4

zConrm set address/function with .

The device applies the setting and returns to

the previous menu entry. .

Display saved error codes

Device errors of the call push-button module that

occur during operation are stored in the the error

memory of the device for diagnosis.

zSelect menu entry with button / and

conrm with

If no error code exists is displayed for 2

seconds and afterwards .

If error codes are saved ashes followed by

the module address and the error code.

zPress button / , to call up further error

codes if necessary.

zPress button to return to menu entry .

Error

code

Error cause Counter actions

Communication error

between device and

call push-button mod-

ule. Once the error

has occurred 3 times,

the system is reset

automatically and the

error code is gener-

ated.

If the error per-

sists, the call

push-button

module must be

replaced.

sticking call button Check call

push-button

module If there

is a defect, re-

place and ad-

dress.

Writing of the call

push-button address

in the call push-button

module fails.

If the error per-

sists, the call

push-button

module must be

replaced and

re-addressed.

Table 2: Error codes and counter actions

The memory should only be deleted once 5

error codes have been stored, so that new error

codes can be saved.

Identical error codes are only saved once.

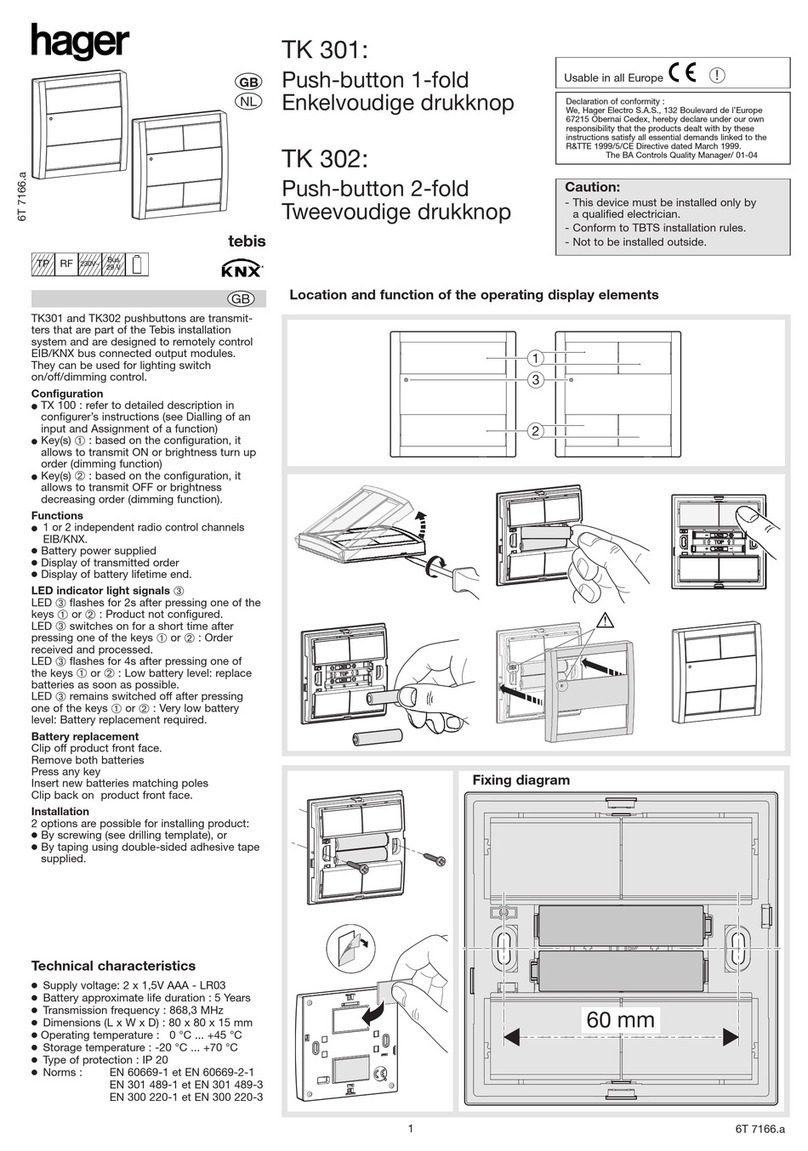

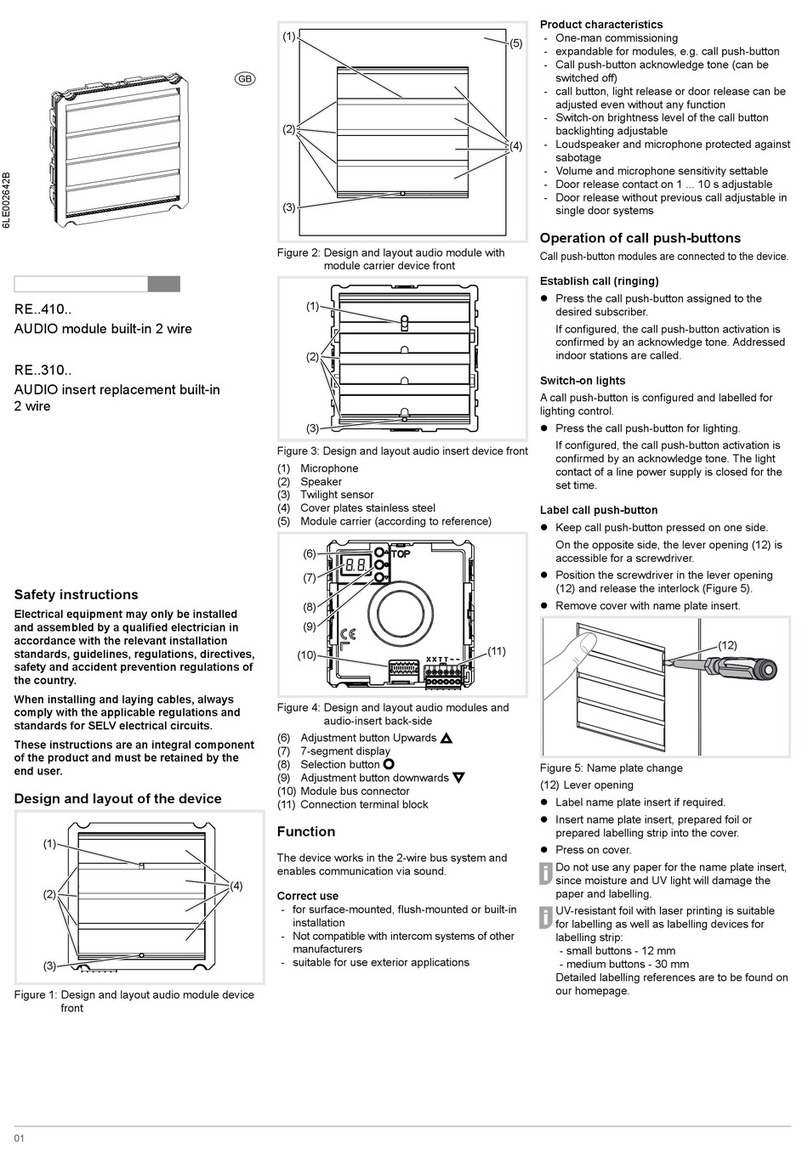

Dismantle call push-button module cover

For cleaning or replacement, the call push-button

module cover can be dismantled from the front.

zLever up the interlocking cover strips (13) at

the top and bottom using the screwdriver and

remove (Figure 11).

(13)

Figure 11: Removing the cover strips

(13) Cover stripes

zLift the call push-button module upper part

in the bottom lever opening slightly with the

screwdriver and guide it forwards (12).

P

P

(14)

Figure 12: Dismantling the call push-button module

cover

(14) Call push-button module cover

Defective covers can only be replaced by

covers with the same number of push-buttons.

zRemove the module to be replaced and install

the new module in reverse order.

Exchange module/insert

Door station is open and activated.

zPull off connection terminal block (11) on the

device.

zRemove the connection cables’ connectors on

the module to be exchanged.

zRemove screws/nuts from mechanic module

mountings and remove module mounting (see

already available installation instruction, e.g.

door station, frame, etc.).

zTo remove the call push-button module,

unlatch the side retaining brackets (15) of the

module mounting by carefully lifting up with a

screwdriver (Figure 13).

(15)

Figure 13: Unlatching module

(15) Retaining brackets module mounting

The module detaches itself from the anchoring.

zRemove the module to be replaced and install

the new module in reverse order.

Re-addressing of the device is required to

operate the door station.

P

P

Appendix

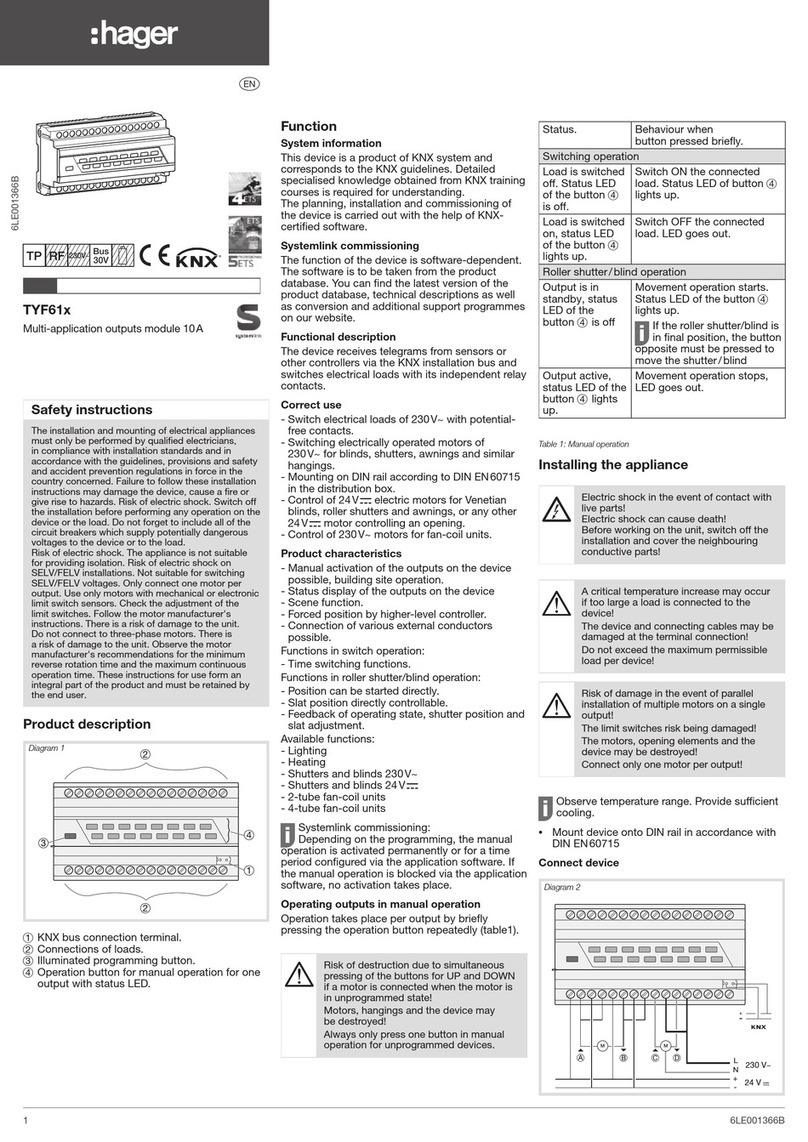

Technical data

Operating voltage 22 ... 24 V=

Current consumption audio Stand by 5 mA

Current consumption audio device operation 110 mA

Current name plate lighting

per call push-button module 45 mA

Menu

setting

Backlighting On Backlighting Off

0 Permanent Off

1

2

3

4

5

6

7

8

9

≈ 750 lx

.

.

.

.

.

.

.

≈ 60 lx

≈ 1600 lx

.

.

.

.

.

.

.

≈ 110 lx

10 Permanent On

Table 3: Brightness of LED backlighting

Door release contact T/T potential-free max. 24 V/1 A

Door release unlocking time 1 ... 10 s

Degree of protection IP 44

Degree of protection (degree of impact resistance) IK07

Relative humidity 0 ... 65% (no condensation)

Operating temperature -20°C … +55°C

Storage/transport temperature -30°C … +80°C

Connecting terminals

for conductor diameter 0.5 ... 0.8 mm

Installation height (middle of the loudspeaker) ca. 1.5 m

Dimensions:

Call push-button button small 75.8 x 14.5 mm

Name plate small 72.1 x 12 mm

Width of name plate insert small max. 0.5 mm

Call push-button button medium 75.8 x 3.6 mm

Name plate medium 72.1 x 30.1 mm

Width of name plate insert medium max. 0.5 mm

Call push-button button large 75.8 x 75.8 mm

Name plate large 72.1 x 66.3 mm

Width of name plate insert large max. 0.3 mm

6LE002642A Ind. A12.2017