Page | 3

LIST OF CONTENTS

______________________________________________________________________

LIST OF CONTENTS.......................................................................................................................3

INTRODUCTION.............................................................................................................................4

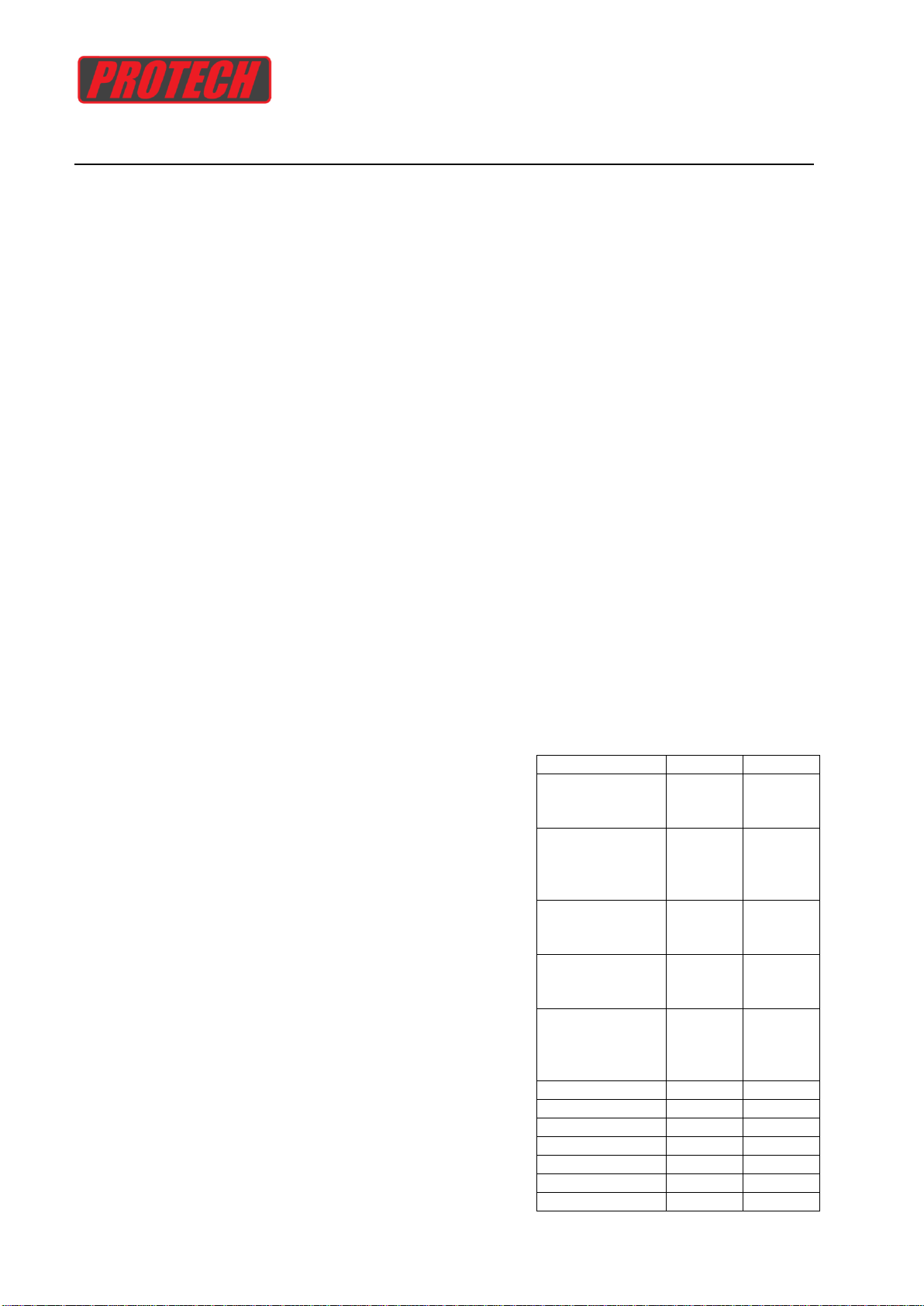

PRODUCT SPECIFICATION..........................................................................................................5

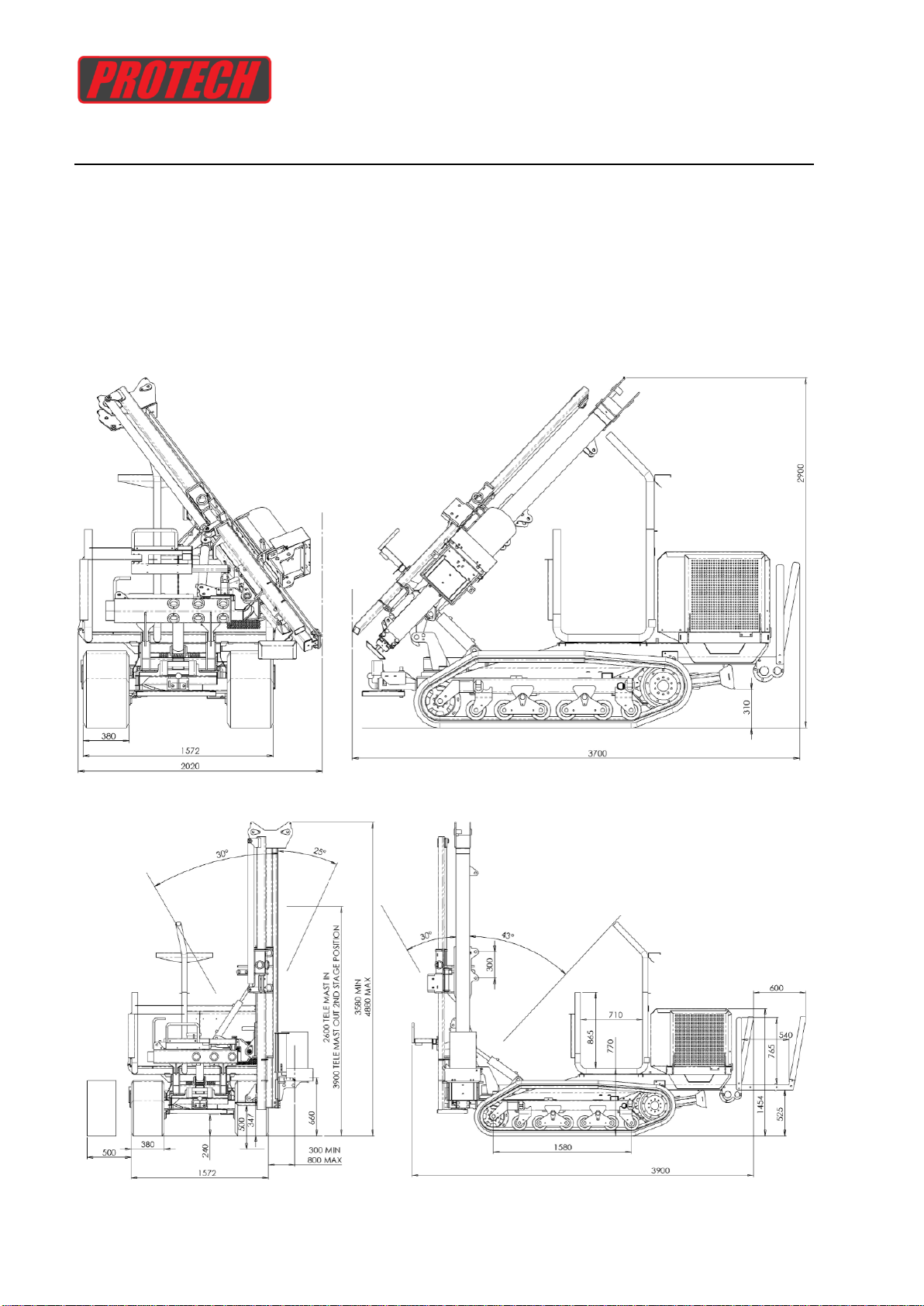

DIMENSIONS - TRANSPORT........................................................................................................6

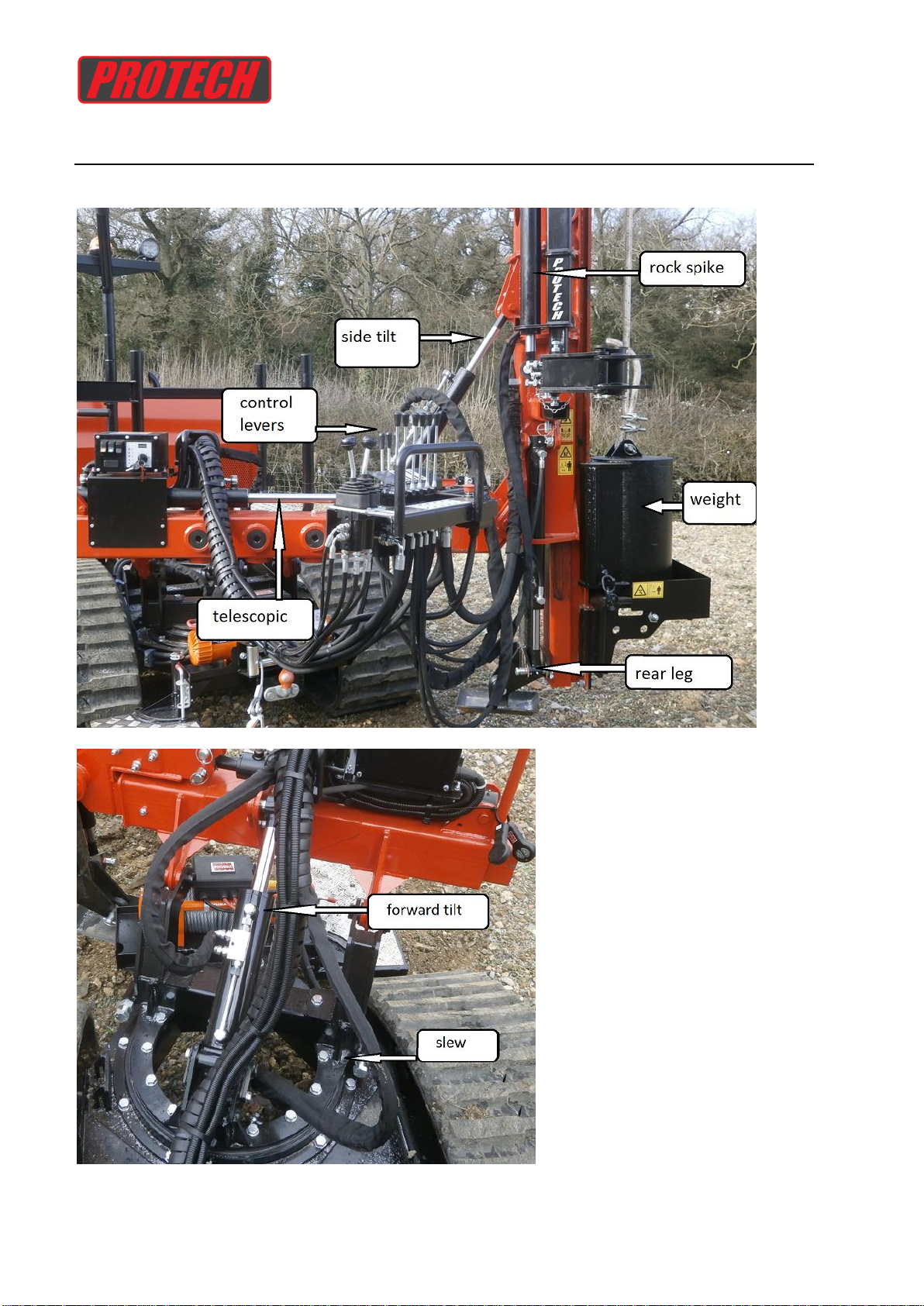

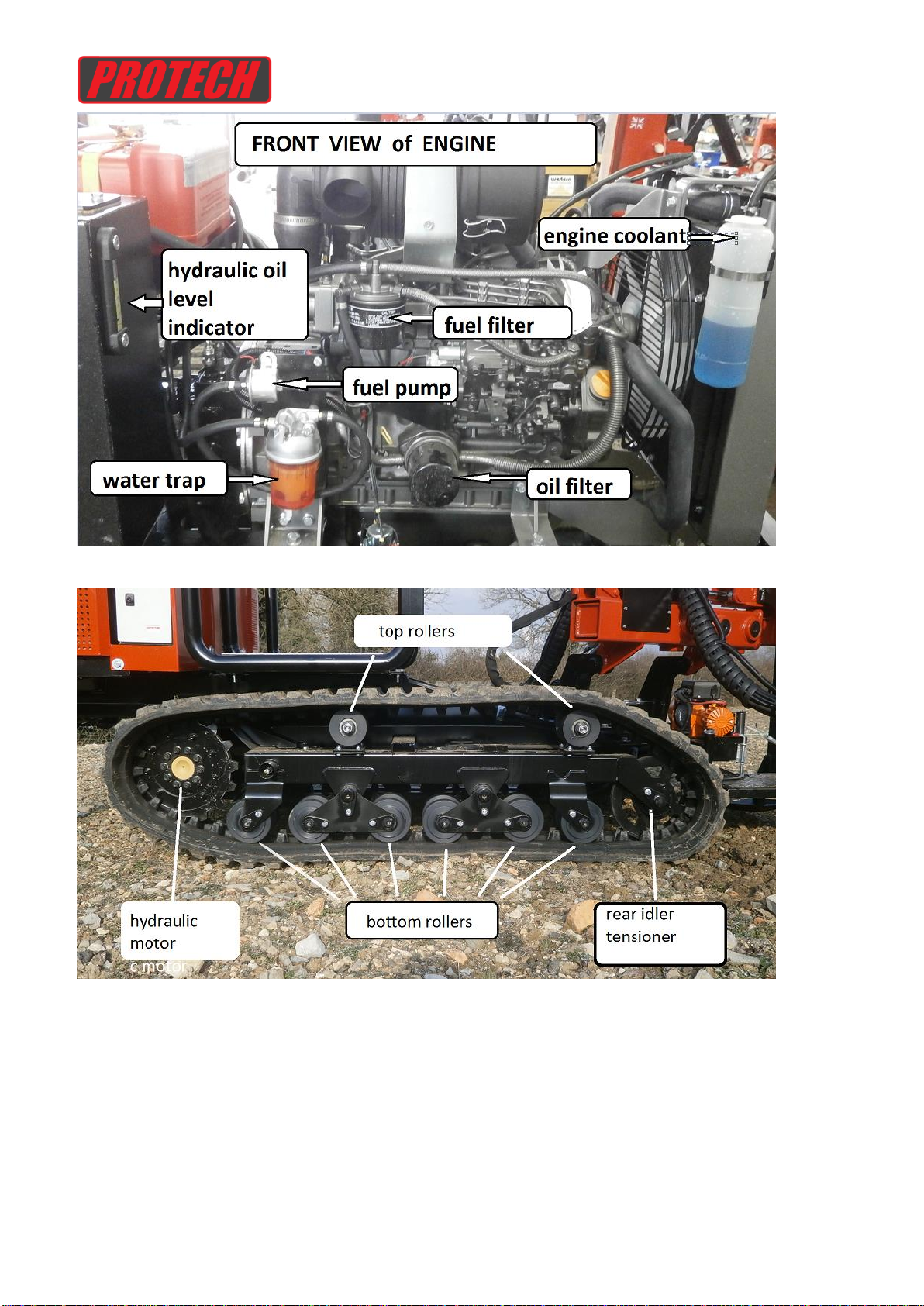

PARTS REFERENCE.......................................................................................................................7

SAFETY STATEMENT.................................................................................................................10

INTERPRETATION AND UNDERSTANDING THIS MANUAL..............................................11

SAFETY INFORMATION.............................................................................................................12

PERSONAL PROTECTIVE EQUIPMENT...................................................................................15

EMERGENCY STOPS / SAFETY DEVICES...............................................................................16

HAZARDS AND SAFE USE OF THE MACHINE AND EQUIPMENT.....................................17

MACHINE OPERATION...............................................................................................................18

MACHINE SAFETY DECALS......................................................................................................19

CONTROL FUNCTIONS OF THE POST DRIVER.....................................................................20

SLEW ARM....................................................................................................................................20

TELESCOPIC ARM.......................................................................................................................21

REAR LEG......................................................................................................................................21

MAST FORWARD TILT...............................................................................................................22

MAST SIDE-TILT..........................................................................................................................23

DRIVER WEIGHT CONTROL .....................................................................................................24

TRACK EXTENSION....................................................................................................................24

TELEMAST CONTROL ................................................................................................................25

ROCK SPIKE CONTROL..............................................................................................................26

AUGER DRIVE..............................................................................................................................27

AUTO-LEVEL................................................................................................................................29

Auto-level setup ..............................................................................................................................30

REMOTE CONTROL.....................................................................................................................31

WELDER ........................................................................................................................................34

INITIAL CHECKS BEFORE OPERATION..................................................................................35

OPERATING THE DRIVE MOTORS AND MOVING THE MACHINE...................................36

USING THE POST DRIVING EQUIPMENT ...............................................................................37

ELECTRICAL FUNCTIONS.........................................................................................................38

Switches and Controls...........................................................................................................38

Junction box...........................................................................................................................39

Cuircuit Diagrams.................................................................................................................40

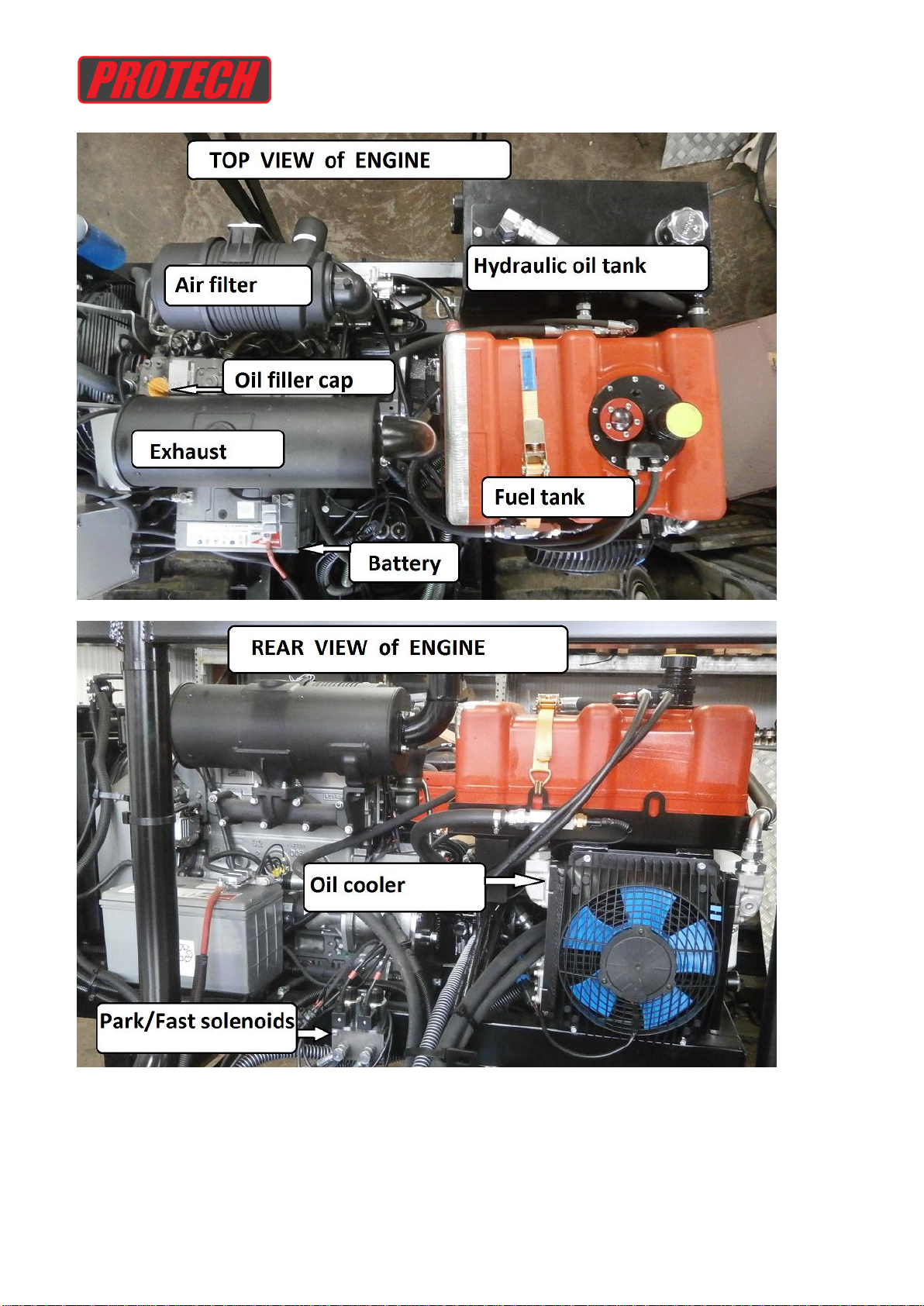

Engine diagram......................................................................................................................42

Engine control box.................................................................................................................43

MAINTENANCE............................................................................................................................44

TRACK TENSION................................................................................................................45

RECOMMANDED LUBRICANTS ....................................................................................46

ENGINE SERVICING..........................................................................................................46

TROUBLE SHOOTING.................................................................................................................47

CHECKLIST...................................................................................................................................48