Adveco TOTEM T10 User manual

PRODUCT MANUAL

TR400061.r1

TOTEM T10, T20, T25

Cogeneration (CHP) Range

EXPERTLY ENGINEERED FOR YOU

Updated UK Maintenance Requirements

INCLUDING SERVICE LOG FOR SITE PERSONNEL & BUILDING CONTROLLERS

SEE PAGE 3 FOR

CRITICAL INFORMATION

Contact Details

2

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

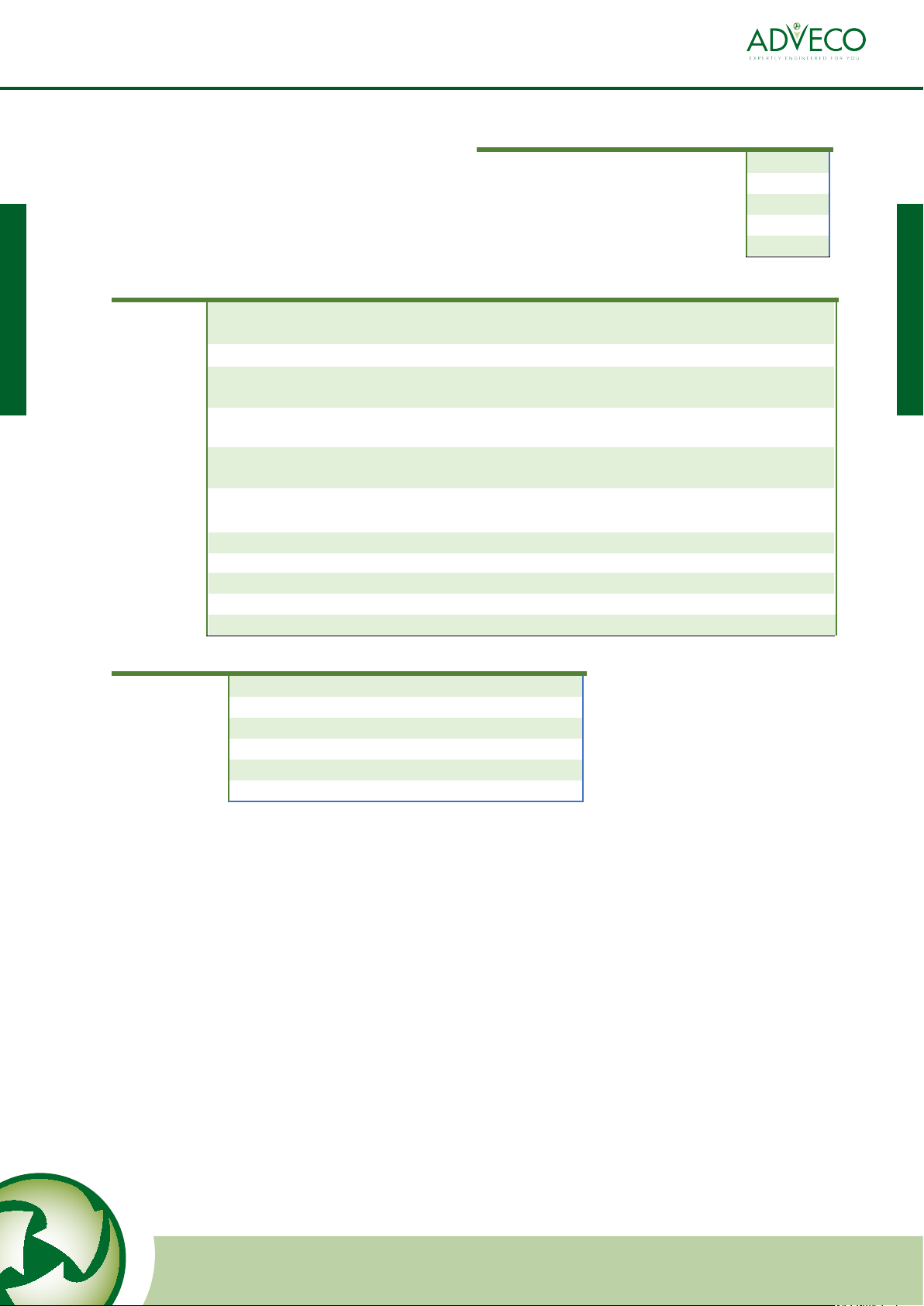

Maintenance Guide Overview .........................................

.

...

.

..............

... 4

A. Purposes of this Guide ................................................................ 4

B. Symbols Used in this Guide ......................................................... 4

C. Safety Instructions ..................................................................... 5

Procedure Overview .............................................................................7

Getting to know the TOTEM CHP..........................................................11

Interrogating and Communicating with the CHP..................................... 13

Dealing with Lamps on the Front Panel.................................................14

Fault Codes.................................................................................

....... 16

Procedure 1: Resetting Alarms and Rebooting.......................................18

Procedure 2: External Checks .............................................................. 21

Prcoedure 3: Checking Water Flow .......................................................22

Procedure 4: Internal Checks............................................................... 23

Procedure 5: Checking Coolant Level.....................................

.

.............

.

24

Procedure 6: Checking Oil Level...........................................................

.

25

Procedure 7: Cleaning Water Strainer...................................................

.

26

Procedure 8: Checking Gas Supply.......................................................

.

27

Procedure 9: Cleaning Gas Sniffer........................................................

.

28

Procedure 10: Tightening Oil Filters......................................................29

Adveco Ltd

Unit 7 Armstrong Mall,Southwood Business Park

Farnborough Hampshire GU14 0NR

Contents

Procedure 0: Checking System Operational Characteristics.................

.

...17

Addendum to the User Guide and Maintenance Reuirements.

.

................. 3

T10 Maintenance Checks by Run Hours...................................................8

T20 Maintenance Checks by Run Hours...................................................9

T25 Maintenance Checks by Run Hours..................................................10

Service Log Book................................................................................30

CO Detector Calibration Book...............................................................32

EXPERTLY ENGINEERED FOR YOU

3

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

Addendum to the USER guide and Maintenance

Requirements of the TOTEM CHP

Valid as of 20 May 2021

A risk of the exhaust manifold assembly cracking has been identified on the Totem CHP. The cause

and pattern of the fault has been investigated, a risk management plan has been prepared and the

Health and Safety Executive has been informed. The HSE has carried out their own investigation and

has agreed the following plan sufficiently manages the risk.

The added measures for the User/ Building Controller are:

• To ensure the maintenance is always carried out on time and in line with manufacturer’s

instructions

• To check the unit weekly by logging in to determine if the maintenance visit is imminent and

booking it in with a service provider to be done on time

• To turn off the unit at the point the service interval is reached if the maintenance cannot be

carried out at that time.

• To review the number of starts against the run hours and if the ratio is under 2 hours/start to

review the design with the BMS company/ Adveco / designer

• Ensure the service provider follows the manufacturer’s instructions on the maintenance

regime, and particularly, that they change the exhaust manifold each service and follow the

maintenance requirements and test the CO detector.

• Arrange for training by Adveco on how to fulfil your Totem CHP maintenance requirements.

This is free.

The requirement to service a CHP system is vitally important, not only for reliability and longevity, but

also for safety. Machinery can become unsafe if not serviced regularly and ensuring regular and

correct maintenance is carried out to ensure safety is the responsibility of the building controller. If

the control measures are followed we are pleased to confirm that building occupants will not be at

risk from leakage of carbon monoxide from defects in the Totem CHP exhaust system.

These instructions may be updated from time to time and it is therefore important to regularly check

for updated information at www.adveco.co/CHPmaintenance/

[Danger] This symbol indicates operating procedures whose incorrect performance can cause injury or even

death.

[Warning] This symbol indicates operating procedures whose incorrect performance can seriously damage the

equipment.

[Information] This symbol indicates important information related to the use of the equipment.

Maintenance Guide Overview

A. Purposes of this Guide

It is the responsibility of the Building Controller to ensure the maintenance is carried out at the

correct interval by a suitably qualified service provider. This is to ensure the equipment continues

to operate in a safe and reliable manner. This document is designed to inform the building controller

of their responsibilities to ensure this work is completed correctly. Further information should be

gained from the Totem installation manual and the Totem user manual. A copy of the Totem

Service manual should be available for the service provider.

This document is also designed to be used be on-site or maintenance personnel to perform basic

maintenance and diagnostic procedures on the TOTEM CHP appliance. It includes an introduction to

the appliance, the interrogator, TOTEM fault codes and suggested resolutions.

All procedures are categorised into three tiers based on the skills, complexity, and risk involved:

Basic: All operators. Procedures at this level require no specialist skills or knowledge, and do not

involve any disassembly of or mechanical work on the appliance.

Intermediate: Operatives with relevant maintenance training and/or experience. Procedures at this

level include basic internal checks within the appliance.

Advanced: Operatives with relevant professional qualifications (gassafe) and experience.

Procedures at this level include works to the appliance gas supply and internal components.

Finally, this document includes the maintenance tasks to be carried out by the service provider on

pages 8-10. This document is in addition to the Totem manual and includes additional tasks

considered specific to the UK. This document must be shown to the service provider. This

information may change over time so at each visit it is necessary to refer to the website

www.adveco.co/CHPmaintenance/ to see if they have been updated.

B. Symbols Used in the Guide

4

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

If you smell gas odor:

turn your gas supply valve off;

ventilate the room;

do not operate any electrical device or appliance, including cell phones; leave the premises and call a

qualified technician or the gas utility company immediately from a different location. If they are

unavailable or in case of an emergency, call the local Fire Brigade;

if the room is equipped with a gas leak detection system, please report any possible malfunctioning of said

active safety equipment.

EXPERTLY ENGINEERED FOR YOU

5

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

If you see water, glycol, oil, or other fluids’ spills on the floor or near the Totem Unit:

turn the unit off;

call a qualified technician;

shut off the User system’s circuits, if any, e.g. water or gas supply

If you smell products of combustion:

turn the appliance off;

ventilate the room;

call a qualified technician;

if the room is equipped with a smoke/carbon monoxide detection system, please report any possible

malfunctioning of said active safety equipment.

C. Safety Instructions

Please refer to the TOTEM User Manual for a comprehensive list of safety instructions and potential

hazards associated with working on or in the vicinity of the TOTEM CHP appliance.

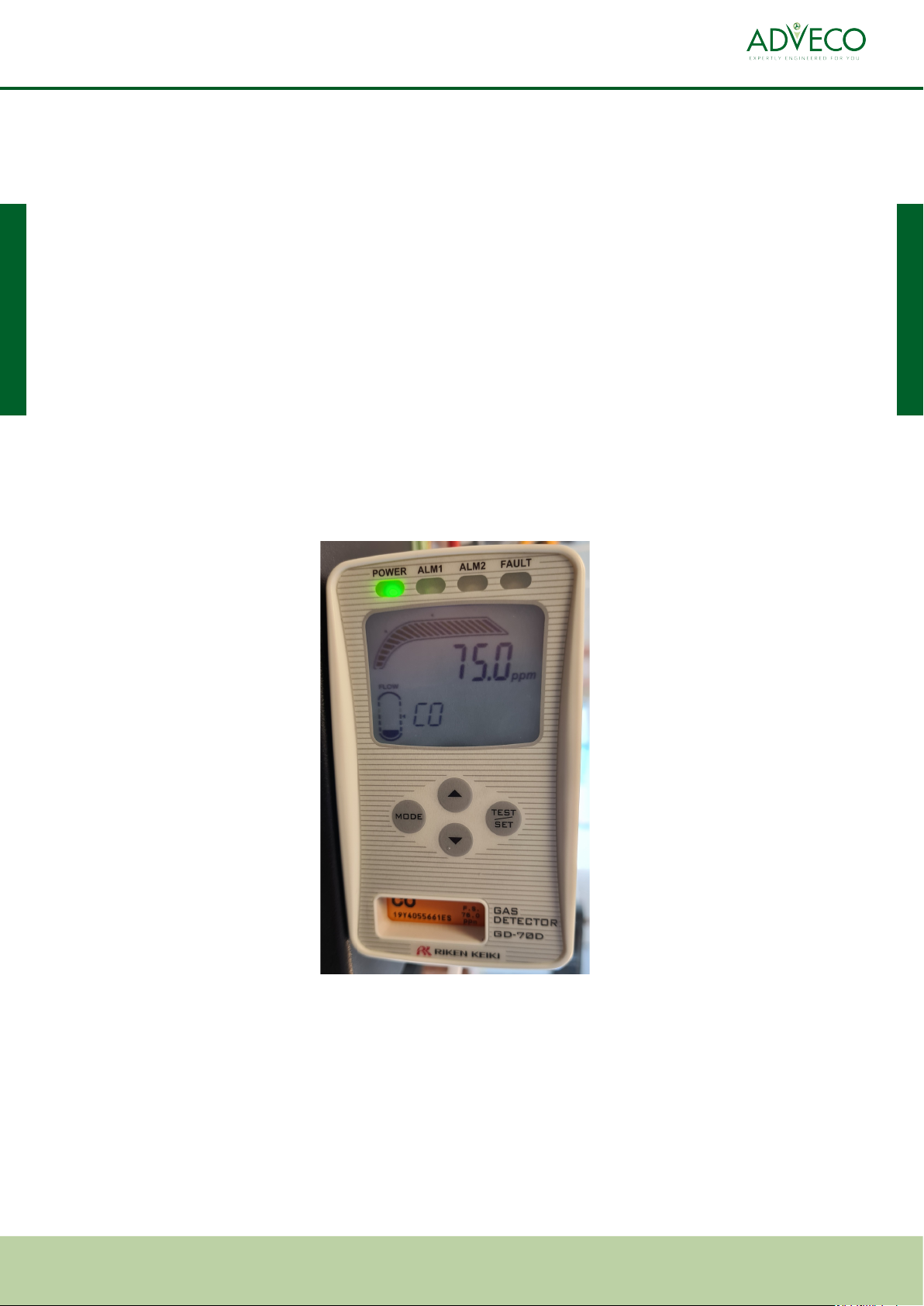

This TOTEM CHP unit has been fitted with an aftermarket CO detector to monitor the warm air

leaving the unit. It is unlikely that the CO detector will go off, however if it does:

•It will shut off the CHP unit

•It will not make a sound, but pressing the blue button on the CHP unit will not reset the CHP - the CO

detector will hold it off.

•It is likely that the CO has come form the CHP unit, but it is possible that it has come from another

appliance in the room, so proceed with caution.

•Do not try and reset the CO detector.

•The CO detector will shut off the TOTEM before the level is unsafe. Once the CHP is off, see if the CO level

reduces. This could take 15 minutes. If it does not reduce, or if it increases, turn off all other gas

appliances and exit the building.

•Call out your service provider.

Installation, calibration and modification of the gas feed system must be performed by a qualified

technician abiding by all applicable national and local standards as well as by the instructions provided in this

Guide.

Installation, calibration or modification of the electrical system must be performed by a qualified

technician abiding by all applicable national and local standards as well as by the instructions provided in this

Guide.

Installation, calibration or modification of the water system must be performed by a qualified technician abiding

by all applicable national and local standards as well as by the instructions provided in this Guide.

It is mandatory to connect the exhaust gas evacuation line of the appliance to an exhaust gas evacuation duct

built in compliance with all applicable legal requirements in force in the place where the TOTEM® unit is

installed. Failure to comply with said rule poses a serious risk to human and animal safety.

According to the provisions for use, the user has an obligation to keep the installed unit in good condition

and to ensure the safe and reliable functioning of the micro cogenerator and of all systems connected thereto,

having the relevant activities performed by qualified technicians.

Before switching the unit on, always ensure that all protective panels and guards have been properly mounted to

avoid risks to the safety of personnel.

Do not obstruct, not even partially, the suction duct and exhaust pipe ends.

Do not use or store any hazardous materials, such as explosive, combustible or flammable materials in the same

room where the micro cogenerator is installed.

When the unit is in operation, do not stay in the room where the unit is installed.

The micro cogenerator, any auxiliary components thereof, the systems needed for its functioning (GAS, water,

power, shut-off devices, firefighting equipment, detectors, panels, switchboards, components of the Totem

Unit’s equipment room etc.) must not be tampered with, modified or otherwise altered for any reason

whatsoever. Failure to comply with this provision may cause injuries or may damage, including severely, people,

animals or things.

6

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

Procedure Basic Intermediate Advanced

1 Resetting Alarms Resetting Alarms Resetting Alarms

2 External visual & audible

checks

External visual & audible

checks

External visual & audible

checks

3 Checking system water flow Checking system water

flow

Checking system water flow

4 Internal visual & audible

checks

Internal visual & audible

checks

5 Checking coolant level &

topping up

Checking coolant level &

topping up

6 Checking oil level Checking oil level

7 Cleaning water strainer Cleaning water strainer

8 Checking gas supply

9 Cleaning gas sniffer

10 Tightening oil filters

0 Checking system

operational parameters

Site Maintenance Items Required Quantity

Engine Oil 4 litres

Coolant Additive 1 litre

Demineralized Water 5 litre

Air Brush Can 1

Microfibre Cloths 10

7

EXPERTLY ENGINEERED FOR YOU

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

Procedure Overview

Checking system

operational parameters

Checking system

operational parameters

Weekly requirements of the building controller:

1. External visual and audible checks

2. Complete log book entry of system operational characteristics, including:

a. Water system flow rate

b. Check and note run hours and starts. Calculate the number of run hours per start and make sure it is

a minimum of 2 hours per start.

c. Check total run hours and compare them to the service interval. Book in a service visit if within 500

hours of the interval.

d. If the interval is about to be exceeded, the machine must be switched off until it has been serviced.

Yearly requirements of the building controller:

•Ensure that the manuals are available on site for the maintenance company

•Ensure a service provider is selected with the correct non-domestic gas safe accreditations including Direct

Gas Fired Engines

•Ensure the service report reflects that the requirements set out within this document have been carried out.

The service manual for the CO detector can be found at www.adveco.co/CHPmaintenance

Maintenance Basic Intermediate Advanced

Weekly 2 2 2

Monthly 3 3 3

4 4

5 5

6 6

Maintenance tasks need to be broken into

weekly checks by 'basic' level staff, and

should be the responsibility of the building

controller. Monthly checks should be by

on-site staff if qualified, or qualified off-site

staff.

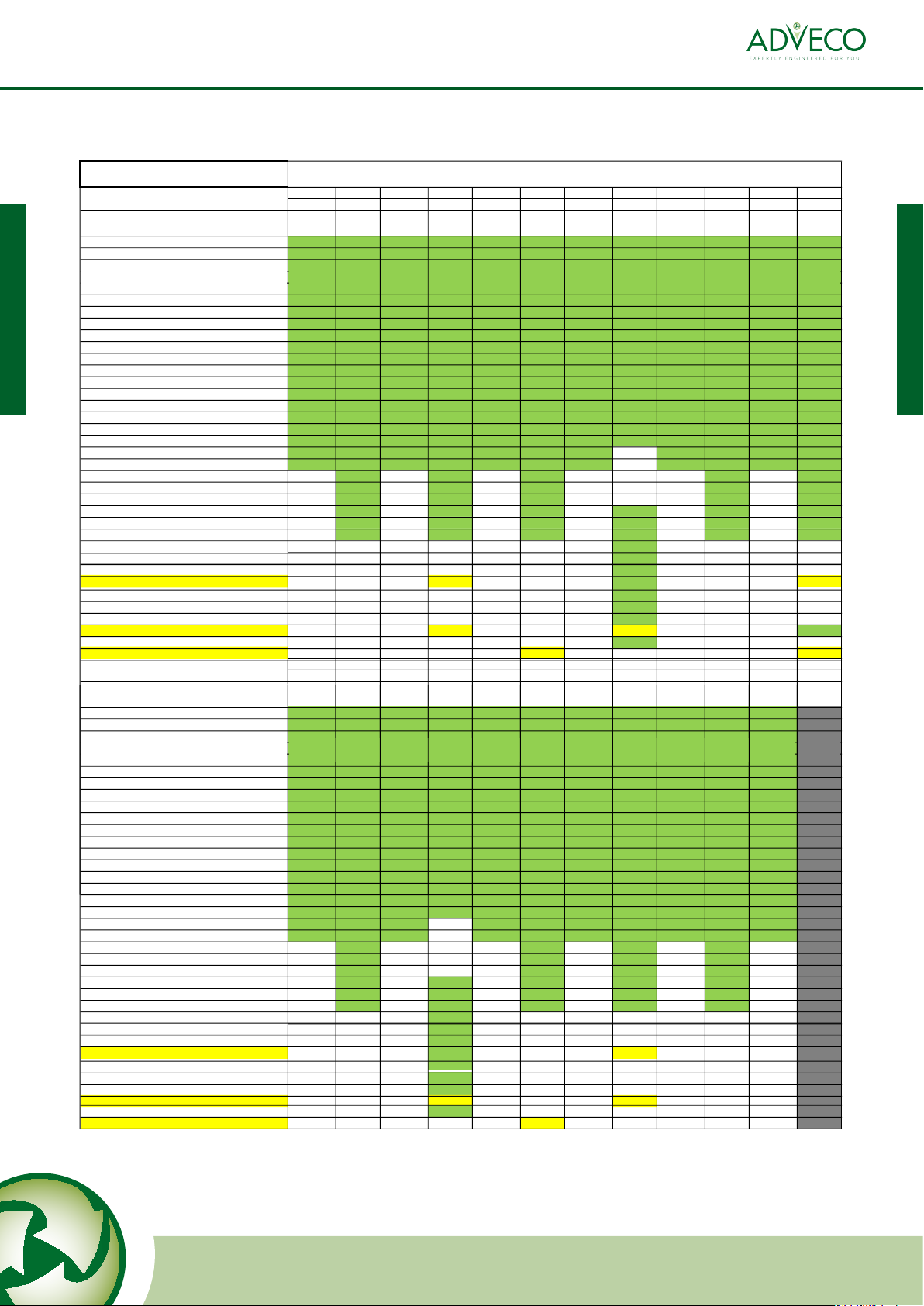

TOTEM 10

3000 6000 9000 12000 15000 18000 21000 24000 27000 30000

±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5%

Maintenance Items T1A T1A T2 T1A T1A T2 T1A T1A T2 T3

General inspection of the unit XXXXXXXXXX

Check torque on fasteners and hoses XXXXXXXXXX

Check the tightness of all electrical connections XXXXXXXXXX

Check engine coolant level XXXXXXXXXX

Check gas leak sensor XXXXXXXXXX

Replace engine oil / refill tank XXXXXXXXXX

Replace oil filters XXXXXXXXXX

Replace primary air filter XXXXXXXXXX

Check valve clearances and adjust if necessary XXXXXXXXX

Replace spark plugs X X X

Replace cylinder head X X X

Replace spark plug cables X X X

Replace timing belt and tensioner X X X

Replace engine coolant X X X X

Replace Lambda probe (pre-cat) X X X X

Replace secondary air filter X X X X

Replace Lambda probe (post-cat) X

Clean exhaust gas heat exchanger (flue gas side) X

Clean exhaust gas heat exchanger (water side) X

Replace catalytic converter X

Replace engine X

Replace battery X

Replace gas actuator X

Replace Flexible Tubes of engine cooling system X X

Replace heat shield insulation panels X

Revamp generator

33000 36000 39000 42000 45000 48000 51000 54000 57000 60000

±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5%

Maintenance Items T1A T2 T1A T1A T2 T1A T1A T2 T1A Overhaul

General inspection of the unit XXXXXXXXX

Check torque on fasteners and hoses XXXXXXXXX

Check the tightness of all electrical connections XXXXXXXXX

Check engine coolant level XXXXXXXXX

Check gas leak sensor XXXXXXXXX

Replace engine oil / refill tank XXXXXXXXX

Replace oil filters XXXXXXXXX

Replace primary air filter XXXXXXXXX

Check valve clearances and adjust if necessary XXXXXXXXX

Replace spark plugs X X X

Replace cylinder head X X X

Replace spark plug cables X X X

Replace timing belt and tensioner X X X

Replace engine coolant X X X

Replace Lambda probe (pre-cat) X X X

Replace secondary air filter X X X

Replace Lambda probe (post-cat)

Clean exhaust gas heat exchanger (flue gas side)

Clean exhaust gas heat exchanger (water side)

Replace catalytic converter

Replace engine

Replace battery

Replace gas actuator

Replace Flexible Tubes of engine cooling system X X

Replace heat shield insulation panels

Revamp generator

SCHEDULED SERVICE PLAN 0 - 60.000 h

Unit Running Hours

Unit Running Hours

Leak check around all flue joints for CO/CO2

Check all traps full of water

Check service log is being filled in, review start/stop ratio

Check for CO leakage around all exhaust joints

Calibrate and service CO detector

Check back pressure on flue from appliance test point

XXXXXXXXXX

XXXXXXXXXX

XXXXXXXXXX

XXXXXXXXXX

XXXXXXXXXX

XXXXXXXXXX

XXXXXXXXXX

Leak check around all flue joints for CO/CO2

Check all traps full of water

Check service log is being filled in, review start/stop ratio

Check for CO leakage around all exhaust joints

Calibrate and service CO detector

Check back pressure on flue from appliance test point

XXXXXXXXX

XXXXXXXXX

XXXXXXXXX

XXXXXXXXX

XXXXXXXXX

XXXXXXXXX

XXXXXXXXX

Check flue is bracketed properly and vibration

downstream of flex is minimal

Check flue is bracketed properly and vibration

downstream of flex is minimal

Check and replace gas hose every 5 years

8

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

T10 Maintenance Checks by Run Hours

TOTEM 20

2500 5000 7500 10000 12500 15000 17500 20000 22500 25000 27500 30000

±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5%

Maintenance Items T1B T2 T1B T2 T1B T2 T1B T3 T1B T2 T1B T2

General inspection of the unit XXXXXXXXXXXX

Check torque on fasteners and hoses XXXXXXXXXXXX

Check the tightness of all electrical connections XXXXXXXXXXXX

Check engine coolant level XXXXXXXXXXXX

Check gas leak sensor XXXXXXXXXXXX

Replace engine oil / refill tank XXXXXXXXXXXX

Replace oil filters XXXXXXXXXXXX

Replace primary air filter XXXXXXXXXXXX

Check valve clearances and adjust if necessary XXXXXXX XXXX

Replace spark plugs XXXXXXX XXXX

Replace cylinder head XXX XX

Replace spark plug cables XXX XX

Replace timing belt and tensioner XXX XX

Replace engine coolant XXXXXX

Replace Lambda probe (pre-cat) XXXXXX

Replace secondary air filter XXXXXX

Replace Lambda probe (post-cat) X

Clean exhaust gas heat exchanger (flue gas side) X

Clean exhaust gas heat exchanger (water side) X

Replace catalytic converter XXX

Replace engine X

Replace battery X

Replace gas actuator X

Replace Flexible Tubes of engine cooling system XXX

Replace heat shield insulation panels X

Revamp generator X X

32500 35000 37500 40000 42500 45000 47500 50000 52500 55000 57500 60000

±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5%

Maintenance Items T1B T2 T1B T3 T1B T2 T1B T2 T1B T2 T1B Overhaul

General inspection of the unit XXXXXXXXXXX

Check torque on fasteners and hoses XXXXXXXXXXX

Check the tightness of all electrical connections XXXXXXXXXXX

Check engine coolant level XXXXXXXXXXX

Check gas leak sensor XXXXXXXXXXX

Replace engine oil / refill tank XXXXXXXXXXX

Replace oil filters XXXXXXXXXXX

Replace primary air filter XXXXXXXXXXX

Check valve clearances and adjust if necessary XXX XXXXXXX

Replace spark plugs XXX XXXXXXX

Replace cylinder head X X X X

Replace spark plug cables X X X X

Replace timing belt and tensioner X X X X

Replace engine coolant XXXXX

Replace Lambda probe (pre-cat) XXXXX

Replace secondary air filter XXXXX

Replace Lambda probe (post-cat) X

Clean exhaust gas heat exchanger (flue gas side) X

Clean exhaust gas heat exchanger (water side) X

Replace catalytic converter X X

Replace engine X

Replace battery X

Replace gas actuator X

Replace Flexible Tubes of engine cooling system X X

Replace heat shield insulation panels X

Revamp generator X

SCHEDULED SERVICE PLAN 0 - 60.000 h

Unit Running Hours

Unit Running Hours

Change old style exhaust manifold

Calibrate and service CO detector

Check back pressure on flue from appliance test point

Leak check around all flue joints for CO/CO2

Check all traps full of water

Check service log is being filled in, review start/stop ratio

Check for CO leakage around all exhaust joints

Check flue is bracketed properly and vibration

downstream of flex is minimal

XXXXXXXXXXXX

XXXXXXXXXXXX

XXXXXXXXXXXX

XXXXXXXXXXXX

XXXXXXXXXXXX

XXXXXXXXXXXX

XXXXXXXXXXXX

XXXXXXXXXXXX

Change old style exhaust manifold

Calibrate and service CO detector

Check back pressure on flue from appliance test point

Leak check around all flue joints for CO/CO2

Check all traps full of water

Check service log is being filled in, review start/stop ratio

Check for CO leakage around all exhaust joints

Check flue is bracketed properly and vibration

downstream of flex is minimal

XXXXXXXXXXX

XXXXXXXXXXX

XXXXXXXXXXX

XXXXXXXXXXX

XXXXXXXXXXX

XXXXXXXXXXX

XXXXXXXXXXX

XXXXXXXXXXX

EXPERTLY ENGINEERED FOR YOU

9

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

T20 Maintenance Checks by Run Hours

Check and replace flexible gas hose every 5 years

TOTEM 25

2500 5000 7500 10000 12500 15000 17500 20000 22500 25000 27500 30000

±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5%

Maintenance Items T1b T2 T1b T2 T1b T3 T1b T2 T1b T2 T1b T3

General inspection of the unit X X X X X X X X X X X X

Check torque on fasteners and hoses X X X X X X X X X X X X

Check the tightness of all electrical connections X X X X X X X X X X X X

Check engine coolant level X X X X X X X X X X X X

Check gas leak sensor X X X X X X X X X X X X

Replace engine oil / refill tank X X X X X X X X X X X X

Replace oil filters X X X X X X X X X X X X

Replace primary air filter X X X X X X X X X X X X

Check valve clearances and adjust if necessary X X X X X X X X X X

Replace spark plugs X X X X X X X X X X

Replace cylinder head X X X X

Replace spark plug cables X X X X

Replace timing belt and tensioner X X X X

Replace engine coolant X X X X X X

Replace Lambda probe (pre-cat) X X X X X X

Replace secondary air filter X X X X X X

Replace Lambda probe (post-cat) X X

Clean exhaust gas heat exchanger (flue gas side) X X

Clean exhaust gas heat exchanger (water side) X X

Replace catalytic converter X X X

Replace engine X X

Replace battery X X

Replace gas actuator XX

Replace Flexible Tubes of engine cooling system X X X

Replace heat shield insulation panels X X

Revamp generator X X

32500 35000 37500 40000 42500 45000 47500 50000 52500 55000 57500 60000

±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5%

Maintenance Items T1b T2 T1b T2 T1b T3 T1b T2 T1b T2 T1b Overhaul

General inspection of the unit X X X X X X X X X X X

Check torque on fasteners and hoses X X X X X X X X X X X

Check the tightness of all electrical connections X X X X X X X X X X X

Check engine coolant level X X X X X X X X X X X

Check gas leak sensor X X X X X X X X X X X

Replace engine oil / refill tank X X X X X X X X X X X

Replace oil filters X X X X X X X X X X X

Replace primary air filter X X X X X X X X X X X

Check valve clearances and adjust if necessary X X X X X X X X X X

Replace spark plugs X X X X X X X X X X

Replace cylinder head X X X X

Replace spark plug cables X X X X

Replace timing belt and tensioner X X X X

Replace engine coolant X X X X X

Replace Lambda probe (pre-cat) X X X X X

Replace secondary air filter X X X X X

Replace Lambda probe (post-cat) X

Clean exhaust gas heat exchanger (flue gas side) X

Clean exhaust gas heat exchanger (water side) X

Replace catalytic converter X X

Replace engine X

Replace battery X

Replace gas actuator X

Replace Flexible Tubes of engine cooling system X X

Replace heat shield insulation panels X

Revamp generator X

SCHEDULED SERVICE PLAN 0 - 60.000 h

Unit Running Hours

Unit Running Hours

Change old style exhaust manifold

Calibrate and service CO detector

Check back pressure on flue from appliance test point

Leak check around all flue joints for CO/CO2

Check all traps full of water

Check service log is being filled in, review start/stop ratio

Check for CO leakage around all exhaust joints

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

X

X

X

X

X

X

X

X X X X X X X X X X X X

Change old style exhaust manifold

Calibrate and service CO detector

Check back pressure on flue from appliance test point

Leak check around all flue joints for CO/CO2

Check all traps full of water

Check service log is being filled in, review start/stop ratio

Check for CO leakage around all exhaust joints

Check flue is bracketed properly and vibration

downstream of flex is minimal

Check flue is bracketed properly and vibration

downstream of flex is minimal

Check and replace flexible gas hose every 5 years

10

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

T25 Maintenance Checks by Run Hours

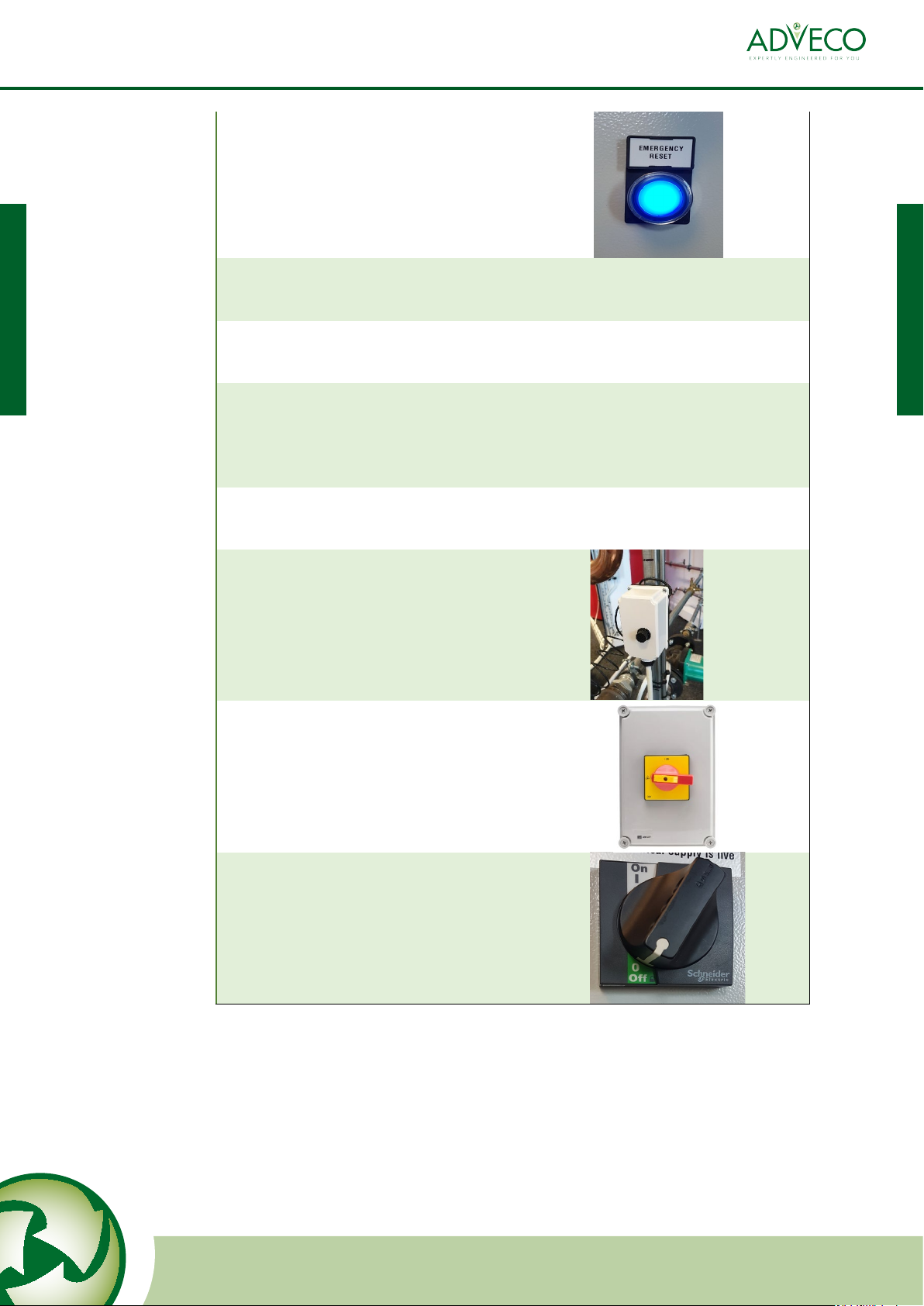

Machine Isolator: Electrical isolator to cut power supply to the unit. Required safe isolation for

servicing and access into the panel. This isolator should isolate all power to the unit, however all

installations are different. Look for labels that indicate multiple live supplies exist within the panel

and if present isolation is necessary at multiple points. Regardless, after gaining access the control

panel should be tested with suitable test equipment to ensure it is safely isolated.

Rotary Isolator: Minimum level of electrical isolation necessary to gain access inside the control panel.

When in the off position the panel can be opened, but there is still live 415V/3phase electricity in the

machine up to the isolator. Not a sufficient level of safe electrical isolation for servicing, this must be

done through the machine isolator. Only trained technicians should access the panel with only the

rotary isolator in the off position.

Informational

(Alarm) Lamp

Rotary Isolator

Grid Connect

Indicator Lamp

Power Indicator

Lamp

Emergency Stop

Button

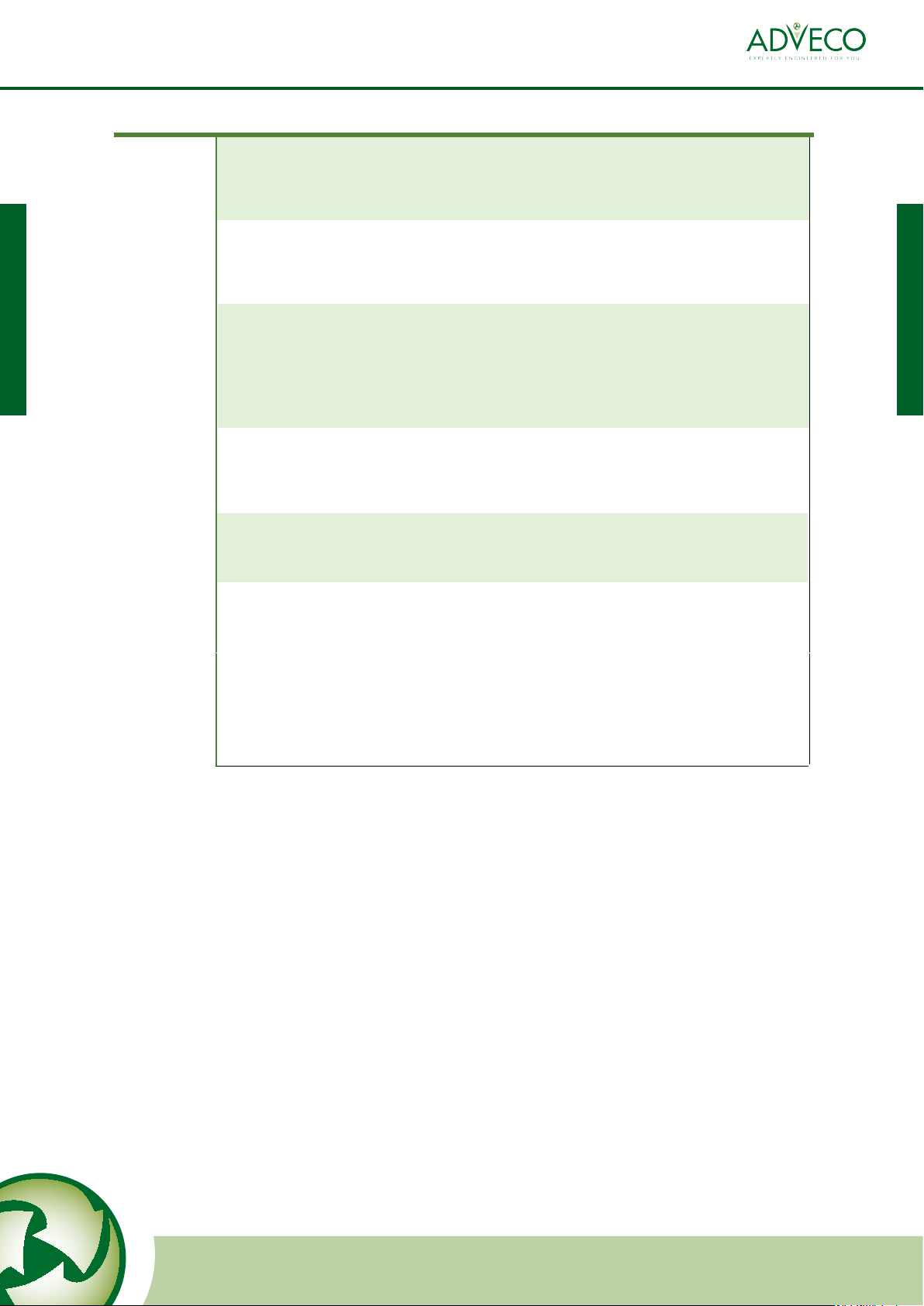

Reset Button/

Lockout (Alarm)

Lamp

On/Off Switch

Machine Isolator

(adjacent to

machine)

Right hand side

Left hand side

Front

Getting to Know the TOTEM CHP

EXPERTLY ENGINEERED FOR YOU

11

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

Informational (Alarm) Lamp: Lamp on indicates the machine is communicating. Could indicate non

critical information, self resetting temporary blocking alarm, lockout that can be reset remotely, or

lockout that must be manually reset on site.

Grid Connect Lamp: Lamp on indicates the machine is generating electricity

Power Indicator Lamp: Lamp on indicates the power is on to the unit

Emergency Stop Button: Press in case of emergency to shut unit off

Reset Button/Lockout (Alarm) Lamp: Lamp on indicates a lockout alarm that must be reset by

pressing the blue button

On/Off Switch: Used to turn off machine to prevent operation, while still leaving the main power on

to keep the battery charged. Should normally be set to On.

CO Detector

12

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

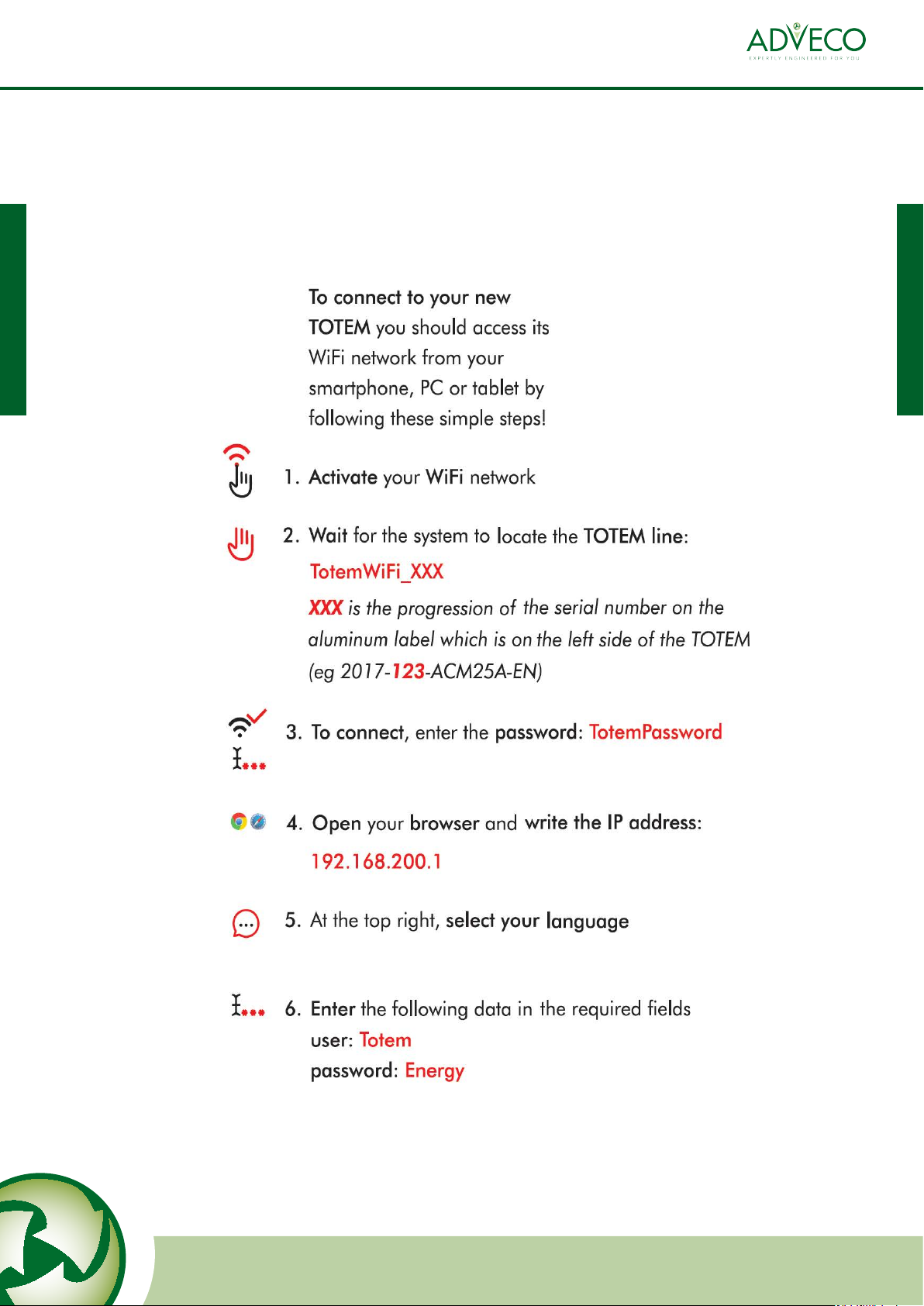

The human/machine interface (HMI) of the Totem CHP is a smartphone or tablet via the Totems

wifi hotspot in the following way:

Once connected press the menu button in the top left corner and select the section that is required.

Interrogating and Communicating with the TOTEM CHP

EXPERTLY ENGINEERED FOR YOU

13

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

Typically there is no reason to connect and interrogate the machine unless user data is required

such as current temperatures, run hours, time until servicing, etc.

There are combinations of illuminated lamps that may require the user to connect and interrogate.

1. Power on lamp illuminated, all other lamps off, Machine NOT running.

a. The machine NOT running is NOT a fault, the machine will run often, but not all the

time. The arrangement explained above is likely to be a healthy condition where the

unit is simply in standby because the system is up to temperature, the system was up

to temperature and now the machine is in ‘anti-cycling’ mode, or the machine does

not have an external run/enable signal. It could also indicate a fault combined with a

faulty lamp.

b. It is recommended that if this is the condition of the unit that nothing is done and it

is checked again 2 hours later. Most conditions that cause this standby arrangement

will clear in 2 hours and the unit will reset.

c. Connect to the unit and check the following in order:

i. Alarms, Check for active alarms

1. If there is an active alarm note it and follow the procedure for that

alarm.

ii. Configurations, Totem Shutdown/Restart temperature

iii. Real time data, Totem Inlet water temperature

1. When the Totem Inlet water temperature reaches the shutdown

temperature the machine will stop. It will restart when the Totem

inlet water temperature drops to the restart temperature. If the

Totem Inlet water temperature is above the restart temperature it

should degrade over time and the machine will restart. Check it

again in a few hours. If the temperature is still high it could indicate

a pump failure or BMS control problem.

iv. Real time data, Engine Inlet water temperature

1. The anti-cycling algorhithm will prevent the machine from restarting

until the engine inlet temperature drops below a setpoint fixed by

machine type, which could be as low as 50C. If the Engine inlet water

temperature is above 50C then recheck in 2 hours and it should have

restarted.

v. Real time data, Logical State of Totem

1. Waiting conditions for engine to start indicates that there is no

enable/run signal from the controls or BMS. Investigate through the

BMS.

Dealing with the Lamps on the Front of the TOTEM CHP

14

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

ii. The machine may have an active alarm that has stopped the unit from

operating, which will automatically reset after a period of time or when the

fault is removed

iii. The machine may have an active alarm that will not automatically reset and

needs to be reset either remotely through the Cloud based monitoring

system or locally by following the reset procedure (Procedure 1)

b. As both conditions in i. and ii. will either reset or not stop the machine from

operating it is recommended that nothing is done immediately and it is checked

again 2 hours later. Most conditions that cause this i. and ii. will clear in 2 hours and

the unit will run.

c. Connect to the unit and check the following:

i. Alarms, Check for active alarms

1. If there is an active alarm note it and follow the procedure for that

alarm.

3. Reset button/ Lockout alarm lamp illuminated, Machine NOT running.

a. This is a lockout alarm. It can only be reset on site by following procedure 1.

2. Power on and Informational (Alarm) Lamps illuminated, Reset button/ Lockout alarm

lamp not illuminated, Machine running or not.

a. This arrangement could be the cause of three conditions.

i. The machine may be healthy (running or in standby) but there is information

being communicated that indicates a part is worn, a service is imminent, or a

sensor is out of calibration. These informational faults do not stop the

machine from operating and will be cleared/rectified during the next service.

EXPERTLY ENGINEERED FOR YOU

15

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

Fault Codes Description Advice/Cause Procedure Basic Intermediate Advanced

5a01 Emergency knock off

button activated

Ascertain

why/who pressed

it before resetting

1 x x x

5a02 Lockout alarm Power cut/safety

chain/high

voltage

1 x x x

5b02, 5b06 QF1 Circuit breaker trip 1 x x

5c01—5c07 Reboot request 1 x x x

5d01,5d02 Enable/run signal not

present

Check the BMS

system

n/a x x x

5e01, 5e02 Grid/current/voltage

imbalance

If recurring

contact Adveco

1 x x x

5e11 – 5e23 Various

voltage/amperage grid

issues

Refer to Adveco

for info

n/a

5428,5401,542d,

5501,5408,540d

Engine/Coolant/

building flow

temperature too high

Building flow too

low

3,7 3 only x x

5432,5412,5413 Temperature in

machine housing

Check plantroom

temperature

2 x x x

5418,541d,541e,

5422

Related to exhaust

temperature

Refer to Adveco n/a

5502 Related to coolant level 4,5 x x x

5601—5604 Related to CHP Oil level 4,6,10 x x x

5f01 – 5f03,

5f06 – 5f11

Related to fuel/air mix

or Lambda

sensors/catalytic

converter

If recurring

contact Adveco

1 x x x

5f04 Incoming gas pressure

low

8 x

5f05 Gas detector activated 9 x

0560 Battery voltage too low Replace battery n/a x x x

5406,5407,5409,

540b, 540c,540e,

5410,5411,5414,

5416,5417,5419,

541b,541c,541f,

5420,5421,5423,

5426,5427,5429,

542b,542c,542e,

5430,5431

Non critical

informational code

regarding sensor

calibration

Inform Adveco

when booking in

service visit

n/a

0300—0304,

1000—1004

Non critical

informational code

indicating that a service

may be imminent

Inform Adveco

when booking

service & if

frequency

increase

n/a

All other alarms Procedure 1 and report to Adveco if

persistent

1 x x x

16

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

Procedure 0Checking System Operational Characteristics

Connect to the machine with a smartphone or tablet as described in

Interrogating and Communicating with the Totem CHP.

Read down the page to find "Number of Engine Starts" to record the total

number of CHP starts.

Find "Hours of Operation on Network" to record the total run hours of

the unit.

Divide the run hours by the number of starts to calculate the average number

of hours run per start.

Refer to the service logbook on the next page of this document and fill in

the above information for the current week.

Use the previous week log book information to calculate the number of

hours run and starts during the last week, and the number of hours since

the last service.

T10 units require servicing every 3000 hours

T20 and T25 units require servicing every 2500 hours

Book a service visit if the unit is within 500 hours of requiring a service.

On the online dashboard, use the menu in the top left of the screen

to navigate to "Real Time Data"

EXPERTLY ENGINEERED FOR YOU

17

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

1

2

3

4

5

6

Procedure 1

Resetting Alarms / Rebooting

1

Connect to the machine with a smartphone or tablet as described in

Interrogating and Communicating with the Totem CHP, go to alarms, and note

the active alarm.

1.1

If the alarm was 5a01, ascertain the

reason someone pressed the emergency

knock off button, then if is safe to do so

turn the button clockwise to reset it (it

must be fully out.)

2

Press the Reset (BLUE) button and hold

for 2 seconds

2.1

The blue lamp should go out and the machine should start within 5 minutes. If

the unit restarts no further action is required.

2.2

If the lamp stays off, but it does not start, refer to ‘dealing with lamps’ page to

interrogate why it has not started.

2.3

If the lamp does not go out, or if it comes back on immediately or comes on

when the machine attempts to operate then go on to section 3.

3

If the unit tried to start, connect to the machine, check and note the alarm code

again

3.1

Turn off the CHP using the rotary isolator

on the control panel and wait 30

seconds.

2

Turn on the CHP using the rotary isolator on the control panel.

3

The internal fan will start and the Reset button/ lockout (alarm) button will

illuminate

4

Wait for up to 5 minutes.

18

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

5

Press the Reset (BLUE) button and hold

for 2 seconds

5.1

The blue lamp should go out and the machine should start within 5 minutes. If

the unit restarts no further action is required.

5.2

If the lamp stays off, but it does not start, refer to ‘dealing with lamps’ page to

interrogate why it has not started.

5.3

If the lamp does not go out, or if it comes back on immediately or comes on

when the machine attempts to operate, and the alarm code is 5a02, 5b02 or

5b06 then go to section 6. For all other alarms contact Adveco and give them

the alarm code.

6

The following checks for 5a02, 5b02, and 5b06 are for intermediate technical

level users

6.1

(5a02 only) Locate the overheat stat in

the flow pipework outside of the

machine and press the button under

the cap. If it clicks go back to section 2.

If it does not click continue to 6.2

6.2

Isolate the machine with the Machine

Isolator adjacent to the machine

6.3

Turn off the CHP using the rotary isolator

on the control panel

EXPERTLY ENGINEERED FOR YOU

19

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

6.4

Open the door using the key provided

6.5

5b02,5b06:

Touching nothing else, locate the rotary

circuit breaker (red circle) and turn the

black dial anticlockwise to 9:00, then turn

it clockwise to 12:00.

5a02:

Locate the multimeter (green circle) and

note down the displayed voltage.

6.6

Close and lock the control panel door, turn the machine on at the Machine

Isolator and the Rotary Isolator

6.7

The internal fan will start and the Reset button/ lockout (alarm) button will

illuminate

6.8

Wait for up to 5 minutes

6.9

Press the Reset (BLUE) button and hold

for 2 seconds

The blue lamp should go out and the machine should start within 5 minutes. If

the unit restarts no further action is required.

If the machine does not successfully run then contact Adveco with the alarm

codes and the voltage reading (if 5a02)

20

TOTEM 10 - TOTEM 20 - TOTEM 25 - On-site Maintenance Procedures

This manual suits for next models

2

Table of contents

Other Adveco Industrial Equipment manuals