Pronomic Squeeze&Turn 19472 User manual

Squeeze&Turn

Model 19472

Also for: 19473, 19476,

19477, 19478

User’s manual

Original instructions

It is important that you read and understand this manual before the attachment is used.

Questions? –Contact your supplier or the manufacturer.

Pronomic AB

Street address:

Domherrevägen 15

192 55 Sollentuna

Postal address:

Box 5504

192 05 Sollentuna

Phone: 08-544 706 60

Fax: 08-544 706 70

E-mail: info@pronomic.se

www.pronomic.se

R181210

Table of Contents

1Description of the attachment Squeeze&Turn ...................................................................4

1.1 Warranty...................................................................................................................................... 4

2Assembly............................................................................................................................5

2.1 Disassembly and scrapping ......................................................................................................... 5

3Use.....................................................................................................................................5

3.1 Rotate .......................................................................................................................................... 5

3.2 Grip and lift.................................................................................................................................. 5

3.3 Moving the load........................................................................................................................... 5

3.4 Release......................................................................................................................................... 6

3.5 Adjustment of the squeeze arms ................................................................................................ 7

4Safety.................................................................................................................................8

4.1 Storage and transport ................................................................................................................. 8

4.2 Moving......................................................................................................................................... 8

4.1 Loading and unloading ................................................................................................................ 8

5Maintenance......................................................................................................................9

5.1 Every day ..................................................................................................................................... 9

5.2 Every month, or as needed ......................................................................................................... 9

Signs and decals ............................................................................................................................................ 9

5.3 Troubleshooting ........................................................................................................................ 10

6Technical data..................................................................................................................11

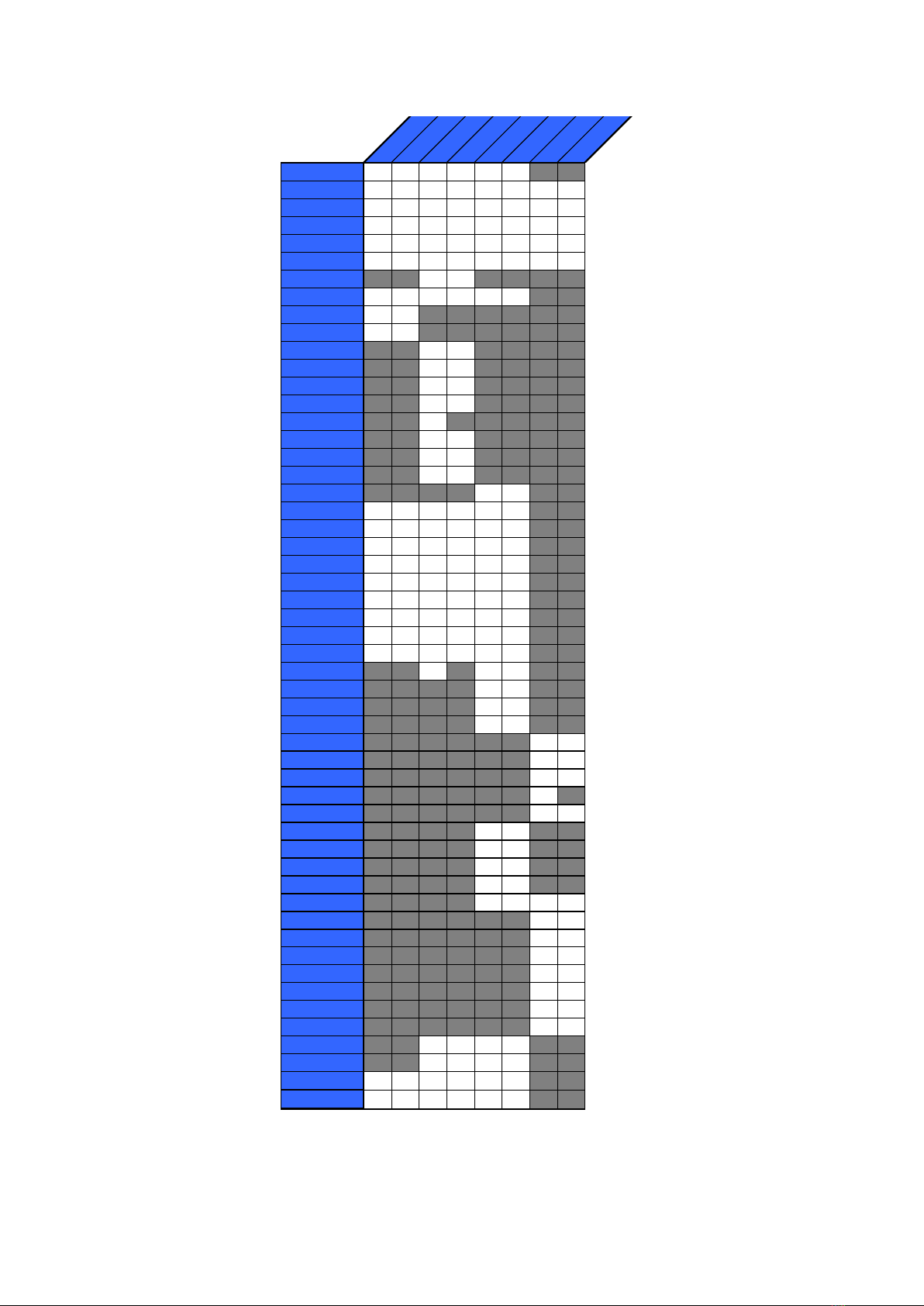

7Approved attachments for Lift&Drive trolleys.................................................................12

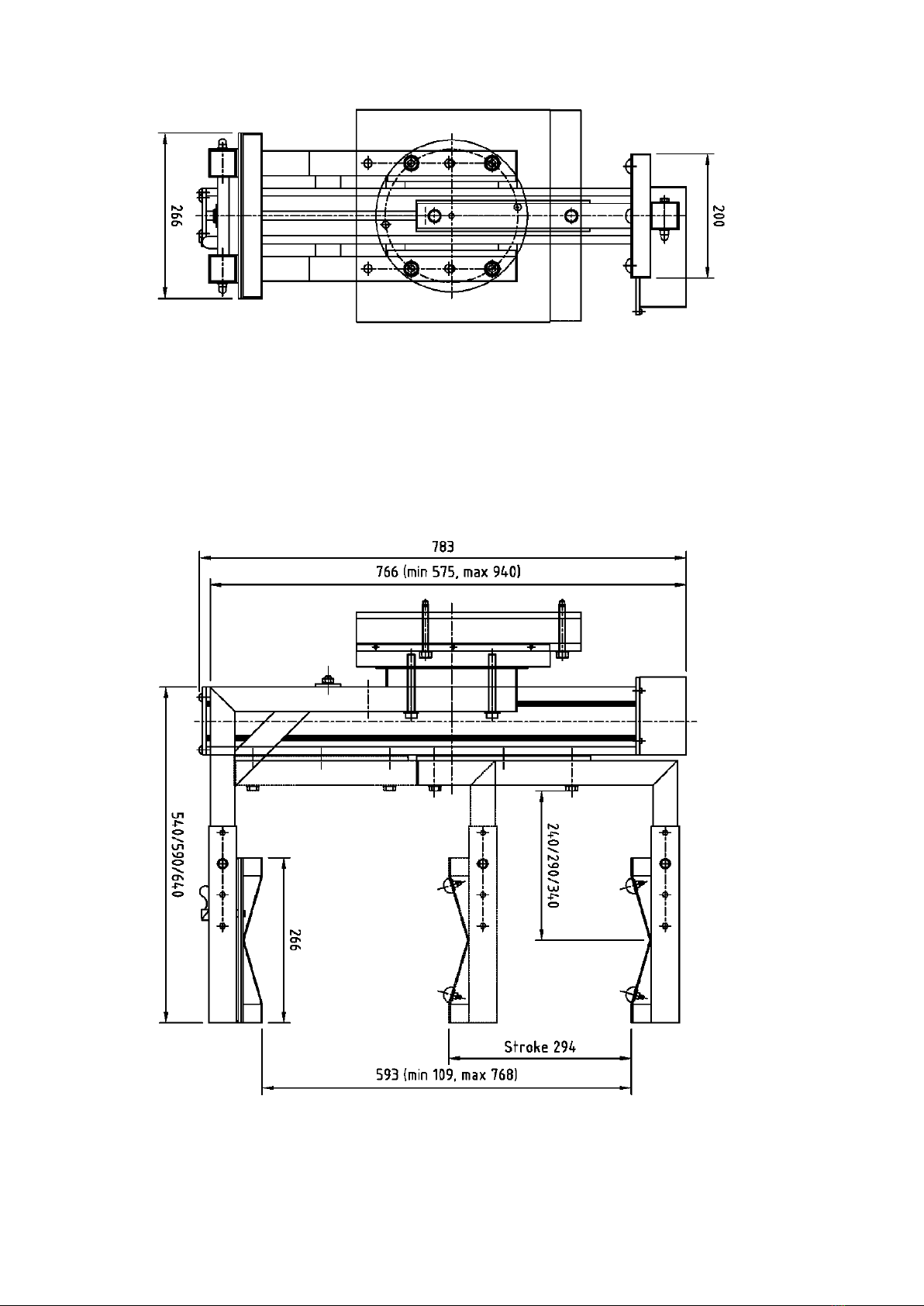

8Drawings ..........................................................................................................................13

8.1 19473 Squeeze & Turn, 60 kg, standard arms .......................................................................... 13

8.2 19477 Squeeze & Turn, 110 kg, standard arms ........................................................................ 14

8.3 19479 Squeeze&Turn, 110 kg, double standard arms.............................................................. 15

8.4 Torque and speed...................................................................................................................... 16

Declaration of incorporation of partly completed machine .....................................................19

________________________________________________________________________________

4 –Squeeze&Turn 19472-19479

1Description of the attachment Squeeze&Turn

Squeeze&Turn is designed to lift/grip and rotate a load. The load is gripped by one or two motor

driven arms squeezing the load. All functions are controlled from the control box on the trolley.

When the load is gripped it can be rotated steplessly with the joystick. The load shall always be

gripped in the center.

The attachment is available in these versions:

19472 Squeeze&Turn, 60 kg, No arms 90P/130P

19473 Squeeze&Turn, 60 kg, Standard arms 90P/130P

19476 Squeeze&Turn, 110 kg, No arms 175P/225P

19477 Squeeze&Turn, 110 kg, Standard arms 175P/225P

19478 Squeeze&Turn, 110 kg, Double, No arms 175P/225P

19479 Squeeze&Turn, 110 kg, Double, Standard arms 175P/225P

Attachments with no arms can be equipped with custom arms. Double refers to two motorized

squeeze arms.

The max load is determined by the model of the trolley and the dimensions of the load. See

chapter 6 “Technical data” for more information regarding loads.

The attachments are only intended to be used with Pronomic AB’s Lift&Drive lift trolleys.

They are only to be used indoors in well-lit environments on level floors.

Additional technical documentation can be ordered from Pronomic AB.

1.1 Warranty

The warranty applies for one (1) year from the date of delivery for material- and manufacturing

errors. For the warranty to apply, maintenance should be carried out according to instructions.

This warranty does not cover normal maintenance, settings or regular adjustments. Neither will

labour costs from such measures be covered by the warranty. Damages caused by abuse or

improper use of the equipment will also void the warranty.

________________________________________________________________________________

5 –Squeeze&Turn 19472-19479

2Assembly

When mounting the attachment, protective shoes should be worn, as the parts can cause injury if

dropped.

2.1 Disassembly and scrapping

When scrapping the attachment and control box should be sent to a recycling center or Pronomic

to guarantee recycling and safe handling of all the consisting parts of the tool.

3Use

It is important for you to read and understand this manual before you begin using your

attachment.

3.1 Rotate

The rotate function is controlled from the control box. To activate this function simply move the

joystick to the left or to the right.

3.2 Grip and lift

The gripping arms should always be positioned in the center of the load (gravity center). Position

the tool using the trolley maneuvering control for up/down and the joystick for rotate. Be sure the

tool will grip the load in a proper way.

Press and hold the squeeze button until it stops and the load is gripped. Make sure the arms have

gripped the load properly and then procced lifting the load.

If the squeeze tool is equipped with one moving arm and one fixed arm position the fixed arm

underneath the roll when loading horizontally. Use the same position when transporting the roll

on the trolley.

3.3 Moving the load

Before moving the load to another location rotate it so that the load is resting on the arms. This is

to prevent the load from slipping out of the gripper due to vibrations. Always lower the tool and

load to the lowest position possible before moving.

________________________________________________________________________________

6 –Squeeze&Turn 19472-19479

Release and inhibit.

Squeeze/ Grip

Rotate

3.4 Release

Lower the load until it rest upon the drop-off surface. To release the load press the release button

and the inhibit button at the same time. Hold until the load is properly released.

The figure below is showing the control box and the different functions.

________________________________________________________________________________

7 –Squeeze&Turn 19472-19479

3.5 Adjustment of the squeeze arms

The squeeze arms are adjustable in both length and height to cover a larger range of roll sizes. The

image below illustrates all adjustments available for the squeeze arms. 60kg Squeeze&Turn (Arms

19421) and 110kg Squeeze&Turn (arms 19423).

________________________________________________________________________________

8 –Squeeze&Turn 19472-19479

4Safety

The operator should use the personal safety equipment (e.g. protective shoes) that handling the

specific goods requires.

Stated maximum load must not be exceeded.

Be aware of the risk of crushing present between the attachment and the trolleys legs or the floor

when raising or lowering the load. Avoid putting hands or other parts of your body under the load.

4.1 Storage and transport

When storing or transporting the trolley the remote control, motor cable and power cable to the

control box should be disconnected.

If the attachment is attached to a trolley when transported, the trolley should be carefully tied

down to minimize the tipping risk.

If the attachment is transported separately it should be carefully packed to protect the expander

and control box.

4.2 Moving

The attachment should always be lowered to the lowest possible position before moving the

trolley to have the safest and most stable handling possible. Be cautious when passing thresholds,

cables and other objects on the floor.

When moving heavy loads the handling can be easier if the directional lock is applied on the

trolley.

4.1 Loading and unloading

The operator is responsible for the correct use of the attachment.

Do not place any parts of your body under the load when lowering the load.

Only use this tool for the intended load. Other loads can be deformed when the gripper applies

pressure on the surface.

________________________________________________________________________________

9 –Squeeze&Turn 19472-19479

5Maintenance

5.1 Every day

T Wipe the attachment clean if it is dirty. Do not use water or pressure washers.

5.2 Every month, or as needed

Make sure the unit sounds normal when rotating and gripping.

Check that the bolts holding the attachment to the mast are correctly tightened.

Check the squeeze arms for any signs of deformation or cracks to the welds.

Check all electrical connections and replace damaged or worn parts.

If needed apply ball bearing grease to the internal parts of the squeeze mast.

Signs and decals

Check that the following signs and decals are attached and are fully legible.

Sign/decal

Description

Placement

Unit designation

Decal with serial number

One decal on the control box

and one decal on the

attachment

Instruction decal

Decal instructing the

operator

Front of the control box

Max load

Max load of the attachment

Back of the attachment

________________________________________________________________________________

10 –Squeeze&Turn 19472-19479

5.3 Troubleshooting

Common faults and solutions.

Other troubles –see the manual for your Lift&Drive trolley.

Contact your dealer or Pronomic AB if the faults cannot be solved using these instructions.

Fault

Action

1

Turn or gripping

function does not start.

A

Check the batteries. Voltage should be 24V.

B

Check the power connection between the trolley and

the control box.

C

Check the motor cable between the turn unit and the

squeeze mast.

3

Rotate and/or gripper is

slow

A

See 1A

4

Turn unit sounds bad

when rotating

A

Se chapter maintenance

________________________________________________________________________________

11 –Squeeze&Turn 19472-19479

6Technical data

Model designation: Squeeze&Turn

Rotate angle: ∞

Speed: (see diagram page 13)

Max vridmoment (see diagram page 13)

Standard models: 19473 19477

Minimum roll diameter 74 mm 162 mm

Maximum roll diameter 640 mm 680 mm

MAX-load 60 kg 110 kg

Weight 43 kg 55 kg

Nominal battery voltage

24 V DC

Noise level

Noise level not exceeding 70 dB(A)

Vibrations

Vibrations level not exceeding 2,5 m/s2

For additional technical data see the manual for your Lift&Drive trolley.

________________________________________________________________________________

12 –Squeeze&Turn 19472-19479

7Approved attachments for Lift&Drive trolleys

70E

90E

90IE

90JE

90P

130P

175P

225P

15012 X X X X X X

15013 X X X X X X X X

15014 X X X X X X X X

15015 X X X X X X X X

15016 X X X X X X X X

15017 X X X X X X X X

15018 X X

15019 X X X X X X

15024 X X

15080 X X

15322 X X

15324 X X

15338 X X

15339 X X

15370-15372 X

16020 X X

16038 X X

16338 X X

17182B X X

17229 X X X X X X

17230 X X X X X X

17230A X X X X X X

17233 X X X X X X

17241 X X X X X X

17710 X X X X X X

17720 X X X X X X

17730 X X X X X X

17740 X X X X X X

17940 X X X

17950 X X

17971 X X

17972 X X

17980 XX

19174 X X

19201 X X

19271 X

19285 X X

19470 X X

19471 X X

19472 X X

19473 X X

19474 X X X X

19475 X X

19476 X X

19477 X X

19478 X X

19480 X X

19510 X X

19980 X X

20022 X X X X

20205A-10 X X X X

20080A X X X X X X

21851-21854 X X X X X X

________________________________________________________________________________

13 –Squeeze&Turn 19472-19479

8Drawings

8.1 19473 Squeeze & Turn, 60 kg, standard arms

________________________________________________________________________________

14 –Squeeze&Turn 19472-19479

8.2 19477 Squeeze & Turn, 110 kg, standard arms

________________________________________________________________________________

15 –Squeeze&Turn 19472-19479

8.3 19479 Squeeze&Turn, 110 kg, double standard arms

________________________________________________________________________________

16 –Squeeze&Turn 19472-19479

8.4 Torque and speed

________________________________________________________________________________

17 –Squeeze&Turn 19472-19479

________________________________________________________________________________

18 –Squeeze&Turn 19472-19479

________________________________________________________________________________

19 –Squeeze&Turn 19472-19479

Declaration of incorporation of partly completed machine

ORIGINAL

(in accordance with 2006/42/EC, Annex II 1B)

Manufacturer

PRONOMIC AB

Box 5504

192 05 Sollentuna

Model designation

❑19472 ❑19473 ❑19476 ❑19477 ❑19478 ❑19479

Serial number

Authorized to compile the

technical file

Samuel Pierre, Pronomic AB, BOX 5504, 192 05 Sollentuna

Applied EC directives:

2006/42/EC

Machinery Directive

2014/30/EU

EMC Directive

Applied standards:

SS-EN ISO 12100: 2010

Safety of machinery - General principles for design –Risk assessment and risk

reduction (ISO 12100:2010)

SS-EN 349+A1: 2008

Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

We hereby declare that the above-referenced machine, built and equipped with attachments included in

this manual, is in conformity with the applicable conditions stated in the directives and standards.

Sollentuna, 2018-12-10

…………………………………………………………

Joakim Stannow, PRONOMIC AB

Distributed by:

This manual suits for next models

4

Table of contents

Other Pronomic Industrial Equipment manuals