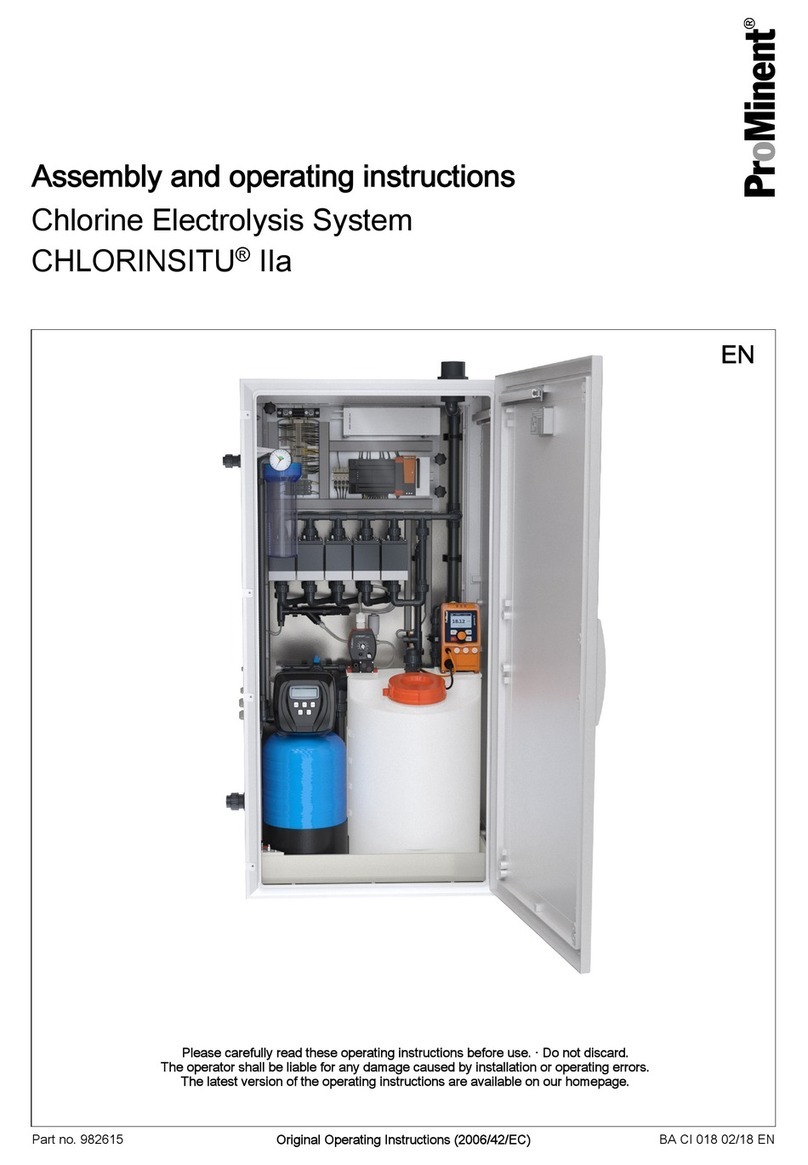

ProMinent CHLORINSITU IIa 625 Technical specifications

Other ProMinent Water Filtration System manuals

ProMinent

ProMinent CHLORINSITU IIa User manual

ProMinent

ProMinent ProMaqua CHLORINSITU V User manual

ProMinent

ProMinent 80 W User manual

ProMinent

ProMinent ProMaqua Bello Zon CDLb Series User manual

ProMinent

ProMinent 1081318 User manual

ProMinent

ProMinent Dulcodes M User manual

ProMinent

ProMinent CHLORINSITU IIa User manual

Popular Water Filtration System manuals by other brands

Atlantic Ultraviolet

Atlantic Ultraviolet Mighty Pure MP16A owner's manual

SunSun

SunSun CBG-500 Operation manual

Hayward

Hayward XStream Filtration Series owner's manual

Contech

Contech DownSpout StormFilter Operation and maintenance

Teka

Teka Airfilter MINI operating instructions

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual

STA-RITE

STA-RITE VERTICAL GRID DE FILTERS S7D75 owner's manual