Protectowire FiberSystem 8000 User manual

FiberSystem 8000

User’s Guide

B-Version

Notices

© The Protectowire

Company, Inc.

No part of this manual may be repro-

duced in any form or by any means

(including electronic storage and

retrieval or translation into a foreign

language) without prior agreement

and written consent from The

Protectowire Company, Inc. as

governed by US and international

copyright laws.

Warranty

This The Protectowire Company, Inc.

instrument product is warranted

against defects in material and

workmanship for a period of one

year from date of shipment. During

the warranty period, The Protectowire

Company, Inc. will, at its option,

either repair or replace products that

prove to be defective.

For warranty service or repair, this

product must be returned to a service

facility designated by The

Protectowire Company, Inc.. Buyer

shall prepay shipping charges to

The Protectowire Company, Inc. and

The Protectowire Company, Inc.

shall pay shipping charges to

return the product to Buyer.

However, Buyer shall pay all

shipping charges, duties, and taxes

for products returned to The

Protectowire Company, Inc. from

another country.

The Protectowire Company, Inc.

warrants that its software and

firmware designated by Protectowire.

for use with an instrument will exe-

cute its programming instructions

when properly installed on that instru-

ment. The Protectowire Company,

Inc. does not warrant

that the

operation of the instrument,

software, or firmware will be uninter-

rupted or error free.

Assistance

Product maintenance agreements

and other customer assistance agree-

ments are available for The

Protectowire Company, Inc.

products. For any assistance contact

The Protectowire Company, Inc..

Certification

The Protectowire Company, Inc.

certifies that this product met its

published specifications at the time

of shipment from the factory.

The Protectowire Company, Inc.

further certifies that its calibration

measurements are traceable to the

United States National Institute of

Standards and Technology,

NIST

(formerly the United States

National Bureau of Standards, NBS)

to the extent allowed by the Insti-

tutes’s calibration facility, and to the

calibration facilities of other Interna-

tional Standards Organization mem-

bers.

Subject Matter

The material in this document is sub-

ject to change without notice.

The Protectowire Company, Inc.

makes no warranty of any kind with

regard to this printed material,

including, but not limited to, the

implied warranties of merchantability

and fitness for a particular purpose.

The Protectowire Company, Inc.

shall not be liable for

errors

contained herein or for incidental or

consequential damages in con-

nection w i th the furnishing,

performance, or use of this material.

ISO 9001 Certification

Produced to ISO 9001 international

quality system standard as part of our

objective of continually increasing

customer satisfaction through

improved process control.

Limitation of Warranty

The foregoing warranty shall not apply

to defects resulting from improper or

inadequate maintenance by Buyer,

Buyer-supplied software or interfac-

ing, unauthorized modification or mis-

use, operation outside of the

environmental specifications for the

product, or improper site preparation

or maintenance.

No other warranty is expressed or

implied. The Protectowire Company,

Inc. specifically disclaims the implied

warranties of merchant ability an d

Fitness for a particular purpose.

Printing History

New editions are complete revisions

of the guide reflecting alterations in

the functionality of the instrument.

Updates are occasionally made to the

guide between editions. The date on

the back page changes when an

updated guide is published. To find

out the current revision of the guide,

or to purchase an updated guide, con-

tact Protectowire Company, Inc.

representative.

Exclusive Remedies

The remedies provided herein are

Buyer’s sole and exclusive remedies.

The Protectowire Company, Inc. shall

not be liable for any direct, indirect,

special, incidental, or consequential

damages whether based on

contract, tort, or any other legal

theory.

Getting Started

5

Introduction & Measurement Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Setting up the FIBERSYSTEM 8000 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting up the Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting to the Controlling PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Front, Rear and Connection Panels of the FIBERSYSTEM 8000 Instrument . . .. . . . . . . . 18

Terminating the Sensor Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting to the Output Relays and Input Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Making Measurements

25

Starting the FIBERSYSTEM 8000 Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

34

Troubleshooting and Maintenance

27

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

What do I need for Proper Cleaning? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cleaning FIBERSYSTEM 8000 Instrument Housings . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Preserving Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning the Optical Connectors and Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Replacing the Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Checking the Operation of the FIBERSYSTEM 8000 system . . . . . . . . . . . . . . . . . . . . . . 33

Returning the Instrument for Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

The Protectowire Company, Inc. Contact . …... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Specifications and Regulatory Information

36

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Definition of Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Angled Connector Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

3

Getting Started

1 Getting Started

Introduction & Measurement Principle. . . . . . . . . . . 6

General Safety Considerations . . . . . . . . . . . . . . . . 8

Setting up the FIBERSYSTEM 8000 System. . . . .

Front, Rear and Connection Panels of the

FIBERSYSTEM 8000 Instrument . . . . . . . . . . . . . .

Terminating the Sensor Cable. . . . . . . . . . . . . . . .

Connecting to the Output Relays and Input Lines.

14

18

20

21

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

5

Getting Started

Introduction & Measurement Principle

The Protectowire Company, Inc. FIBERSYSTEM 8000 PTS

(Protectowire Temperature Sensing) Series is optimized and

certified for

fire detection applications. The instrument can be

configured for

various alarm criteria and can be connected to a

fire control panel

using the relay inputs and outputs. It is

categorized as a DTS (Distributed Temperature Sensing) System

which are optical fibers functioning as linear sensors. For the

purposes of this manual these two acronyms (PTS and DTS) are

used interchangeable.

The Protectowire Company, Inc.’s distributed temperature

measurement is based on

the proven Raman-Optical Time-

Domain-Reflectometry (OTDR)

technique. An optical laser

pulse propagating through the fiber

gets scattered light back

to the transmitting end, where it is

analyzed. The intensity of

the Raman signals is a measure for

the temperature along the

fiber.

The backscattered light is spread across a range of wavelengths.

Some of these wavelengths are affected by temperature changes

while others are immune. By very accurately measuring the

Difference in the signal intensity of the backscattered light an

Accurate temperature measurement can be made.

The local position of the temperature is determined by measuring

the arrival timing of the returning light pulse similar to a radar

echo showing the distance of a car or plane.

6

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

Getting Started

The temperature resolution is dependent on several factors:

Measurement time, spatial resolution, the length of the fiber, the

loss of the fiber, splices or connectors.

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

7

Getting Started

General Safety Considerations

This product has been designed and tested in accordance with

the standards listed on the manufacturer ’s Declaration of

Conformity, and has been supplied in a safe condition. The

documentation contains information and warnings that must be

followed by the user to ensure safe operation and to maintain the

product in a safe condition.

SafetySymbols

The caution sign denotes a hazard. It calls attention to a

procedure which, if not correctly performed or adhered to,

could result in damage to or destruction of the product. Do

not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

The warning sign denotes a hazard. It calls attention to

a procedure which, if not correctly performed or

adhered to, could result in injury or loss of life. Do not

proceed beyond a warning sign until the indicated

conditions are fully understood and met.

8

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

WARNING

CAUTION

Getting Started

InstrumentMarkings

The instruction manual symbol. The product is marked

with this warning symbol when it is necessary for the user

to refer to the instructions in the manual.

In this case, this is to change the fuse. Please refer to

“Replacing the Fuse” on page 38.

The laser radiation symbol. This warning symbol is

marked on products which have a laser output.

The DC (direct current) symbol is used to indicate the

input power connecting terminal.

Certification Marking as VdS certified fire detector (linear

heat detector).

Certification Marking as UL certified fire detector (linear

heat detector).

This symbol indicates the earth connecting terminal.

The ON symbol is used to show that the power switch is in

the on position, and the instrument is in operating mode.

The stand-by symbol is used to show the power switch is

in the stand-by position and the instrument is in stand-by

mode.

Conformity Marking of the European Union

General Recycling Mark for plastic parts used in the

product

If this product is not used as specified, the protection

provided by the equipment could be impaired. This

product must be used in a normal condition (in which

all means for protection are intact) only.

Operator access to the inside of the instrument is

limited to the procedures described in “Setting up the

FIBERSYSTEM 8000 System” in chapter 1. Other areas

and parts inside

the instrument are not for service by

the operator.

Refer servicing to qualified service

personnel.

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

9

WARNING

WARNING

Getting Started

To prevent electrical shock, disconnect the instrument

from the power source before cleaning. Use a dry

cloth or one

slightly dampened with water to clean the

external case parts.

Do not open the card cage inside the FIBERSYSTEM

8000, or attempt to

clean it internally.

Using controls or adjustments or performing

procedures other than those specified in the

documentation supplied with your equipment can

result in hazardous radiation exposure.

This product complies with IEC Pollution Degree 2.

When installing the instrument using power supply, make

sure the detachable power cord is readily identifiable and is

easily reached by the operator.

Do not connect a light source to the optical output or the

connected fiber to prevent potential interferences or

damages of optical or opto-electrical components.

For operation of the instrument use a power supply certified

in compliance with EN54-22 and certified to UL/ULC for

UL/ULC compliance.

Please note, the The Protectowire Company, Inc. AC/DC

adapter A1011A (18V DC, 3.5 A) is not suitable for

certified fire detection application.

10

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

Getting Started

Laser SafetyInformation

The laser source specified by this user guide is classified

according to IEC 60825-1 (2007).

The laser source complies with 21 CFR 1040.10 except for

deviations pursuant to Laser Notice No. 50, dated 2001-July-26

1

Max. average output power means the highest possible average

power that the laser source can produce at its output.

Max. permissible average output power is the highest optical

power that is permitted within the appropriate IEC laser class.

2

According to IEC Laser class 1M the laser activity and the laser

power is not dangerous for the user as long as no optical

instruments like magnifying glasses or microscopes are used.

Laser class 1M label

The instrument has built-in safety circuitry, which will disable the

optical output in the case of a fault condition.

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

11

FIBERSYSTEM

8000 unit

Laser type

Semiconductor

Laser

Wavelength

1064 nm

Max. average output power1

17 mW

Beam waist diameter

50 µm

Numericalaperture

0.2

Laser class according to IEC 60825-1

(2001)

1M

Max. permissible average output

power2

20 mW

Getting Started

Please pay attention to the following laser safety

warnings:

•

Even the laser power of the FIBERSYSTEM 8000

instrument does not

generate direct danger for your eyesight we suggest

not to look into the end of an optical cable attached to

the optical output when the device is operational.

The use of optical instruments with this product will

increase the hazard to your eyes.

•

•

Refer servicing

personnel.

only

to

qualified

and

authorized

12

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

WARNING

Getting Started

EnvironmentalInformation

This product complies with the WEEE Directive (2002/96/EC)

marking requirements. The affixed label indicates that you must

not discard this electrical/ electronic product in domestic

householdwaste.

Product Category: With reference to the equipment types in the

WEEE Directive Annex I, this product is classed as a "Monitoring

and Control instrumentation" product.

Do not dispose in domestic household waste.

For product disposal you can return it to The Protectowire

Company, Inc. after

arrangement. Please contact your local

Protectowire distributor for details.

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

13

Getting Started

Setting up the FIBERSYSTEM 8000 System

Setting up the Hardware

1.

At receipt of shipment.

a)

Inspect the shipping containers for damage.

If the shipment was damaged, contact the carrier, then contact

The Protectowire Company, Inc..

Keep the shipping containers and cushioning material and use

it for further shipping e.g. in case of Service & Support needs.

b)

Verify that you received the options and accessories that

you ordered. Compare the package contents with the bill of

order.

If anything is missing or defective, please contact The

Protectowire Company, Inc..

To avoid the possibility of injury or death, you must

observe the following precautions before switching on

the instrument.

•

Do not remove protective covers while the instrument

is powered.

Do not open the inner card cage. Component

replacement and internal adjustments must be made

only by qualified service personnel.

Instruments that appear damaged or defective should

be made inoperative and secured against unintended

operation until they can be repaired by qualified

service personnel.

Defective, damaged, or malfunctioning instruments

must be returned to The Protectowire Company, Inc.

•

•

•

Do not operate the instrument in the presence of

flammable gases or fumes. Operation of any electrical

instrument in such an environment constitutes a safety

hazard.

14

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

WARNING

Getting Started

Before you connect any fiber-optic cable to the

FIBERSYSTEM 8000 unit, please ensure the optical

connectors have been properly cleaned.

Fiber-optic connectors are easily damaged when connected

to dirty or damaged cables and accessories. When you use

improper cleaning and handling techniques, you risk

expensive instrument repairs, damaged cables, and bad

measurements.

If the device was stored outside the operating temperature

range, you should first wait for the device to acclimatize

before turning it on.

2. Attach the FIBERSYSTEM 8000 to a fire safety certified

power supply which provides the required safety extra-low

voltage as specified. Reference controller Internal Wiring

Diagram (IWD drawing) for precise connection points.

3. Switch on the power.

Installing the Software

1.

Install the Agilent IO Libraries Suite from the supplied CD on

the PC you would like to use to control the FIBERSYSTEM

8000 instrument.

If you are using the FIBERSYSTEM 8000 Configurator

software to control the

FIBERSYSTEM 8000 instrument,

install this from the CD, too. (The FIBERSYSTEM 8000

Configurator software is the easiest way to configure the

FIBERSYSTEM 8000 instrument).

2.

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

15

CAUTION

CAUTION

Getting Started

Connecting to the Controlling PC

1. Connect the distributed temperature system to the controlling

PC.

When you connect a USB device, Windows will display a Found

New Hardware Wizard. Because your USB device is an Agilent

USBTMC instrument, you do not need to insert a CD when

prompted by the wizard, because all the drivers you need have

already been installed with the IO Libraries Suite. Simply click

Next until the wizard completes.

If a second Found New Hardware Wizard appears, continue to

click Next until that wizard completes as well. These wizards

place the installed USB drivers in the appropriate locations for

Windows torecognize your device.

If you are controlling the distributed temperature system over

the LAN, you will need to first connect to the distributed

temperature system via USB and set the IP address with the

FIBERSYSTEM 8000 Configurator (see FIBERSYSTEM

8000 Configurator Guide), if DHCP is

not activated or

supported by the network.

The default settings are

DHCP:

enabled

IP-address:

Host name:

0.0.0.0

A-N4387B-xxxxxx

where xxxxxx denote the last 6 digits of the serial

number

The default domain name is an empty string.

255.255.255.0

0.0.0.0

Domainname:

Subnet Mask:

DefaultGate-

way:

To change these values:

a)

Run the “Agilent Connection Expert:” If the Agilent

Connection Expert utility does not run automatically at this

time, click the IO Control (IO icon in the Windows

notification area) and then click Agilent Connection Expert.

b)

The Agilent Connection Expert will automatically detect

most interfaces and instruments, and will assign names and

other default configuration settings. If you want to change

16

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

NOTE

Getting Started

these parameters, you can do so in the Agilent Connection

Expert window.

i

Select the FIBERSYSTEM 8000 instrument or

interface in the explorer

pane in the center of the Agilent Connection Expert

window.

The properties of the selected item appear in the

properties pane on the right. When you right-click on an

item in the explorer pane, you see a shortcut menu of

actions that you may take on that item. These actions

are also available from the menus at the top of the

Agilent Connection Expert window. The most common

actions are also listed in the Agilent Connection Expert’s

task guide (the left pane of the window).

ii

You may also add instruments or interfaces manually to

your test system configuration if the Agilent Connection

Expert does not automatically detect the hardware (for

example, if it is connected via Ethernet).

See the Agilent IO Libraries Suite Online Help for more

information on the Agilent Connection Expert and on

configurationchanges.

Test instrument connections:

The Agilent Connection Expert will automatically send an

identification query (*IDN?) to any instrument that has its

auto-identify property set to Yes. (See the Agilent IO

Libraries Suite Online Help if you want to turn this function

off.)

When you see a green check mark on the icon representing

an instrument, this means that the instrument has

responded as expected. (Note that some instruments do

not support the *IDN? query and will not respond

appropriately.) The instrument’s identification information is

displayed in the properties pane on the right side of the

Agilent Connection Expert window.

You can explicitly test the connections to your instruments,

and exercise more of their functionality, by selecting Send

commands to this instrument in the task guide or shortcut

menu. This starts the Interactive IO utility, which allows you

to send commands to your instruments and see their

responses. Note that some commands (such as *TST?,

instrument self-test) may take longer than Interactive IO’s

default timeout; you can modify the timeout in the

Interactive IO window by selecting Interact > Options...

c)

2. Continue with “Starting the FIBERSYSTEM 8000

Instrument” on page 32.

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

17

Getting Started

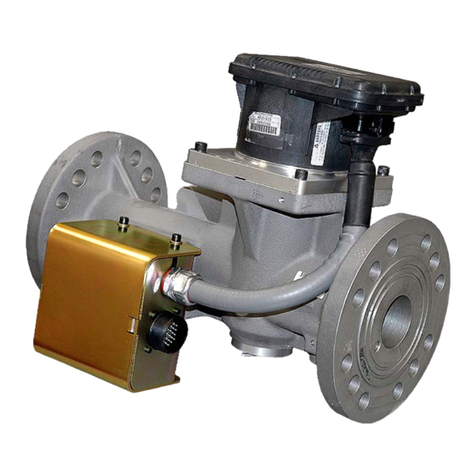

Front, Rear and Connection Panels of the FIBERSYSTEM

8000 Instrument

FIBERSYSTEM 8000 Indoor Housing

(19”, Option - H01D)

Frontpanel

Color display

Top line indicates system

status (e.g. Ready, Error,

Measuring) -Bottom lines

indicate alarm conditions.

Display color

indicates:

white(=default),red

(=alarm),yellow

(=fiber break)

Power LED

Switches on

after booting as

readiness

indicator.

Tx/Rx LED

Indicates

communication

activity

between

the

FIBERSYSTEM 8000

and the

controller.

Alarm LED

Fault LED

Indicates the

FIBERSYSTEM 8000

has an

error condition

(e.g. fiber

break).

On when a temperature value

measured exceeds alarm

limits

on one or more

channels.

18

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

Fiber Optic

Linear Heat Detection

POWER

TX/RX

FAULT

ALARM

Getting Started

Cardcage

Bottom view

USB

USB connector, for

link

to configuration

computer.

LAN

LAN connector, for

link to network.

RS 232

Not used

Fuse

Replace only with

same type (T4A L

250V, P/N 2110-

1362).

Power

Connect to DC

power supply.

Channel

Connectors to

optical fibres (

E2000-

ConnectionAPC)

(depending on

channeloptions)

Memory card slot

Disabled;for

further use

On/Off

To switch

FIBERSYSTEM

8000

instrument

on

or off.

Relays

Connectors to input and output

relays

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

19

The Protectowire Company, Inc.

FIBERSYSTEM 8000 - Linear Heat

Series

Getting Started

Terminating the Sensor Cable

To

guarantee

the

specification

throughout

the

whole

measurement distance,we recommend excess cable of 20 m and

a proper fiber termination (for low back reflection).

This can be achieved by ending the cable with a clean angled

E2000connector.

Acceptable alternatives are

•

•

winding at least 5 loops with diameter smaller than 5 mm

polishing an angle or cleaving of more than 14° to the cable

end (and cleaning)

immersing the (clean) end of the cable in index matching fluid

any combination of winding, polishing and immersing

according to this discribtion here.

•

•

Note: To terminate the sensor cable by polishing or immersing, a

clean cable end is necassary.

20

Table of contents

Popular Controllers manuals by other brands

Cooper Power Systems

Cooper Power Systems VR-32 quick start guide

Woodward

Woodward TecJet 52 Installation and operation manual

Epson

Epson S1D16000 Series Technical manual

Webasto

Webasto SmartControl operating instructions

Ascon tecnologic

Ascon tecnologic KM1E Engineering manual

jokab safety

jokab safety Vital 1 instructions