Technical

Information

FLEXA, FLXA and SENCOM are trademarks or registered trademarks of Yokogawa Electric Corporation.

All other company and product names mentioned in this user’s manual are trademarks or registered trademarks of their respective companies.

We do not use TM or ® mark to indicate those trademarks or registered trademarks in this user’s manual.

TB820D, TB830D

Sampling System Selection

Manual

TI 12E01B30-01EN

TI 12E01B30-01EN

©Copyright Oct. 2022

3rd Edition Mar. 2023

CONTENTS

Introduction .............................................................................................................2

1 Dimensions ...................................................................................................3

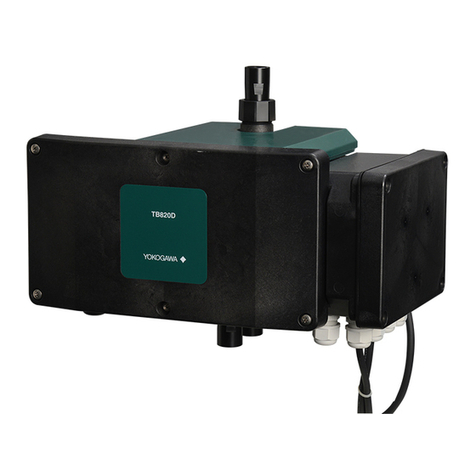

1.1 TB820D Dimensions ............................................................................................ 3

1.2 TB830D Dimensions ............................................................................................ 6

2.

Installation .................................................................................................... 16

3. Piping.......................................................................................................... 17

3.1 TB820D (-NN, -A5) Piping .................................................................................. 17

3.1.1 Head tank and Piping Parts ................................................................ 27

3.1.2 System without a Head Tank .............................................................. 31

3.2 TB830D (-NN, -A5) Piping .................................................................................. 32

3.2.1 Piping type .......................................................................................... 33

3.2.2 Head tank............................................................................................ 34

4. Wiring.......................................................................................................... 35

4.1 TB820D wiring .................................................................................................... 35

4.1.1 SENCOM cable for turbidity and chlorine (A) ..................................... 39

4.1.2 Power cable for FLXA402T (B)........................................................... 39

4.1.3 Power supply cable (C)....................................................................... 39

4.1.4 Wiring with PG400 .............................................................................. 40

4.1.5 When Relay box for solenoid valve is included .................................. 40

4.2 TB830D Wiring.................................................................................................... 44

4.2.1 SENCOM cable for Turbidity/Chlorine (A) .......................................... 47

4.2.2 FLXA402T power supply cable (B)..................................................... 47

4.2.3

TB830D power supply cable (C), Relay box power supply cable (D)

........... 47

4.2.4 Power supply cable (E) ....................................................................... 47

4.2.5

Without a sampling system and with a Relay box for solenoid valve

............ 51

5 Zero Turbidity Filter................................................................................... 54

6 Operation.................................................................................................... 55

6.1 TB820D Supplying a Sample and Adjusting the Flow Rate .......................... 55

6.2 TB830D Preparation for Operation .................................................................. 56

7. Automatic cleaning/Automatic zero calibration Sequence.................. 58

7.1 TB820D Sequence ............................................................................................. 58

7.2 TB830D Sequence ............................................................................................. 60

Revision Information ........................................................................................... 62