Prosense ETS Series User manual

ProSenSe eTS SerieS

DigiTal TemPeraTure SenSorS

oPeraTing inSTrucTionS

ProSense ETS Series Digital Temperature Sensors

Part Number Measuring

Range

Thread

Size Length Output

ETS50N-30-1001

-58 to 302°F

(-50 to 150°C)

1/2”

MNPT

30mm

Output 1: switch

PNP, N.O./N.C.,

selectable or

4-20 mA*

Output 2: switch

PNP, N.O./N.C.,

selectable or

4-20 mA*

ETS50N-50-1001 50mm

ETS50N-100-1001 100mm

ETS50N-150-1001 150mm

ETS25N-30-1001 1/4”

MNPT

30mm

ETS25N-50-1001 50mm

ETS50N-30-1003

1/2”

MNPT

30mm

Output 1: switch

PNP, N.O./N.C.,

selectable

Output 2: switch

PNP, N.O./N.C.,

selectable

ETS50N-50-1003 50mm

ETS50N-100-1003 100mm

ETS50N-150-1003 150mm

ETS25N-30-1003 1/4”

MNPT

30mm

ETS25N-50-1003 50mm

* Only one output can be configured as analog.

User Manual - ETS Series Digital Temperature Sensors

ETS Digital Temperature Sensors Rev. 1

2

1 Document Information������������������������������������������������������������������������������������������3

1.2 Notes on Safety Conventions and Icons.................................................................................. 3

2 Basic Safety Instructions����������������������������������������������������������������������������������������3

2.1 Designated Use....................................................................................................................... 3

2.2 Installation, Commissioning and Operation ............................................................................ 3

2.3 Operational Safety .................................................................................................................. 3

2.4 Certificates and Approvals ...................................................................................................... 4

3 Installation �������������������������������������������������������������������������������������������������������������4

3.1 Installation Conditions ............................................................................................................ 4

3.2 Mounting the Device.............................................................................................................. 4

4 Electrical Connection���������������������������������������������������������������������������������������������5

5 Operating Options�������������������������������������������������������������������������������������������������5

5.1 On-Site Operation .................................................................................................................. 5

5.2 Navigating in the Operating Menu......................................................................................... 6

5.3 Structure of the Operating Menu for 2x Switch Outputs ........................................................ 7

5.4 Structure of the Operating Menu for 1x Switch Output and 1x Analog Output (4 to 20mA) . 8

5.5 Basic Settings.......................................................................................................................... 9

5.6 Settings for Output - 2x Switch Output.................................................................................. 9

5.7 Settings for Output - 1x switch output and 1x analog output

(4 to 20mA).......................................................................................................................... 11

5.8 Settings for Service Functions ............................................................................................... 13

5.9 Programming with XT-SOFT Software .................................................................................. 14

5.10 Additional Operating Options............................................................................................. 14

6 Diagnostics and Troubleshooting �����������������������������������������������������������������������14

6.1 Diagnostic Information on Local Display............................................................................... 14

7 Maintenance ��������������������������������������������������������������������������������������������������������16

8 Technical Data �����������������������������������������������������������������������������������������������������16

User Manual - ETS Series Digital Temperature Sensors

3

ETS Digital Temperature Sensors Rev. 1

1 Document Information

1.2 Notes on Safety Conventions and Icons

Always refer to the safety instructions in these Operating Instructions labeled with the

following symbols:

Symbol Meaning

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid

this situation can result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid

this situation can result in a minor or medium injury.

NOTICE

This symbol contains information on procedures and other facts

which do not result in personal injury.

This symbol indicates additional information or tip

2 Basic Safety Instructions

2.1 Designated Use

The ProSense ETS Series digital temperature sensor is for monitoring, displaying and

regulating process temperatures. The device has been safely built with state-of-the-art

technology and meets the applicable requirements and European Community (EC)

Directives. It can, however, be a source of danger if used incorrectly or for anything

other than the designated use.

2.2 Installation, Commissioning and Operation

Installation, electrical connection, commissioning, operation and maintenance of the

measuring system must be carried out by trained, qualified specialists authorized to

perform such work by the facility’s owner-operator. The specialist must have read

and understood these Operating Instructions and must follow them. The device may

only be modified and repair work carried out if this is explicitly permitted in the

Operating Instructions. Damaged devices which could be a source of danger may not be

commissioned and must be labelled and identified as defective.

2.3 Operational Safety

The measuring device meets the general safety requirements according to EN 61010-1

and the EMC requirements according to IEC/EN 61326 in addition to the NAMUR

recommendations NE 21, NE 43 and NE 53.

• Functional safety

The ProSense ETS Series digital temperature sensors are were developed according

to the standards IEC 61508 and IEC 61511-1 (FDIS). The device version with

PNP switch output and additional analog output is equipped with fault detection

and fault prevention facilities within the electronics and software.

User Manual - ETS Series Digital Temperature Sensors

ETS Digital Temperature Sensors Rev. 1

4

• Hazardous Locations

The ProSense ETS Series is not approved for use in Hazardous Locations.

2.4 Certificates and Approvals

CE mark, declaration of conformity

The device is designed to meet state-of-the-art safety requirements and left the factory

in a condition in which it is safe to operate. The device complies with the standards EN

61010-1 “Protection Measures for Electrical Equipment for Measurement, Control,

Regulation and Laboratory Procedures” and with the EMC requirements of IEC/EN

61326. The device meets the legal requirements of the EU Directives. The manufacturer

confirms a positive completion of all tests by fitting the unit with a CE mark.

UL Approval

UL Listed

3 Installation

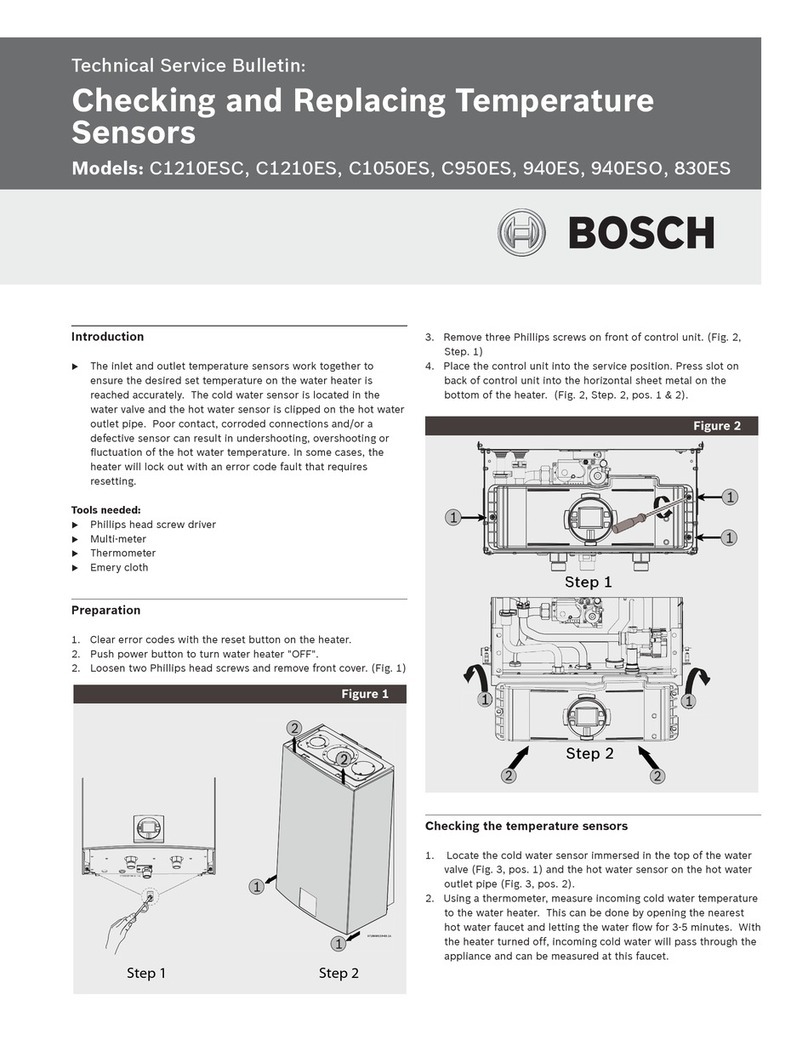

3.1 Installation Conditions

Do not thread sensor into process connection by turning the housing. Always use a

wrench on the wrench flats to tighten the sensor into the process connection.

3.2 Mounting the Device

Possible installation options for temperature monitoring in pipes:

A

1B

C

120 °C

C°021

120 °C

1 Hexagonal screw on sensor module

General mounting instructions:

• Installation at angle pieces, against the direction of flow (item A).

• Installation in smaller pipes, inclined against the direction of flow (item B).

• Installation vertical to the direction of flow (item C).

• The on-site display can be rotated electronically 180°.

• The housing can be rotated up to 310°.

User Manual - ETS Series Digital Temperature Sensors

5

ETS Digital Temperature Sensors Rev. 1

4 Electrical Connection

A1: 2x PNP switch outputs R1 and (R2)

A1’: 2x PNP switch outputs R1 and (diagnosis/NC contact with "DESINA" setting)

A2: 1x PNP switch output and 1x analog output (4 to 20 mA)

A3: 1x analog output (4 to 20 mA) and 1x PNP switch output (R2)

A3’: 1x analog output (4 to 20 mA) and 1x PNP switch output

(diagnosis / NC contact with "DESINA" setting)

4...20mA

4...20mA

L–

L–

L–

L+

L+

L+

2

2

2

1

1

1

3

3

3

4

4

4

R1 R1

A1

A1’

A3

A3’

A2

1

1

ETSxxN-xx-1001

ETSxxN-xx-1003

ETSxxN-xx-1001

ETSxxN-xx-1001

1

1

1

1

Cable Assembly Wiring Colors:

Pin 1 - Brown

Pin 2 - White

Pin 3 - Blue

Pin 4 - Black

Note: Wiring colors are based on AutomationDirect CD12L

and CD12M 4-pole cable assemblies.

Wiring diagram is based on user selected configuration.

To avoid the analog input damaging of a PLC, do not connect the active PNP switch

output of the device to the 4...20 mA input of a PLC.

For more information about DESINA, see www.desina.de

(See also Basic Settings section in this manual.)

5 Operating Options

5.1 On-Site Operation

The ProSense ETS Series is programmed and operated by means of three keys or by

using XT-SOFT programming software (see the Programming with XT-SOFT Software

section of these instructions). The digital display and the light emitting diodes (LEDs)

support navigation in the operating menu.

Operating keys

E

Communication jack

for personal computer

LED for status

Green = ok

Red = error/fault

LED red/ green blinking = warning

Digital display

Illumination white (= ok)

Illumination red (= error/fault)

Yellow LEDs for swit ching states

LEDon = switch closed

LEDoff = switch open

4

1

3

2OUT2

+12 to 30VD

C

0VDC

OUT1

User Manual - ETS Series Digital Temperature Sensors

ETS Digital Temperature Sensors Rev. 1

6

5.2 Navigating in the Operating Menu

A Function group selection

AB

E

E

E E E E

> 3 s

> 3 s

SAVE

E

E

E

E

E

4.

3.

2.

1.

5.

7.

5.

6.

BASE

B Function selection

1. Enter the operating menu.

Press the E key for longer than 3 seconds.

2. Select the “Function group” with the + or - key.

3. Select the “Function” with the E key.

4. Enter or change parameters with the + or - key.

Then return to “Function” with the E key.

Note: If software locking is enabled, it must be disabled before making entries or

changes.

5. Press the E key several times to return to the “Function group” - until the appropriate

function group is reached again.

6. To exit, press the E key for longer than 3 seconds. If changes were made, see step 7.

7. Query to save data (select “YES” or “NO” with the + or - key) - confirm with the E

key.

Changes to the parameter settings only become effective if you choose ‘YES’

when asked to save data.

User Manual - ETS Series Digital Temperature Sensors

7

ETS Digital Temperature Sensors Rev. 1

5.3 Structure of the Operating Menu for 2x Switch Outputs

BASE

OUT

OUT2

SERV

UNIT

FUNC

FNC2

SIM

SIM2

PRES

LOCK

DISP

DESI

ZERO

GET’Z

TAU

SP

SP2

RSP

RSP2

TSP

TSP2

MAX’

TRSP

TRS2

MIN’

REV’C

LST’A

CODE

°C

WINC

WINC

OFF

OFF

NO

0

PV

NO

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0

0

0

°F

HYNC

HYNC

OPEN

OPEN

YES

PVRO

YES

SPRO

K

WINO

WINO

CLOS

CLOS

OPS FF

HYNO

HYNO

OFFR

E+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+ +

+

+

+ +

E

E

E

ABC

+

-

+

-

+

-

+

-

Operating menu: A=function groups, B=functions, C=settings

User Manual - ETS Series Digital Temperature Sensors

ETS Digital Temperature Sensors Rev. 1

8

5.4 Structure of the Operating Menu for 1x Switch Output and 1x Analog

Output (4 to 20mA)

Devices with analog output either output 1 or output 2 can be configured as an analog

output. It is possible to configure both output 1 and output 2 as a switch output.

Operating menu: A=function groups, B=functions, C=settings

*The function group 4-20 is available only if the 4 to 20mA analog output

(4-20) is selected in the function group OUT or OUT2 under FUNC or

FNC2.

User Manual - ETS Series Digital Temperature Sensors

9

ETS Digital Temperature Sensors Rev. 1

5.5 Basic Settings

Function

Group Function Settings Description

BASE

UNIT Technical unit

°C

°F

K

Select technical unit: °C, °F, K

Factory setting: °F

ZERO Configure zero

point 0 . 0 Position adjustment: within ±18ºF/K

(±10ºC) of the upper range limit

GET’Z Accept zero point 0 . 0 No settings possible (not available in

XT-SOFT)

DISP Display

PV

PVRO

SP

SPRO

OFF

OFFR

PV: measured value display

PVRO: measured value display rotated

180°

SP: set switch point display

SPRO: set switch point display rotated

180°

OFF: display off

OFFR: display off rotated 180°

Factory setting: measured value PV

TAU

Damping: display

value, output

signal

0 . 0

Measured value damping with regard to

display value and output: 0 (no damping)

or 9 to 40s (in increments of 1 second)

Factory setting: 0s

BASE DESI DESINA NO

YES

PIN assignment of the M12 connector

is in accordance with the guidelines of

DESINA

Factory setting: No

5.6 Settings for Output - 2x Switch Output

• Hysteresis function

The hysteresis function enables two-point control via a hysteresis. Depending on the

temperature (T), the hysteresis can be set via the switch point (SP) and the switch-back

point (RSP).

• Window function

The window function enables the monitoring of a process temperature range.

• NO contact or NC contact

This switch function is freely selectable.

• Delay times for switch point (SP) and switch-back point (RSP) can be set in

increments of 1 second to filter out undesirable temperature peaks of short duration or

high frequency.

User Manual - ETS Series Digital Temperature Sensors

ETS Digital Temperature Sensors Rev. 1

10

• Factory setting: Switch point SP 1: 113.0°F (45°C); Switch-back point RSP 1: 112.1°F

(44.5°C) Switch point SP 2: 131.0°F (55°C); Switch-back point RSP 2: 130.1°F

(54.5°C)

• Range of adjustment

LRL = Lower Range Limit

URL = Upper Range Limit

LRV = Lower Range Value

URV = Upper Range Value

t

t

1

23

4

T

AB

T

SP

SP

RSP

RSP

0

0

0

0

1

1

1

1

Pos. A: Hysteresis-function

1 Window - NC contact

2 Hysteresis - NC contact

3 Window - NO contact

4 Hysteresis - NO contact

SP switch point; RSP switch-back point

Pos. B: Window-function

Function

Group Function Settings Description

OUT

Output 1

OUT 2

Output 2

FUNC

FNC2

Switching

characteristic

WINC

HYNC

WINO

HYNO

WINC:

window/NC contact

HYNC:

hysteresis/NC contact

WINO:

window/NO contact

HYNO:

hysteresis/NO contact

Factory setting: HYNO

SP

SP2

Switch point

value 0 . 0 Switch point: -57.1 to 302°F (-49.5 to

150°C) in increments of 0.18°F (0.1°C)

RSP

RSP2

Switch-back point

value 0 . 0 Switch-back point: -58 to 300°F (-50 to

149°C) in increments of 0.18°F (0.1°C)

TSP

TSP2

Switch point

delay 0 . 0 Delay time: 0...99s in increments of 0.1s

Factory setting: 0s

TRSP

TRS2

Switch-back point

delay 0 . 0 Delay time: 0...99s in increments of 0.1s

Factory setting: 0s

Min. distance between SP and RSP: 0.9°F/K (0.5°C)

User Manual - ETS Series Digital Temperature Sensors

11

ETS Digital Temperature Sensors Rev. 1

5.7 Settings for Output - 1x switch output and 1x analog output

(4 to 20mA)

Function

Group Function Settings Description

OUT

Output 1

OUT 2

Output 2

FUNC

FNC2

Switching

characteristic

WINC

HYNC

WINO

HYNO

4-20

WINC:

window/NC contact

HYNC:

hysteresis/NC contact

WINO:

window/NO contact

HYNO:

hysteresis/NO contact

4-20: analog output

Factory setting: HYNO

SP

SP2

Switch point

value 0 . 0

Switch point

-57.1 to 302°F (-49.5 to 150°C)

in increments of 0.18°F (0.1°C)

RSP

RSP2

Switch-back point

value 0 . 0

Switch-back point

-58 to 300°F (-50 to 149°C)

in increments of 0.18°F (0.1°C)

TSP

TSP2

Switch point

delay 0 . 0

Delay time

0...99s

in increments of 0.1s

Factory setting: 0s

TRSP

TRS2

Switch-back point

delay 0 . 0

Delay time

0...99s

in increments of 0.1s

Factory setting: 0s

Min. distance between SP and RSP: 0.9°F/K (0.5 °C)

User Manual - ETS Series Digital Temperature Sensors

ETS Digital Temperature Sensors Rev. 1

12

Function

Group Function Settings Description

4-20

Analog output

SETL Value for 4mA

(LRV) 0 . 0

-58 to 266°F (-50 to 130°C)

Lower range value in increments of

0.18°F (0.1°C)

Factory setting: 32.0°F (0.0°C)

SETU Value for 20mA

(URV) 0 . 0

-22 to 302°F (-30 to 150°C)

Upper range value in increments of

0.18°F (0.1°C)

Factory setting: 302°F (150°C)

GET’L Temperature

applied for 4mA

(LRV) 0 . 0 Take temperature value as lower range

value (not via XT-SOFT)

GET’U Temperature

applied for 20mA

(URV) 0 . 0 Take temperature value as upper range

value (not via XT-SOFT)

FCUR Error current

MIN

MAX

HOLD

Current value in event of error:

MIN = ≤ 3.6 mA

MAX = ≥ 21.0 mA

HOLD = last value

Factory setting: MAX

Min. distance between SETL and SETU: 36°F/K (20°C)

The function group 4-20 is available only if the 4 to 20mA analog output (4-20) is selected

in the function group OUT or OUT2 under FUNC or FNC2.

User Manual - ETS Series Digital Temperature Sensors

13

ETS Digital Temperature Sensors Rev. 1

5.8 Settings for Service Functions

Function

Group Function Settings Description

SERV

Service

functions

LOCK Locking code 0Enter the locking code for enabling the

device.

CODE Change locking

code 0

Freely selectable code 1...9999.

0 = no locking

A locking code already assigned can only

be changed by first entering the old code

for enabling the device.

PRES Reset NO

YES

Resets all entries to the factory setting

(not via XT-SOFT)

REV’C Revision counter 0Increases by 1 with each configuration

LST’A Last device

status 0Displays the last device status to occur

≠ 0

SIM

SIM2

Simulation output

1 or 2

OFF

OPEN

CLOS

3.5

(if analog

output

available)

OFF:

No simulation

OPEN:

Switch output open

CLOS:

Switch output closed

3.5:

Simulation values for analog output in

mA (3.5 / 4.0 / 8.0 / 12.0 / 16.0 / 20.0

/ 21.7)

MAX’ Max. indicator 0.0 Display of max. measured process value

MIN’ Min. indicator 0.0 Display of min. measured process value

User Manual - ETS Series Digital Temperature Sensors

ETS Digital Temperature Sensors Rev. 1

14

5.9 Programming with XT-SOFT Software

The ETS Series can be programmed using XT-SOFT programming software, available

as a free download at www.automationdirect.com, and an XT-USB configuration cable

(purchased separately). The operating options listed in the previous “On-Site Operation”

section are available via XT-SOFT except as noted.

ETS Series

XT-USB

Conguration

Cable

External power

not required for

programming via

XT-USB & XT-SOFT

5.10 Additional Operating Options

In addition to the operating options listed in the previous “On-Site Operation” section,

the XT-SOFT software provides the following read-only information.

Function Group Description

Service Setting

Number of switch changes for output 1

Number of switch changes for output 2

Device status

Identification

Tag number

Order code

Limit switch serial number

Sensor serial number

Electronics serial number

Device release (change status)

Hardware version

Software version

6 Diagnostics and Troubleshooting

6.1 Diagnostic Information on Local Display

If an error in the device occurs, the color of the status LED changes from green to red

and the digital display illumination changes from white to red. A status LED flashing red

and green signals a warning. The display shows:

External power

not required for

programming via

XT-USB & XT-SOFT

Note: XT-SOFT version 1.27.15.0

or later required for use

with the ETS Series.

User Manual - ETS Series Digital Temperature Sensors

15

ETS Digital Temperature Sensors Rev. 1

• E-code for errors

In the event of an error message, the measured value is uncertain.

• W-code for warnings

In the event of a warning, the measured value is reliable.

Code Explanation Remedy

E011 Device configuration faulty Reset device (See Settings for Service

Functions).

E012 Error in measurement or medium temperature

outside specification

Check medium temperature. Contact

AutomationDirect’s Returns Department

for warranty status.

E019 Power supply outside specification Check operating voltage

E015

Memory error Contact AutomationDirect’s Returns

Department for warranty status.

E020

E021

E022

Power is only supplied to the device via the

communication interface (measurement is

deactivated)

Check operating voltage

E025 Switching contact 1 is not open although it

should be

Switching contact defective. Contact

AutomationDirect’s Returns Department

for warranty status.

E026 Switching contact 2 is not open although it

should be

Switching contact defective. Contact

AutomationDirect’s Returns Department

for warranty status.

E040 VCC (Controller voltage) is out of working area Contact AutomationDirect’s Returns

Department for warranty status.

E042

Output current can no longer be generated

(only for 4 to 20 mA output, e.g. load at analog

output too high or open analog output).

Check load. Switch off analog output

via configuration, if it isn’t required, see

Settings for Output section.

E044 Output current drifts too much (± 0.5 mA) Contact AutomationDirect’s Returns

Department for warranty status.

W107 Simulation active Switch off the output simulation for output

1 and output 2

W202 Measured value outside of the sensor range Operate the device in the specified

temperature range

W209 Device starts

W210 Configuration modified (warning code will be

displayed for approximately 15 seconds)

W212 Sensor signal outside the permitted range Operate the device in the specified

temperature range

W250 Number of switch cycles exceeded Contact AutomationDirect’s Returns

Department for warranty status.

W270 Short-circuit or overload at output 1 Check output wiring. Increase the load

resistance at output 1

W280 Short-circuit or overload at output 2 Check output wiring. Increase the load

resistance at output 2

User Manual - ETS Series Digital Temperature Sensors

ETS Digital Temperature Sensors Rev. 1

16

7 Maintenance

Any buildup on the sensor can have a negative effect on the sensor response time. For

this reason, check the sensor for buildup at regular intervals.

Removing the device

Make sure the process is unpressurized before you remove the device! Do not twist the

device out of the process connection thread at the housing. Always use a suitable

open-ended wrench on the wrench flats for disassembly work.

8 Technical Data

For further technical data and scale drawing visit:

www.automationdirect.com.

This manual suits for next models

12

Table of contents