Toro 22590 User manual

FormNo.3460-579RevA

GrappleBucket

CompactToolCarriers

ModelNo.22590—SerialNo.400000000andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3460-579*

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thegrapplebucketisaload-bearingattachment

intendedtobeusedonaT orocompacttoolcarrier.It

isdesignedprimarilyforgrabbing,dragging,lifting,

andremovingmaterialswithoutpickinguptopsoil

onresidentialorcommercialproperties.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g321300

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2022—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SlopeSafety.......................................................4

GrappleBucketSafety........................................4

MaintenanceandStorageSafety........................4

SafetyandInstructionalDecals..........................5

ProductOverview.....................................................6

Specications....................................................6

MaximumMaterialDensityatCapacity...............6

Operation..................................................................7

InstallingandRemovingtheAttachment.............7

GrappleBucketOperationandControl...............8

FillingtheBucket................................................9

TransportPosition..............................................9

Maintenance...........................................................10

RecommendedMaintenanceSchedule(s)...........10

LubricatingtheBucket......................................10

CheckingtheHydraulicLines...........................10

Storage....................................................................11

Safety

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

•Donotexceedtheratedoperatingcapacity,asthe

machinemaybecomeunstable,whichmayresult

inlossofcontrol.

•Donottransportanattachmentwiththearms

raisedorextended(ifapplicable).Always

transporttheattachmentclosetotheground;refer

toTransportPosition(page9).

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsawayfromthemachine.

•Stopthemachine,shutoffthemachine,and

removethekeybeforeservicing,fueling,or

uncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

3

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.Anempty

load-bearingattachmentmakestherearofthe

machinetheheavyend,andafullload-bearing

attachmentmakesthefrontofthemachinethe

heavyend.Mostotherattachmentsmakethefront

ofmachinetheheavyend.

•Raisingorextending(ifapplicable)theloaderarms

onaslopeaffectsthestabilityofthemachine.

Keeptheloaderarmsintheloweredandretracted

positionwhenonslopes.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.Tallgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Evaluatetheareatoensurethatthegroundis

stableenoughtosupportthemachine.

•Usecautionwhenoperatingthemachinenearthe

following:

–Drop-offs

–Ditches

–Embankments

–Bodiesofwater

Themachinecouldsuddenlyrolloverifatrack

goesovertheedgeortheedgecavesin.Maintain

asafedistancebetweenthemachineandany

hazard.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

GrappleBucketSafety

•Alwayslowertheattachment,closethejaws,and

shutoffthemachineeachtimeyouleavethe

operatingposition.

•Whenliftingtheattachment,keepitleveland

preventtheloadfromspillingbackward.

•Alwaysclosethejawsoftheattachmentwhen

notinuse.

•Alwaysgrabandliftlongitemsnearthecenter.

•Donotusethejawsforhookingand/orpulling.

Alwaysclampthematerialsecurely.

MaintenanceandStorage

Safety

•Checkfastenersatfrequentintervalsforproper

tightnesstoensurethattheequipmentisinsafe

operatingcondition.

•RefertothisOperator’sManualforimportant

detailsifyoustoretheattachmentforanextended

periodoftime.

•Maintainorreplacesafetyandinstructionlabels,

asnecessary.

4

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal125-6110

125-6110

1.Crushinghazard—donotstandunderanypartofthe

machine.

decal133-8061

133-8061

decal138-0537

138-0537

1.Warning—readthe

Operator’sManual.

2.Entanglementhazard,

grapple—keepbystanders

away.

decal144-2006

144-2006

1.Tippinghazard—readtheOperator’sManual;themaximumloadcapacityfortheTX1000is245kg(540lb);themaximumload

capacityfortheTX525/TX427is167kg(370lb);themaximumloadcapacityfortheDingo323/323-Dis72kg(160lb);the

maximumloadcapacityforthee-Dingois167kg(370lb).

5

ProductOverview

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width85.6cm(33.5inches)

Length78.2cm(30.8inches)

Height53.6cm(21.1inches)

Weight115kg(253lb)

Maximumloadrating

TX1000245kg(540lb)

TX525andTX427167kg(370lb)

323and320-DCompactT ool

Carrier

72kg(160lb)

e-Dingo167kg(370lb)

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

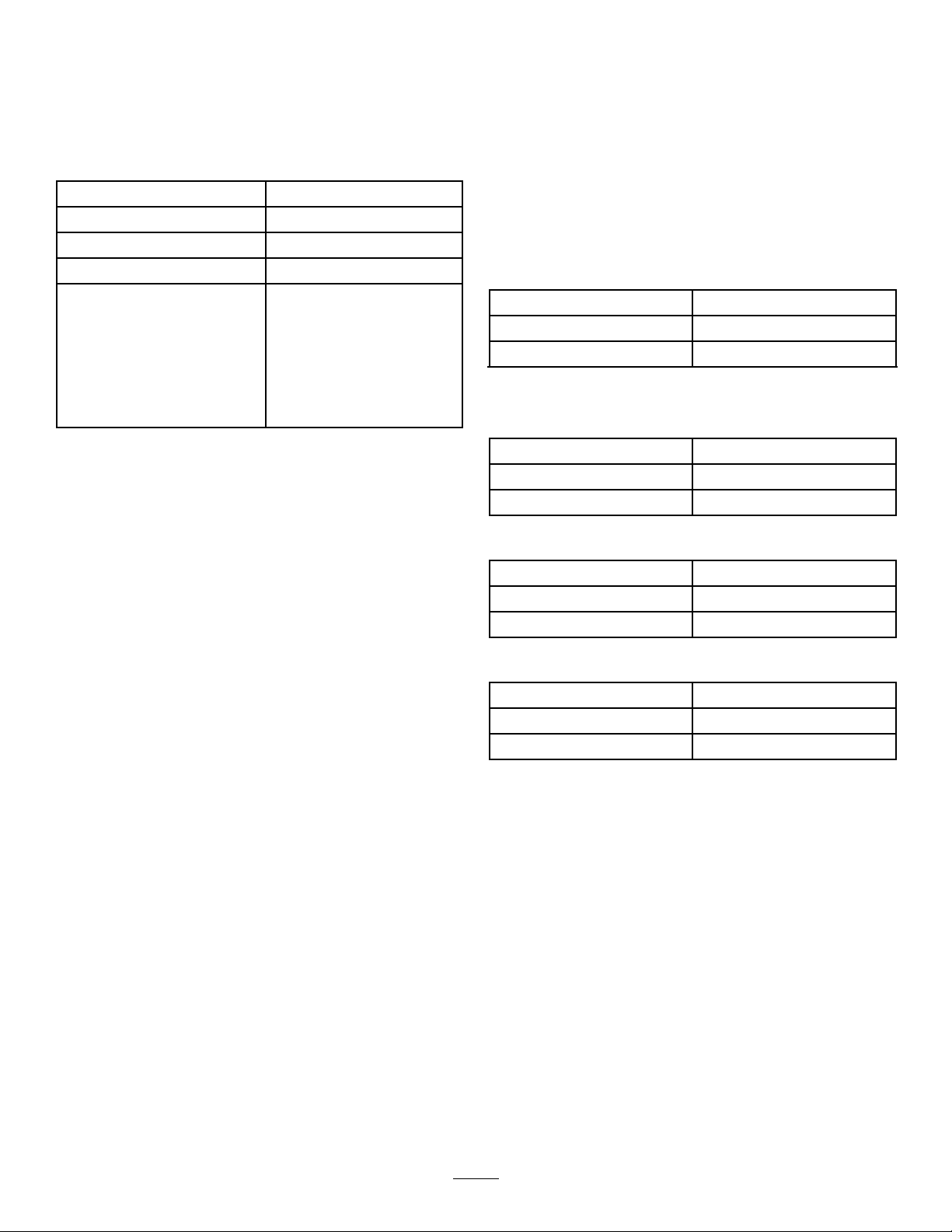

MaximumMaterialDensityat

Capacity

Thedensityofthematerialsmovedbythebucket

variesand,therefore,sodoestheamountofmaterial

thatthebucketcancarrybeforereachingthe

maximumloadrating.Therst2tablesliststhe

densityofmaterialthatcanbecarried,bothheaped

andstruck(i.e.,leveledoff),inthebucket.The

MaterialDensitytablelistscommonmaterialsand

theirdensities.

TX1000

BucketCapacityMaximumDensity

Struck(leveled)bucket3962kg/m3(259lb/ft3)

Heapedbucket3170kg/m3(212lb/ft3)

Note:Maximumdensity=Maximumloadrating/Capacity

TX525andTX427

BucketCapacityMaximumDensity

Struck(leveled)bucket2262kg/m3(148lb/ft3)

Heapedbucket1810kg/m3(121lb/ft3)

323and320-DCompactToolCarrier

BucketCapacityMaximumDensity

Struck(leveled)bucket1185kg/m3(74lb/ft3)

Heapedbucket961kg/m3(60lb/ft3)

e-Dingo

BucketCapacityMaximumDensity

Struck(leveled)bucket2611kg/m3(163lb/ft3)

Heapedbucket208kg/m3(13lb/ft3)

6

MaterialDensity

MaterialDensity(Approximate)

Caliche1250kg/m3(78lb/ft3)

Clay:

Naturalbed1600kg/m3(104lb/ft3)

Dry1480kg/m3(93lb/ft3)

Wet1660kg/m3(104lb/ft3)

Withgravel,dry1420kg/m3(89lb/ft3)

Withgravel,wet1540kg/m3(96lb/ft3)

Coal:

Anthracite,broken1100kg/m3(69lb/ft3)

Bituminous,broken830kg/m3(52lb/ft3)

Earth:

Dry,packed1510kg/m3(94lb/ft3)

Wet,packed1600kg/m3(100lb/ft3)

Loam1250kg/m3(78lb/ft3)

Granite,brokenorlarge

crushed

1660kg/m3(104lb/ft3)

Gravel:

Dry1510kg/m3(94lb/ft3)

Pitrun(graveledsand)1930kg/m3(120lb/ft3)

Dry,13to51mm(1/2to2

inch)

1690kg/m3(106lb/ft3)

Wet,13to51mm(1/2to2

inch)

2020kg/m3(126lb/ft3)

Limestone,brokenorcrushed1540kg/m3(96lb/ft3)

Sand:

Dry1420kg/m3(89lb/ft3)

Wet1840kg/m3(115lb/ft3)

Withgravel,dry1720kg/m3(107lb/ft3)

Withgravel,wet2020kg/m3(126lb/ft3)

Sandstone,broken1510kg/m3(94lb/ft3)

Shale1250kg/m3(78lb/ft3)

Slag,broken1750kg/m3(109lb/ft3)

Stone,crushed1600kg/m3(100lb/ft3)

Topsoil950kg/m3(59lb/ft3)

Operation

Determinetheleftandrightsidesofthemachinefrom

thenormaloperatingposition.

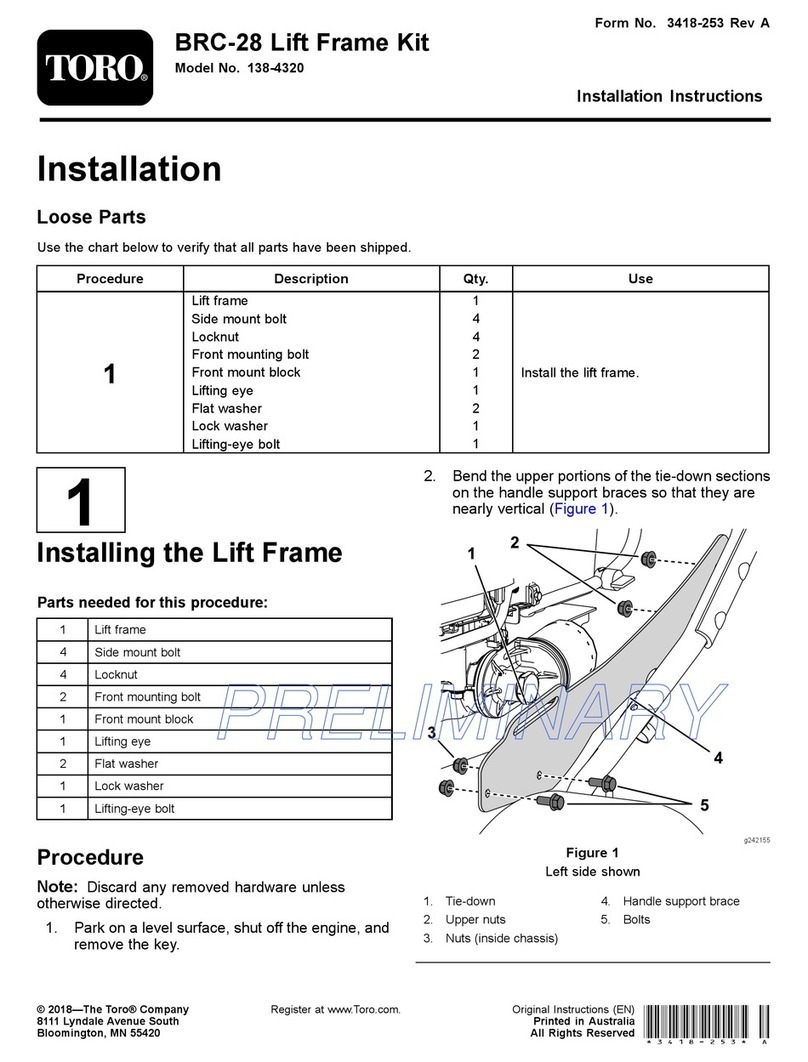

InstallingandRemoving

theAttachment

RefertotheOperator’sManualforthetractionunitfor

theinstallationandremovalprocedure.

Important:Beforeinstallingtheattachment,

positionthemachineonalevelsurface,ensure

thatthemountplatesarefreeofanydirtordebris,

andensurethatthepinsrotatefreely.Ifthepins

donotrotatefreely,greasethem.

Note:Alwaysusethetractionunittoliftandmove

theattachment.

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

7

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponents,youmaybeburned.

•Weargloveswhendisconnectingthe

hydrauliccouplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

GrappleBucketOperation

andControl

Afteryouattachthegrapplebuckettothemountplate

ofthetractionunit,ensurethatthehydrauliccouplers

areconnected.Startandrunthemachineatfull

throttle(maximumenginespeed).

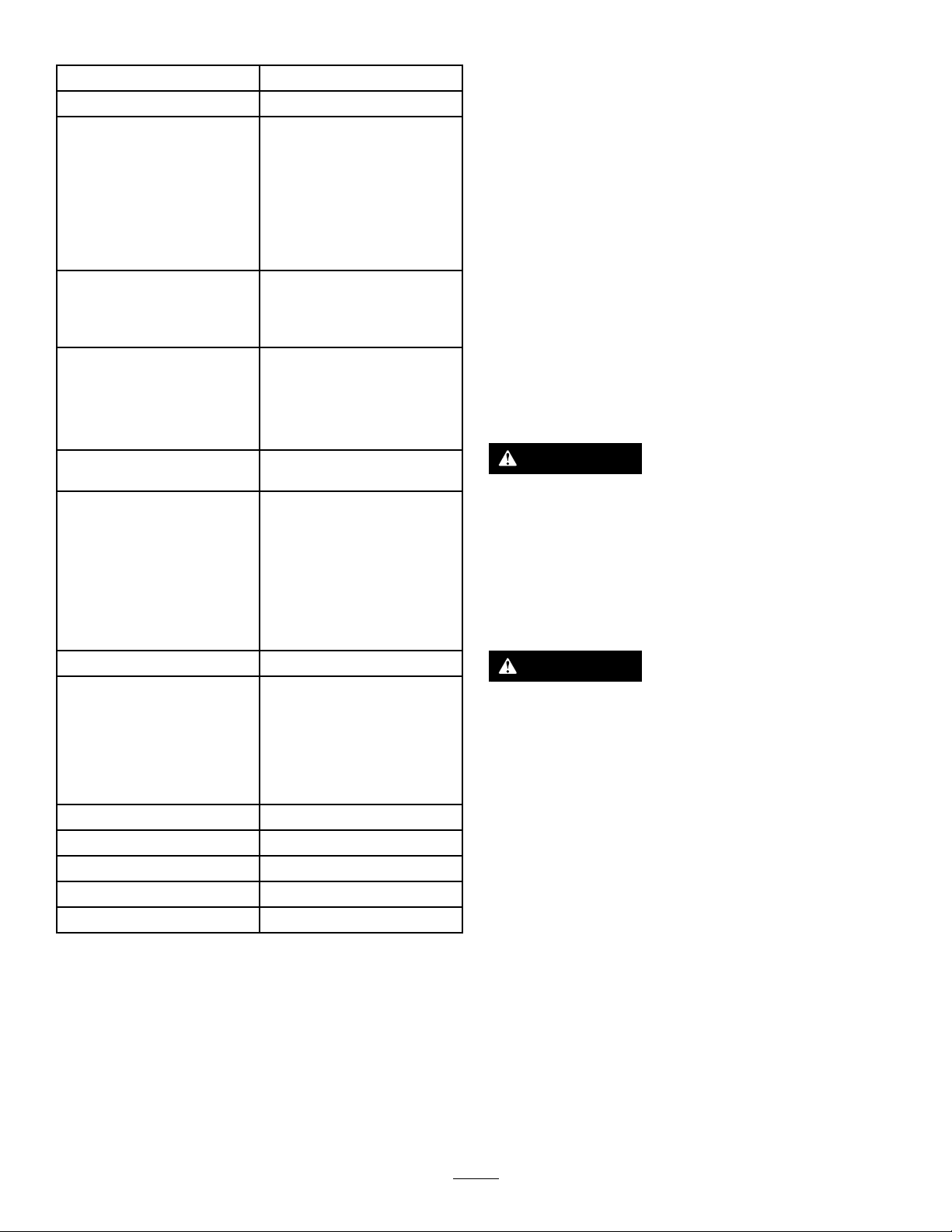

Digging/RakingwiththeJaw

1.Todigorrakeusingthejaw,openthejawallthe

way,andtilttheattachmentforwarduntilthejaw

teethtouch(orpenetrate)theground.

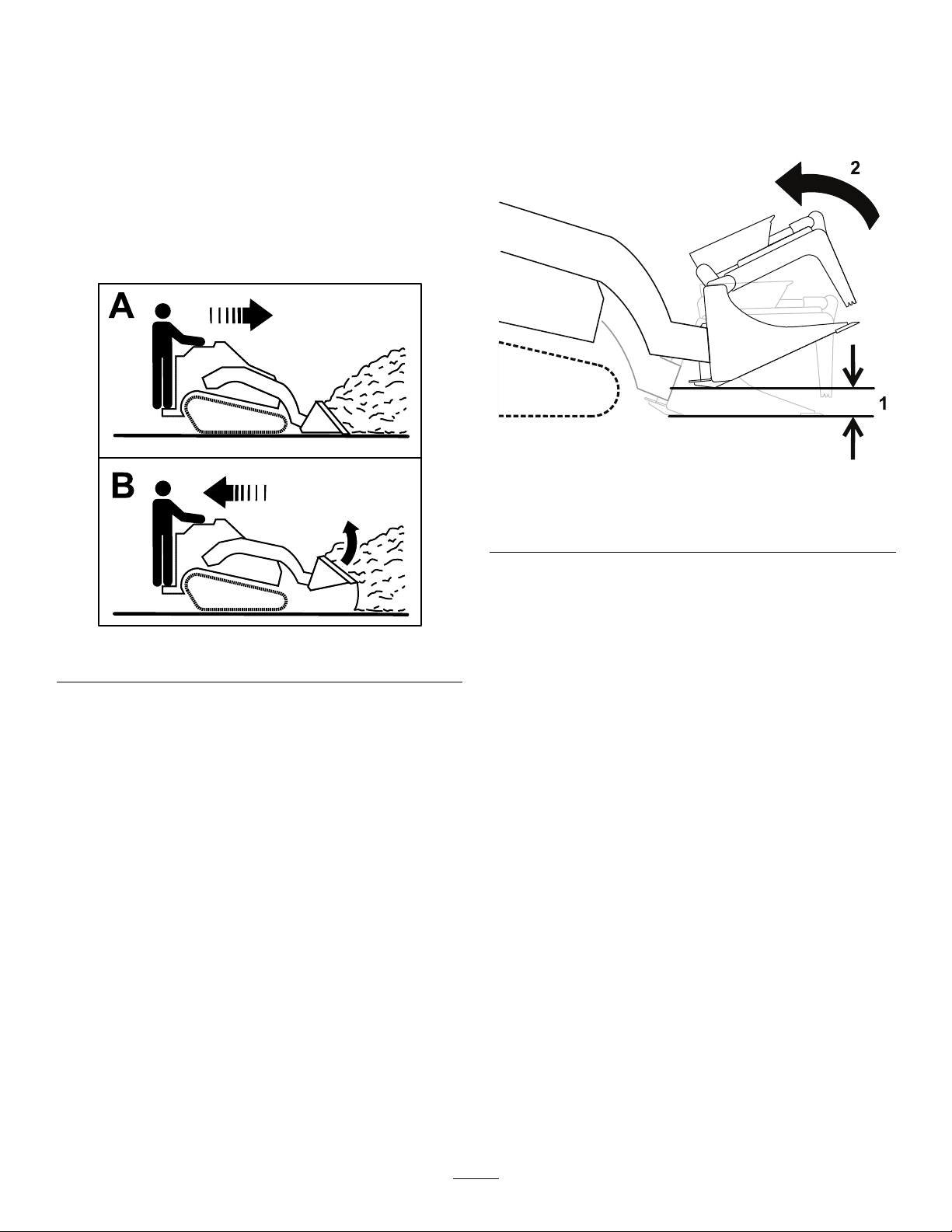

2.Drivethemachinerearwards.Torakeuploose

sticksandotherdebris,whichyoucanthengrab

withthejaws,placetheteethontheground.To

digfurrowsintheearthandbreakupthesod,

penetratethegroundwiththeteeth(Figure3).

g324965

Figure3

3.Youcanalsousethismethodtoripoutbushes.

Placetheupperjawteethintothegroundonthe

farsideofthebush,closethejawsaroundthe

bushandroots,thentilttheattachmentrearward

toripthebushoutoftheground.

BucketOperation

Withthejawsopen,youcanusethisattachmentas

astandardbucket.

Whenloadingmaterial,alwayshavethebucketlevel

tothegroundandmoveforwardintothematerialto

belifted.Whenthebucketisfull,tiltitrearwardto

decreasetheliftingresistancewhenyoulifttheload.

Whentransportingaload,keepthebucketasclose

tothegroundaspossible.

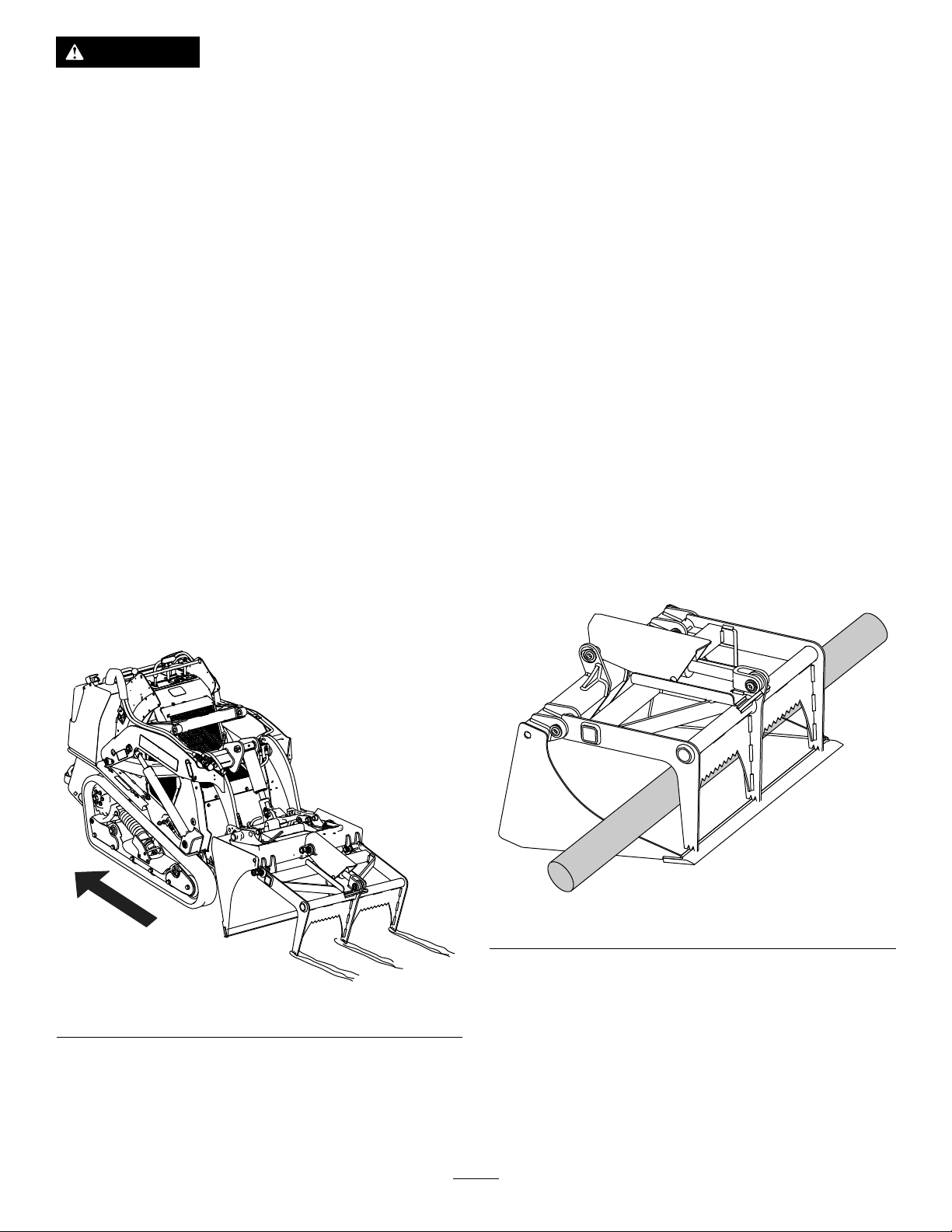

GrappleOperation

Usethejawsforpickingupmaterialbyclosingthem

overobjectsormaterialstobetransported(Figure4).

Important:Grabobjectsfromthecenter.

Neverliftmorethantheratedliftcapacityof

theattachmentaslistedonthedecals.When

transportingaload,keepitasclosetotheground

aspossiblewiththeloaderarmsretracted.

Important:Ifyouareliftingmoredelicateor

hollowitems,suchascrates,closethejawswith

caresoasnottocrushtheitembeingmoved.

Note:Takecarewhenusingthismethodthatyoudo

notcrushanobjectthatyouarepickingupbetween

thejaws.

g320031

Figure4

8

FillingtheBucket

1.Positionthebucketleveltotheground.

2.Driveforwardandinsertthebucketintothepile

ofmaterial.

3.Whenthebucketisfull,drivethemachinein

reverseandgentlytiltthebucketrearwardto

decreasetheliftingresistancewhenyouliftthe

load.

Important:Alwayscarryloadsclosetothe

ground;refertoTransportPosition(page9).

g266856

Figure5

TransportPosition

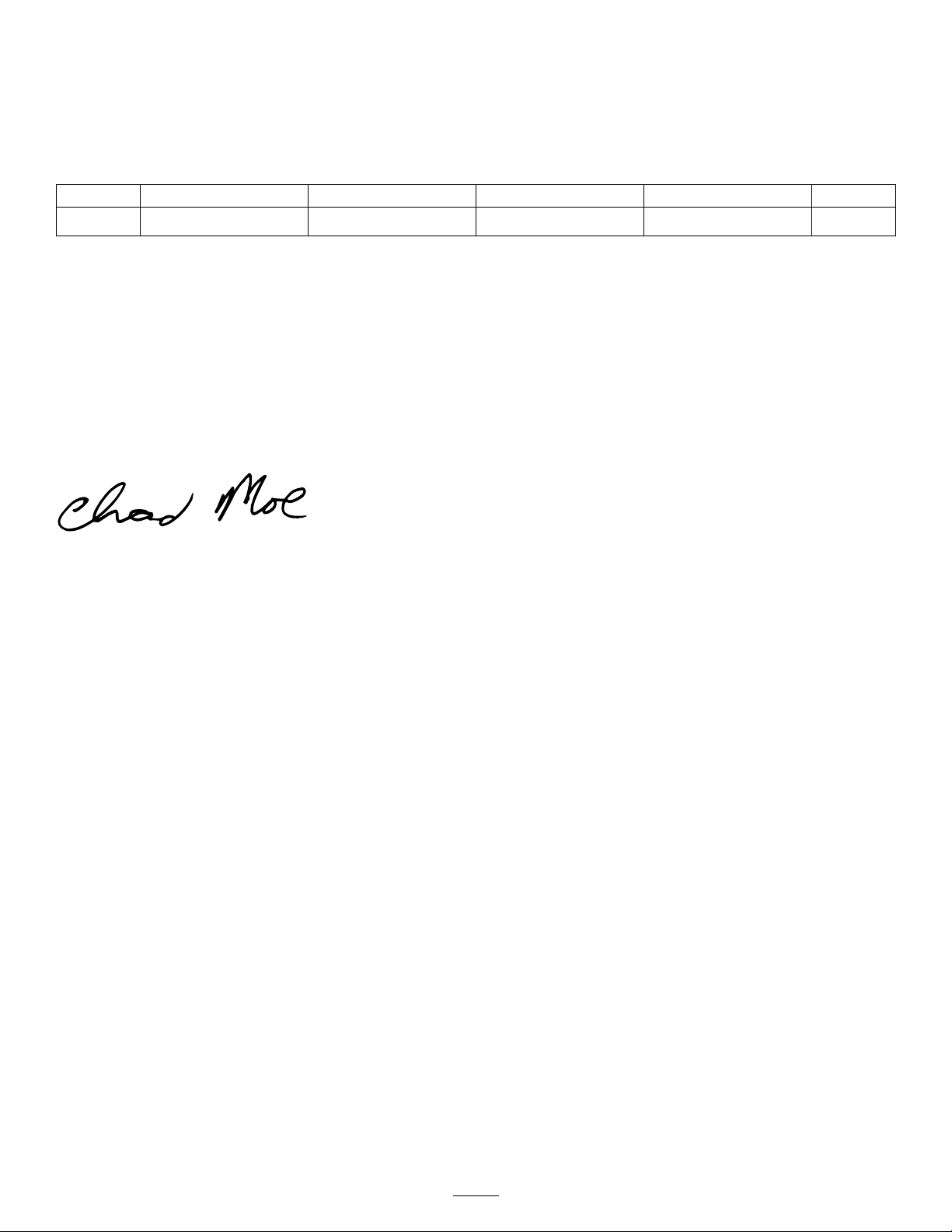

Whentransportingaload,keeptheattachmentas

closetothegroundaspossible,nomorethan15cm

(6inches)abovetheground.Tiltitrearwardtokeep

theloadlevel.

g319918

Figure6

1.Nomorethan15cm(6

inches)abovetheground

2.Tilttheloadrearward

9

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Beforeeachuseordaily

•Lubricatethebucket.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Ensurethatallfastenersaresecurelytightened.

•Cleantheareasaroundthebucketcylinderandmountplatepivot.

•Checkforwearofpins,linkages,andcuttingedges.

Every200hours•Inspectthehydraulichosesandreplacethemiftheyaredamaged.

Beforestorage

•Inspectthehydraulicsystemforleaksandloosettings.

•Inspectthehydraulichosesandreplacethemiftheyaredamaged.

•Paintchippedorwornsurfaces.

LubricatingtheBucket

ServiceInterval:Beforeeachuseordaily

Usingagreasegun,pumpgeneralpurposegrease

intoeachofthe4greasettingsonthegrapplebucket

untilthegreasebeginstoooze(Figure7).Wipeaway

anyexcessgreasewithashopcloth.

g320032

Figure7

Leftsideshown

1.Greasettings

CheckingtheHydraulic

Lines

ServiceInterval:Beforeeachuseordaily

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

10

Storage

1.Beforelong-termstorage,washtheattachment

withmilddetergentandwatertoremovedirtand

grime.

2.Checkandtightenallhardware.Repairor

replaceanypartthatisdamagedorworn.

3.Ensurethatallofthehydraulichosecouplers

areconnectedtogethertopreventcontamination

ofthehydraulicsystem.

4.Paintallscratchedorbaremetalsurfaces.

Note:PaintisavailablefromyourAuthorized

ServiceDealer.

5.Greasethepivotpoints;refertoLubricatingthe

Bucket(page10).

6.Storetheattachmentinaclean,drygarageor

storagearea.

7.Coverthebuckettoprotectitandkeepitclean.

11

DeclarationofIncorporation

TheToroCompany,8111LyndaleAvenueSouth,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionDirective

22590400000000andUpGrappleBucket,Compact

ToolCarriersDINGOBUCKETGRAPPLEBucket2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

ChadMoe

Sr.EngineeringManager

8111LyndaleAve.South

Bloomington,MN55420,USA

November21,2022

UKDeclarationofIncorporation

TheToroCompany,8111LyndaleAvenueSouth,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)totheregulationslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsonto

certainToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionRegulation

22590400000000andUpGrappleBucket,Compact

ToolCarriersDINGOBUCKETGRAPPLEBucketS.I.

2008/1597

RelevanttechnicaldocumentationhasbeencompiledasrequiredperSchedule10ofS.I.2008No.1597.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantregulations.

Thisdeclarationhasbeenissuedunderthesoleresponsibilityofthemanufacturer.

TheobjectofthedeclarationisinconformitywithrelevantUKlegislation.

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroU.K.Limited

SpellbrookLaneWest

Bishop'sStortford

CM234BU

UnitedKingdom

ChadMoe

Sr.EngineeringManager

8111LyndaleAve.South

Bloomington,MN55420,USA

November21,2022

EEA/UKPrivacyNotice

Toro’sUseofYourPersonalInformation

TheToroCompany(“Toro”)respectsyourprivacy.Whenyoupurchaseourproducts,wemaycollectcertainpersonalinformationaboutyou,eitherdirectly

fromyouorthroughyourlocalT orocompanyordealer.Torousesthisinformationtofullcontractualobligations-suchastoregisteryourwarranty,

processyourwarrantyclaimortocontactyouintheeventofaproductrecall-andforlegitimatebusinesspurposes-suchastogaugecustomer

satisfaction,improveourproductsorprovideyouwithproductinformationwhichmaybeofinterest.T oromayshareyourinformationwithoursubsidiaries,

afliates,dealersorotherbusinesspartnersinconnectiontheseactivities.Wemayalsodisclosepersonalinformationwhenrequiredbylaworin

connectionwiththesale,purchaseormergerofabusiness.Wewillneversellyourpersonalinformationtoanyothercompanyformarketingpurposes.

RetentionofyourPersonalInformation

Torowillkeepyourpersonalinformationaslongasitisrelevantfortheabovepurposesandinaccordancewithlegalrequirements.Formoreinformation

aboutapplicableretentionperiodspleasecontact[email protected].

Toro’sCommitmenttoSecurity

YourpersonalinformationmaybeprocessedintheUSoranothercountrywhichmayhavelessstrictdataprotectionlawsthanyourcountryofresidence.

Wheneverwetransferyourinformationoutsideofyourcountryofresidence,wewilltakelegallyrequiredstepstoensurethatappropriatesafeguardsare

inplacetoprotectyourinformationandtomakesureitistreatedsecurely.

AccessandCorrection

Youmayhavetherighttocorrectorreviewyourpersonaldata,orobjecttoorrestricttheprocessingofyourdata.Todoso,pleasecontactusbyemail

at[email protected].IfyouhaveconcernsaboutthewayinwhichT orohashandledyourinformation,weencourageyoutoraisethisdirectlywithus.

PleasenotethatEuropeanresidentshavetherighttocomplaintoyourDataProtectionAuthority.

374-0282RevC

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all.

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromToroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifT orodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Table of contents

Other Toro Industrial Equipment manuals

Toro

Toro MB TX 2500 User manual

Toro

Toro BRC-28 User manual

Toro

Toro 60216C User manual

Toro

Toro 110-5076 User manual

Toro

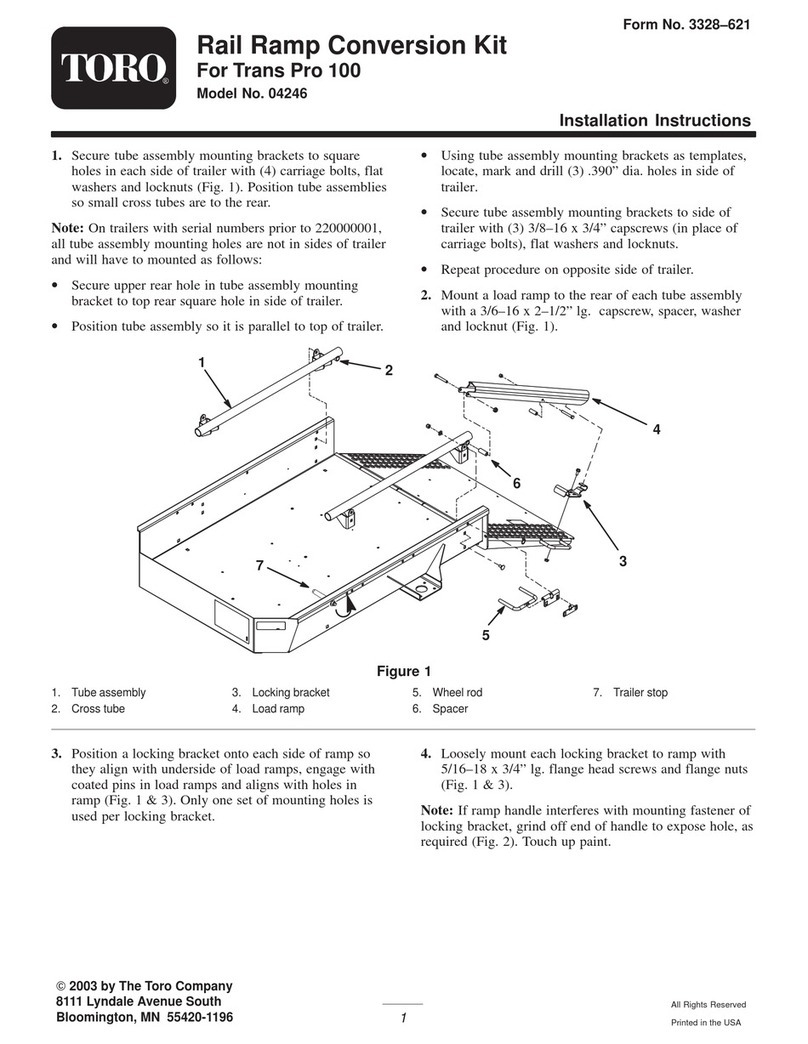

Toro 04246 User manual

Toro

Toro 22340 User manual

Toro

Toro Ultra Buggy e2500 User manual

Toro

Toro Groundsmaster 3320 User manual

Toro

Toro 301 High Lift User manual

Toro

Toro OSMAC G3 Satellite User manual

Toro

Toro MB TX 2500 User manual

Toro

Toro TX 1300 User manual

Toro

Toro Workman Topdresser 1800 User manual

Toro

Toro LAC TM User manual

Toro

Toro MH-400SH2 User manual

Toro

Toro MH-400SH2 User manual

Toro

Toro Greensmaster eFlex 1021 User manual

Toro

Toro Workman 07224-90001 Instruction Manual

Toro

Toro FM 330 User manual