Page 2

6. Exhaust may be remotely vented by installing tubing to the 1/4” NPT port. (E Option)

7. Apply pipe compound or sealing tape to the mail pipe threads prior to installing regulator/filter. Use caution to prevent the sealant from getting

inside the regulator/filter.

OPERATION

1. Prior to turning on supply air, back off adjusting screw until there is no compression of the range spring.

2. After applying the air supply, outlet pressure will be increased by rotating the adjustment screw clockwise. Pressure can be decreased by

turning counter clockwise.

3. Tighten locknut to maintain desired pressure setting.

MAINTENANCE

1. To remove condensate, from the Type-330/335/345, slowly open drain valve by turning clockwise and bleed accumulated liquid.

2. To clean filter element (Type-330/335/345)

a) Shut off supply pressure and relieve all internal pressure.

b) Drain condensate from drip well.

c) Remove four corner bolts from bottom of unit and remove drip well housing.

d) Remove filter retaining screw.

e) Remove filter retainer, filter o-ring seals and filter.

f) Clean parts and reassemble in reverse order.

3. To clean/replace pintle assembly

a) Follow steps (a) through (d) above.

b) Unscrew collar and remove. (1/2” NPT only)

c) Remove pintle spring. The Type-340 does not contain a filter or collar. The pintle and pintle spring will be accessible upon removal

of base.

d) Clean or replace parts as required. Apply a high quality lubricant to all cleaned or replaced o-ring seals.

e) Reassemble in reverse order.

4. To clean/replace diaphragm assembly

a) Back out the adjusting screw until the spring is no longer compressed.

b) Remove the four bonnet screws and separate the bonnet from the body of the regulator. Remove the spring guide and spring.

c) Remove the diaphragm assembly, clean or replace it as necessary and reassemble in reverse order. After placing the diaphragm

assembly on the body, push down the assembly to make sure that the pintle is seated properly and strokes smoothly.

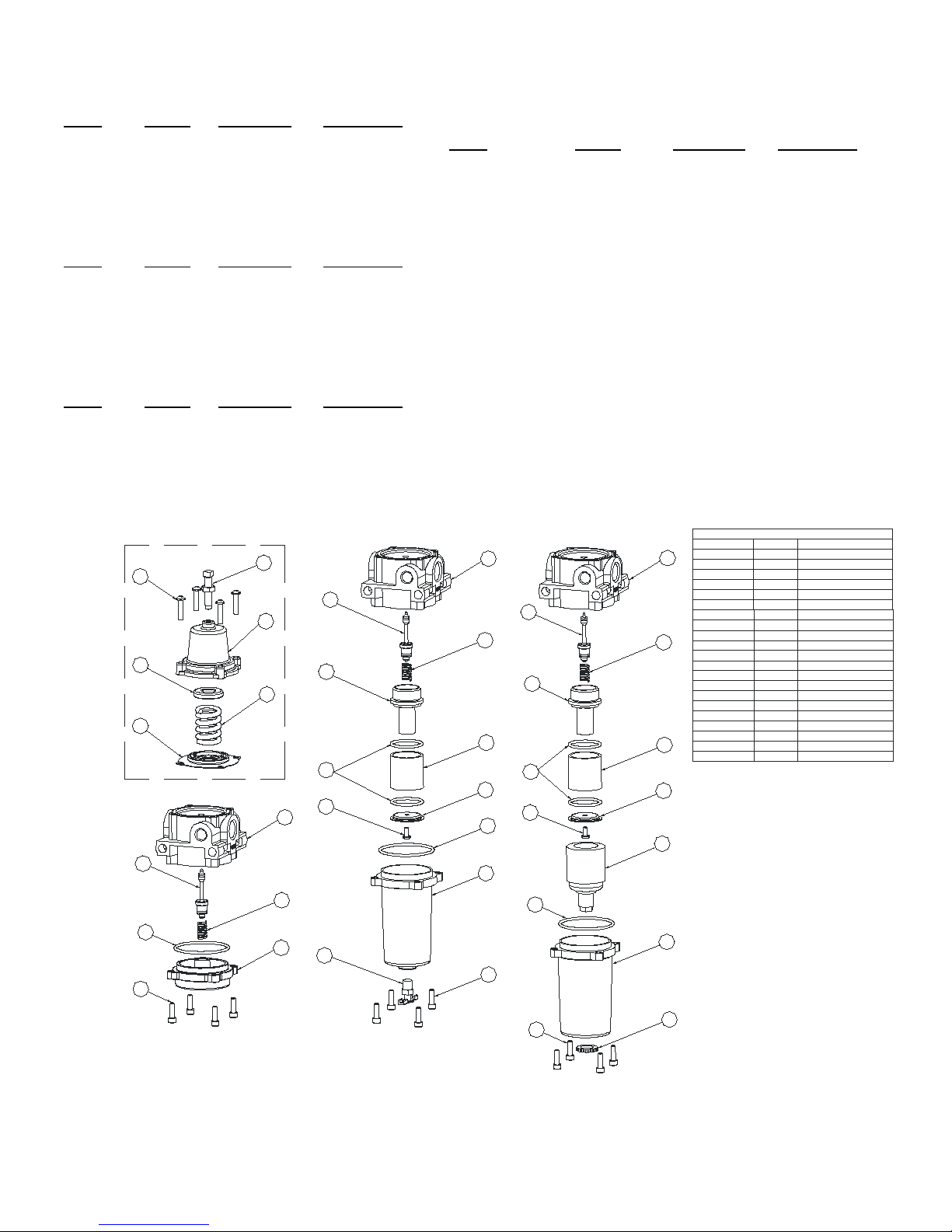

5. Repair kits/replacement parts

a) Repair kits include all parts marked with an asterisk (*).

b) Order kit as described in exploded view below

c) Shut off supply air. Back out adjusting screw

d) Remove four corner bolts from bottom of the unit and four screws on top and remove all parts.

e) Replace all parts that show excessive wear. Apply a high quality lubricant to all cleaned or replaced o-ring seals.

f) Clean all parts and replace in reverse order

WARNING:Only qualified personnel should install or service a regulator. Regulators should be installed, operated, and maintained in

accordance with international and applicable codes and regulations, and ControlAir instructions. If the regulator vents fluid or a leak

develops in the system, it indicates that service is required. Failure to take the regulator out of service immediately may create a

hazardous condition. Personal injury, equipment damage, or leakage due to escaping fluid or bursting of pressure-containing parts may

result if this regulator is over pressured or is installed where service conditions could exceed the limits given in the Specifications section,

or where conditions exceed any rating of the adjacent piping or piping connections. To avoid such injury or damage, provide pressure-

relieving or pressure-limiting devices (as required by the appropriate code, regulation, or standard) to prevent service conditions from

exceeding limits. Additionally, physical damage to the regulator could result in personal injury and property damage due to escaping fluid.

To avoid such injury and damage, install the regulator in a safe location. The internal relief valve in the Type-330 regulators does not

provide full overpressure protection. The internal relief valve is designed for minor seat leakage only.

WARNING:To avoid personal injury resulting from sudden release of pressure, isolate the regulator from all pressure before attempting

disassembly.

WARNING:To avoid personal injury, property damage, or equipment damage caused by sudden release of pressure or explosion of

accumulated gas, do not attempt any maintenance or disassembly without first isolating the regulator from system pressure and relieving all

internal pressure from the regulator.

WARNING:The materials of the Type-330/335/340/345 are compatible with natural gas. The user should be warned, however, that the

Type-330/335/340 regulator/filter may vent some gas to the atmosphere. In hazardous or flammable service, vented gas may accumulate

and cause personal injury, death, or property damage due to fire or explosion. If regulator is used in a hazardous gas service area, the

regulator must be vented to a remote, safe location away from air intakes or any other hazardous area. The vent line or stack

be protected against conden

sation or clogging. Do not use these products where pressure and temperatures can exceed those listed under

specifications.