Protrol IPS2 24 VDC User manual

Ver 1710 Rev 1

IPS2 24 VDC

Fault Detector

IPS2 24 VDC is a fault detector for overcurrent and directional earth

faults that indicates faults using its relay outputs and IEC 60870-5-

101.

Since the algorithm for earth fault detection does not require a

voltage transformer, IPS2 gives a very cost-efficient fault detection

with high sensitivity for pass through faults in impedance earthed

networks.

Ver 1710 Rev 1

M A N U A L

1 Contents

1Contents ___________________________________________________________________ 2

2Schematic Overview __________________________________________________________ 3

3Safety Information ___________________________________________________________ 4

4Functional Description ________________________________________________________ 5

4.1 Detector Function _______________________________________________________________ 5

4.2 Remote Terminal Unit Function ____________________________________________________ 7

4.3 System and service interfaces______________________________________________________ 8

5Hardware __________________________________________________________________ 9

5.1 IPS2 24 VDC Main Printed Circuit Board Rev. C ________________________________________ 9

5.2 IPS2 24 VDC Top Printed Circuit Board______________________________________________ 11

5.3 Protrol Tool for IPS2 ____________________________________________________________ 13

5.4 Setting the IPS2 to Service Interface Mode __________________________________________ 13

5.5 Communication Cable ___________________________________________________________ 13

5.6 Protrol Main Window ___________________________________________________________ 14

5.7 IPS2 Transient Fault Recorder_____________________________________________________ 16

6Configuration of IPS2 24 VDC __________________________________________________ 18

6.1 Creating or Adjusting a Configuration File ___________________________________________ 18

6.2 Download a Configuration File to the IPS2 Device_____________________________________ 21

7Testing and Commissioning of IPS2 _____________________________________________ 23

7.1 Binary I/O_____________________________________________________________________ 23

7.2 Current Injection Test ___________________________________________________________ 23

7.3 EF Trig Level Check _____________________________________________________________ 24

7.4 Test of IPS after Commissioning ___________________________________________________ 24

7.5 Offset Elimination (zero offset calibration) __________________________________________ 24

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 3e-mail: info@protrol.se

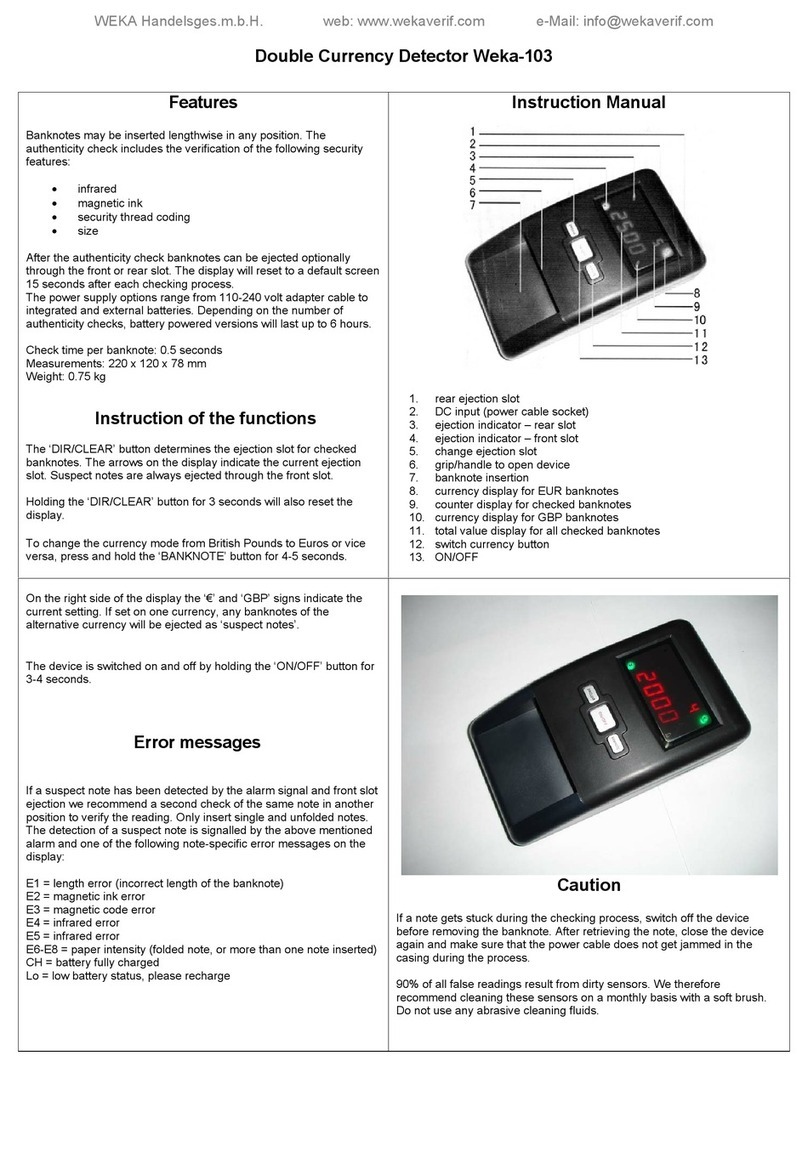

2 Schematic Overview

RS232

Fault indication

Internal

port

5

012

3

4

6

7

89

5

012

3

4

6

7

89

PWR

ST

I>

I0>

IPS2

0 OFF 0.04 s

1 0.5x 0.1 s

2 0.75x 0.2 s

3 1.0x 0.4 s

4 1.5x 0.6 s

5 2.0x 0.8 s

6 2.5x 1.0 s

7 3.0x 2.0 s

OFF 0.04 s

1.0 A 0.1 s

1.5 A 0.2 s

2.0 A 0.5 s

2.5 A 1.0 s

3.0 A 2.0 s

5.0 A 5.0 s

10 A 30 s

I>

I0> tI> t

X2 X3 X4 X6

X5

X1

Binary

inputs

123

C21 21

IA

1A

C2

IB

1A

C4

IC

1AC 6

35

12

RS485

RX/TX

1

24-48 VDC

+

GND

__

2 3

-

1

+-

Ack

t

5

012

3

4

6

7

89

5

012

3

4

6

7

89

I0>

t

21

X7

EXT

LED

Figure 1. IPS2 24 VDC overview.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 4e-mail: info@protrol.se

3 Safety Information

The device should be connected to a ground terminal.

If the cover is removed, avoid contact with the main circuit board and terminals. The unit is

powered by 24 VDC but the wires to binary inputs and outputs are designed for higher signal

voltages.

If the unit is disconnected and the cover is removed, make sure that proper precautions are made

to protect the unit from electrostatic discharges.

When connecting and disconnecting the current terminals always short-circuit the current path to

avoid open circuits!

Short circuiting the current terminals when the earth fault detector is enabled is likely to be

interpreted as an apparent earth fault. If the EF detector has no binary input qualification enabled

the IPS2 unit should either be switched off or pluggable connectors in X2-X3 should be

disconnected.

Hint: This “feature” can be used for example in a test situation when the whole chain from IPS2 to

the SCADA system should be verified. When the IPS2 unit is in operation and there is a normal load

current it is usually possible to activate the earth fault detector by short-circuiting one phase on the

terminal screws with a short cable.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 5e-mail: info@protrol.se

4 Functional Description

4.1 Detector Function

True Fault Pass Through Earth Fault Detection

Protrol’s patented Fault Pass Through earth fault detection is suitable for all indirectly earthed networks. It

is capable of detecting high impedance and arcing earth faults. It analyses the transient nature of phase and

neutral currents and points reliably out the fault direction with respect to the measurement point. Note

that no voltage measurement is necessary for good selectivity at very low currents. The sensitivity is

comparable with that of a directional earth fault protective relay.

At an earth fault the detector will set itself into Trig state and evaluate if the fault is upstream or

downstream the unit. If the fault is downstream, it will switch to Start state. In this mode, the detector

evaluates the I0residual current until the Operation Delay has passed. If the residual is high after the set

time, the detector will enter Trip state.

Note that both a Start and a Trip indication means that an earth fault has occurred downstream the

detector. A Start without a subsequent Trip indication means that either the fault current is too low, or the

fault was of transient type and was gone after the Operation Delay time. Thus, the Start object, available

remotely, can be used as an early indication of an incipient fault.

Some periods after the disturbance has vanished, the detector returns to its normal state.

High I0Detection

The IPS2 supervision alarm for high residual current if the steady-state I0 current exceeds 16 times the I0

pickup level, as specified by the rotary switch on the front panel

1

.

The main purpose of this alarm is to indicate that something is wrongly connected, either wrong polarity or

missing phase.

An alarm is indicated by flashing the I0>LED, also see the Section 5.2 IPS2 24 VDC Top Printed Circuit

Board.

Overcurrent Detection

The IPS2 unit has one overcurrent stage that can be configured using the rotary switch at the front panel.

Phase Break Detection

The phase break detection alarm is activated - if one phase is “dead” while the other two are “alive”, a

phase break is signaled locally and on the system interface. A phase is considered “dead” if the current is

lower than the I0pickup level, and “alive” if the current is higher than 4 x the I0pickup level.

2

An alarm is indicated by flashing the I> LED, also see the Section 5.2 IPS2 24 VDC Top Printed Circuit

Board.

1

If the earth fault stage is deactivated, the High I0 steady-state limit is set to 160 A.

2

If the earth fault stage is deactivated, the “dead” threshold is set to 5 A while “alive” is 20 A.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 6e-mail: info@protrol.se

Output relays

The output power relays in the IPS detector enable direct operation of switching devices. Thus, it is possible

to disconnect faults before the protection in the distribution substation reacts, minimizing the

consequences for the users upstream the fault.

Fault acknowledgement

The LEDs including the external LED can be reset either by pressing the Ack-button or automatically when

the time of the Protrol Tool parameter LED flashing time has elapsed.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 7e-mail: info@protrol.se

4.2 Remote Terminal Unit Function

The IPS2 unit includes a Remote Terminal Unite (RTU) function that can be employed to share Start and

Trip information as well as other binary and analogue objects.

Binary objects

There are nine objects for internal signals and the two binary inputs of the IPS2 unit that can be transmitted

on the RS485 System Interface (Single Point) using the IEC 60870-5-101 protocol.

▪I0> Start

▪I0> Trip

▪I> Start

▪I> Trip

▪I0> Arcing

▪Phase break

▪Binary Input 1

▪Binary Input 2

▪High residual current

Analogue objects

Five analogue objects, three phase currents, residual current and fault detected phase, can be transmitted

for supervision/ information purposes. See the Table 1 Explanation of the Protrol IPS2 24 VDC Configuration

settings for more information.

Protocol

The available protocol is:

▪IEC 60870-5-101

Supported selection of ASDUs:

Standard range

No

Type ID

Description

<1>

M_SP_NA_1

Single-point information

<2>

M_SP_TA_1

Single-point information with time tag

<9>

M_ME_NA_1

Measured value, normalized value

<11>

M_ME_NB_1

Measured value, scaled value

<13>

M_ME_NC_13

Measured value, short floating point number

<100>

C_IC_NA_1

Interrogation command

<103>

C_CS_NA_1

Clock synchronization command

3

M_ME_NC_1 R32-IEEE STD 754

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 8e-mail: info@protrol.se

4.3 System and service interfaces

The IPS2 unit has a system interface for RTU communication and a service interface for handling of

transient fault recorder data.

A hardware and a protocol configuration must be made to switch between the two different interfaces.

Hardware configuration is made with a jumper on a 3-pole header, see the coming chapter “IPS2 24 VDC

Main Printed Circuit Board Rev. ” for details.

The device protocol is switched by pressing and holding the ACK button until the changed mode is indicated

by a short flash on the I> or I0>LED.

System interface

The physical port for the system interface is the RS485 port (X5), see the chapter “Schematic Overview” for

connector placement.

The jumper in the 3-pole header must be placed in position 2 –3 for RS485 communication.

The device protocol is switched by pressing and holding the ACK button until the changed mode is indicated

by a short flash on the I0>LED.

The device is always initiated, after a power down or reset, with the system interface protocol activated.

Service interface

The physical port for the service interface is the internal RS232 port, see chapter “IPS2 24 VDC Main Printed

Circuit Board Rev. ” for details.

The jumper in the 3-pole header must be placed in position 1 –2 for RS232 communication.

The device protocol is switched by pressing and holding the ACK button until the changed mode is indicated

by a short flash on the I> LED.

Please observe that the IPS2 is always initiated, after a power down or reset, with the system interface

protocol activated.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 9e-mail: info@protrol.se

5 Hardware

The IPS2 unit is composed of two printed circuit boards (PCBs); one large circuit board forming the base and

a top circuit board that is located above of the other just beneath the front panel.

To access the reset button, firmware download port (C2 interface) and the internal serial port of IPS2, the

front cover must be removed. This is easily accomplished by removing the four screws in the corners of the

cover. Note that the screws need only to be turned 90 degrees.

5.1 IPS2 24 VDC Main Printed Circuit Board Rev. C

Pluggable Terminal Blocks

External cables are attached to the lower side of the IPS2 using pluggable contacts. For more information

about each conductor in the contacts, please refer to the Schematic Overview in Figure 1.

Figure 2. IPS 24 VDC Main PCB Rev C.

Service Port

C2 Port

Reset switch

3-pole header

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 10 e-mail: info@protrol.se

Reset button

Pressing the orange button results in a reset of the unit. All recordings from previous faults and events are

lost. Configuration settings are kept during reset.

Service Port

The service port connector is found on the upper side of the circuit board. The service port is used together

with any computer with Protrol Tool. Protrol Tool is a service tool for analysis of transient fault recordings

and is described more in details in the following chapter. Analysis requires the 9-pole DSUB adapter cable

with article number 606535.

C2 Port

Configuration of the IEC 60870-5-101 protocol is done using the C2 Port which is the grey socket labeled J6

on the Main PCB. Configuration is described in the following chapter, and requires the 9-pole DSUB adapter

cable with article number 606537.

3-pole Header

There is a 3-pole header located on the Main PCB. Using a jumper to short circuit two leads will configure

the IPS2 unit to use the RS232 Service Port or the RS485 System Interface. The connectors are number 1-2-

3 from left to right.

▪Jumper position 1 –2: RS232 Service Port

▪Jumper position 2 –3: RS485 System Interface Port.

The device protocol is switched by pressing and holding the ACK button until the changed mode is indicated

by a short flash on the I> or I0>LED.

A flash on the I0>LED indicates that the service protocol is activated.

The device is always initiated, after a power down or reset, with the system interface protocol activated.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 11 e-mail: info@protrol.se

5.2 IPS2 24 VDC Top Printed Circuit Board

The top printed circuit board for IPS2 serves as local Human Machine Interface (HMI) and offers basic

settings and status information.

The IPS2 HMI has rotary switches for settings, Light Emitting Diodes (LEDs) for status information and an

acknowledge button.

Figure 3. IPS2 24 VDC front panel HMI.

The yellow numbers in Figure 3 are explained in the following.

1. I> –A solid LED indicates a detected but unacknowledged overcurrent. A ½ Hertz flashing LED

indicates that there is a phase break.

2. I0>–A solid LED indicates a detected but unacknowledged earth fault. A ½ Hertz flashing LED

indicates a high I0.

3. ST –ST is a ½ Hertz flashing LED indicating correct operation.

4. Ack –Acknowledge button for LEDs. –Turns off the I0>LED, I> LED and the external LED.

5. PWR –PWR is lit when power is applied.

6. Rotary switch for overcurrent settings, start level as a nominal current multiplier.

7. Rotary switch for overcurrent settings, time in seconds.

8. Rotary switch for earth fault settings, start level in primary current.

9. Rotary switch for earth fault settings, time in seconds.

Rotary switches

After changing position of a rotary switch the IPS2 unit needs to be powered off/on or reset for the new

settings to come into effect. Keep the power off for at least 5 seconds before restoring the power supply.

To reach the reset button the front cover must be removed.

1

2

3

4

5

6

7

8

9

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 12 e-mail: info@protrol.se

The I> pickup level setting is a per unit value related to the current transformer ratio.

Example: 300/1 ratio and pickup level 2.5 corresponds to a primary current level of

300 × 2.5 A = 750 A

The I0> pickup settings in Amperes are based on a current transformer ratio of 300/1. In the case a different

ratio is used the levels are scaled proportionally.

Example: 150/1 ratio and pickup level of 2 corresponds to a primary current setting of

150/300 × 2 A = 1 A

I>I>

Position

Pickup level [pu]

0

OFF

1

0.5

2

0.75

3

1.0

4

1.5

5

2.0

6

2.5

7

3

8-9

Not used

I>t

Position

Pickup delay [s]

0

0.04

1

0.1

2

0.2

3

0.4

4

0.6

5

0.8

6

1.0

7

2.0

8-9

Not used

I>I0>

Position

Pickup level [A]

0

OFF

1

1.0

2

1.5

3

2.0

4

2.5

5

3

6

5

7

10

8-9

Not used

I>t

Position

Pickup delay [s]

0

0.04

1

0.1

2

0.2

3

0.5

4

1.0

5

2.0

6

5.0

7

30

8-9

Not used

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 13 e-mail: info@protrol.se

5.3 Protrol Tool for IPS2

Protrol Tool is available for Windows 7/8.1/10 and can be downloaded from Protrol’s web page

(www.protrol.se).

5.4 Setting the IPS2 to Service Interface Mode

Set the jumper on the 3-pole header in position 1-2, see chapter “IPS2 24 VDC Main Printed Circuit Board

Rev. ” and figure 2.

Change the device protocol by pressing and holding the ACK button. Changed mode is indicated by a short

flash on the I0>LED.

5.5 Communication Cable

To be able to use Protrol Tool with the IPS2 24 VDC unit, a special 9-pole DSUB adapter cable with article

number 606535 is required. If the workstation lacks a physical COM port, which most new laptops do, a

special USB –COM converter must be added between the computer and the DSUB adapter cable. Such

adapter cables can be acquired where computer accessories are available.

The service port connector is found on the upper side of the circuit board.

Note that the 3-pole header must have the jumper in position 1 –2 to enable the Service Port.

Figure 4. The RS232 adapter cable is attached to the RS232 socket in the upper left corner of the Main PCB.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 14 e-mail: info@protrol.se

5.6 Protrol Main Window

Protrol Tool is used for the following IPS application:

▪TFR, Transient Fault Recorder

Figure 5. Protrol Tool main window.

Protrol Tool uses the serial port of the engineering workstation. However, this has in most computers been

replaced by the more common USB interface. Before using Protrol Tool for the first time, the corresponding

serial port - USB driver must be installed in your computer. If it will not be automatically installed by your

operating system, a link is available at www.protrol.se in the download section. When starting Protrol Tool

for the first time, verify that the COM port settings are correct, see Figure 6. The Port shall be the specific

COM port associated with the USB driver on the engineering workstation. A description how this is found is

available at the download page for Protrol Tool on www.protrol.se.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 15 e-mail: info@protrol.se

Figure 6. COM port settings pop-up. Important: Select the assigned USB - COM port!

Acknowledge by pressing OK and then try to connect by pressing Connect. If the dialog LED Running is

flashing, connection has been established.

Communication settings can be stored in the Registry by pressing the Store ComPort Settings button. Next

time Protrol-Tool is started the selected port is opened automatically.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 16 e-mail: info@protrol.se

5.7 IPS2 Transient Fault Recorder

The IPS2 detector has a built-in transient fault recorder which can be accessed from Protrol-Tool for further

analysis of the recordings.

Figure 7. The Transient Fault Recorder

If the IPS detector has registered a fault, the Transient Fault Recordings, TFR, for the last faults can be

uploaded by pressing the Upload TFR button. A curve is three power frequency cycles with approximately

10 ms of prefault data.

By pressing the ShowCurves or AutoScale buttons, the TFR data will be displayed in the oscillogram. If

Primary values is checked the curves are scaled to primary values, otherwise they represent unscaled

binary values.

If AutoScale is not pressed the amplitude scale can be selected arbitrarily by changing the Ampl.scale field

shown in Figure 8 . Magnification of the amplitude axis is done in the Magnification field while Horiz.

pix/sample zooms in on the time axis.

Figure 8. The amplitude and time scaling fields.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 17 e-mail: info@protrol.se

The Phase checkboxes above the oscillogram is used to display the signals graphically, while the radio

buttons below each signal are used for phase selection.

Figure 9. Checkboxes and radio buttons for graphical display options.

It is possible to trace a single curve. Select the curve of interest with the phase selection radio buttons

above the graph, then push the left mouse button on the graph and drag the cursor horizontally along the

time axis until the marker is at the desired location.

Each sample value is displayed numerically together with the time tag to the right of the phase selection

radio buttons. If the RMS checkbox is checked the corresponding RMS value for one cycle ahead of the

cursor is shown instead of the sample value.

Instead, if the right mouse button is pressed anywhere along a signal, all sample values at a given time are

displayed in a popup, see Figure 10.

Figure 10. Sample popup.

A useful feature of the transient fault recorder is the possibility to make a snapshot of the actual phase

currents by pressing the Freeze button and then the Upload TFR button. The Freeze button is not available

unless any registered faults have been Acknowledged (see Section 4.1Detector Function)! Observe that a

manually initiated TFR replaces the last saved TFR –it is therefore recommended to upload any recordings

of interest before a snapshot is made.

Please notice the scroll box to the left containing the samples as a numerical table. It also contains meta

information that describes the conditions when the recording was made. It is possible to add additional

observations or notes to the scroll box by starting each row with a “;”.

File Handling

When uploading a TFR from the IPS2 a question dialog is displayed asking for saving the file. This can also

be done later by pressing the Save File button. Saved files can be retrieved later by pressing the Open File

button.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 18 e-mail: info@protrol.se

6 Configuration of IPS2 24 VDC

6.1 Creating or Adjusting a Configuration File

Configuration of an IPS2 24 VDC is done with a stand-alone tool for Windows. This tool is used for basic

configuration and allows the user to create or edit settings for an IPS2, to save and load this information

to/from disk and download a file to a unit. A screenshot of the configuration tool with factory settings is

shown in the figure below.

Figure 14. The Protrol IPS2 24 VDC Configuration Tool with factory settings.

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 19 e-mail: info@protrol.se

IPS2 24 VDC Configuration Settings

Table 1: Explanation of the Protrol IPS2 24 VDC Configuration settings.

Parameter

Range

Unit

Default

Comment

General Settings

Reignition time [ms]

0..10000

ms

2000

A reoccurring fault within the reignition time window

overrides the EF time rotary switch and sets the operate

time to a minimum. 0 disables the reigniting faults function

LED flashing time [min]

0..1440

min

120

The flashing time of the external LED in minutes also is used

to acknowledge the front panel indication LEDs.

Analogue update [s]

0..65535

s

0

Cyclic update of analogue values. No cyclic update if the set

value is 0, however, the deadband is activated instead

CT ratio

50..1200

-

300

Relay choice

0..3

-

0

0: X2: Start, X3: Trip.

1: X2: EF Trip, X3: OC Trip

2: X2: Watchdog, X3: Trip (Hardware version 3 only)

3: X2 and X3: General Trip

Operation mode

0..1

Bit 5: On

All other: Off

Checkbox 7: DIR bit in balanced mode

Checkbox 6: Balanced mode

Checkbox 5: Send analog objects

Checkbox 4: Time tag

Checkbox 3: Not used

Checkbox 2: Not used

Checkbox 1: See relay choice

Checkbox 0: See relay choice

OC level shift factor

0..8

-

0

0: Not used

1: Trip level divided by 2

2: Trip level divided by 4, etc.

IEC 60870-5-101 Communication

Configuration

RTU Link Address

1..255

-

1

Common Address

1..65534

-

1

Common Address of ASDU

RTU Link Address size

1..2

-

1

Number of octets for RTU Link Address

Cause of Transmission size

1..2

-

2

Number of octets for Cause of Transmission

Common Address size

1..2

-

2

Number of octets for Common Address

Information Object Address size

1..3

-

3

Number of octets for Information Object Address

Baudrate

9600, 19200

bit/s

9600

Standard rates for the IEC-101 port

Ver 1710 Rev 1

Protrol AB Tel: 031- 45 82 00

Ullevigatan 19 internet: www.protrol.se

411 40 Göteborg 20 e-mail: info@protrol.se

IEC 60870-5-101 Object Settings

Time Tag

0..1

0

0: No time tag included

1: Time tag included

Address [8]

1..255

0

The highest address octet

Address [16]

0.. 65534

1 to 9

The two lowest address octets

Analogue type

0..3

1

0: Raw, rated current 3800 units

1: Normalized to the nominal CT ratio

2: Scaled to integer primary current in Amperes.

3: Floating point primary current in Amperes

Deadband

1..50

%

10

Deadband for the update of analogue objects in percent of

rated current (CT ratio)

Remark: The deadband for I0is half of the I0setting. If the I0

stage is disabled, the deadband is 2.5 A

Factory Defaults

It is possible to reset all settings in the configuration tool to factory defaults by pressing the Factory button.

Open Configuration File

Previously saved settings can be reloaded to the configuration tool by pressing the Open button. A dialog

opens and it is possible to browse and choose the desired configuration file. Press Open to read the file.

Edit Configuration Data

After the Factory or Open buttons have been pressed it is possible to adjust configuration data.

Save Configuration File

The current settings can be save by pressing the Save button. A dialog opens and it is possible to adjust the

file name before Save is pressed a second time.

Clear Display

It is possible to clear all settings in the configuration tool by pressing the Clear Display button.

Download Configuration File

The current configuration file can be downloaded to a connected IPS2 unit by pressing the Download…

button. Please see the chapter “Download a Configuration File to the IPS2 Device” for detailed information

and instructions.

Table of contents

Other Protrol Security Sensor manuals