PROMIX SHERIFF-1 premium User manual

30.08.2017

2

3

b

4

b

5

7

6

1

4а

8

3а

SHERIFF-1 premium

ELECTROMECHANICAL LOCK

OPERATING MANUAL

TU 3428 – 003 – 80210527 – 14

PATENT OF INVENTION №238261

1. APPLICATION

Electromechanical lock "Sheriff-1 premium" is designed for locking hinged doors, opening inward and outward, with a possibility of

remote opening them with the controllers of access control systems, audio and video door phones, code access panels. The lock

design and the method of installation allowyou to place the lock indoor and outdoor of protected premises.

2. OPERATING CONDITIONS

Climatic operating conditions:

- ambient air temperature: from -40 to +50°С;

- relative air humidity not more than 95% at 35°Сand with lower temperatures without condensation and frost formation;

- installing indoors in any type of doors;

- resistance to the environmental exposure complies with GOST 15150-69:UHL2.

3. TECHNICAL SPECIFICATIONS

The lock "Sheriff-1 premium" is produced in the normally open type (or fail-safe), the lock remains open when the voltage

supply is off and is closed when the voltage supply is on. The lock has two integrated sensors: of the door position and of the lock

status.

Integrated sensor of the door position consists of the reed switch placed on the lock case and the magnet placed on the

movable bush of the lock and moved by the deadbolt. The reed switch contacts are open when the door is open (the deadbolt is out

of the lock) and are closed when the door is closed (the deadbolt abuts to the lock).

Integrated sensor of the lock status consists of the reed switch fixed to the electromagnet coil of the lock. The reed switch

contacts are open when the voltage supply is off, and are closed when the current flows on the coil.

Thus, if insert consistently both sensors in the circuit, then the circuit will be closed only when the deadbolt is in the lock (the

door is closed) and the lock draws current (the status is closed).

* Note: 1. The lock in this delivery set (see Para. 4) is designed to be mounted on the door with the door stop width more than 25,5mm

and the door leaf thickness 25-45mm. To mount the lock on the door with other dimensions needed to use the Additional

fixation set (see the Operating Manual).

2. The length of the bolt М8х35 for

deadbolt

fixing (without head) should be less than the thickness of the door on 3-7mm

(shorten the bolt if needed).

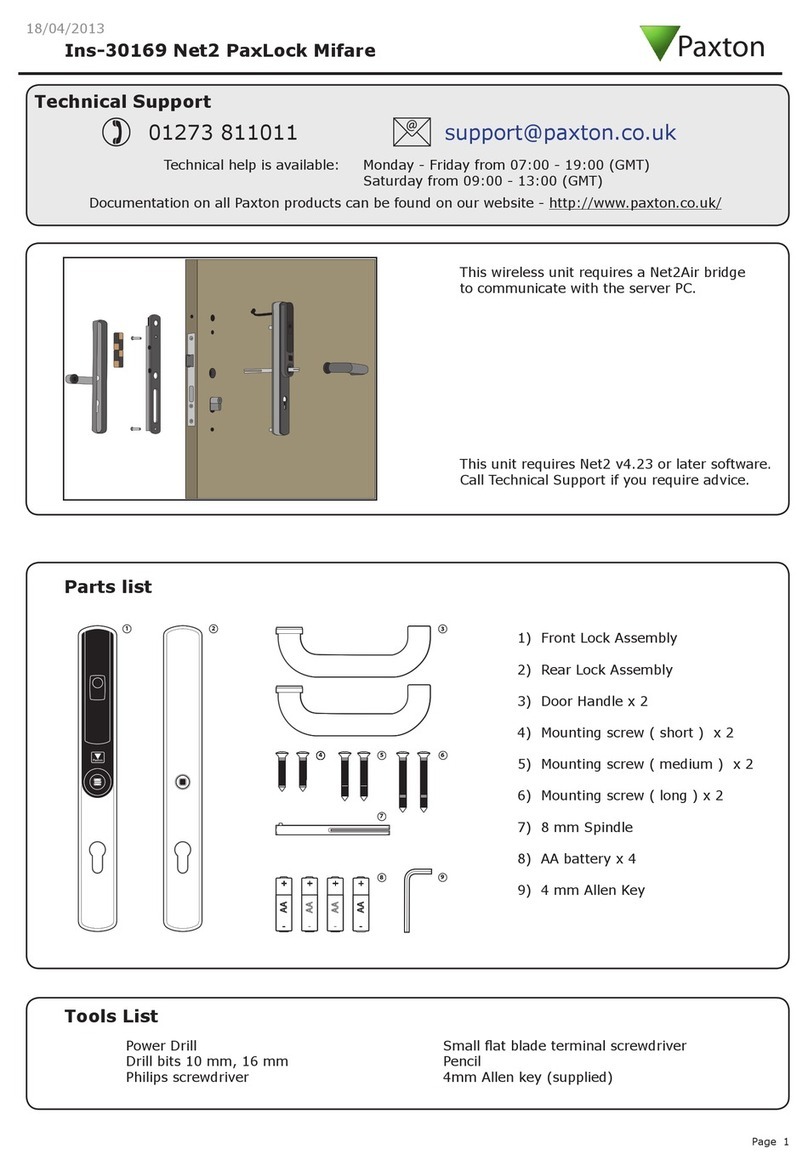

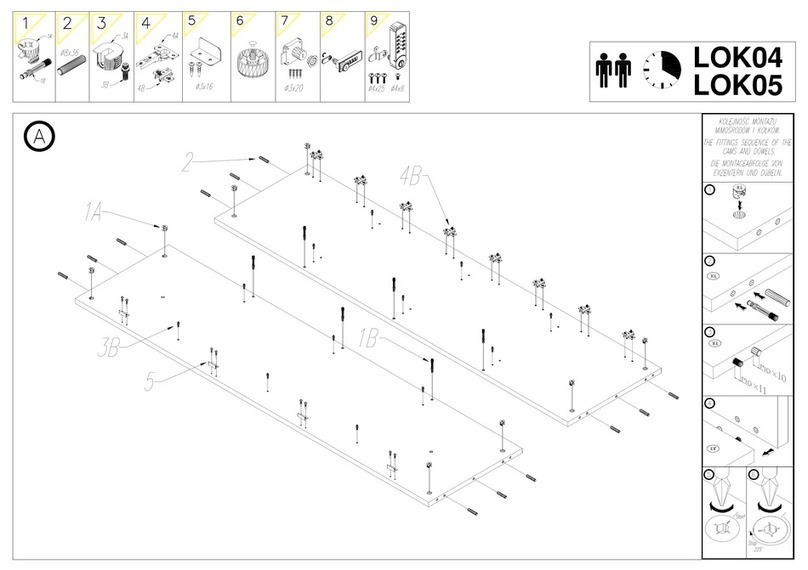

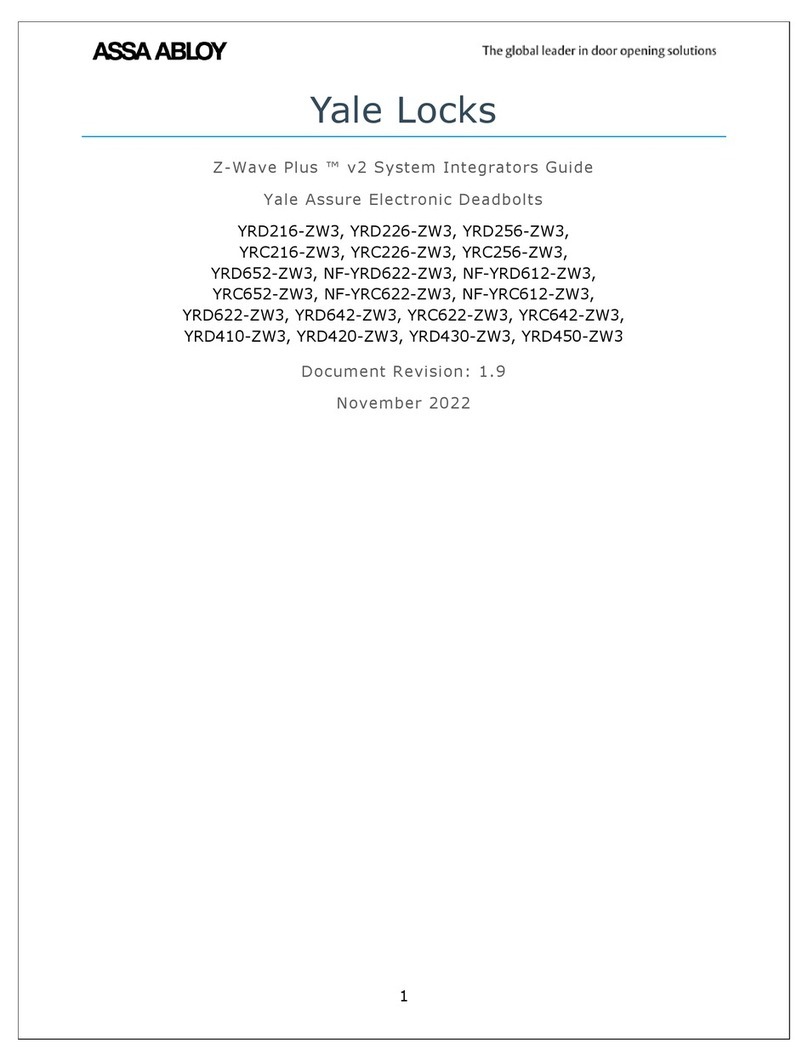

4. DELIVERY SET

1 – Lock 1 pc.

2 – Bracket 1 pc.

3а– Binder bolt M4 for lock fixing 2 pcs.

3б– Screw М4 2 pcs.

4а– Screw 4х30 for bracket fixing 2 pcs.

4б– Countersunk screw 4х30 for bracket

fixing 2 pcs.

5 – Deadbolt assembly 1 pc.

6 – Bolt М8х35 for deadbolt fixing 1 pc.

7 – Template for brackets fixing 1 pc.

8 – Marking tool 1 pc.

9 – Operating manual 1 pc.

10 – Additional fixation set 1 pc.

Check completeness of the delivery set while purchasing.

Subsequently, the company-manufacturer does not accept any claims over completeness of the delivery set.

The maximum current of the reed

switches, A, not more than 0.5

The

maximum

voltage

of

the

reed

switches, V, not more than

36

Product type

normally open

Door leaf thickness, mm

25-70*

Possible adjustments

of the locking bolt length;

automatic deadbolt

alignment in the lock

opening

Holding force, kg, no less than 400

DC voltage supply, V

10 - 15

Current consumption

(12

V

),

m

А

,

not

more than

105

L

ock

weight

,

kg

,

not more than

0.3

Dimensions (WхHхL), mm

34х30х130

Four wire cable and power cable

length, m

0.3

Reliability of operation cycles, not

less than

400, 000

Color:

□

white,

□

silver,

□

brown

Production date:

30.08.2017

5. INSTALLATION AND WIRING

The lock should be mounted in the place protected from the direct

It is recommended to install the lock in

conjunction

its service life.

The lock design and the method of

installation

ATENTION!!! 1) When the door

is closed

2) The lock does not operate, when

the

the door - for instance, the door

handle

When the lock is correctly set,

the necessary

open lock during the power supply

may not closed

5.1 INSTALLATION OF THE LOCK

ATENTION!!! (The possibility to use

this

outdoor) is determined by the installer

company

the level of premise accountability, assignment of access restriction

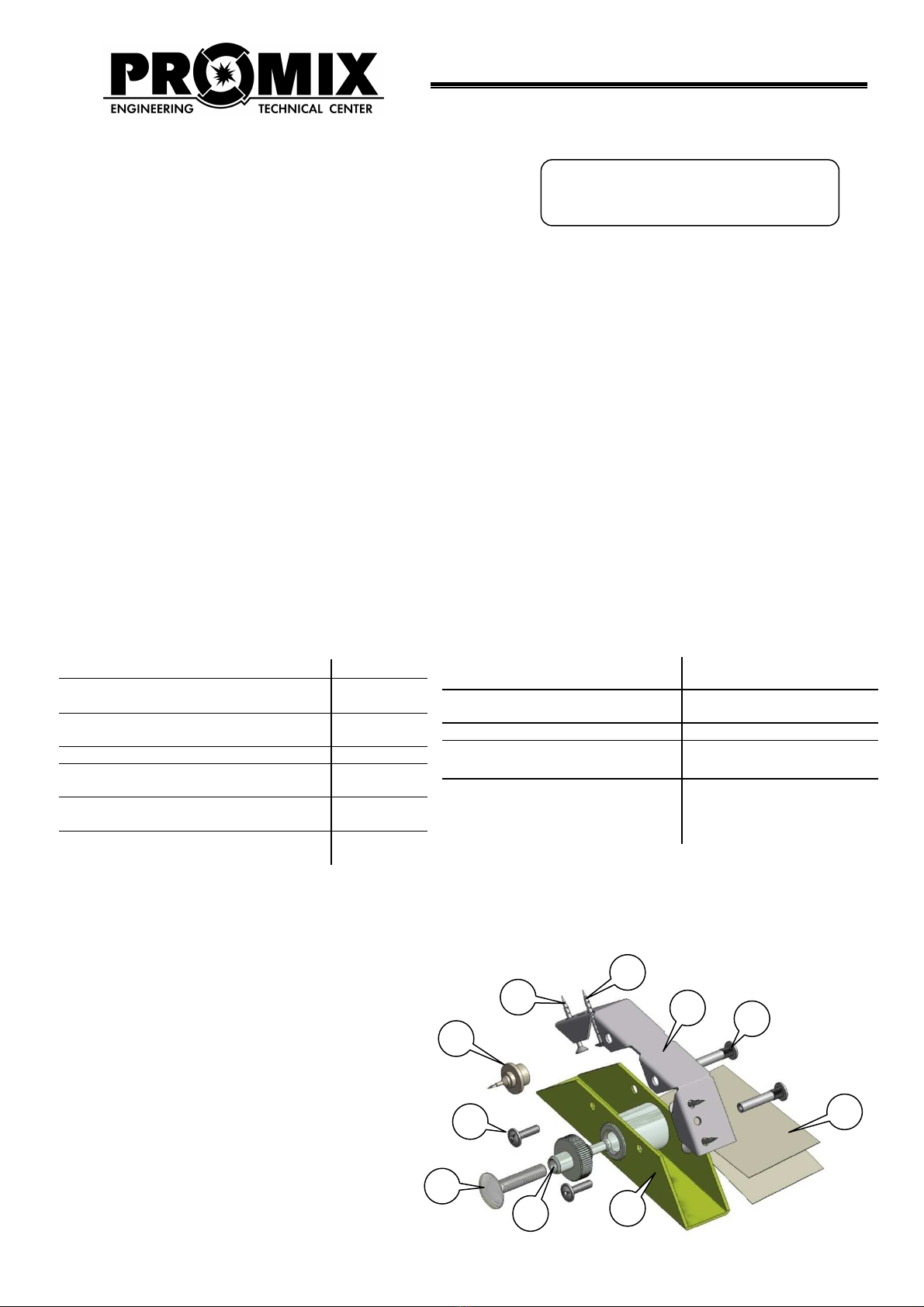

1. Close tightly the door.

2. Place the template 7 above the door

handle

of the door frame. Press down firmly the

marked

template to the door leaf.

3. Puncture th

e template with an awl to mark

holes in the door frame.

For easy mounting of the lock

BE VERY PRECIS

E WHILE MARKING

4. Drill the marked centers of the holes in

the

2mm-diameter-holes for bracket fixing,

5mm-diameter-hole for power cable.

6. Pass the power cable and the four-wire

cable

through the prepared hole; mount the

lock

Rotate binder bolts 3аaround their

axis achieving their easy

insertion in holes and fix them with screws

DO NOT DAMAGE CABLES

WHILE INSTALLING BIN

BOLTS!

DOOR

DOOR

FRAME

2

3

b

2

The lock should be mounted in the place protected from the direct

moisture ingress.

conjunction

with a door closer – it decreases the

impact

installation

allow you to

place the lock indoor and outdoor of protected premises.

is closed

, the deadbolt should be inserted in the lock

to the stop

the

door is in a "tension" state, i.e.

there is an external effort applied for opening

handle

is pulled.

the necessary

clearance (gap) of the door is

2.5-3

mm

.

may not closed

(see Para. 6)!

this

lock to restrict access to premises and the place

of

company

based on the characteristics of the design

and

the level of premise accountability, assignment of access restriction

and other factors (security,

handle

in the top corner

marked

edge of the

e template with an awl to mark

the centers of the

For easy mounting of the lock

E WHILE MARKING

!

the

door frame

5. Fix the bracket 2 with 2 pan

head

countersunk screws 4b.

cable

of the lock

lock

1in the bracket 2.

axis achieving their easy

insertion in holes and fix them with screws

3b.

WHILE INSTALLING BIN

DER

7.Insert the marking tool 8in

the lock

8.Close the door and

press it with an effort

9.

On the door remains the mark, where it is necessary to drill

the through hole 8mm in diameter.

pronounced if

previously to stick on the door the piece of

adhesive tape, duct tape, etc.

7

1

2

1

2

3

4

8

3

a

impact

load on the lock and increases

place the lock indoor and outdoor of protected premises.

to the stop

.

there is an external effort applied for opening

.

If the gap is less, the normally

of

mounting the lock (indoor or

and

the method of installation,

and other factors (security,

CCTV).

head

screws 4аand 2

the lock

1opening.

press it with an effort

.

On the door remains the mark, where it is necessary to drill

the through hole 8mm in diameter.

The mark will be more

previously to stick on the door the piece of

adhesive tape, duct tape, etc.

4

a

Press the

door with

an effort

4

b

30.08.2017

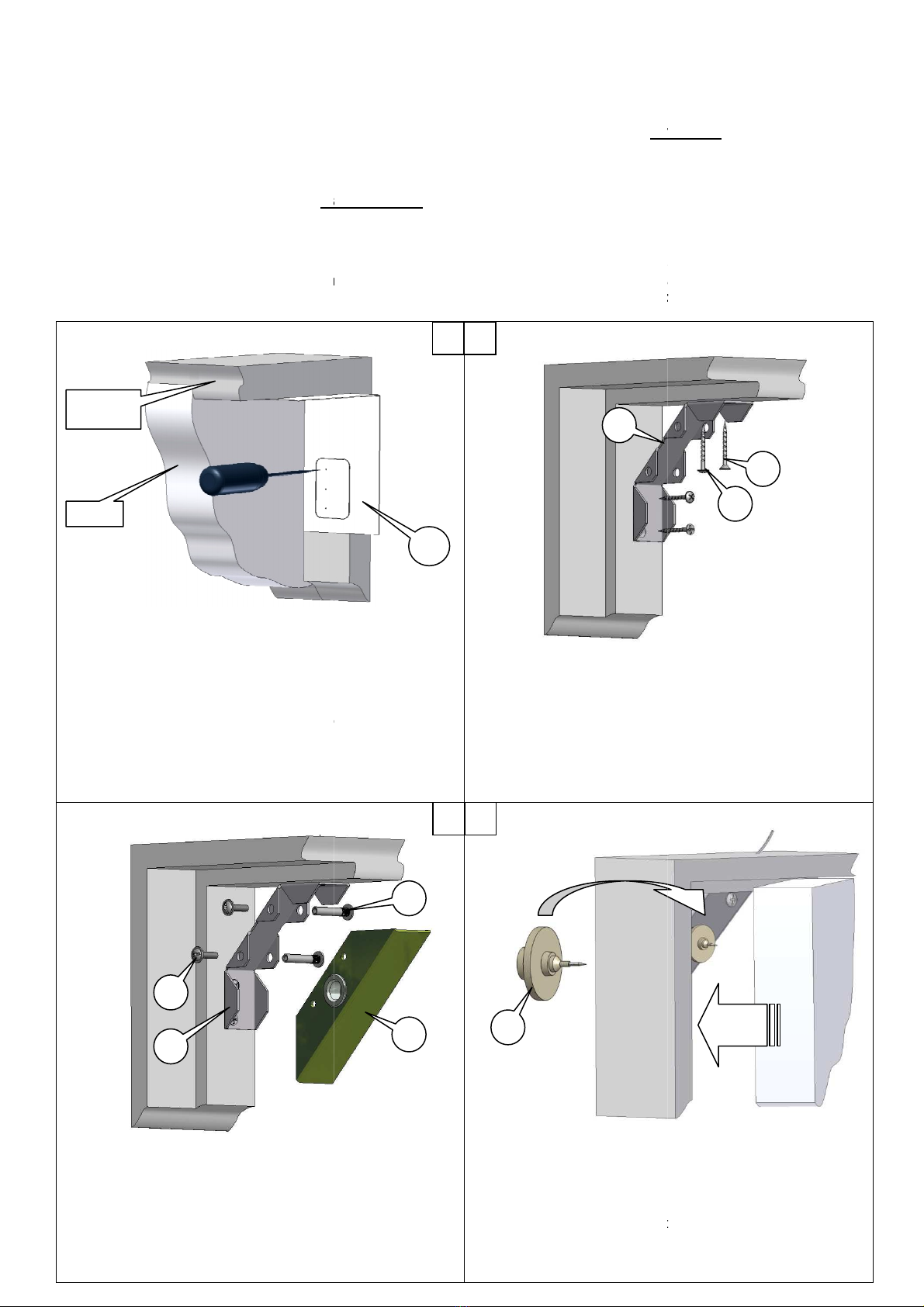

10. Drill the hole in the door where the

deadbolt

10mm in diameter to a depth not less than

11. Insert the bolt 6 in the outside of the

door

hitting it with a hammer.

12. Insert the deadbolt 5in the other side

of

manually tighten it to block. To provide

one may insert in the side of the

deadbolt

rod, a nail, a drill, an awl, etc. (

not included in delivery

While installing the lock and the deadbolt, it is necessary to comply with their axial alignment within the permissible clear

of the deadbolt.

5.2 WIRING ORDER

The lock operates when applying and

interrup

switch (button). Controller installation is

done accord

Attention:

power of the lock is supplied by the voltage from 10 to 15 V of

When the power supply is on the lock is closed, when it is off the lock is open.

The wire assignment:

Red (black with red stripe) –

positive pole of the power supply;

Black –

negative pole of the power supply;

(The reverse polarity voltage supply

does

White, Green – sensor output of

the lock status

Brown, Yellow – sensor output of

the door position

Provide reliable electrical contact. I

solate the connection points to

6. POSSIBLE FAILURES,

INSTALLATION PROBLEM

Failures

and problems

Enlarged clearance

of

the

deadbolt

(more than 2.5mm) when the lock is

closed

The deadbolt does not hold the lock

(the door does not close)

The large gap is between the door

and the door frame during closing the

door (the deadbolt abuts to the lock)

When the status is

"

open

"

, but

the

door does not open. To open the

door needed to press it tighter to the

door frame

During

operation

the

door

is

sagging

(automatic centering of the deadbolt

lacked), as a result the deadbolt

does not reach into the lock opening,

or when it reaches the lock, the

deadbolt clings

The deadbolt does not reach the end

of the lock opening ("balls are stuck")

5

min 16

10 8

Necessarily

of the hole to the door

3

deadbolt

5is fixing,

10mm in diameter to a depth not less than

14mm.

door

and press on it,

of

the door, and

easy tightening

deadbolt

opening a metal

not included in delivery

).

13.

If it is necessary, arrange the length of the

14.

The lock installation is done

While installing the lock and the deadbolt, it is necessary to comply with their axial alignment within the permissible clear

interrup

ting the power supply, and for it

is usually used a controller (contro

done accord

ing to the technical data sheet.

power of the lock is supplied by the voltage from 10 to 15 V of

the direct current.

When the power supply is on the lock is closed, when it is off the lock is open.

positive pole of the power supply;

negative pole of the power supply;

does

not provide operability of the lock, but does not

damage

the lock status

;

the door position

.

solate the connection points to

avoid short-circuiting.

INSTALLATION PROBLEM

S AND TROUBLESHOOT

Troubleshoot

Reduce the length of the locking bolt

. For this purpose

one hand, screw the locking bolt

to the nut with the other hand (or combination

pliers).

Set the lock in the "closed" status (turn on the vo

ltage

polarity and make sure that the power supply corresponds with the required

one.

Fix the knurled nut with one hand, unscrew the

locking bolt

the other hand (or combination pliers).

Fix the knurled nut with one hand, screw the

locking bolt

other hand (or combination pliers).

•Eliminate the causes

of loose fit of the door to the door frame.

•Use the door closer.

•Increase the length of the deadbolt.

Re-establish the door position. If it is impossible,

remove the fastener of

deadbolt from the door. Drill

out a hole in the door with a larger diameter.

Mount the deadbolt

on the door, providing alignment with the lock opening.

Turn off the power supply of the lock. Insert tightly

the steel rod

drill bit, etc.) with diameter 3-

5mm in the lock opening and pull it out.

6

5

6

Necessarily

provide

the

perpendicularity

of the hole to the door

surface!!!

If it is necessary, arrange the length of the

locking bolt.

The lock installation is done

.

While installing the lock and the deadbolt, it is necessary to comply with their axial alignment within the permissible clear

ance

is usually used a controller (contro

l board) or a

the direct current.

damage

it).

. For this purpose

, fix the knurled nut with

to the nut with the other hand (or combination

ltage

supply). Check the

polarity and make sure that the power supply corresponds with the required

locking bolt

from the nut with

locking bolt

to the nut with the

of loose fit of the door to the door frame.

remove the fastener of

the

out a hole in the door with a larger diameter.

on the door, providing alignment with the lock opening.

the steel rod

(screwdriver,

5mm in the lock opening and pull it out.

30.08.2017

4

7. MAINTENANCE

Maintenance of a lock is performed at least once per two months and includes:

- Examination of the lock to check fixation reliability. If it is necessary, tighten up fixing elements of the lock and the deadbolt.

- Check the length of the locking bolt. In case if the locking bolt abuts to the lock, and this is causing a loose fit of the door to

the door frame, or when the door is closed and the lock does not hold the deadbolt - it is necessary to adjust the length of the

locking bolt (see para.6 of the Operating Manual).

The lock does not need lubrication.

8. MANUFACTURER'S WARRANTY

Engineering & Technical Center PROMIX, LLC guarantees the conformity of the electromechanical lock "Sheriff-1 premium" to

the requirements of applicable TU standards under the regulations of operation and installation established in this operating

manual. The warranty period is 18 months commencing from the date of acceptance by Quality Control Department.

Within the warranty period, Engineering & Technical Center PROMIX, LLC undertakes to repair the defective product free of

charge. The shipping cost to the place of repair and back shall be borne by the Buyer.

The warranty shall not cover defects or damages, resulting from:

- improper maintenance by the Buyer;

- using the lock in conditions that do not conform to the operating requirements;

- mechanical damages or disassembly of the lock by the Buyer;

- violation of transportation and storage regulations.

PACKING AND ACCEPTANCE CERTIFICATE

Electromechanical lock "Sheriff-1 premium" with the specified date of manufacture is made and accepted in accordance with TU 3428–

003–80210527–14, obligatory requirements of state standards and applicable technical documents, found fit for service and packed

by Engineering & Technical Center PROMIX, LLC.

QCD seal

Engineering & Technical Center PROMIX, LLC

Russia, 214030, Smolensk city, Krasninskoye Hwy, 35

Tel. (4812) 619-330

www.itc-promix.ru RUSS RU.ММ07.Н00002

PATENT OF INVENTION №238261

Please send us all your comments and suggestions concerning our products via e-mail: [email protected].

Thank you in advance!

30.08.2017

5

SHERIFF-1 premium

ELECTROMECHANICAL LOCK

INSTALLATION MANUAL

ADDITIONAL FIXATION SET

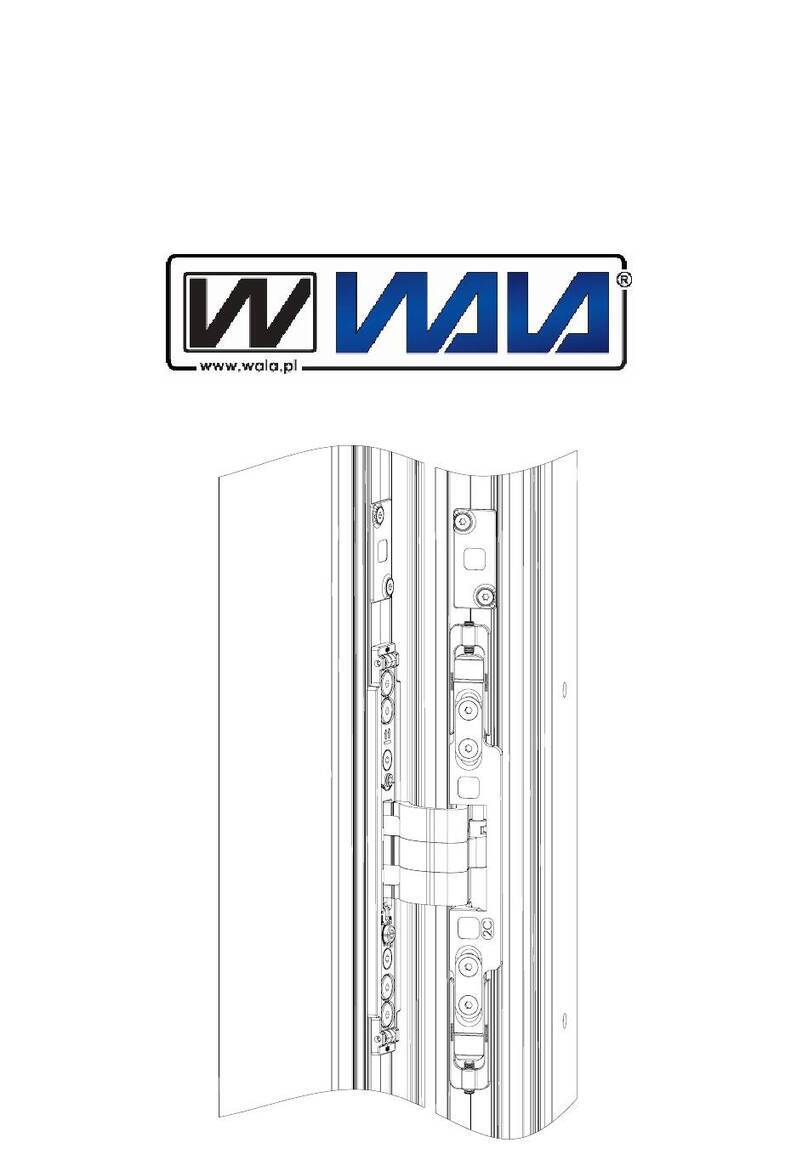

1. APPLICATION

The additional fixation set is designed for mounting Electromechanical lock "Sheriff-1 premium" on the metal, plastic, wood and

other doors with the door stop width from 0 to 25.5mm and the thickness of the door leaf 45-70mm.

2. DELIVERY SET

1. Left angular bracket with hole pattern 1 pc.

2. Right angular bracket with hole pattern 1 pc.

3. Bolt М8х35 for deadbolt fixing 1 pc.

4. Screw М4х8 4 pcs.

5. Nut М4 4 pcs.

6. Locking washer for М4 4 pcs.

7. Installation manual 1 pc.

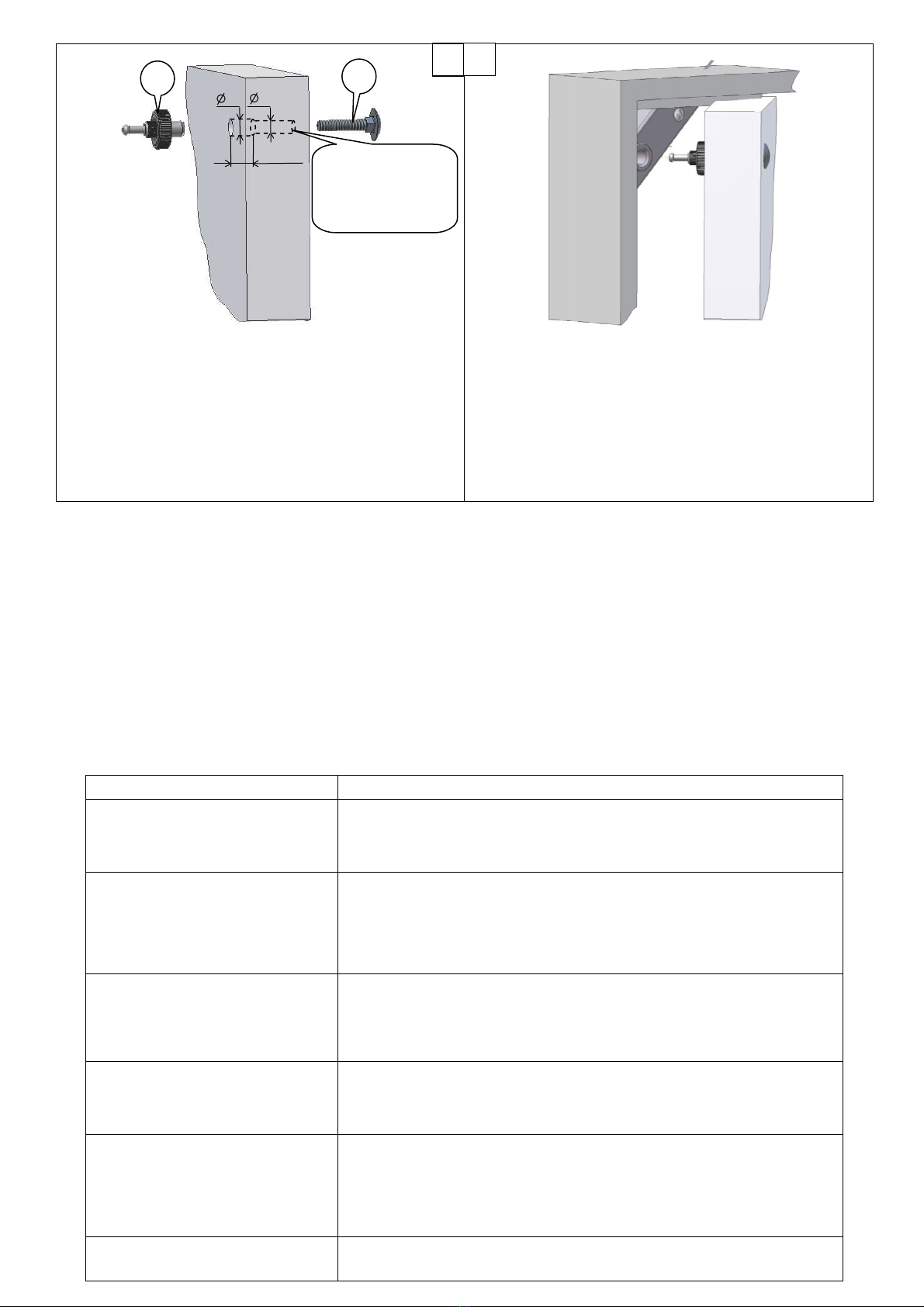

3. INSTALLATION OF THE LOCK

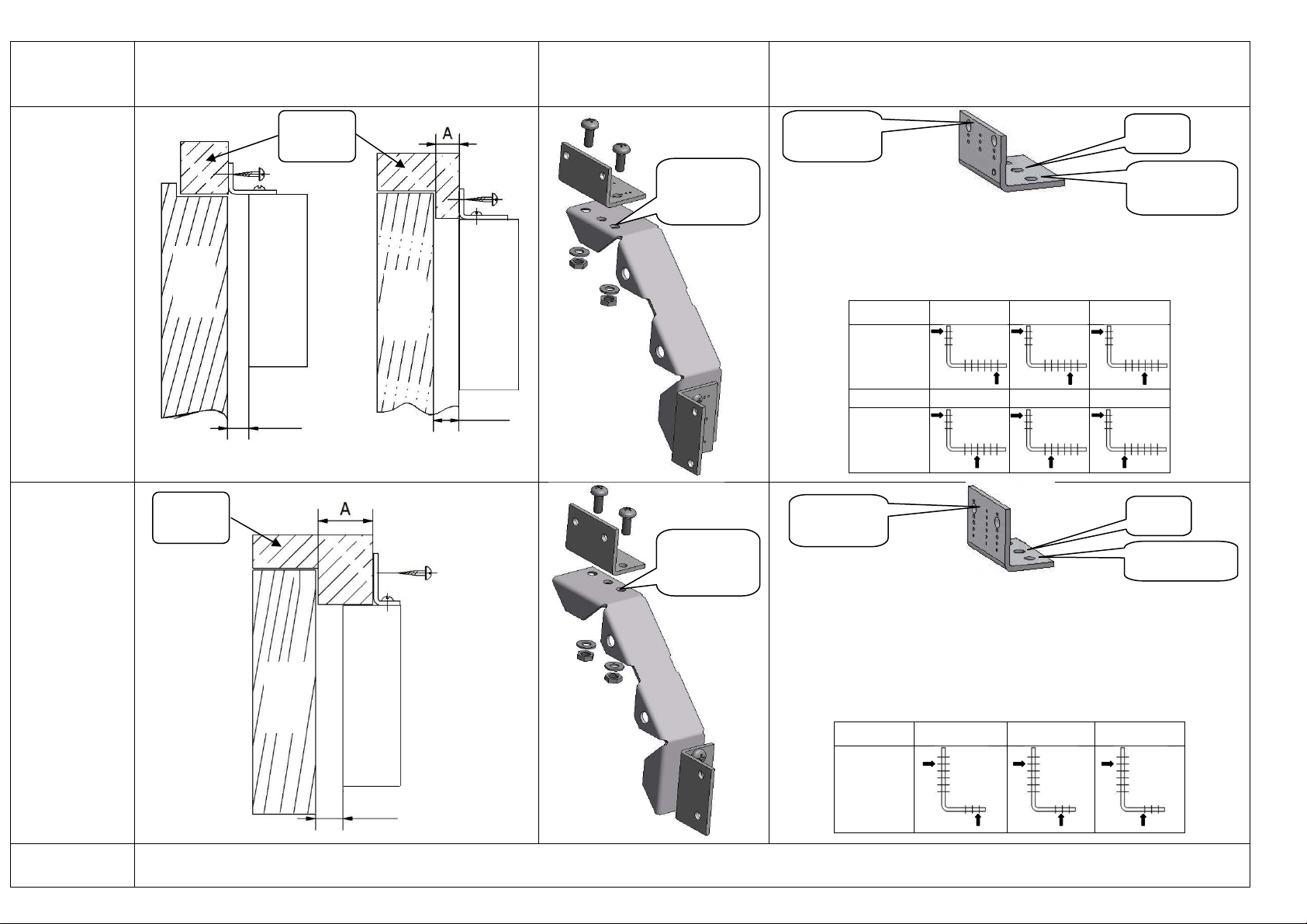

Mounting of the lock depends on the door stop width A (see next page). Drill in specified location (see Table 1, 2) of the

angular bracket 5 holes in diameter 4.2...4.7mm: for fixing to the lock bracket (2 pc.), for power cable (1 pc.), for fixing to the door

frame (2 pcs.). Fix with screws angular brackets and the lock bracket. Fasten the brackets to the lock. Fix the lock to the door

frame. Plug the lock, mark and mount the deadbolt to the door in accordance with the Operating Manual.

In all versions of lock mounting it is necessary, that the distance between the door and the lock case will be from 10 to 13.5mm. The

length of the locking bolt, established for the distance from the door to the lock case - 10mm, is 26.5 mm. When the distance is more,

adjust the length by unscrewing the locking bolt. Herewith the length of the locking bolt should not be more than 31mm (see Fig. 1)!

The length of the bolt М8х60 for the deadbolt fixing (without head) should be less than the thickness of the door on 3-7mm

(shorten the bolt if needed).

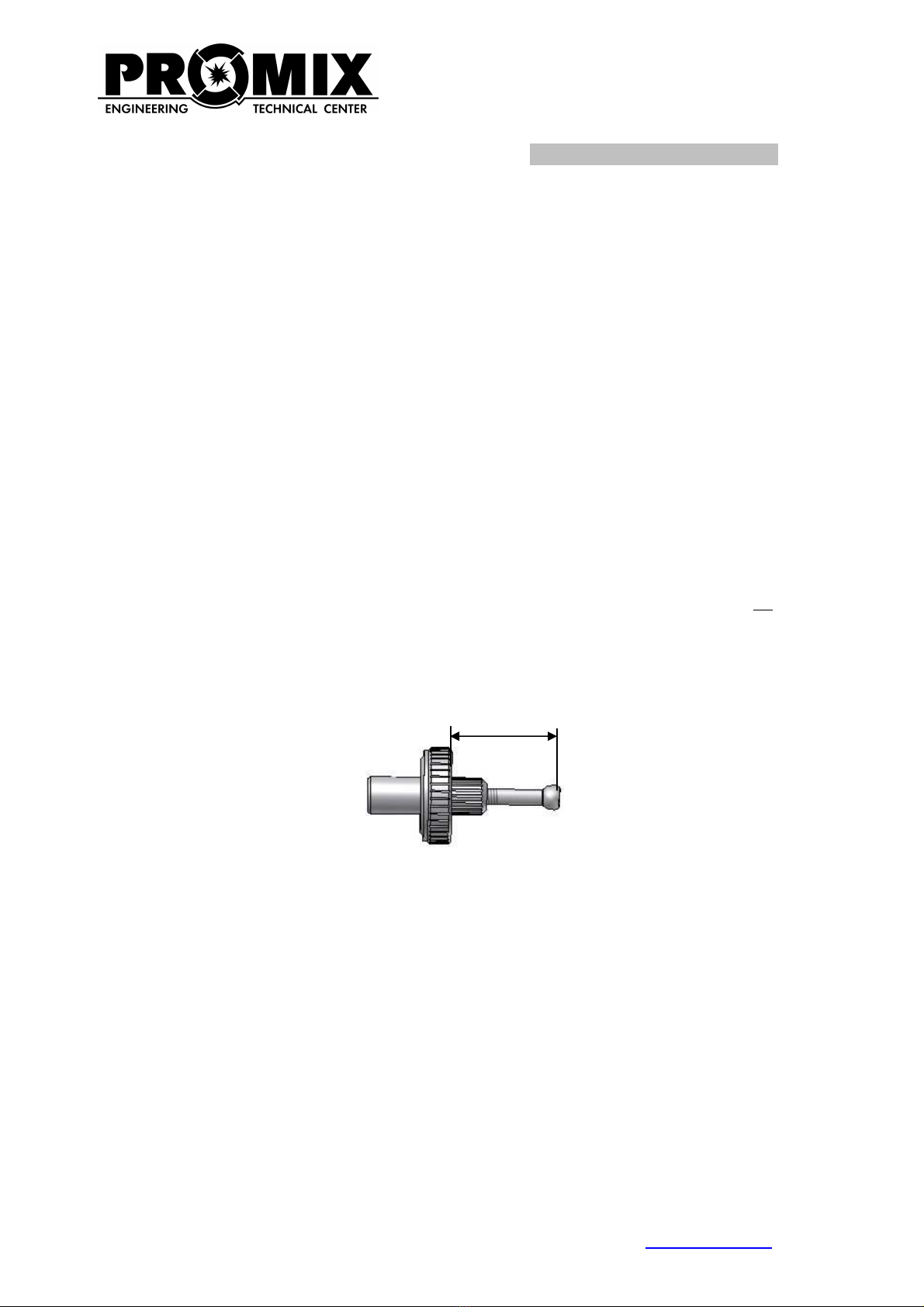

Fig. 1. The length of the locking bolt

Engineering & Technical Center PROMIX, LLC

Russia , 214030, Smolensk city, Krasninskoye Hwy, 35

Tel. (4812) 619-330

www.itc-promix.ru

Please send us all your comments and suggestions concerning our products via e-mail: [email protected].

Thank you in advance!

26.5

÷

31

6

Door stop

width А(see

Fig.) Installation option Assembly order Explanations

0…17mm

Depending on the door stop width A drill five holes in

diameter 4.2...4.7mm at specified locations of the angular

bracket (see Table 1). Table 1

А, мм 0…2.5 2.5…5.0 5.0…7.5

Holes

drilling

location

А, мм 7.5…10 10…12.5 12.5…17.0

Holes

drilling

location

17…25.5mm

Depending on the door stop width A drill five holes in

diameter 4.2...4.7mm at specified locations of the angular

bracket (see Table 2).

Swap and turn over the lock brackets during the

installation. Table 2

А, мм 17.0…20.5 20.5…23.0 23.0…25.5

Holes

drilling

location

25.5mm and

more The lock fixing carried out in accordance with the Operating Manual.

LOCK

Door

frame

LOCK

LOCK

Door

frame

DOOR

DOOR

DOOR

Locations of

fixing to the

door frame

Locations of

fixing to the lock

bracket

Cable

location

Locations of

fixing to the

door frame

Cable

location

Locations of fixing

to the lock bracket

Please note the

holes locations!

Please note the

holes locations!

10

mm

10

mm

10

mm

Table of contents