ PPL0

0

E

R LUBRICA

N

o

Drill™ slips i

n

h

t pressure, a

c

in that it creat

e

u

d. This redu

c

m

the bit with

a

bit. Once ag

a

v

iously above.

the bit is turni

n

o

r approximat

e

b

ushing mount

e

w

ith the optiona

h

e arbor into th

will remove th

e

a

maged remna

ProTractor™ i

n

g the opposite

w

ise direction,

e

peat this moti

o

damaged stu

d

ighly recomm

e

o

llowed by the

™

tooling to foll

o

h

e optional hig

h

d

ebris. Use a

d

n

dations and p

nd tapered left

In addition, th

e

i

ng cutting spe

8

@300, SSS

C

c

hets may not

g

m

axxtool.com.

o

le.

ENGINEERE

D

U

R NEW DEV

I

T

ENDED WA

R

L

WAYS USE

A

P

ROTECTIVE

G

X

X® Exhaust

M

u

ds in the For

d

reduce repair

t

Once cleaned

,

n stainless ste

r

-powered drill

a

0

1 machinist c

u

N

TS. Insert th

e

n

to the bushing

c

tivate your dril

e

s a “seat” for

t

c

es the probabi

a

shop towel w

a

in, place one

d

While continu

o

n

g, extract the

e

ly every ten s

e

e

d in the ProPl

l ProCutter™

P

e hole created

e

burr and cor

r

nt. Utilize the

n

to the depth

o

end of the Pr

o

and then in th

e

o

n several tim

e

d

fails to releas

e

e

nded for Ford

ProTractor™

P

o

w the SSSC1

8

h

-quality ProM

A

d

rill depth stop

rocedures.

-handed scre

w

e

se extractors

eds (Under lo

a

C

266@250. O

P

g

enerate suffic

Use optional

P

D

TO CLOSE

T

I

CE. SPECIF

Y

R

RANTY COV

E

A

PPROPRIAT

E

G

LOVES WHI

L

M

anifold Repai

d

Modular V8 g

t

ime. Before u

,

mount the Pr

o

el fasteners. I

n

a

nd use the dr

u

tting oil or eq

u

e

mounted Pro

D

and contacts

t

l both on and

o

t

he bit to rest

a

lity of tooling b

h

ich will remo

v

d

rop of ProLub

o

usly running

y

bit while maint

e

conds progre

s

ate™. Once t

h

P

PC007A. Ad

d

from the Pro

D

r

osion that ofte

optional spline

o

f the line. Pla

c

o

Tractor™ and

e

counter-cloc

k

e

s slowly incre

a

e

, STOP and r

e

6.8L V-10) usi

n

P

PT188. In ex

t

8

8. This step

w

A

XX® ProCha

collar for larg

e

w

extractors as

cannot be tur

n

a

d): MIN: SSS

C

P

TIMUM: SSS

C

ient RPM und

e

P

roPin™ wher

e

T

OLERANCE

S

Y

PROMAXX®

E

RAGE.

E

SAFETY EQ

U

L

E USING TH

I

r Kit! We engi

n

as and Ford 6

.

se, it is recom

m

o

Plate™ to th

e

nsert the prop

e

r

ill depth gaug

e

u

ivalent on the

D

rill™ into the

t

he surface of

t

o

ff in approxim

a

nd ensures th

a

b

it breakage an

v

e steel fragm

e

e™ PPL001 t

o

y

our drill at the

t

aining it in the

s

sively exertin

g

h

e machining

o

d

two drops of

D

rill™. Apply

m

e

n restrict rem

o

e

d ProTractor

™

c

e the include

d

using a high-

q

k

wise direction

a

sing applied t

emove the Pr

o

ng the optiona

t

reme cases,

u

w

ill leave only

t

ser™ PPC00

8

e

r bits. In the

u

the

y

have the

n

ed clockwise t

C

125

/

SSSC03

0

C

125

/

SSSC03

e

r load to be e

f

e

only one tap

p

S

(+) .000” AN

®

GENUINE R

E

U

IPMENT INC

I

S DEVICE A

N

Pro

M

n

eered this kit

.

0L/6.4L/INT’L

m

ended that t

h

e

cylinder head

e

r ProBushing

™

e

machined int

o

end of the bit

p

hardened stee

t

he damaged

s

ately one sec

o

a

t the bit will s

t

n

d drilling off c

e

e

nts that have

b

o

the end of th

e

proper RPM,

s

bushing to all

o

g

more pressu

r

o

peration is co

ProLube™ P

P

m

oderate press

o

val of the dam

™

PPT125 by p

d

slip-nut over

t

q

uality calibrat

e

to loosen the

d

t

orque and bei

n

o

Tractor™. In

m

l ProDrill™ SS

u

tilize the optio

t

he threads of

8

or ProTap™

P

u

nlikely event

a

potential to de

t

o unlock the d

a

0

@300 RPM,

0 @500 RPM,

f

fective. SEE

P

p

ed hole is av

a

D (-) .002” TO

E

PLACEMEN

T

C

LUDING OSH

N

D PERFORM

I

M

AXX®Bushi

for fast and e

a

Diesel 365 an

d

h

e cylinder he

a

in any one of

t

™

and corresp

o

the ProPlate

™

p

rior to drilling.

l drill bushing

f

s

tud. This will

e

o

nd intervals fo

t

ay on stud ce

n

e

nter of the da

m

b

een case har

d

e

bit and reins

e

s

lowly apply m

o

w the bit to “cl

r

e until the drill

mplete, remov

e

P

L001 to the e

n

ure, toggling y

o

m

aged stud the

r

lacing a mark

a

t

he ProTracto

r

e

d torque wren

damaged stud

n

g careful NO

T

m

ore challengi

SC188 and th

e

nal ProMAXX

®

the broken stu

P

PT008 precis

a

n extractor fai

l

form the remn

a

a

maged remn

a

SSSC188@2

0

SSSC188@2

5

P

roMaxx® Pro

R

a

ilable, mount t

ENSURE AC

C

T

PARTS AND

A APPROVE

D

I

NG THIS OP

E

ngSelection

a

sy removal an

d

MaxForce7

®

a

d be free from

t

he positions s

onding ProDril

™

to set the pr

AVOID

f

irst by slowly

a

e

nsure the cutt

r five to ten

n

ter and not fol

m

aged stud.

d

ened and ext

e

e

rt the bit into t

h

ore pressure f

o

l

ean” cutting d

e

chuck is

e

the ProPlate

n

d of the cutter

o

ur drill on an

d

r

eby increasin

g

a

pproximately

r

™ and slide it

ch, slowly and

. DO NOT

T

TO EXCEED

i

ng cases,

e

correspondin

®

ProDrill™

d remaining.

S

ion machinist t

l

s, contact tec

h

a

nt in the cylin

d

a

nt. USE ONL

Y

0

0, SSSC266

@

5

0,

R

atchet #PPR

5

he ProPlate™

C

URATE

A

N

D

TOOLING FO

D

SAFETY

E

RATION.

Chart

d

®

hown

l

™

o

per

a

nd

i

ng

l

ow

e

nd

h

e

o

r

e

bris

™

d

off

g

your

¼”

up

safe

g

imply

a

p to

h

nical

d

er

Y

@

150.

5

250,

with

R

Popular Automobile Accessories manuals by other brands

Mountain Top

Mountain Top MTS FO10 A01 installation manual

Safe Fleet

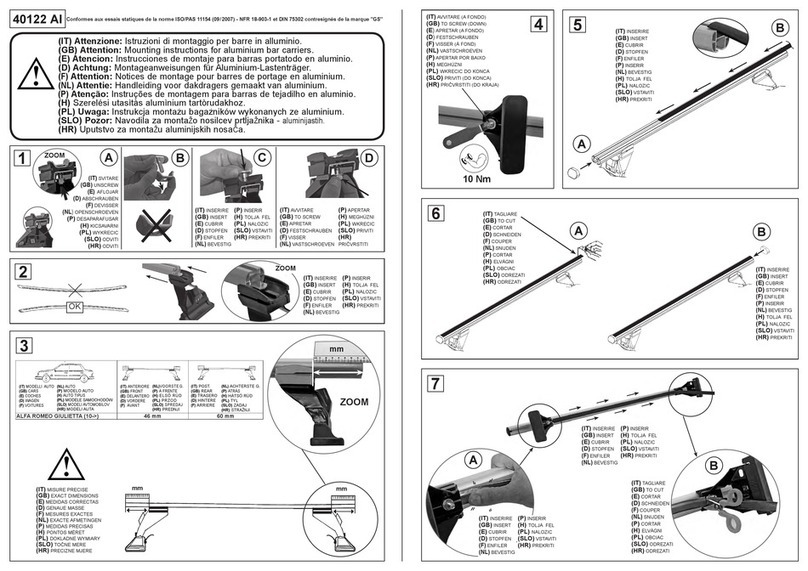

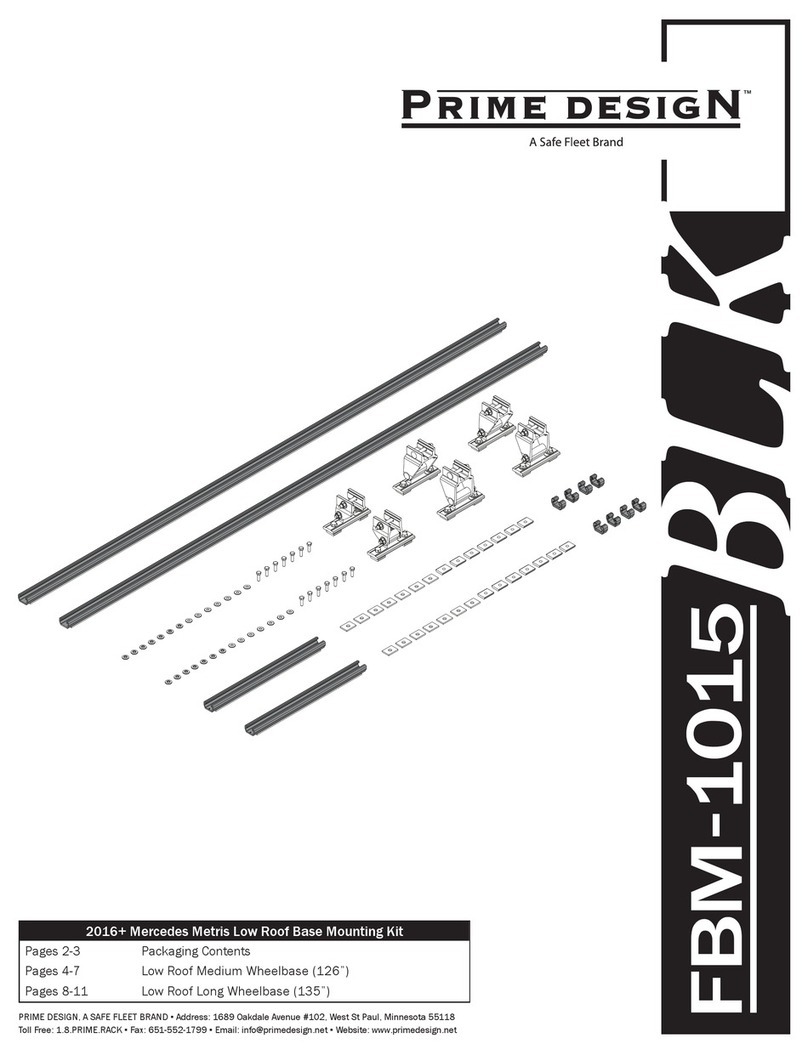

Safe Fleet PRIME DESIGN FBM-1015-BLK Assembly instructions

Ironman4x4

Ironman4x4 Monster Winch user guide

Directed

Directed Directechs DB3 installation guide

RVS

RVS RVS-082507 Product manual installation & instructions

Laser

Laser 4769 instructions