promesstec WTR 190 User manual

Version 2.2.1

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

User manual

Resistance thermometer WTR 190

2

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Content

1. General................................................................................................................ 4

1.1 Brief description..............................................................................................4

1.2 Overview presentation....................................................................................4

1.3 Drawings, shortcut..........................................................................................5

2. Transport, Packaging, Storage............................................................................ 5

2.1 Transport........................................................................................................5

2.2 Packaging.......................................................................................................6

2.3 Storage...........................................................................................................6

3. Safety instructions.............................................................................................. 6

3.1 Intended use of the product............................................................................6

3.2 Stuff qualification............................................................................................6

3.3 Special hazards..............................................................................................7

4. Starting operation............................................................................................... 8

4.1 Connection .....................................................................................................8

4.2 Mechanical assembly.....................................................................................9

4.3 Electrical assembly.........................................................................................9

5. Putting into operation.......................................................................................... 9

5.1 Configuration DMU 50..................................................................................10

5.1.1 Windows Software „pmtKonfigTool“.......................................................10

5.1.2 pmtKonfigTool - Connection between WTR190-DMU and PC...............11

5.1.3 pmtKonfigTool –read.............................................................................11

5.1.4 pmtKonfigTool –write ............................................................................11

5.1.5 pmtKonfigTool - Factory settings ...........................................................11

5.1.6 Status.....................................................................................................11

5.1.7 Temperature ..........................................................................................12

5.1.8 Display...................................................................................................12

5.1.9 Fault current...........................................................................................12

5.1.10 4..20mA Current output..........................................................................12

5.2 Configuration KMU 100 ................................................................................12

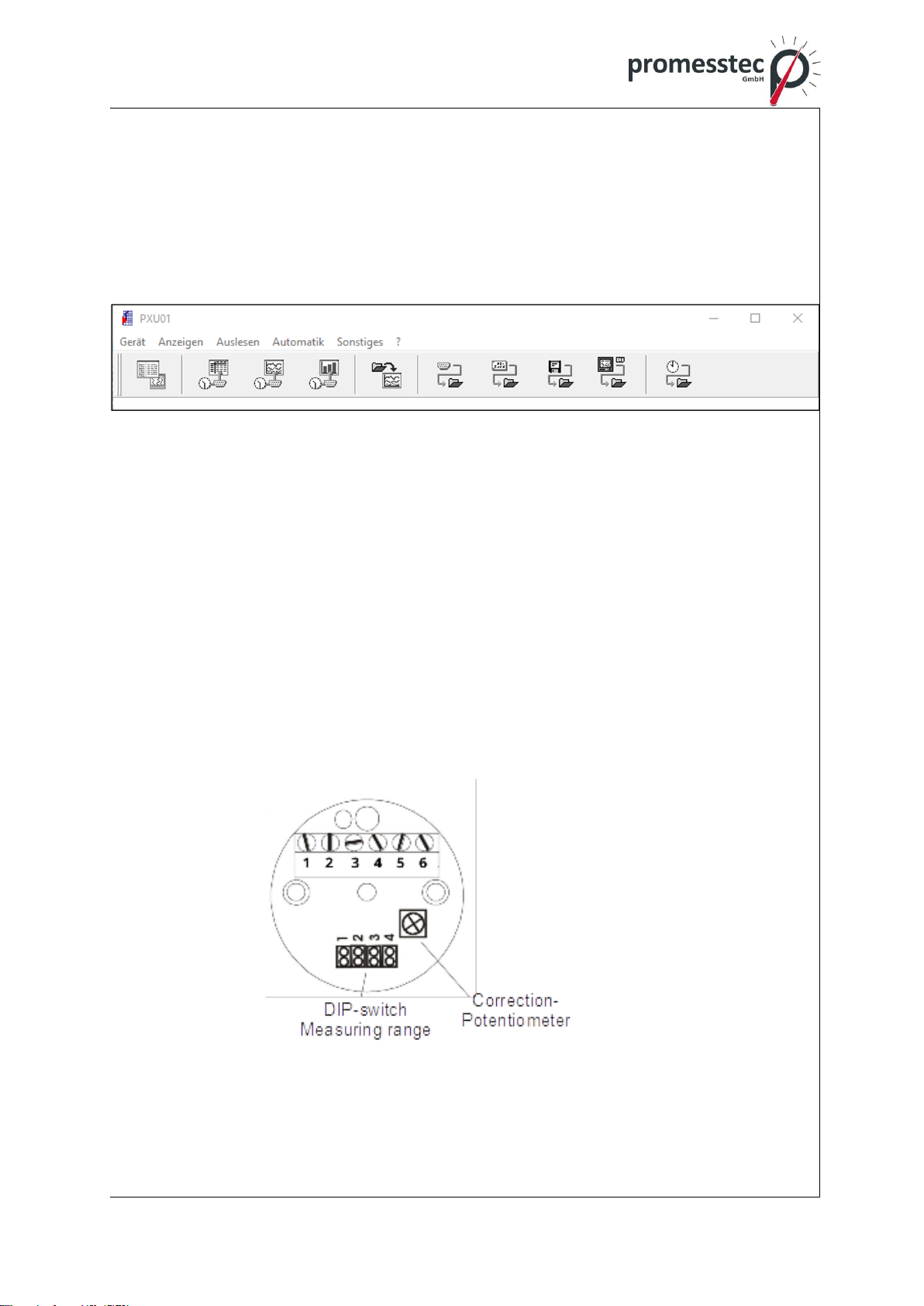

5.2.1 Windows Software „PXU01“...................................................................13

5.2.2 „PXU01“ - Connection between WTR 190-KMU and PC .......................13

5.3 Configuration KMUS 100..............................................................................13

5.3.1 Measuring range selection by DIP-switch..............................................14

5.3.2 Fine adjustment by correction potentiometer.........................................14

3

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

6. Technical specifications.................................................................................... 14

6.1 Technical data DMU 50................................................................................15

6.2 Technical data KMU 100..............................................................................15

6.3 Technical data KMUS 100............................................................................15

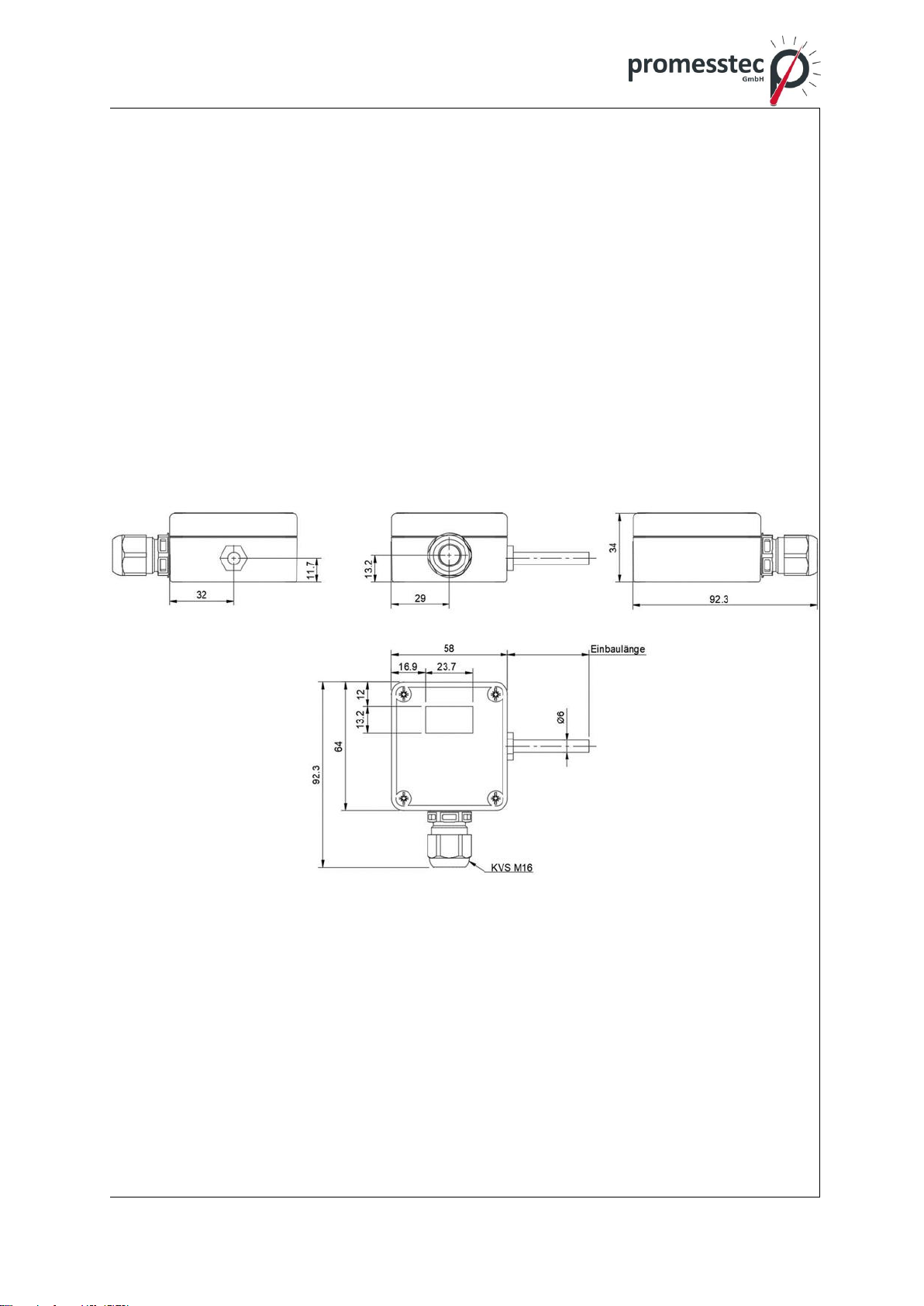

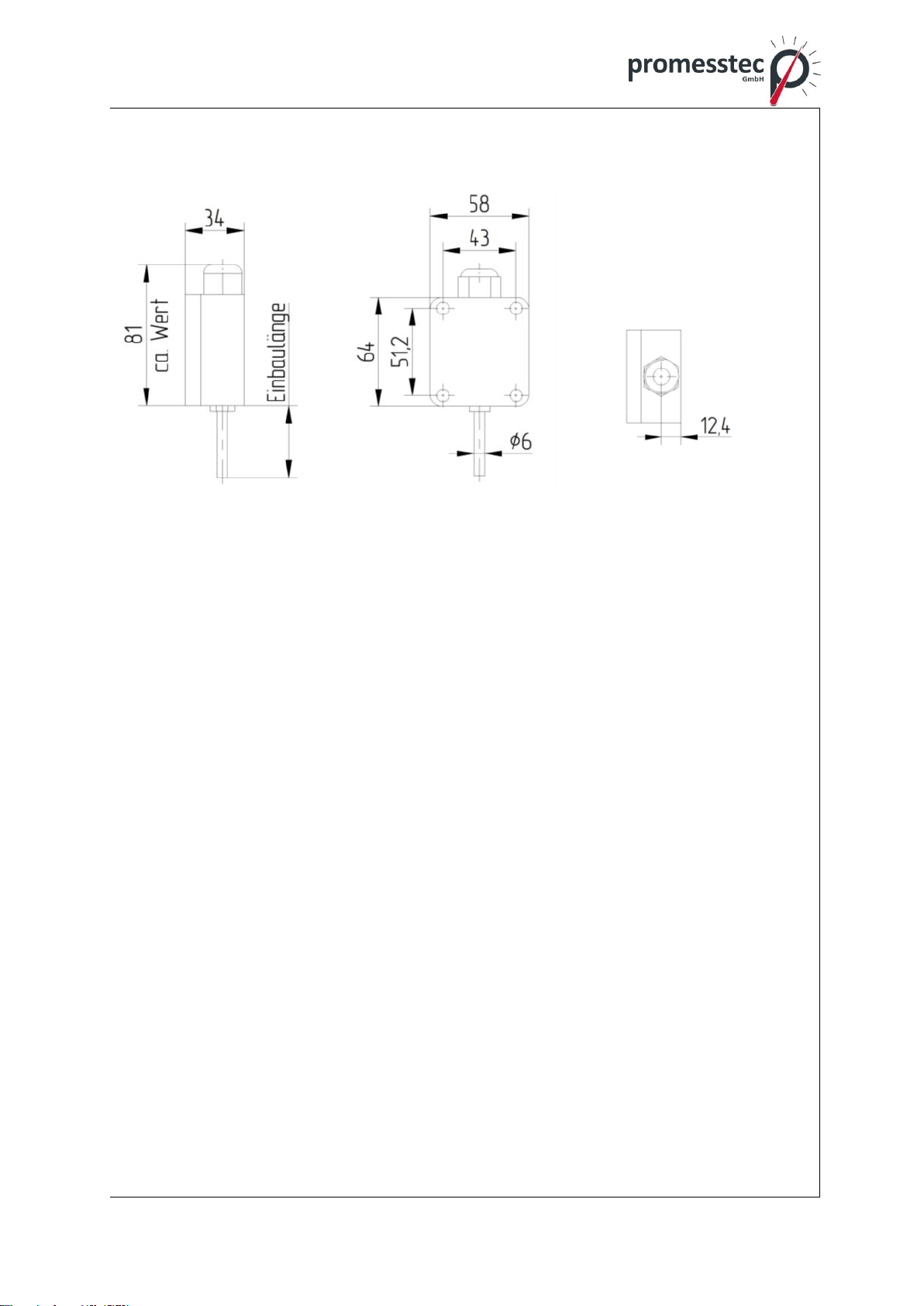

6.4 Technical drawing.........................................................................................16

7. Dismounting, Return, Cleaning, Disposal......................................................... 18

7.1 Dismounting .................................................................................................18

7.2 Return...........................................................................................................18

7.3 Cleaning.......................................................................................................18

7.4 Disposal........................................................................................................18

4

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

1. General

1.1 Brief description

The WTR 190 is a temperature sensor in a wall-mounted housing. This makes it the

right choice for reliably detecting temperatures in rooms or in outdoor areas. Thanks

to the robust polyamide housing, the WTR 190 can also be used without any prob-

lems in blast freezers, deep-freeze warehouses and in aggressive ambient condi-

tions in industry. Optionally, the WTR 190 is available with KMU 100 or KMUS 100.

The KMU100 has a 4..20mA and the KMUS 100 a 0..10V output. The WTR 190 is

also available with DMU 50. The DMU has a 4..20mA output and a high resolution

OLED display.

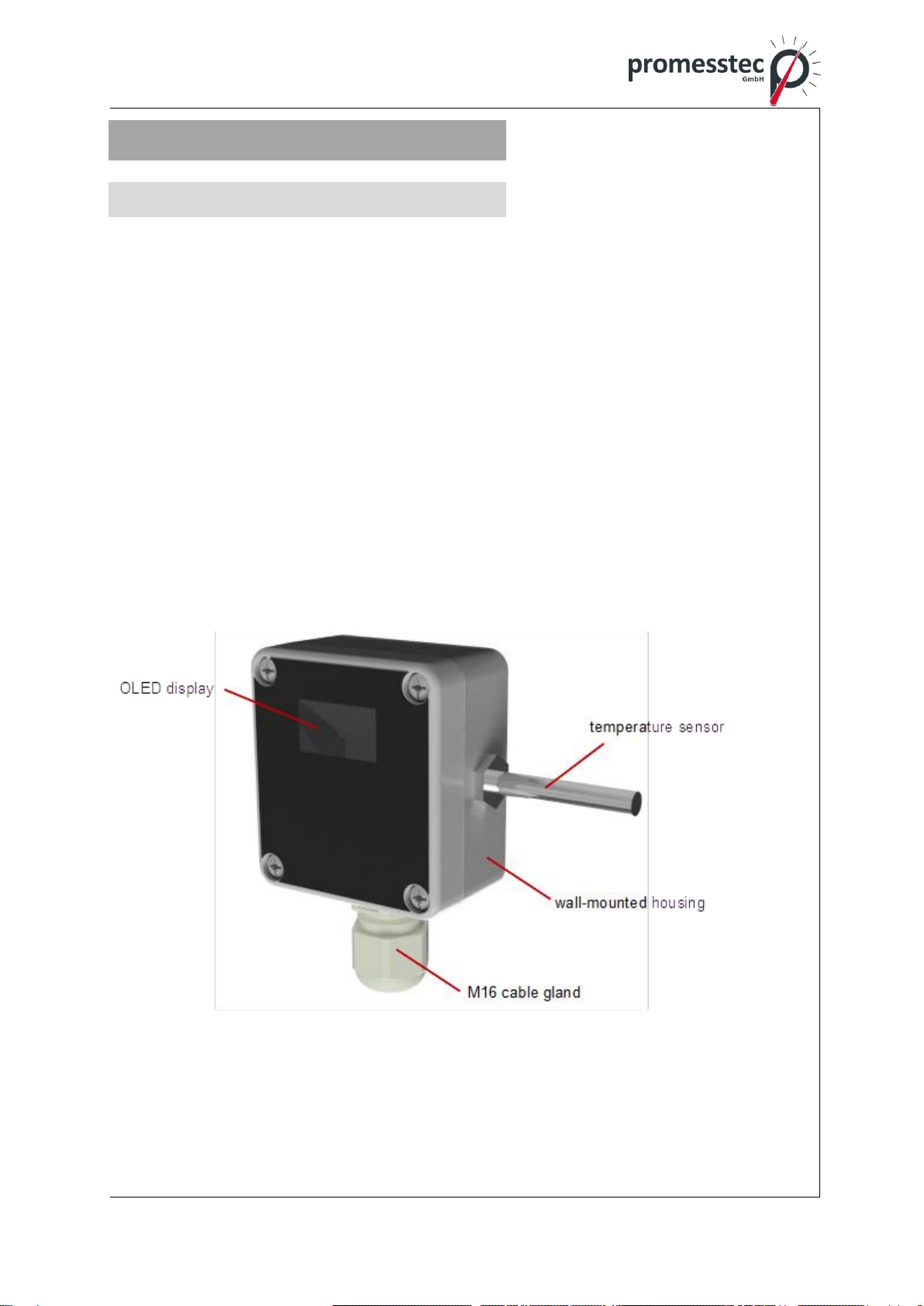

1.2 Overview presentation

WTR 190-C1-1A2/PT1000-DMU

Resistance thermometer WTR 190

5

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

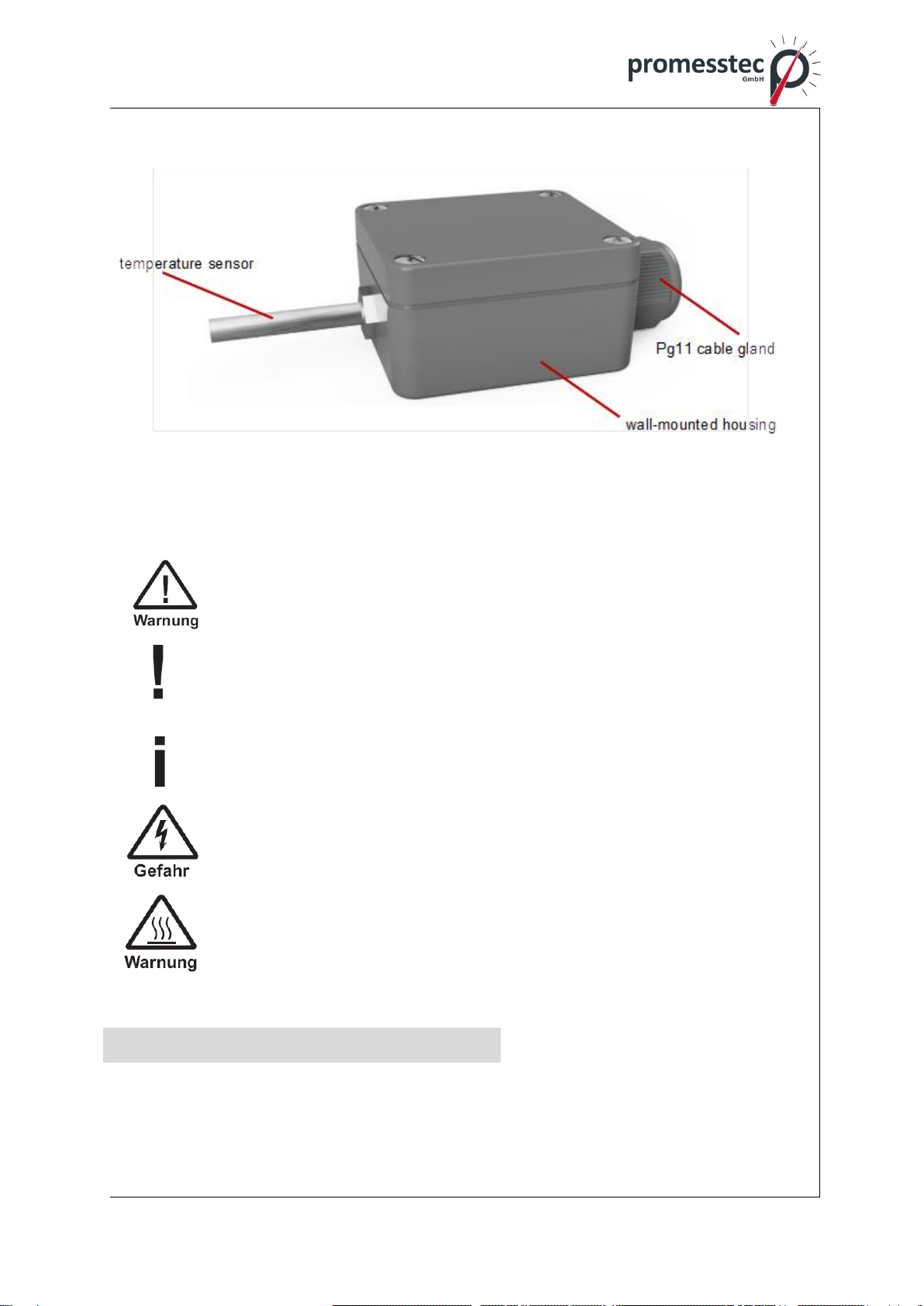

WTR 190-A1-1A3-KMU/ WTR 190-A1-1A3-KMUS

1.3 Drawings, shortcut

Warning!

A non-observance can cause injuries to persons and/or the demoli-

tion of the device. There can be a dangerous to life.

Attention!

A non-observance can cause a faulty operation of the device or lead

to property damage.

Information!

A non-observance can have influence on the operation of the device

or cause unintentional reactions of the device.

Danger!

When not observing the safety instructions, there is a risk of serious

or fatal injuries caused by electrical power.

Warning!

Possibly a dangerous situation can occur, which results in burns be-

cause of hot surfaces or liquids, if not avoided.

2. Transport, Packaging, Storage

2.1 Transport

6

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Check the instrument for any damage that may have been caused during transpor-

tation. If, report them immediately. The temperature during transportation and stor-

age of the meter must be within the range of -10 °C to 50 °C.

2.2 Packaging

Do not remove packaging until just before mounting. Keep the packaging as it will

provide optimum protection during transport (e.g. change in installation site, sending

back).

2.3 Storage

For longer term storage avoid the following influences:

1. Direct sunlight or proximity to hot objects

2. Mechanical vibration, mechanical shock (putting it hard down)

3. Soot, vapour, dust and corrosive gases

If possible store the device in its original package or an equivalent one

3. Safety instructions

More important safety instructions can be found in the individual

chapters.

3.1 Intended use of the product

The sensor has been designed and built solely for the intended use described here

and may only be used accordingly. The technical specifications contained in these

operating instructions must be observed. Improper handling or operation of the in-

strument outside of its technical specifications requires the instrument to be taken

out of service immediately and an inspection by the manufacturer. When the instru-

ment is transported from a cold into a warm environment, the formation of conden-

sation may result in the instrument malfunctioning. Before putting it back into oper-

ation, wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation con-

trary to the intended use.

3.2 Stuff qualification

7

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Improper handling can result in considerable injury and damage to

equipment. The activities described in these operating instructions

may only be carried out by skilled stuff who have the qualifications

described below. Keep unqualified stuff away from hazardous areas.

For installation and starting of the flow-meter the stuff has to be familiar with the

relevant regulations and directives of the country and must have the qualification

required. They must have knowledge on measurement and control technology, have

to be acquainted with electric circuits, are capable of carrying out the work described

and can independently recognize potential hazards. Depending on the operation

conditions of the application they have to have the corresponding knowledge, e.g.

of aggressive media.

3.3 Special hazards

For hazardous media such as oxygen, acetylene, flammable or toxic

gases or liquids, refrigeration plants, compressors, etc., in addition to

all standard regulations, the appropriate existing codes or regulations

must also be followed. If you do not observe the appropriate reg-

ulation, serious injuries and/or damage can occur!

A protection from electrostatic discharge (ESD) is required. The

proper use of grounded work surfaces and personal wrist straps is

required when working with exposed circuitry (PCB, printed circuit

boards), in order to prevent static discharge from damaging sensitive

electronic components.

There is a danger of death caused by electric current. Upon contact

with life parts, there is a direct danger of death. Electrical instruments

may only be installed and connected by skilled electrical personnel.

Operation using a defective power supply unit (e.g. short circuit from

the mains voltage to the voltage output) can result in life-threatening

voltages at the instrument.

Residual media in dismounted instruments can result in a risk to per-

sonnel, the environment and equipment. Take sufficient precaution-

ary measures. Do not use this instrument in safety or Emergency

Stop devices. Incorrect use of the instrument can result in injury.

Should a failure occur, aggressive media with extremely high tem-

perature and under high pressure or vacuum may be present at the

instrument.

8

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

4. Starting operation

4.1 Connection

WTR 190 passiv WTR 190 with DMU 50

WTR 190 with KMU 100 WTR 190 with KMUS 100

9

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

4.2 Mechanical assembly

The WTR 190 is designed as a wall-mounted sensor. Use the holes provided in the

housing for mounting. Use suitable screws that do not destroy the housing. Only by

this we can assure you an optimal measuring point incl. the protection class.

After mounting the sensor, check the tightness of the housing and after installing the

connection cable, check the tightness of the screw connection (cable entry).

Please read the safety instructions on page 11 before assembly and keep these in-

structions for future reference.

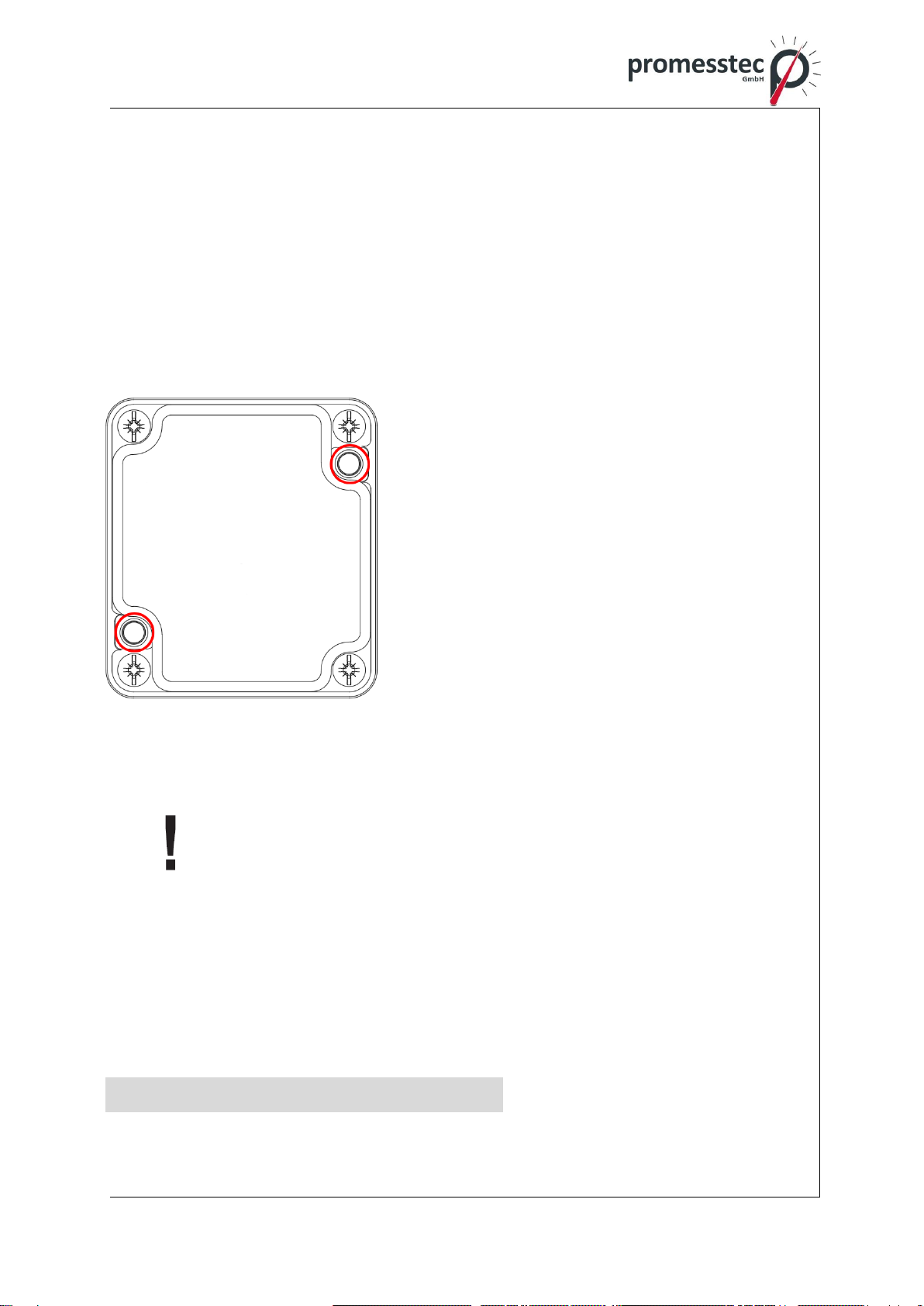

1. Loosen the screws of the device cover and

remove the cover.

2. Fasten the device to the wall using suitable

screws through the holes provided in the

housing.

1. Screw the device cover back on.

Provided holes for mounting

4.3 Electrical assembly

The electrical installation must be carried out in a de-energized

state.

- Insert the connection cable into the cable entry (gland). Make sure not to

damage the seal of the cable gland.

- Connect the connecting cables according to your task.

- If a transmitter is used, it can be configured via the respective interfaces.

- Close the housing and switch on the voltage.

5. Putting into operation

10

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Before switching on the device, it should be checked whether the

sensor has been correctly installed and wired.

5.1 Configuration DMU 50

If the WTR 190 is used with a DMU 50, the settings of the DMU can be read out,

graphically displayed and changed via the Windows software "pmtKonfigTool". In the

following the configuration of the DMU with the "pmtKonfigTool" software is ex-

plained.

5.1.1 Windows Software „pmtKonfigTool“

The current settings of the DMU can be read out and changed via the "pmtKon-

figTool" software. The installation file of the application can be downloaded from the

website www.promesstec.de

The configuration options include the display orientation, the scaling of the current

output and the overflow and underflow behavior of the measuring range. In addition,

the status, the measured value and the current value are read out in real time.

11

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

5.1.2 pmtKonfigTool - Connection between WTR190-DMU and PC

Loosen the cover of the WTR 190 to access the USB C interface of the DMU.

Connect the transmitter to the PC via a commercially available USB C cable.

ATTENTION: WTR 190 restarts after connection via USB! Now start the Windows

software "pmtKonfigTool".

To access the display, the first thing to do is to select the correct COM port. All COM

ports are listed in the "Port" drop-down list. The button updates the drop-down list.

As soon as a connection could be established successfully, the status changes to

"Connected" and the name of the connected device is displayed.

5.1.3 pmtKonfigTool –read

As soon as a connection with the DMU has been established, the settings are read

out and displayed in the software. The status, the temperature and the current value

are continuously updated. In addition, it is possible to press the "Read out" button to

read out and display all settings again.

5.1.4 pmtKonfigTool –write

To change the settings of the DMU, the desired values must be entered in the Win-

dows software and the corresponding options selected. However, the settings are not

applied until the "Write" button has been pressed. If the write operation cannot be

performed successfully, the old settings of the DMU are displayed again.

5.1.5 pmtKonfigTool - Factory settings

By pressing the "Factory settings" button, all parameters and settings are reset to the

delivery state.

Factory settings: Display: 0°

Fault current: activates

MeasuringRangeMin.: -30,0 °C

MeasuringRangeMax.: +80,0°C

5.1.6 Status

In total, the DMU can assume four different statuses, which provide information about

the current loop and the measurement of the current.

Ok: The DMU works flawlessly.

Cable break: There is a cable break in the connected PT 1000.

Underflow: The measured temperature is smaller than the smallest value

which can be can be transmitted with the 4..20mA interface.

12

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Overflow: The measured temperature is greater than the largest value that

can be transmitted with the can be transmitted with the 4..20mA

interface.

Error evaluation: There is an error in the evaluation of the PT 1000.

5.1.7 Temperature

Under the "Temperature" tab, the currently measured temperature is displayed in real

time.

5.1.8 Display

Under Alignment, the orientation of the display can be rotated by 180°. Thus, the

WTR 190-DMU can also be mounted overhead (cable outlet upwards).

5.1.9 Fault current

Through the check box "Underflow/Overflow", which can be found under "Fault cur-

rent", the overflow and underflow function can be activated or deactivated. If the func-

tion is activated, the DMU will output a current of 20.5mA if the measured tempera-

ture exceeds the maximum temperature of the 4..20mA loop and 3.5mA if the mea-

sured temperature falls below the minimum temperature of the 4..20mA loop. If the

function is disabled, a current of 20mA and 4mA will flow in case of exceeding and

falling below. Regardless of the overflow and underflow function, a current of 21mA

always flows if there is a cable break in the temperature sensor (PT 1000).

5.1.10 4..20mA Current output

Under the tab "4..20mA current output" on the one hand the current of the current

loop is displayed in real time and on the other hand the scaling of the loop is configu-

red. For this purpose, the minimum temperature value for 4mA and the maximum

temperature value for 20mA must be specified.

5.2 Configuration KMU 100

If the WTR 190 is used with a KMU 100, the settings of the KMU can be read out and

changed via the Windows software "PXU01". The parameterization software kit

PXU01 is required for this. This contains the Windows software "PXU01" on CD, an

interface converter (USB adapter) and a plug adapter for the KMU. The configuration

of the KMU with the "PXU01" software is explained below.

13

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

5.2.1 Windows Software „PXU01“

The current settings of the KMU can be read out and changed via the "PXU01" soft-

ware. The installation file of the application is provided via a CD or optionally via a

download link. To obtain the link, contact promesstec GmbH.

The configuration options include scaling of the current output. In addition, the mea-

sured value is read out in real time.

5.2.2 „PXU01“ - Connection between WTR 190-KMU and PC

Loosen the cover of the WTR 190 to access the programming interface of the KMU.

Connect the KMU to the PC via the plug adapter included in the PXU01 paramete-

rization software kit and the interface converter.

To access the device, a connection must first be established in the application. The

settings of the KMU can then be read out and changed.

5.3 Configuration KMUS 100

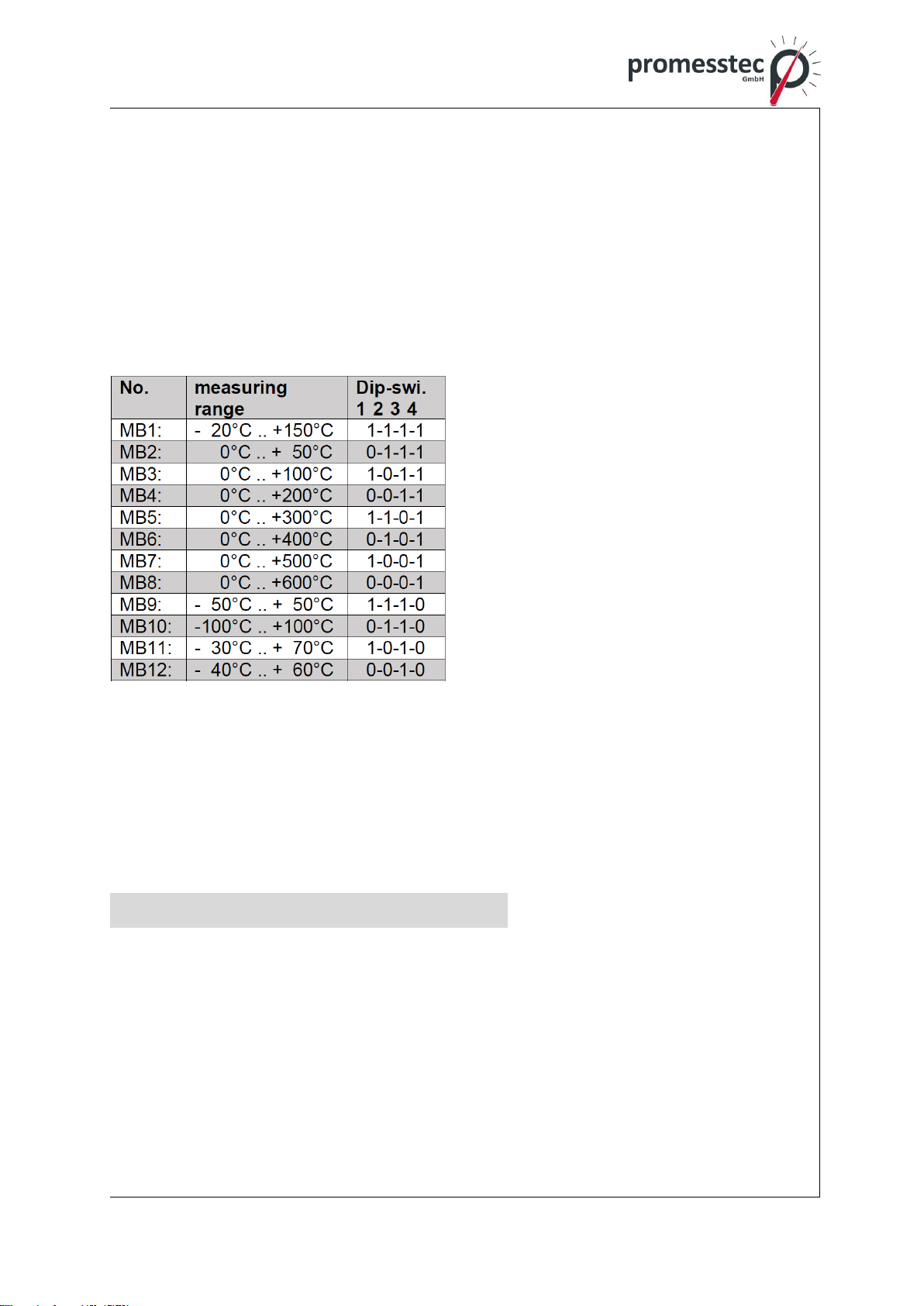

The KMUS 100 is configured via a potentiometer and four DIP-switches. Configura-

tion on the PC is not necessary.

14

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

5.3.1 Measuring range selection by DIP-switch

Four DIP-switches can be used to set 12 different measuring ranges. These are lis-

ted in the table below.

The query for the measuring range is permanent. Thus, the voltage supply does not

have to be interrupted after a change of the measuring range. The recognition of the

sensor (Pt 100/Pt 1000) is also done automatically during operation.

Attention: For Pt 1000 only the ranges 1..5 are available.

Jumper = 1: plugged

Jumper = 0: not plugged

5.3.2 Fine adjustment by correction potentiometer

As can be seen in the picture above, the correction potentiometer is located on the

top of the KMUS. This can be used for fine adjustment of the output voltage. A seal

secures the potentiometer against accidental adjustment.

6. Technical specifications

material protective fitting: stainless steel 1.4571 (V4A)

length of sensor: 45 mm other lengths on request

connecting box: plastic polyamide

dimensions: 58 x 64 x 34 mm

protection class: IP 65 according to DIN 60529

operating temperature: -50 °C bis +130 °C

(deviation when using a transmitter)

15

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

6.1 Technical data DMU 50

operating temperature: -30 °C bis +80 °C

operating voltage: UB = 10..35 V DC

electricity demand: 7,3 mA (UB=24V) + 4..20mA output

input: PT1000 2-wire

measuring range max.: -100°C bis +650°C

measuring span min.: 10K

accuracy: <+-0,1% from final value

output: 4..20mA 3-wire active (underflow 3,5mA,overflow

20,5mA)

sensor break: 21mA

standard configuration: 4mA = -50°C, 20mA = 150°C

(more temperature range parameterizable)

max. permissible load: Rmax=[(UB –6V) / 0,021 A] Ω

display: high-resolution OLED display 0,96 Zoll

alignment display: 0° oder 180°

display-digits: 4-digits

displayrange: -99,9 bis +999,9°C

electrical connection: 5x terminal connection 1,5 mm²

configuration: commercial USB Typ C cable (no programming

adapter necessary)

windows application for configuration („pmtKonfig-

Tool“)

6.2 Technical data KMU 100

operating temperature: -40 °C bis +85 °C

operating voltage: UB = 10..35 V DC

electricity demand: 4..20mA output

input: PT100 2-, 3-, 4- wire

measuring range max.: -200°C bis +650°C

Measuring span min.: 10K

accuracy: <+-0,1% from final value

output: 4..20mA 2-wire passive (underflow 3,5mA, overflow

21mA)

sensor break: 22mA

standard configuration: 4mA = -50°C, 20mA = 150°C

(more temperature range parameterizable)

electrical connection: 6x screw terminal 1,5mm²

configuration: programming adapter PXU01

windows application for configuration („PXU01“)

6.3 Technical data KMUS 100

operating temperature: -40 °C bis +85 °C

16

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

operating voltage: UB = 15..35 V DC

electricity demand: max. 10mA

input: PT100/PT1000 2-, 3-, 4-wire

measuring range: 12 measuring ranges, see page 3

accuracy: <+-0,3% from measuring range

output: 0..10V 3-wire

sensor break: >10V

standard configuration: 0V = -20°C, 10V = 150°C

electrical connection: 6x screw terminal 1,5mm²

configuration: DIP-switch (12 different measuring ranges)

6.4 Technical drawing

WTR 190 mit DMU 50

17

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

WTR 190 passiv/ WTR 190 with KMU 100 / WTR 190 with KMUS 100

18

promesstec GmbH I Niedersachsenstraße 4 I D-48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

7. Dismounting, Return, Cleaning, Disposal

7.1 Dismounting

Residual media in dismounted instruments can result in a risk of per-

sonnel, the environment and equipment. Take sufficient precaution-

ary measures.

There is a risk of burns. Let the instrument cool down sufficiently

before dismounting. During dismounting there is a risk of danger-

ously hot pressure media escaping.

Only disconnect the resistance thermometer once the system has

been depressurised.

7.2 Return

When returning the instrument, use the original packaging or a suit-

able package.

To avoid a damage, use for example antistatic plastic film, shock-

absorbent material, a marking as highly sensitive measuring instru-

ment.

7.3 Cleaning

Before cleaning the instrument disconnect the electrical connection.

Clean the instrument with a moist cloth. Electrical connections must

not come into contact with moisture. Wash or clean the dismounted

instrument before returning it in order to protect personnel and the

environment from exposure to residual media.

Residual media in dismounted instruments can result in a risk to

persons, the environment and equipment. Take sufficient precau-

tionary measures.

7.4 Disposal

Dispose instrument components and packaging materials in accord-

ance with the respective waste treatment and disposal regulations

of the region or country to which the sensor is supplied.

Other manuals for WTR 190

1

Table of contents

Other promesstec Thermometer manuals

promesstec

promesstec WTR 290 Series User manual

promesstec

promesstec WTR 280 Series User manual

promesstec

promesstec WTR 270 Series User manual

promesstec

promesstec WTR 190 How to use

promesstec

promesstec WTR 120 User manual

promesstec

promesstec WTR 230 User manual

promesstec

promesstec WTR 230 User manual

promesstec

promesstec WTR 420 Series User manual