Pronomic 19470 User manual

Complete Turn Device

Model 19470

Also for 19471, 19474, 19475, 19480

User’s manual

Original instructions

It is important that you read and understand this manual before the attachment is used.

Questions? –Contact your supplier or the manufacturer.

Pronomic AB

Visiting address:

Bäckvägen 18

192 54 Sollentuna

Sweden

Postal address:

Box 5504

192 05 Sollentuna

Sweden

R210831

Contents

1Description of the attachment Expand&Turn.....................................................................1

1.1 Warranty...................................................................................................................................... 1

2Assembly............................................................................................................................2

2.1 Mounting the turn plate on the 90/130P trolley ........................................................................ 2

2.2 Mounting the turn plate on the 175/225P trolley ...................................................................... 2

2.3 Disassembly ................................................................................................................................. 3

3Use.....................................................................................................................................3

3.1 Operating instructions................................................................................................................. 3

4Safety.................................................................................................................................3

4.1 Storage and transport ................................................................................................................. 3

5Maintenance......................................................................................................................3

5.1 Every day ..................................................................................................................................... 4

5.2 Every month, or as needed ......................................................................................................... 4

5.3 Sign and decals ............................................................................................................................ 4

5.4 Troubleshooting .......................................................................................................................... 4

6Technical data....................................................................................................................6

6.1 Max torque .................................................................................................................................. 7

6.2 Time for 90 degree turn .............................................................................................................. 7

7Approved attachments for Lift&Drive trolleys....................................................................8

8Drawings ............................................................................................................................9

8.1 Overview...................................................................................................................................... 9

8.2 Dimensions ................................................................................................................................ 10

EC DECLARATION OF CONFORMITY FOR PARTIAL MACHINERY ......................................................... 11

1

1Description of the attachment Turn

The Turn device is ergonomically designed for maximum handling safety. Before using Turn, the

manual must be read and understood in order to guide you to operate the device in a correct and

safe way.

In order to operate the complete device, i. e. the Turn device mounted on the lift-trolley, it is

important to read this manual in combination with the separate manual delivered with the lift-

trolley.

After many years of service, your trolley and turn plate should be discarded in an environmentally

correct way.

1.1 Warranty

The warranty applies for one (1) year from the date of delivery for material- and manufacturing

errors. For the warranty to apply, maintenance should be carried out according to instructions.

This warranty does not cover normal maintenance, settings or regular adjustments. Neither will

labour costs from such measures be covered by the warranty. Damages caused by abuse or

improper use of the equipment will also void the warranty.

2

2Assembly

When mounting the attachment, protective shoes should be worn, as the parts can cause injury if

dropped.

2.1 Mounting the turn plate on the 90/130P trolley

1. Undo the screws in the slide that are provided to hold the end effector. Fit the turn plate

with the screws into the slide of the column.

2. Detach the handlebar of the trolley. Slide the motor control box into the slot in the back of

the column so that it comes above the power pack and tighten the screws. Refit the

handlebar. The cable carrier between the motor control box and the turn plate should now

be on the left-hand side of the column. Plug the power cable of the turn plate to the “power

out” socket of the power pack.

3. Trolleys with an extended column, +300 mm or +500 mm, a steel strip must be mounted on

the column (above the handlebar) to prevent the cable carrier being bent backwards. Fit

this item into the slot in the back of the column and make it tight.

4. When test-running be careful to see that the turn plate module does not foul any part of

the trolley and that the cable carrier is not too short or too long.

2.2 Mounting the turn plate on the 175/225P trolley

1. Undo the screws in the slide that are provided to hold the loading platform. The screws that

come with the trolley cannot be used, since they are too long. Lift the turn plate into place

against the slide and position the accompanying spacer key between the turn plate and the

slide. Tighten the turn plate assembly using the screws that come with the turn plate.

2. Detach the handlebar of the trolley. Slide the motor control box into the slot in the back of

the column so that it comes above the power pack and tighten the screws. Refit the

handlebar. The cable carrier between the motor control box and the turn plate should now

be on the left-hand side of the column. Plug the power cable of the turn plate to the “power

out” socket of the power pack.

3. On the 175P a steel slip must be fitted (above the handlebar) to prevent the cable carrier

being bent backwards. Fit this item into the left-hand slot in the back of the column and

make it tight.

4. When test-running be careful to see that the turn plate module does not foul any part of

the trolley and that the cable carrier is not too short or too long.

3

2.3 Disassembly

To disassemble the turn plate, proceed as in sub-section .1.1 Mounting the turn plate on the

90/130P trolley, but in the reverse order.

3Use

3.1 Operating instructions

The turn plate functions are controlled from the motor control box. The

motor control box functions vary depending of the end effectors used

together with the turn plate. The joystick controls the variable rotation

speed of the turn plate. The turn plate has endless rotation angle.

4Safety

The maximum load must not be exceeded (max-load, se heading 6

Technical specifications). The trolley and the end effectors may not be used for lifting people. The

operator is asked to be aware of the risk of injury that exists when raising or lowering the end

effector. Avoid putting your arm through the handlebar when trying to get hold of or pick up

something from the end effector. The operator must always be aware of not holding his hands or

other parts of his body under a hanging load.

Always lower the end effector to the lowest possible level that the circumstances at ground level

allow for, before any transport of goods is attempted. The load shall always be centered and stand

as close to the column as possible in order to provide maximum stability. Be especially careful

when passing over thresholds, door steps, cables and other

4.1 Storage and transport

When transporting and storing the turn plate attached to a lift-trolley, the power cable between

the lifters power pack and the motor control box must be unplugged.

The trolley is only intended for in-door use and on flat plain ground.

5Maintenance

To ensure that your Turn device will function at its best it is important to give it regular

maintenance as specified below

4

5.1 Every day

Wash off the turn plate with a cleaning agent suitable for Aluminum and stainless steel. Follow

instructions on the bottle or can. Wipe off the turn plate. Do not use high-pressure flushing, which

is liable to damage both the electronics and the chassis

5.2 Every month, or as needed

Check that no abnormal noises have arisen in the motor and gear.

1. Electrical connections: check all connections and deal with any damage or wear. If necessary,

replace with new parts.

2. Screws and nuts: check that all screws and nuts have been made tight.

3. Labels: check that the labels are secure and fully legible. They are there for your safety.

5.3 Sign and decals

Check that the following signs and decals are attached and are fully legible.

Sign/decal

Description

Placement

Unit designation

Decal with serial number

One decal on the control box

and one decal on the

attachment

Instruction decal

Decal instructing the

operator

Front of the control box

5.4 Troubleshooting

The Turn device is designed for safe and effective operation on condition that the routine

maintenance is looked after in accordance with instructions. Should any problem arise, advice on

what to do is to be found in the trouble-shooting list below.

If the problem persists after this, contact a serviceman or Pronomic AB.

5

Symptom

To do

1

Motor does not turn at all

A

Check the battery voltage which should be 24 volt.

B

Make sure the connections with motor are intact.

C

Make sure the connections from the power pack to the motor control box

are intact.

2

The turn plate does not turn, but

the motor works

A

See above under heading Symptom, section 1.

B

Check through the listed tasks in section 2.5 maintenance.

3

The turn plate moves slowly

A

See above under heading Symptom, section 1.

4

The turn plate sounds strange

while turning

A

Check through the listed tasks in section 2.5 Maintenance.

6

6Technical data

The measured square value for vibrations while squeezing does not exceed 2,5 m/s2.

The sound level while rotating does not exceed 70 dB(A).

Material: aluminum and stainless steel, 18/8.

Type:

Complete turn devices 19470-19480

Turn 19400, 19401, 1940

Outer dimensions LxWxH

34x1 16x361

Rotation angle

~

Dimension from floor to rotation center

point:

Lift & Drive 90P/130P

305 mm

Lift & Drive 175/225P

300 mm

Turning speed w/o load

(see diagram)

Max torque

(see diagram)

Max load

220 kg, depending of the maximum

capacity of the lift trolley

Weight of unit

21.5 kg

Intermittence

15% per 10 min, maximum load

Voltage

24 V DC

7

6.1 Max torque

6.2 Time for 90 degree turn

Table on turning speed

8

70E

90E

90IE

90JE

90P

130P

175P

225P

325P+

15012 XXXXXX

15013 XXXXXXXX

15014 XXXXXXXX

15015 XXXXXXXX

15016 XXXXXXXX

15017 XXXXXXXX

15018 X X

15019 XXXXXX

15024 X X

15080 X X

15322 X X

15324 X

15338 X

15370-15372 X

16020 X X

16038 X X X

16338 X

16041-16044 X X

16048-16049 X X

17182 X X

17231 XXXXXX

17241 XXXXXX

17710 XXXXXX

17720 XXXXXX

17730 XXXX

17740 XXXX

17940 X X X

17972 X X

17980 XX

19511 X X

19201 X X

19285 X X

19470 X X

19471 X X

19472 X X

19473 X X

19474 X X

19475 X X

19476 X X

19477 X X

19478 X X

19479 X X

19480 X X

20205A-10 XXXX

20080 XXXXXX

21851-21854 XXXX

220066-220069 XXX

220100 XXX

7Approved attachments for Lift&Drive trolleys

Complete Turn Devices 19470-19480

9

8Drawings

8.1 Overview

10

8.2 Dimensions

11

9EC DECLARATION OF CONFORMITY FOR PARTIAL MACHINERY

ORIGINAL

(in accordance with 2006/42/EC, Annex II 1B)

Manufacturer

Pronomic AB

Box 5504

192 05 Sollentuna

Model

Turn unit 19470/ 19471/ 19474/ 19475/ 19480

Authorized to compile the

technical file

Samuel Pierre, Pronomic AB, BOX 5504, 192 05 Sollentuna, Sweden

Applied directives:

2006/42/EC

Machinery directive

2014/30/EU

EMC directive

Applied standards:

SS-EN ISO 12100:2010

Safety of machinery –General principles for design. Risk assessment and risk

reduction

SS-EN ISO 13854:2019

Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

We hereby declare that the above referenced machine, built and equipped with attachments included in

this manual, is in conformity with stated directives and standards.

Sollentuna, 2021-08-31

…………………………………………………………

Joakim Stannow, PRONOMIC AB

12

………………………………………………………………………………………………………….…………………………………………………

Serial number

…………………………………………………………………………………………

Signature, Inspector

…………………………………………………………………………………………

Place, date

Pronomic AB –SWEDEN

Box 5504

192 05 Sollentuna

Turn Unit

19470

19474

19480

19471

19475

Distributed by:

This manual suits for next models

4

Table of contents

Other Pronomic Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley PowerMonitor 5000 Unit user manual

Sulzer

Sulzer XJ Series Assembly and installation instruction

Barco

Barco ISIS LFC installation guide

TECNA

TECNA 9354AX instruction manual

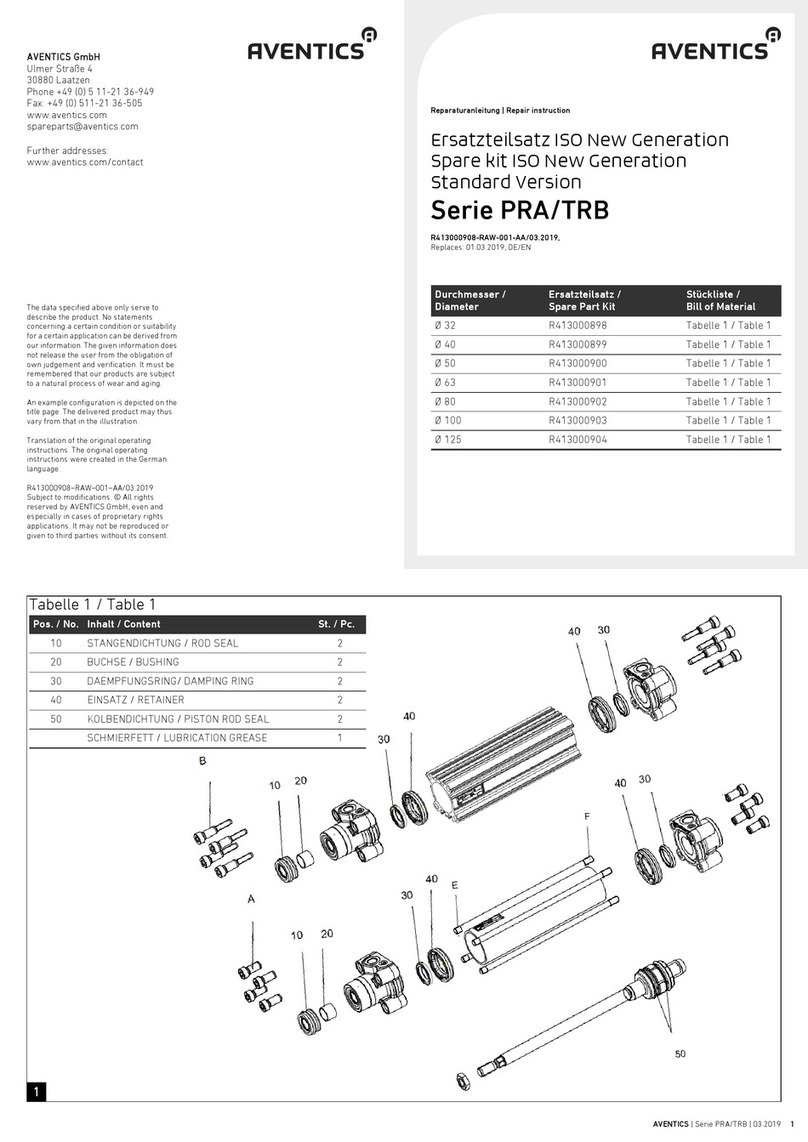

Aventics

Aventics TRB Series Repair instructions

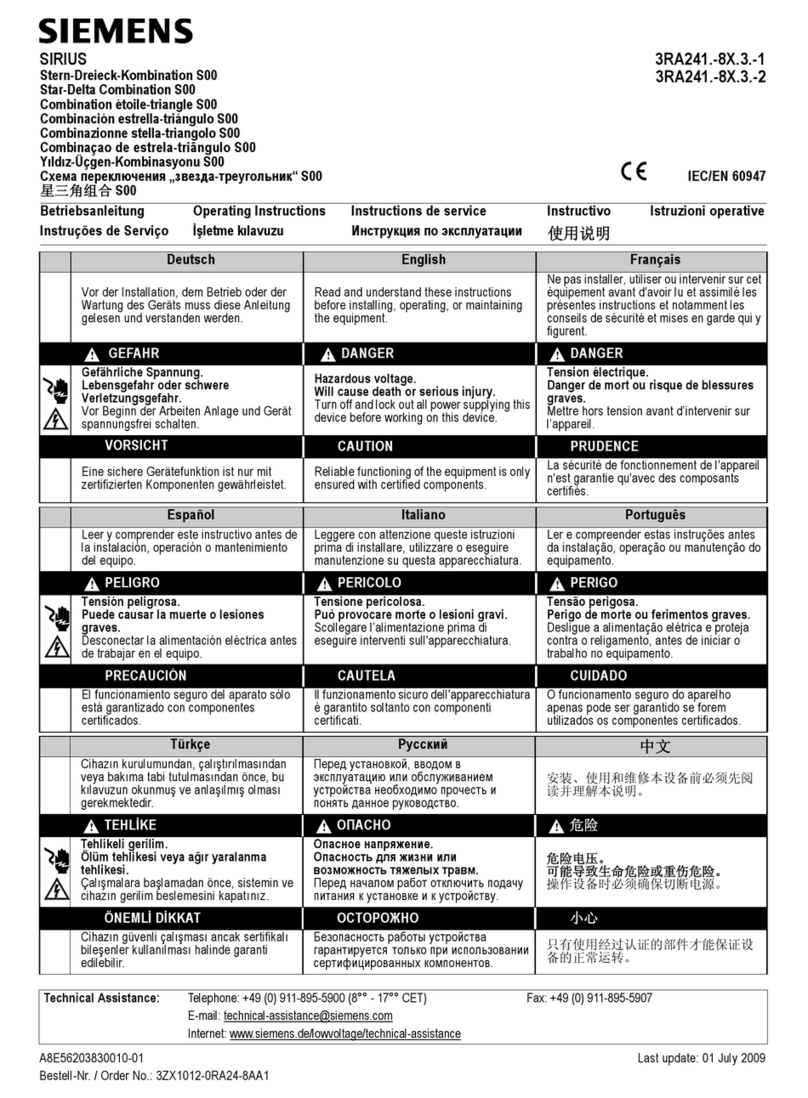

Siemens

Siemens SIRIUS S00 operating instructions

HYDAC International

HYDAC International CS 2000 Series Operating and maintenance instructions

Flonidan

Flonidan Uniflo 1200 GVEC manual

ABB

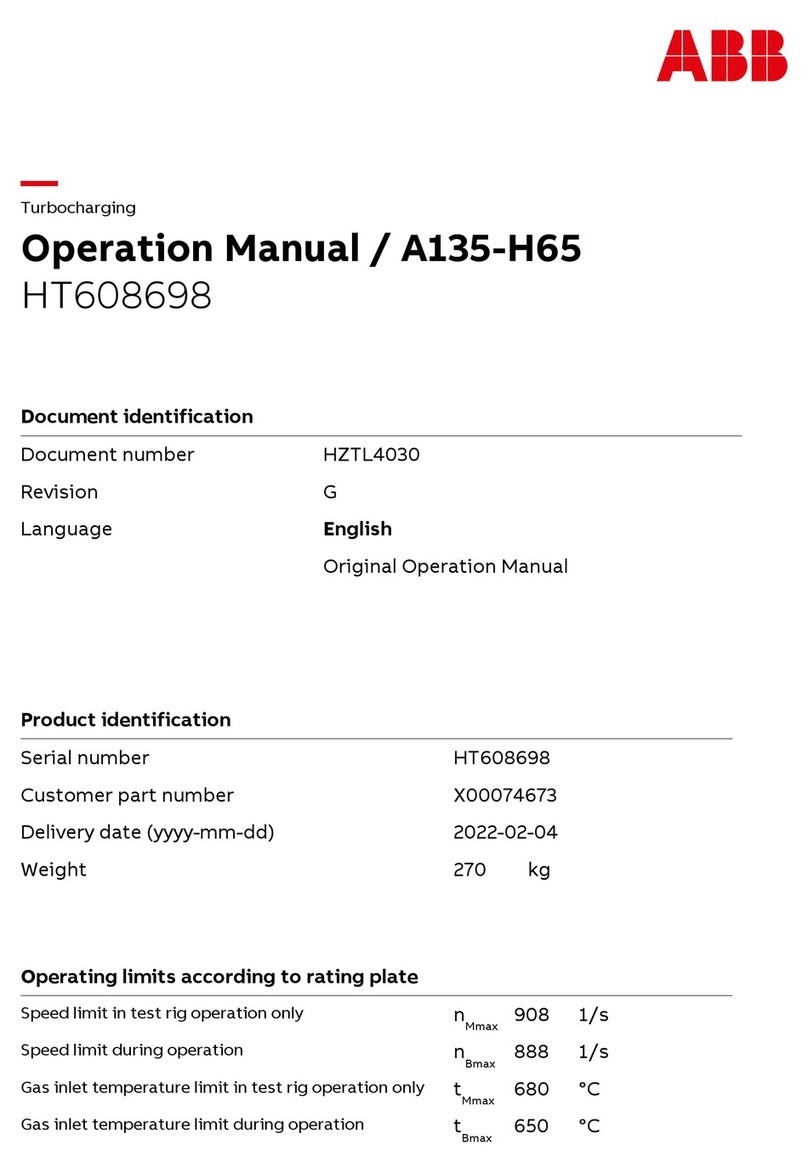

ABB HT608698 Operation manual

Daikin

Daikin ECORICH EHU 40 Series instruction manual

Traub

Traub TNX65/42 Maintenance Instruction

Eriez

Eriez HD-46 Installation, operation and maintenance instructions