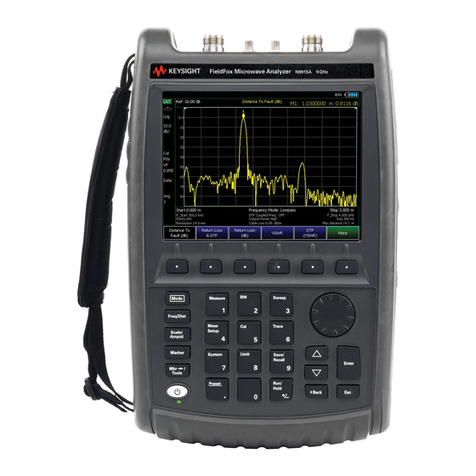

ProParts Spek 14820 User manual

Wiring Installation Instructions for : R M Tachometer

21/16” Controller

S EK™ MONITOR AND CONTROL ERFORMANCE GAUGE TACHOMETER

FEATURES:

S EK ERFORMANCE GAUGE TACHOMETER FEATURES:

• INTELLIGENT ELECTRICAL GAUGES.

• GAUGES ARE PROGRAMMED THROUGH COMMAND KEYS ON FACEPLATE.

• STEPPER MOTOR DRIVES THE GAUGE POINTER OVER A 280 DEGREE SWEEP.

• WIDE-ANGLE-DIAL™ HAS A 15% LARGER VIEWING AREA ON A 2 1/16” GAUGE.

• PROGRAMMABLE 7 COLOR DIAL AND RED POINTER ILLUMINATION.

• OPTIONAL OUTPUT CONTROL MODULE.

INSTALLATION INSTRUCTIONS:

1DISCONNECT NEGATIVE (-) BATTERY TERMINAL.

2 VARIOUS MOUNTING SOLUTIONS ARE PRESENTED BY PROPARTS

DASH INSTALLATION: SELECT LOCATION IN THE DASH TO MOUNT GAUGE AND

CUT A 2 1/16” HOLE. USE A FILE TO INCREASE THE HOLE SIZE IF REQUIRED. BE SURE THERE IS

SUFFICIENT ROOM BEHIND THE HOLE FOR THE METER CASE AND THE CONNECTORS YOU WILL USE.

3IF A SUITABLE HOLE IN THE FIRE WALL IS NOT AVAILABLE, CUT AN 11/16” HOLE.

4TWO GROMMETS MUST BE CUT TO PERMIT INSTALLATION OF WIRING HARNESS. (SEE DIAGRAM 1)

5INSTALL THE GROMMET AND MOUNTING CUP ON THE WIRING HARNESS AS SHOWN IN DIA-

GRAM 1. GROMMET IS FOR THE HOLE IN THE FIREWALL AND IF REQUIRED, THE SECOND IS FOR

THE BACK OF THE GAUGE MOUNTING CUP.

ACKAGE CONTAINS:

• Tachometer Gauge 2 1/16” INCH

• Wiring Harness

• Mounting Cup (Not required for pod installation)

• (2) Neoprene EDPM Grommets

• Output Control Module : Part #’s 14820, 14826, 14829

ACKAGE CONTAINS:

6DO NOT CONNECT WIRING HARNESS TO THE GAUGE UNTIL THE OTHER CONNECTIONS HAVE

BEEN MADE AND TESTED.

7CONNECT THE RED (+ 12 VOLT SUPPLY) WIRE TO “ON” CIRCUITS THAT GET POWER WHEN THE

IGNITION IS TURNED-ON. THIS CIRCUIT MUST BE FUSED BEFORE THE

IGNITION SWITCH (1 AMP, 3AG FAST ACTING FUSE® #312001 OR EQUIVALENT).

8CONNECT THE BLACK WIRE TO A GOOD GROUNDING POINT ON THE CAR’S CHASSIS.

9CONNECT THE WHITE WIRE TO THE DIMMER VOLTAGE GOING TO THE DASH LIGHTS. THIS WILL

CAUSE THE METER BRIGHTNESS TO TRACK THE BRIGHTNESS OF THE REST OF THE INDICATORS.

THIS CIRCUIT MUST PRODUCE 3 TO 12VDC BEFORE THE PPR CAN BE PROGRAMMED.

10 CONNECT THE SENSING WIRE TO THE PRIMARY TERMINAL ON THE IGNITION COIL

(STANDARD-TYPE COIL) OR TO THE AUXILIARY TERMINAL MEANT FOR THE TACH WIRE (AFTER

MARKET, HIGH PERFORMANCE COIL). DO NOT CONNECT TO COIL ON MSD IGNITION. ATTACH ONLY

TO TACH TERMINAL.

11 PLUG THE WIRING HARNESSES INTO THE GAUGE AND MOUNT IN POD OR DASH.

12 FOR DASH INSTALLATION, ATTACH MOUNTING CUP OVER THE BACK OF THE GAUGE AND HAND

TIGHTEN. DO NOT OVER TIGHTEN. MOUNT CUP BEFORE INSTALLING GROMMET. FAILURE TO DO

SO WILL TWIST WIRES CAUSING A SHORT CIRCUIT.

13 POWER UP THE GAUGE AND INSPECT ALL CONNECTIONS. IF GAUGE IS OPERATING NORMALLY,

PROCEED TO “PROGRAMMING MANUAL”.

Wiring Installation Instructions for : R M Tachometer

21/16” Controller

PIN 12 Ground/Black

PIN 8 +12 VDC/Red

PIN 5 1.9 Amp Fet Output/ Purple

PIN 6 Dimmer/White

PIN 11 Tachometer Input/Green

GREEN - TACH INPUT

TACHOMETER

Terminal

Electronic Ignition

WARNING

Warranty will be void if

connected to Coil on HSD Terminal.

Attach only to TACHOMETER Terminal

Black-Chassis Ground

Firewall

Grommet

10-Pin Wiring

Harness & Plug

GAUGE

5-Pin Wiring Harness

3-Pin Wiring Harness

OR

CUP

Grommet

Red-12V

Ignition Switch

White-12V

Dash Lighting

HEADLIGHT

SWITCH

Fuse

Grommet

Cut

85

86

87A

30

87

Gauge

PIN 8 Output/Purple

FET

Output

CAUTION: 12 VOLT DC POWER

MUST BE CONNECTED TO THE

IGNITION POWER AFTER A

20 AMP FUSE (USER SUPPLIED)

WARNING: OUTPUT CONTROL MODULE

NOT TO EXCEED 1.5 AMPS AT 12 VOLTS DC.

WARRANTY WILL BE VOID IF INCREASED

OUTPUT VOLTAGE OR CURRENT IS APPLIED.

OPTIONAL: PART# 14820

OUTPUT CONTROL MODULE:

ALL SPEK GAUGES HAVE A

PROGRAMMABLE LIMIT SETTING .

WHEN A SETTING IS TRIPPED,

AN OUTPUT SIGNAL IS

GENERATED. THIS CAN BE

USED TO SWITCH ON A

RUGGED 35 AMP RELAY

TO ACTIVATE A LOW OIL ENGINE

KILL, ALARMS, CUT THROTTLE

BODY SENSOR TO DEFUEL

KILL BOOST VALVE.

A

TO OUTPUT

CONTROL MODULE

A

TO: RED

IGNITION

SWITCH

+12VDC

DIAGRAM 1

ATENTED WIDE ANGLE DIAL

FOR SU ERIOR VISIBILITY

U.S ATENT #7,278,749

Wiring Installation Instructions for : R M Tachometer

21/16” Controller

DIAGRAM 2

CAUTION:

DIMMER CIRCUIT MUST

HAVE 3 TO 12VDC TO

PROGRAM PPR.

1 2 3 4 5 6

7 8 9 10 11 12

Wiring Installation Instructions for : R M Tachometer

21/16” Controller

THERE ARE THREE SECTIONS TO THIS MANUAL: WIRING INSTRUCTIONS, ROGRAMMING

INSTRUCTIONS AND FLOW CHART ROGRAMMING INSTRUCTIONS. LEASE READ EACH

SECTION CAREFULLY BEFORE ATTEM TING TO INSTALL OR O ERATE THIS RODUCT.

WARNING:

• ALL INSTRUCTIONS IN THIS MANUAL MUST BE FOLLOWED TO INSURE SAFE INSTALLA-

TION AND O ERATION OF THIS RODUCT.

• NEVER DISASSEMBLE MODIFY OR TAM ER WITH THIS RODUCT. THIS COULD CAUSE

DAMAGE AND MAKE THEM UNSAFE TO USE. TAM ERING WITH THE RODUCT WILL VOID

THE LIMITED WARRANTY.

• INSTALLATION MUST BE ERFORMED BY AN EX ERIENCED AUTOMOTIVE TECHNICIAN.

• INSTALLER MUST USE SAFETY GLASSES.

• DISCONNECT THE NEGATIVE BATTERY TERMINAL BEFORE BEGINNING INSTALLATION.

RO ARTS LLC IS NOT RES ONSIBLE FOR DAMAGE TO ENGINE, VEHICLE OR UNIT CAUSED

BY ELECTRICAL SHORTS.

• DURING INSTALLATION, DO NOT INTERFERE WITH ANY EXISTING CONNECTIONS OR

WIRES.

• ALL ELECTRICAL CONNECTIONS USE SOLDER LESS CONNECTORS AND INSULATE ALL

CONNECTIONS WITH ELECTRICAL TA E.

• AVOID WIRING NEAR ENGINE, EXHAUST SYSTEM, TURBINE OR ANY AREA THAT MAY RE-

SULT IN DAMAGE.

• DISCONTINUE USE OF THE RODUCT IF SMOKE OR A STRANGE ODOR IN RESENT.

CAUTION

• RO ARTS LLC IS NOT RES ONSIBLE FOR INCORRECT INSTALLATION OR ROGRAMMING

OF S EK™ GAUGES OR CONTROLLERS.

• S EK™ GAUGES AND CONTROLLERS ARE DESIGNED FOR 12V DC ELECTRICAL SYSTEMS

WITH A NEGATIVE GROUND.

• DO NOT ADJUST THE GAUGES OR GAUGE ROGRAM WHILE DRIVING

• OBEY ALL RULES AND REGULATIONS OF HIGHWAY AND STREET DRIVING.

• INSTALL SENSOR AND WIRE AWAY FROM HIGH HEAT AND / OR VIBRATION AREAS.

• USE CARE WHEN CONNECTING OR DISCONNECTING THE WIRING HARNESS. ULL OUT

EACH CONNECTOR WHILE RESSING THE LOCK OF THE CONNECTOR FIRMLY.

• IF THE BATTERY TERMINAL IS DISCONNECTED, THE AUDIO, CLOCK AND OTHER MEMORY

DATA MAY BE LOST. THE NECESSARY DATA WILL HAVE TO BE RESET AFTER INSTALLA-

TION.

ro arts, LLC Limited Warranty:

ProParts, LLC warrants all merchandise against defects in factory workmanship and material for 12 months from

date of original purchase. Proof of purchase is required: otherwise the warranty period shall default to 12 months

from date of manufacture as indicated by the date code on the product. This warranty applies to the first retail

purchaser and covers only those products exposed to normal use or service. This warranty excludes items used

for a purpose for which it is not designed, or which has been altered in any way that would be detrimental to the

performance or life of the product or misapplication, misuse, negligence or accident. When it is determined by

ProParts, LLC after examination that a product is defective, ProParts, LLC will repair, replace or issues credit for

any defective product through the original selling dealer or on a direct bases. In no event shall this warranty ex-

Wiring Installation Instructions for : R M Tachometer

21/16” Controller

ceed the original price of the product. ProParts, LLC assumes no responsibility for diagnosis, removal and/ or in-

stallation labor, loss of vehicles use, loss of time, inconvenience or any other consequential expense. ProParts,

LLC disclaims any liability for consequential damages due to breach of any written or implied warranty on all

products manufactured by ProParts LLC. Warranty is valid only for original purchaser and is not transferable. This

Warranty gives you specific legal rights, and may also have other rights which may vary from state to state. Cus-

tomer agrees to insure the Product or assume the risk of loss or damage in transit, to prepay shipping charges to

ProParts, and to use the original shipping container or equivalent.

Important Disclaimer:

This product may not be lawful for use on public roadway. No warranty is made or implied regarding the legality

of offered products when they are installed in a motor vehicle in any particular state, province or municipality. It

is the user’s responsibility to determine the legality of any automotive alterations made in connection to products

made by, obtained from or distributed by ProParts, LLC.

The purchaser or user of any products, sold or manufactured by ProParts, LLC assumes all risk related to and/ or

arising from the ownership or use of said product and agrees to indemnify and hold ProParts, LLC harmless from

any and all claims brought by any person or entity against ProParts, LLC related to and/or arising from ownership

and/or use of said products.

Non-Warranty Repair/Retest

Products returned due to damage or misuse and Product retested with no problem found are subject to

repair/retest charges. A purchase order or credit card number and authorization must be provided in order to ob-

tain an RMA (Return Merchandise Authorization) number prior to returning product.

no event shall this warranty exceed the original price of the product. ProParts LLC assumes no responsibility for

diagnosis, removal and/or installation labor, loss of vehicles use, loss of time, inconvenience or any other

consequential expense. ProParts LLC disclaims any liability for consequential damages due to breach of any

written or implied warranty on all products manufactured by ProParts LLC.

The purchaser or user of any products distributed, sold or manufactured by ProParts, LLC assumes all risk related

to and/or arising from the ownership or use of said product and agrees to indemnify and hold ProParts, LLC

harmless from any and all claims brought by any person or entity against Proparts, LLC related to and/or arising

from ownership and/or use of said product.

Programming Instructions for : RPM achometer

21/16” Controller

SPEK™ MONI OR AND CON ROL PERFORMANCE GAUGE ACHOME ER

Refer to the “Flow Chart Programming Instructions” while reviewing this guide.

Gauge is field programmable by the operator while installed in the vehicle. This programming is

accessed by pressing the control buttons located on the face or the meter dial, ONE A A IME.

The “Down” and “Up” buttons move the pointer to a desired setting or controls the faceplate

illumination. The center “Mode” button will save the setting you choose and proceed to the next

level. Pressing the “Mode” and “Up” or “Mode” and “Down” buttons simultaneously and holding

them for 5 seconds in any level will shift you to the Submenu.

DOWN MODE UP

+

–

MAIN MENU

NORMAL OPERA ION

PEAK PLAYBACK

HIGH RED-LINE SE ING

LOW HRESHOLD SE ING

COLORSCHEME

DIAL BRIGH NESS

SUBMENU

OP ION:SELEC PPR

OP ION:RES ORE FAC ORY DEFAUL

OP ION: DEMO MODE

OP ION: POIN ER BRIGH NESS

U. S. PATENTS 7,612,660 AND 7,278,749 ADDITIONAL PATENTS PENDING.

PROGRAMMING S AR S IN

MAIN MENU

PRESS PROGRAM BUTTO O E (1) AT A TIME I THE MAI ME U MODE.

1NORMAL OPERA ION:

On power up, the meter usually starts in NORMAL operating mode. The Tachometer will read en-

gine’s RPM. Press the center “mode” button to advance to 2PEAK PLAYBACK

2PEAK PLAYBACK:

Reads the highest value displayed on the meter since the last time the “Peak” value was displayed.

Pressing the “Down” or “Up” control button will control the gauge dial illumination. Press the center

“Mode” button to advance to 3HIGH RACING RED-LINE SE ING

3HIGH RACING RED-LINE SE ING:

Sets the point at which “HIGH” warning RED-LI E is reached for that specific gauge. The “Down and

“Up” buttons will move the dial pointer to select “Maximum RED-LI E”. During normal operation the

gauge constantly monitors the sensor value and compares it to the “HIGH” RED-LI E. If the

threshold is exceeded, the red “HI” indicator is turned on and an output signal generated. Press the

center “Mode” button to save the setting and advance to 4LOW RACING YELLOW-LINE

SE ING

4LOW RACING YELLOW-LINE SE ING:

Set the Minimum RED-LI E: Sets the point at which “LOW” warning threshold is reached for that

specific gauge. The “Down” and “Up” buttons will move the dial pointer to select the LOW

RACING YELLOW-LINE SE ING. During normal operation the gauge constantly monitors the

sensor value and compares it to the “LOW” threshold. If the sensor value drops below the threshold,

the yellow “LOW” indicator is turned on and an output signal generated. Press the center “Mode”

button save the setting and advance to 5COLORSCHEME

5COLORSCHEME:

Set Faceplate Color Scheme: Operator can select the color of the gauge dial illumination. Each time

you press the “Down” control button you scroll through dial color selection until the dial light goes

off. Then press the “Up” button to reverse the scroll. Select your dial color illumination by pressing

the center “Mode” button to save the setting and advance to NORMAL OPERA ION.

6DIAL BRIGH NESS:

Adjust the dial brightness for day or evening driving conditions The RIGHT and LEFT command but-

tons will dim or brighten the faceplate illumination. Press the center “Mode” button to save the set-

ting and advance you to ORMAL OPERATIO

Programming Instructions for : RPM achometer

2 1/16” Controller

SUBMENU

SUBME U IS ACCESSED THROUGH THE MAI ME U. FIRST GO TO THE APPROPRIATE LEVEL OF THE

MAI ME U A D THE FOLLOW THE I STRUCTIO S I THE PROGRAMMI G FLOW DIAGRAM TO

E TER THE SUBME U. PRESS THE “MODE” A D “UP” OR “MODE” A D “DOW ” BUTTO S

SIMULTA EOUSLY FOR 5 SECO DS TO E TER THE SUBME U A D O E BUTTO AT A TIME WHILE

I THAT SUBME U.

OP ION:SELEC PPR: (Pulses Per Revolution) Select the PPR value by pressing “Down or “Up”

button to move dial pointer to corresponding RPM. For additional information see the Tachometer

Sense Line Attachment and Meter Setting section on page 4.

OP ION:RES ORE FAC ORY DEFAUL : TO RESTORE FACTORY DEFAULTS, PRESS THE

:MODE” BUTTO O CE TO E TER THE PEAK PLAYBACK.THE PRESS A D HOLD THE “MODE” A D

“UP” BUTTO S FOR FIVE SECO DS. Activation of the Default will erase all field calibration setup

settings that are programmed. Factory calibrations will not be affected.

OP ION A:DEMO MODE: Displays the features of the meter. The pointer goes up and down

the scale, the dial colors change and the HI,LOW and PEAK warning indicators light. The Demo

mode does not time out. If the gauge is turned off in the Demo mode, it will start up in the Demo

Mode. Press the “Mode” button to return the gauge to ORMAL operation.

OP ION: POIN ER BRIGH NESS MODE: The “Down” and “Up” buttons adjust the dial

pointer brightness to blend in with original manufacturer’s gauges and the owner’s requirements

Press the center MODE button to save the setting and return to ORMAL OPERATIO

PROGRAMMING INFORMA ION:

• TO RESET THE PROGRAM TO ORMAL OPERATIO FROM A Y MODE PRESS THE “UP” A D “DOW ”

BUTTO S SIMULTA EOUSLY. THIS SOFT RESET CA CELS THE I FORMATIO YOU PROGRAMMED I

THAT MODE O LY A D RETUR YOU TO ORMAL OPERATIO .

• THE FACEPLATE WILL “FLASH” WHE BUTTO S ARE DEPRESSED TO ACK OWLEDGE COMMA DS.

• PROGRAMMI G ERRORS WILL BE SIG ALLED BY FLASHI G THE FACEPLATE LIGHTI G “PURPLE”,

“BLUE”, “GREEN” THE “ORANGE”.

• IF PROGRAMMI G IS I ACTIVE FOR 60 SECO DS THE MODE WILL TIME OUT A D THE GAUGE

WILL RETUR TO ORMAL OPERATIO , EXCEPT FOR THE DEMO STRATIO MODE. THE DEMO MODE

WILL OT TIME OUT U TIL THE CE TER “MODE” BUTTO IS PRESSED IF THE GAUGE IS TUR ED

OFF I THE DEMO MODE, IT WILL START UP I THE DEMO MODE.

Programming Instructions for : RPM achometer

21/16” Controller

ACHOME ER SENSE LINE A ACHMEN S AND ME ER SCALING

GASOLINE ENGINES

he WHI E/DIMMER circuit must be installed and supply 3 to 12vdc before the PPR can be

progammed

Attach the sensing line to the primary side of a spark coil, and then set the calibration PPR value for

your spark configuration, using directions for the CALIBRATIO option.

Once upon a time, there was just one configuration: a spark coil, a distributor, and then wires from the

distributor cap to the individual sparkplugs. If your car is like this, use the table below:

FOR "CLASSIC" ONE-IGNI ION-COIL ENGINES

IF YOU HAVE ONE COIL PER PLUG CONNEC O ANY SPARK COIL PRIMARY

IF YOU HAVE ONE COIL PER WO PLUGS CONNEC O ANY SPARK COIL PRIMARY

DIESEL ENGINES

Modern diesel engines usually have camshaft sensors or electronic injector pumps. If there is one

injector per cylinder, the signal from the pump drive will be 1/2 PPR. Similarly, if there is a camshaft

sensor signal the signal will be ½ PPR. Set the calibration at a reading of 500.

If there is no electronic cam sensing or fuel injection in your diesel engine, the procedure is more com-

plex. A signal can be obtained from the alternator by attaching a wire directly to the winding of the sta-

tor before it goes to one of the rectifier diodes. This signal will be proportional to engine speed, but the

proportionality must be learned. See the TACH CALIBRATIO procedure for details, using meter setting

Programming Instructions for : RPM achometer

21/16” Controller

# PLUG

2

4

6

8

10

12

PULSES PER

REVOLU ION (PPR)

1

2

3

4

5

6

ME ER

SE ING

1000

2000

3000

4000

5000

6000

# PLUG

Any

PULSES PER

REVOLU ION (PPR)

1/2

ME ER

SE ING

500

# PLUG

Any

PULSES PER

REVOLU ION (PPR)

1

ME ER

SE ING

1000

0 to force learning.

SPECIAL SCALING FUNC IONS

Several Proparts meters require a setup procedure to define the kind of input they are looking at.

These are:

achometer – the user needs to tell it the number of “pulses per revolution” (PPR) coming into its

sense line. This number varies widely between makes and models of cars. The default value is an

eight cylinder engine with 4 PPR. The program setting is 4000RPM.

Speedometer – the user needs to tell it the number of pulses that come in, per mile of travel.

O2 sensor – the user needs to tell it whether the sensor is narrowband (with a 0-1 volt output) or a

wideband sensor with a 0...5 volt output Once the meter is hooked up, the procedures are relatively

painless.

O SE UP SCALING

Turn the ignition off and on again to assure that the meter is in a reset state.

If it starts up with the face changing color and the pointer going up and down continuously, the meter

is in demo mode. Press the center button before continuing.

ACH CALIBRA ION

First read the section on TACHOMETER SE SE LI E ATTACHME TS A D METER SCALI G in order to

find out how you need to set the meter. When you have figured out what PPR setting you are to use,

press the Mode and Up buttons simultaneously for five (5) seconds. The dial will flash blue rapidly.

This places the meter in the scale-setting mode. Use the Down and Up buttons to move the meter

pointer to the appropriate RPM reading according to the table. If you have selected an “RPM” reading

of 1000 or up, just press the center button to leave the scale setting mode and resume normal

operation with the selected scaling.

If you were forced to use the alternator as a signal source, you selected an RPM of “0.” ow you must

tell the motor when it is operating at 2000 RPM. Using a strobe light, slowly increase the engin

speed till you hit 2000 RPM. The meter will read some nonzero value that increases and decreases

with engine speed, but it will not be accurate. While the engine is running steadily at 2000 RPM, press

the mode button. Your meter is calibrated. You can verify the setting by turning the ignition switch off

and on again, starting the car, and checking whether the idle speed on your tachometer is the same as

the speed you measure with a strobe light.

Programming Instructions for : RPM achometer

21/16” Controller

U.S. PATENT # 7,612,660

U.S. PATENT # 7,278,749

ADDITIONAL PATENTS PENDING

PEAK

LIGHT LIT

PEAK LO HI

LO

LIGHT LIT

PEAK LO HI

PEAK,LO ,HI

LIGHT LIT

PEAK LO HI

PEAK,LO ,HI

LIGHT LIT

PEAK LO HI

LO

LIGHT LIT

PEAK LO HI

PEAK

LIGHT LIT

PEAK LO HI

LO RACING YELLO -LINE SETTING:

Press the center button to advance to

COLORSCHEME.

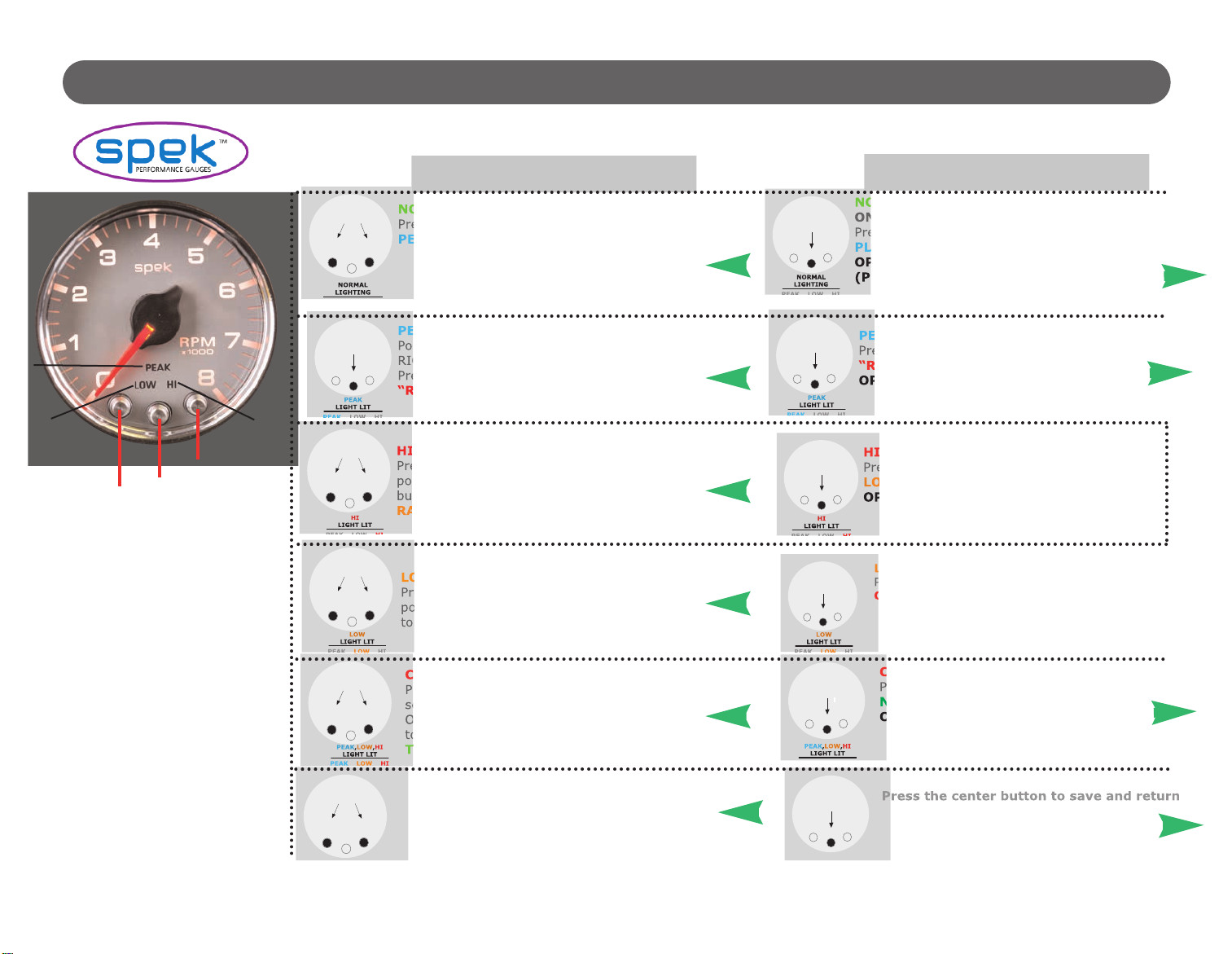

PROGRAM MAIN MENU

START HERE

MAIN MENU

(Press one

button at a time)

NORMAL OPERATION:

Press the center button to save and advance to

PEAK PLAYBACK.

NORMAL

LIGHTING

PEAK LO HI

PEAK PLAYBACK:

Pointer will now display peakplayback. Press the

RIGHT or LEFT button to adjust dial brightness.

Press the center button to advance to HIGH

“RACING” RED-LINE SETTING.

HIGH “RACING”RED-LINE SETTING:

Press the RIGHT or LEFT button to move dial

pointer to the high setting. Press the center

button to save and advance to LO

RACING YELLO -LINE SETTING.

HI

LIGHT LIT

PEAK LO HI

LO RACING YELLO -LINE SETTING:

Press the RIGHT or LEFT button to move

pointer to low SETTING. Press the center but-

ton to save and advance to COLORSCHEME.

COLORSCHEME:

Press down and up buttons to select a color

scheme. ( FF-VI LET-BLUE-GREEN-YELL W-

RANGE-RED-WHITE). Press the center button

to save and advance to NORMAL OPERA-

TION.

NORMAL OPERATION:

ON PO ER UP THE GAUGE READS THE RPM.

Press the center button to save and advance to PEAK

PLAYBACK.

OPTION: SELECT PULSES PER REVOLUTION

(PPR)

NORMAL

LIGHTING

PEAK LO HI

PEAK PLAYBACK:

Press the center button to advance to HIGH

“RACING” RED-LINE SETTING. R

OPTION:RESTORE FACTORY DEFAULT

HIGH “RACING”RED-LINE SETTING:

Press the center button to advance to

LO RACING YELLO -LINE SETTING.

OPTION:SET THRESHOLD ALERT SIGNAL

HI

LIGHT LIT

PEAK LO HI

COLORSCHEME:

Press the center button to advance to

NORMAL OPERATION. R

OPTION A:DEMO MODE

Down

Button

PEAK

LO HI

Up

Button

Mode

Button

TACHOMETER

NORMAL MODE

PRESS ONE

AT A TIME

D WN

-UP

+

PRESS

PRESS ONE

AT A TIME

D WN

-UP

+

PRESS ONE

AT A TIME

D WN

-UP

+

PRESS ONE

AT A TIME

D WN

-UP

+

PRESS

PRESS

PRESS

PRESS

Flow Chart Programming Instructions for : RPM TACHOMETER 2 1/16” CONTROLLER

Patent Pending All Rights Reserved

PRESS ONE

AT A TIME

D WN

-UP

+

PRESS

Dial Brightness:

Press down and up buttons to adjust dial bright-

ness. Press the center button to save and return

to N RMAL PERATI N

Dial Brightness:

to NORMAL OPERATION. R

OPTION: POINTER BRIGHTNESS

Flow Chart Programming Instructions for : RPM TACHOMETER 2 1/16” CONTROLLER

SUBMENU

(ENTER FROM MAIN MENU)

(Press two(2) buttons simultaneously for 5 seconds)

OPTION:RESTORE FACTORY DEFAULT:

While in PEAK PLAYBACK, press and hold the

center and right buttons for five seconds. Dial

pointer will step five times and return to zero.

This will erase all user-programmed calibrations

and settings, and return to NORMAL OPERA-

TION.

PEAK

LO

HI

OPTION: SELECT PPR (Pulses Per Revolution)

The WHITE/DIMMER circuit must be installed and produce 12vdc before PPR

can be programmed. While in NORMAL OPERATION, press and hold center

and right buttons for 5 seconds. Dial will flash blue rapidly. Press down and up

buttons to select PPR value by moving dial pointer to corresponding RPM. Press

the center button to save and return to NORMAL OPERATION.

(See PPR Chart Page 4-5)

OPTION :POINTER BRIGHTNESS:

While in DIAL BRIGHTNESS, press and hold the

center and left buttons for five seconds to enter

pointer brightness mode. The dial pointer will start

to flash and point to the upper right.

OPTION A:DEMO MODE:

WHILE IN COLORSCHEME, press and hold the center and right buttons for

five seconds. Dial will scroll through the seven color schemes. The HI,LO

and PEAK will light, and the dial pointer will move. Press the center button to

return to NORMAL OPERATION.

OPTION: POINTER BRIGHTNESS:

Press down and up buttons to

adjust the pointer brightness. Press the

center button to save and return to

NORMAL OPERATION

PRESS

BOTH

PRESS

BOTH

PRESS ONE

AT A TIME

D WN

-UP

+

U.S. Patent # 7,612,660 & 7,278,749

PRESS

BOTH

PRESS

BOTH

• Tachometer Gauge 2 1/16” INCH

• Wiring Harness

• Mounting Cup (Not required for pod installation)

• (2) Neoprene EDPM Grommets

PACKAGE CONTAINS:

FEATURES:

SPEK PERFORMANCE GAUGE TACHOMETER FEATURES:

• INTELLIGENT ELECTRICAL GAUGES.

• GAUGES ARE PROGRAMMED THROUGH COMMAND KEYS ON FACEPLATE.

• STEPPER MOTOR DRIVES THE GAUGE POINTER OVER A 280 DEGREE SWEEP.

• WIDE-ANGLE-DIAL™ HAS A 15% LARGER VIEWING AREA ON A 2 1/16” GAUGE.

• PROGRAMMABLE 7 COLOR DIAL AND RED POINTER ILLUMINATION.

• OPTIONAL OUTPUT CONTROL MODULE.

INSTALLATION INSTRUCTIONS:

1 DISCONNECT NEGATIVE (-) BATTERY TERMINAL.

2 VARIOUS MOUNTING SOLUTIONS ARE PRESENTED BY PROPARTS,

DASH INSTALLATION: SELECT LOCATION IN THE DASH TO MOUNT GAUGE AND

CUT A 2 1/16” HOLE. USE A FILE TO INCREASE THE HOLE SIZE IF REQUIRED. BE SURE THERE IS

SUFFICIENT ROOM BEHIND THE HOLE FOR THE METER CASE AND THE CONNECTORS YOU WILL USE.

3 IF A SUITABLE HOLE IN THE FIRE WALL IS NOT AVAILABLE, CUT AN 11/16” HOLE.

4 TWO GROMMETS MUST BE CUT TO PERMIT INSTALLATION OF WIRING HARNESS. (SEE DIAGRAM 1)

5 INSTALL INSTALL THE GROMMET AND MOUNTING CUP ON THE WIRING HARNESS AS SHOWN IN

DIAGRAM 1. GROMMET IS FOR THE HOLE IN THE FIREWALL.

SPEK™ MONITOR AND CONTROL PERFORMANCE GAUGE TACHOMETER

Wiring Installation Instructions for : RPM Tachometer

2 1/16” Controller

6 DO NOT CONNECT WIRING HARNESS TO THE GAUGE UNTIL THE OTHER CONNECTIONS HAVE

BEEN MADE AND TESTED.

7 CONNECT THE RED (+ 12 VOLT SUPPLY) WIRE TO “ON” CIRCUITS THAT GET POWER WHEN THE

IGNITION IS TURNED-ON. THIS CIRCUIT MUST BE FUSED BEFORE THE iGNITION SWITCH (1 AMP,

3AG FAST ACTING).

8 CONNECT THE BLACK WIRE TO A GOOD GROUNDING POINT ON THE CAR’S CHASSIS.

9 CONNECT THE WHITE WIRE TO THE DIMMER VOLTAGE GOING TO THE DASH LIGHTS. THIS WILL

CAUSE THE METER BRIGHTNESS TO TRACK THE BRIGHTNESS OF THE REST OF THE INDICATORS.

THIS CIRCUIT MUST PRODUCE 3 TO 12VDC BEFORE THE PPR CAN BE PROGRAMMED.

10 CONNECT THE SENSING WIRE TO THE PRIMARY TERMINAL ON THE IGNITION COIL

(STANDARD-TYPE COIL) OR TO THE AUXILIARY TERMINAL MEANT FOR THE TACH WIRE (AFTER

MARKET, HIGH PERFORMANCE COIL). DO NOT CONNECT TO COIL ON MSD IGNITION. ATTACH ONLY

TO TACH TERMINAL.

11 PLUG THE WIRING HARNESSES INTO THE GAUGE AND MOUNT IN POD OR DASH.

12 FOR DASH INSTALLATION, ATTACH MOUNTING CUP OVER THE BACK OF THE GAUGE AND HAND

TIGHTEN. DO NOT OVER TIGHTEN. MOUNT CUP BEFORE INSTALLING GROMMET. FAILURE TO DO

SO WILL TWIST WIRES CAUSING A SHORT CIRCUIT.

13 POWER UP THE GAUGE AND INSPECT ALL CONNECTIONS. IF GAUGE IS OPERATING NORMALLY,

PROCEED TO “PROGRAMMING MANUAL”.

2

Wiring Installation Instructions for : RPM Tachometer

2 1/16” Controller

GREEN - TACH INPUT

TACHOMETER

Terminal

Electronic Ignition

.

Black-Chassis Ground

Firewall

Grommet

10-Pin Wiring

Harness & Plug

GAUGE

5-Pin Wiring Harness

3-Pin Wiring Harness OR

CUP

Grommet

Red-12V

Ignition Switch

White-12V

Dash Lighting

HEADLIGHT

SWITCH

Fuse

Grommet

Cut

85

86

87A

30

87

Gauge

PIN 8 Output/Purple

FET

Output

CAUTION: 12 VOLT DC POWER

MUST BE CONNECTED TO THE

IGNITION POWER AFTER A

20 AMP FUSE (USER SUPPLIED)

WARNING: OUTPUT CONTROL MODULE

NOT TO EXCEED 1.5 AMPS AT 12 VOLTS DC.

WARRANTY WILL BE VOID IF INCREASED

OUTPUT VOLTAGE OR CURRENT IS APPLIED.

Optional relay: May use Dedebear

HPR or equivalent.

PROGRAMMABLE LIMIT SETTING .

WHEN A SETTING IS TRIPPED,

AN OUTPUT SIGNAL IS

GENERATED. THIS CAN BE

USED TO SWITCH ON A

RUGGED 35 AMP RELAY

TO ACTIVATE A LOW OIL ENGINE

KILL, ALARMS, CUT THROTTLE

BODY SENSOR TO DEFUEL

KILL BOOST VALVE.

A

TO OUTPUT

CONTROL MODULE

A

TO: RED

IGNITION

SWITCH

+12VDC

WARNING

Warranty will be void if connected to coil when using

an aftermarket ignition box such as, but not limited to

products from the following manufacturers: MSD, Crane,

Jacobs, Mallory, Holley, Etc.. Prior to installation of your

tachometer, check with the ignition box manufacturer for

recommended tachometer signal location.

DIAGRAM 1

PATENTED WIDE ANGLE DIAL

FOR SUPERIOR VISIBILITY

U.S PATENT #7,278,749

3

Wiring Installation Instructions for : RPM Tachometer

2 1/16” Controller

DIAGRAM 2

CAUTION:

DIMMER CIRCUIT MUST

HAVE 3 TO 12VDC TO

PROGRAM PPR.

1 2 3 4 5 6

7 8 9 10 11 12

Wiring Installation Instructions for : RPM Tachometer

2 1/16” Controller

4

THERE ARE THREE SECTIONS TO THIS MANUAL: WIRING INSTRUCTIONS, PROGRAMMING

INSTRUCTIONS AND FLOW CHART PROGRAMMING INSTRUCTIONS. PLEASE READ EACH

SECTION CAREFULLY BEFORE ATTEMPTING TO INSTALL OR OPERATE THIS PRODUCT.

WARNING:

• ALL INSTRUCTIONS IN THIS MANUAL MUST BE FOLLOWED TO INSURE SAFE

INSTALLATION AND OPERATION OF THIS PRODUCT.

• NEVER DISASSEMBLE MODIFY OR TAMPER WITH THIS PRODUCT. THIS COULD CAUSE

DAMAGE AND MAKE THEM UNSAFE TO USE. TAMPERING WITH THE PRODUCT WILL VOID

THE LIMITED WARRANTY.

• INSTALLATION MUST BE PERFORMED BY AN EXPERIENCED AUTOMOTIVE TECHNICIAN.

• INSTALLER MUST USE SAFETY GLASSES.

• DISCONNECT THE NEGATIVE BATTERY TERMINAL BEFORE BEGINNING INSTALLATION.

PROPARTS LLC IS NOT RESPONSIBLE FOR DAMAGE TO ENGINE, VEHICLE OR UNIT CAUSED

BY ELECTRICAL SHORTS.

• DURING INSTALLATION, DO NOT INTERFERE WITH ANY EXISTING CONNECTIONS OR

WIRES.

• ALL ELECTRICAL CONNECTIONS USE SOLDER LESS CONNECTORS AND INSULATE ALL

CONNECTIONS WITH ELECTRICAL TAPE.

• AVOID WIRING NEAR ENGINE, EXHAUST SYSTEM, TURBINE OR ANY AREA THAT MAY

RESULT IN DAMAGE.

• DISCONTINUE USE OF THE PRODUCT IF SMOKE OR A STRANGE ODOR IN PRESENT.

CAUTION

• PROPARTS LLC IS NOT RESPONSIBLE FOR INCORRECT INSTALLATION OR PROGRAMMING

OF SPEK™ GAUGES OR CONTROLLERS.

• SPEK™ GAUGES AND CONTROLLERS ARE DESIGNED FOR 12V DC ELECTRICAL SYSTEMS

WITH A NEGATIVE GROUND.

• DO NOT ADJUST THE GAUGES OR GAUGE PROGRAM WHILE DRIVING

• OBEY ALL RULES AND REGULATIONS OF HIGHWAY AND STREET DRIVING.

• INSTALL SENSOR AND WIRE AWAY FROM HIGH HEAT AND / OR VIBRATION AREAS.

• USE CARE WHEN CONNECTING OR DISCONNECTING THE WIRING HARNESS. PULL OUT

EACH CONNECTOR WHILE PRESSING THE LOCK OF THE CONNECTOR FIRMLY.

• IF THE BATTERY TERMINAL IS DISCONNECTED, THE AUDIO, CLOCK AND OTHER MEMORY

DATA MAY BE LOST. THE NECESSARY DATA WILL HAVE TO BE RESET AFTER INSTALLATION.

Programming Instructions for : RPM Tachometer

2 1/16” Controller

5

DOWN MODE UP

+

–

MAIN MENU

NORMAL OPERATION

PEAK PLAYBACK

HIGH RED-LINE SETTING

LOW THRESHOLD SETTING

COLORSCHEME

DIAL BRIGHTNESS

SUBMENU

OPTION:SELECT PPR

OPTION:RESTORE FACTORY DEFAULT

OPTION: DEMO MODE

OPTION: POINTER BRIGHTNESS

U. S. PATENTS 7,612,660 AND 7,278,749 ADDITIONAL PATENTS PENDING.

Refer to the “Flow Chart Programming Instructions” while reviewing this guide.

Gauge is field programmable by the operator while installed in the vehicle. This programming is

accessed by pressing the control buttons located on the face or the meter dial, ONE AT A TIME.

The “Down” and “Up” buttons move the pointer to a desired setting or controls the faceplate

illumination. The center “Mode” button will save the setting you choose and proceed to the next

level. Pressing the “Mode” and “Up” or “Mode” and “Down” buttons simultaneously and holding

them for 5 seconds in any level will shift you to the Submenu.

SPEK™ MONITOR AND CONTROL PERFORMANCE GAUGE TACHOMETER

PROGRAMMING STARTS IN

MAIN MENU

PRESS PROGRAM BUTTON ONE (1) AT A TIME IN THE MAIN MENU MODE.

1 NORMAL OPERATION:

On power up, the meter usually starts in NORMAL operating mode. The Tachometer will read en-

gine’s RPM. Press the center “mode” button to advance to 2 PEAK PLAYBACK

2PEAK PLAYBACK:

Reads the highest value displayed on the meter since the last time the “Peak” value was displayed.

Pressing the “Down” or “Up” control button will control the gauge dial illumination. Press the center

“Mode” button to advance to 3 HIGH RACING RED-LINE SETTING

3HIGH RACING RED-LINE SETTING:

Sets the point at which “HIGH” warning RED-LINE is reached for that specific gauge. The “Down and

“Up” buttons will move the dial pointer to select “Maximum RED-LINE”. During normal operation the

gauge constantly monitors the sensor value and compares it to the “HIGH” RED-LINE. If the

threshold is exceeded, the red “HI” indicator is turned on and an output signal generated. Press the

center “Mode” button to save the setting and advance to 4 LOW RACING YELLOW-LINE

SETTING

4LOW RACING YELLOW-LINE SETTING:

Set the Minimum RED-LINE: Sets the point at which “LOW” warning threshold is reached for that

specific gauge. The “Down” and “Up” buttons will move the dial pointer to select the LOW

RACING YELLOW-LINE SETTING. During normal operation the gauge constantly monitors the

sensor value and compares it to the “LOW” threshold. If the sensor value drops below the threshold,

the yellow “LOW” indicator is turned on and an output signal generated. Press the center “Mode”

button save the setting and advance to 5 COLORSCHEME

5COLORSCHEME:

Set Faceplate Color Scheme: Operator can select the color of the gauge dial illumination. Each time

you press the “Down” control button you scroll through dial color selection until the dial light goes

off. Then press the “Up” button to reverse the scroll. Select your dial color illumination by pressing

the center “Mode” button to save the setting and advance to NORMAL OPERATION.

6 DIAL BRIGHTNESS:

Adjust the dial brightness for day or evening driving conditions The RIGHT and LEFT command but-

tons will dim or brighten the faceplate illumination. Press the center “Mode” button to save the set-

ting and advance you to NORMAL OPERATION

Programming Instructions for : RPM Tachometer

2 1/16” Controller

6

SUBMENU

SUBMENU IS ACCESSED THROUGH THE MAIN MENU. FIRST GO TO THE APPROPRIATE LEVEL OF THE

MAIN MENU AND THEN FOLLOW THE INSTRUCTIONS IN THE PROGRAMMING FLOW DIAGRAM TO

ENTER THE SUBMENU. PRESS THE “MODE” AND “UP” OR “MODE” AND “DOWN” BUTTONS

SIMULTANEOUSLY FOR 5 SECONDS TO ENTER THE SUBMENU AND ONE BUTTON AT A TIME WHILE

IN THAT SUBMENU.

OPTION:SELECT PPR: (Pulses Per Revolution) Select the PPR value by pressing “Down or “Up”

button to move dial pointer to corresponding RPM. For additional information see the Tachometer

Sense Line Attachment and Meter Setting section on page 4.

OPTION:RESTORE FACTORY DEFAULT: TO RESTORE FACTORY DEFAULTS, PRESS THE

:MODE” BUTTON ONCE TO ENTER THE PEAK PLAYBACK. THEN PRESS AND HOLD THE “MODE” AND

“UP” BUTTONS FOR FIVE SECONDS. Activation of the Default will erase all field calibration setup

settings that are programmed. Factory calibrations will not be affected.

OPTION A:DEMO MODE: Displays the features of the meter. The pointer goes up and down

the scale, the dial colors change and the HI, LOW and PEAK warning indicators light. The Demo

mode does not time out. If the gauge is turned off in the Demo mode, it will start up in the Demo

Mode. Press the “Mode” button to return the gauge to NORMAL operation.

OPTION: POINTER BRIGHTNESS MODE: The “Down” and “Up” buttons adjust the dial

pointer brightness to blend in with original manufacturer’s gauges and the owner’s requirements

Press the center MODE button to save the setting and return to NORMAL OPERATION

PROGRAMMING INFORMATION:

• TO RESET THE PROGRAM TO NORMAL OPERATION FROM ANY MODE PRESS THE “UP” AND “DOWN”

BUTTONS SIMULTANEOUSLY. THIS SOFT RESET CANCELS THE INFORMATION YOU PROGRAMMED IN

THAT MODE ONLY AND RETURN YOU TO NORMAL OPERATION.

• THE FACEPLATE WILL “FLASH” WHEN BUTTONS ARE DEPRESSED TO ACKNOWLEDGE COMMANDS.

• PROGRAMMING ERRORS WILL BE SIGNALLED BY FLASHING THE FACEPLATE LIGHTING “PURPLE”,

“BLUE”, “GREEN” THEN “ORANGE”.

• IF PROGRAMMING IS INACTIVE FOR 60 SECONDS THE MODE WILL TIME OUT AND THE GAUGE

WILL RETURN TO NORMAL OPERATION, EXCEPT FOR THE DEMONSTRATION MODE. THE DEMO

MODE WILL NOT TIME OUT UNTIL THE CENTER “MODE” BUTTON IS PRESSED IF THE GAUGE IS

TURNED OFF IN THE DEMO MODE, IT WILL START UP IN THE DEMO MODE.

Programming Instructions for : RPM Tachometer

2 1/16” Controller

7

TACHOMETER SENSE LINE ATTACHMENTS AND METER SCALING

GASOLINE ENGINES

The WHITE/DIMMER circuit must be installed and supply 3 to 12vdc before the PPR can be

progammed

Attach the sensing line to the primary side of a spark coil, and then set the calibration PPR value for

your spark configuration, using directions for the CALIBRATION option.

Once upon a time, there was just one configuration: a spark coil, a distributor, and then wires from the

distributor cap to the individual sparkplugs. If your car is like this, use the table below:

FOR “CLASSIC” ONE-IGNITION-COIL ENGINES

IF YOU HAVE ONE

COIL PER PLUG CONNECT TO ANY SPARK COIL PRIMARY

IF YOU HAVE ONE COIL PER TWO PLUGS CONNECT TO ANY SPARK COIL PRIMARY

DIESEL ENGINES

Modern diesel engines usually have camshaft sensors or electronic injector pumps. If there is one

injector per cylinder, the signal from the pump drive will be 1/2 PPR. Similarly, if there is a camshaft

sensor signal the signal will be ½ PPR. Set the calibration at a reading of 500.

If there is no electronic cam sensing or fuel injection in your diesel engine, the procedure is more com-

plex. A signal can be obtained from the alternator by attaching a wire directly to the winding of the sta-

tor before it goes to one of the rectifier diodes. This signal will be proportional to engine speed, but the

Programming Instructions for : RPM Tachometer

2 1/16” Controller

8

# PLUG

2

4

6

8

10

12

PULSES PER

REVOLUTION (PPR)

1

2

3

4

5

6

METER

SETTING

1000

2000

3000

4000

5000

6000

# PLUG

Any

PULSES PER

REVOLUTION (PPR)

1/2

METER

SETTING

500

# PLUG

Any

PULSES PER

REVOLUTION (PPR)

1

METER

SETTING

1000

This manual suits for next models

2

Table of contents

Popular Measuring Instrument manuals by other brands

SBC

SBC Saia PCD ALD1D5FM Assembly and operating instructions

Cantium Scientific

Cantium Scientific MicroBio MB2-RSH Installation and Operation Supplement

GE

GE DigitalFlow DF868 Programming manual

ERT

ERT AM3 Instructions for use

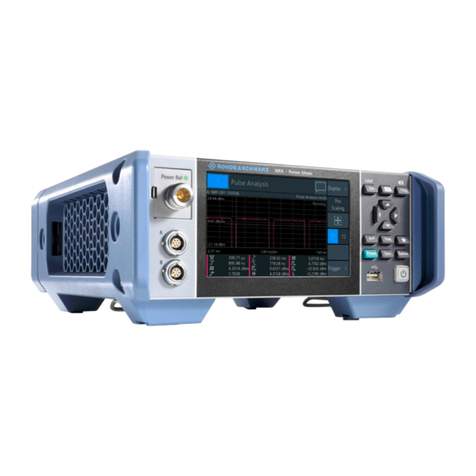

Rohde & Schwarz

Rohde & Schwarz R&S NRX Series Getting started

TESTO

TESTO 550 quick start guide