Proven B-180 User manual

P. O. Box 12010

Oklahoma City, OK 73157-2010

www.provenp mps.com

B-180 thru B-500

SERIES

Enclosed with your Proven pump is an instruction sheet which provides you with

information required to safely own and operate your Proven pump. The instruction

sheet primarily covers the standard models of each pump series. The form is appli-

cable to other models in the series not listed by catalog number in the replacement

parts list section of the instruction sheet. If the catalog number of your pump is not

listed in the replacement parts list section, then caution should be exercised when

ordering replacement parts. lways give the catalog number of your pump when

ordering replacement parts.

The Proven unit you have purchased is of the highest quality workmanship and

material. It has been engineered to give you long and trouble-free service. The

Proven pumps are carefully packaged, inspected and tested to insure safe operation

and delivery. When you receive your pump, examine it carefully to determine that

there are no broken or damaged parts that may have occurred during shipment. If

damage has occurred, make notation and notify the firm that you purchased the

pump from. They will assist you in replacement or repair, if required.

RE D INSTRUCTIONS C REFULLY BEFORE TTEMPTING TO INST LL, OPER TE

OR SERVICE THE PROVEN PUMP. KNOW THE PUMP PPLIC TION, LIMIT TIONS,

ND POTENTI L H Z RDS. PROTECT YOURSELF ND OTHERS BY OBSERVING

LL S FETY INFORM TION. F ILURE TO COMPLY WITH INSTRUCTIONS COULD

RESULT IN PERSON L INJURY ND/OR PROPERTY D M GE! RET IN INSTRUC-

TIONS FOR FUTURE REFERENCE.

SAFETY GUIDELINES

1. Make certain that the unit is disconnected from the power source before attempting to

service or remove any component.

2. Do not use to pump flammable or explosive fluids such as gasoline, fuel oil, kerosene,

etc. Do not use in explosive atmospheres. Pump should only be used with liquids

compatible with pump component materials.

3. Do not handle pump with wet hands or when standing on a wet or damp surface or in

water.

4. This pump is supplied with a grounding conductor and/or grounding type attachment

plug. To reduce the risk of electric shock, be certain that it is connected to a properly

grounded grounding type receptacle.

5. In any installation where property damage and/or personal injury might result from an

inoperative or leaking pump due to power outages, discharge line blockage, or any

other reason, a backup system(s) and/or alarm should be used.

6. Support pump and piping when assembling and when installed. Failure to do so may

cause piping to break, pump to fall, motor bearing failures, etc.

7. If pump is an oil-filled pump, the motor housing is filled with a dielectric lubricant at the

factory for optimum motor heat transfer and lifetime lubrication of the bearings. Use of

any other lubricant could cause damage and void the warranty. This lubricant is non-

toxic; however, if it escapes the motor housing, it should be removed from the surface

quickly by placing newspapers or other absorbent material on the water surface to soak

it up, so aquatic life is undisturbed.

8. This pump has been tested using water only. The suitability of this pump for use with

liquids other than water is the responsibility of the end-user.

9. This pump is not intended for permanent mounting to a building structure by bolting or

similar means.

ELECTRICAL CONNECTIONS

1. Check the pump label for proper voltage required. Do not connect to voltage other than

that shown.

2. If pump is supplied with a 3-prong electrical plug, the third prong is to ground the pump to

prevent possible electrical shock hazard. DO NOT REMOVE the third prong from the plug.

separate branch circuit is recommended. Do not use an extension cord. Do not cut plug from the

cord. If the plug is cut or the cord is shortened, then this action will void the warranty.

Fig. 1

INTRODUCTION

3. If the cord is equipped with stripped lead wires, such as on 230v models, be sure that

the lead wires are connected to a power source correctly. The (green/yellow) wire is the

ground. The (blue or white) and the (brown or black) are live.

4. ll wiring should be performed by a qualified electrician.

5. Grounding: Sheet metal screws shall not be used to secure equipment grounding

conductor.

CONSULT INSTRUCTION SHEET ILLUSTR TIONS FOR PROPER SSEMBLY ND DIS-

SSEMBLY OF YOUR PROVEN PUMP.

OPERATION

1. The B-180 thru B-500 series pumps are designed to operate submerged or in-line. The

pump can be positioned in any attitude, but preferably the volute should be located to

the side.

2. If the surface is dirt or sand, place pump on a flat surface such as a piece of wood or

metal to prevent it from being clogged.

3. The weight of the pump must be supported adequately. DO NOT support the pump by

the intake or discharge connections alone.

4. Do not attempt to restrict the intake side of these pumps. Restricting the intake

may cause damage to the seal and may starve the pump. If you require

reduced flow rates, then place a valve on the discharge side of the pump or if

flexible vinyl tubing is used, a clamp can be used on the tubing to restrict

the flow.

5. Do not let the unit operate dry. It is designed to be cooled by pumping fluid. You may

damage the seal and the motor may fail if the pump is allowed to run dry.

6. If the unit is going to be idle for a period of time, follow the cleaning instructions outlined

in the next section. Do not let the unit freeze in the wintertime. This may cause cracking

or distortion that may destroy the unit.

7. If fused type plug is used on 230 volt units, a 2.0 amp fuse is recommended.

SERVICE INSTRUCTIONS

M KE CERT IN THE UNIT IS DISCONNECTED FROM THE POWER SOURCE BEFORE

TTEMPTING TO SERVICE OR REMOVE NY COMPONENT!

1. This unit is permanently lubricated. Oiling is not required. Do not, in any case,

open the sealed portion of the unit or remove housing screws. The power cord

on these units cannot be replaced. In case of damage the whole unit must be

replaced.

2. Periodic cleaning of the pump parts will prolong the LIFE and EFFICIENCY of the pump.

Refer to the assembly and disassembly of the pumping head.

3. First remove the intake screen from the pump. Then remove the volute mounting screws.

(DO NOT remove other screws which may be exposed.)

4. Lightly clean any corrosion or debris which may clog the impeller. Use a brush and

penetrating oil and lightly scrape to remove encrusted material.

5. Turn the impeller by hand to make sure it turns freely. Set pump down so the

pump and impeller are not touching anything. Plug the unit into GFCI circuit

for 10 seconds to see if the impeller turns; a) If it is rotating and GFCI did not trip,

unplug unit and install parts in reverse order in which they were removed. b) If it

does not rotate, if pump is tripping circuit breakers, or not operating properly after

cleaning, return to Proven Pump or its authorized service center. DO NOT attempt

repairs yourself.

6. Be certain power cord is in good condition and contains no nicks or cuts.

7. The motor is a continuous duty type sealed in oil with an automatic thermal overload

protector device.

WARNING: THE PUMP MOTOR IS EQUIPPED WITH AN AUTOMATIC RESETTING

THERMAL PROTECTOR AND MAY RESTART UNEXPECTEDLY. PROTECTOR

TRIPPING IS AN INDICATION OF MOTOR OVERLOADING AS A RESULT OF

OPERATING THE PUMP AT LOW HEADS (LOW DISCHARGE RESTRICTION),

EXCESSIVELY HIGH OR LOW VOLTAGE, INADEQUATE WIRING, INCORRECT

MOTOR CONNECTIONS, OR A DEFECTIVE MOTOR OR PUMP.

8. The pump can run against a restricted discharge such as a fountain without damage to

the pump.

3XPS6HULHV 5HSDLU.LW 'HVFULSWLRQ

%

%

%

%

5HSDLU.LWLQFOXGHV

VFUHHQVFUHZVYROXWH

JDV HWUHWDLQLQJULQJ

DQGLPSHOOHU

PROBLEM

Pump fails to run.

Pump runs but no fluid flows.

Flow rate is low.

Pump starts and stops pumping.

CORRECTIVE ACTION

1. Be sure correct voltage is available.

2. Clean impeller.

3. Replace pump.

1. Lower the height.

2. Clean or replace.

3. Open the valve.

4. Purge to eliminate air.

5. Refill.

6. Pump inlet must be below liquid level (flooded).

1. Be sure correct voltage is available.

2. Clean impeller.

3. Clean plumbing.

4. Replace with larger plumbing.

5. Lower the height.

1. Clean impeller and screen.

2. Replace pump.

3. Be sure correct voltage and frequency is supplied to pump.

PROBABLE CAUSES

1. No electricity or low voltage.

2. Impeller clogged.

3. Motor has open circuit.

1. Discharge height too great.

2. Inlet screen clogged.

3. Discharge valve closed.

4. ir trapped in pump.

5. No water in reservoir.

6. Pump inlet located above liquid level.

1. Low voltage.

2. Impeller clogged.

3. Inlet or discharge plumbing restricted.

4. Discharge plumbing undersized.

5. Discharge height too great.

1. Impeller or inlet screen clogged.

2. Defect in motor.

3. Incorrect voltage or frequency.

©Copyright 2003

Form 998234 02/2003

LIMITED WARRANTY

Your Proven product is guaranteed to be in perfect condition when it leaves our Factory. It

is warranted against defective materials and workmanship for a period of 12 months (90

day warranty on Models: BPL , 360, 361, 365, 366, 370 and 371) from date of purchase

by the user. No warranty on brush wear, impeller or cam in Models BPL , 360, 361, 365,

366, 370 and 371.

ny product that should fail for either of the above two reasons and is still within the

warranty period will be repaired or replaced at the option of Proven as the sole remedy of

buyer. For our customers in the CONTINENT L UNITED ST TES: Please return the de-

fective unit, postage paid, to the factory at 301 North Mac rthur Blvd., Oklahoma City, OK

73127-6616. ll defective product returned under warranty will be fully inspected to deter-

mine the cause of failure before warranty is approved.

For our customers located elsewhere; it is not economical, due to duties and freight, to

return the pump to the factory for inspection. Please return the defective unit to any autho-

rized distributor or dealer with a brief written explanation of the problem. If there are no

apparent signs of customer abuse, unit will be repaired or replaced. If dispute arises over

replacement of the pump, the distributor or dealer is to segregate such items and hold for

inspection by a representative of Proven Pumps or notify factory with details of the prob-

lem for factory disposition and settlement of warranty claim.

DISCL IMER: THE FOREGOING W RR NTY IS N EXCLUSIVE W RR NTY IN LIEU OF

NY OTHER EXPRESS W RR NTIES. NY IMPLIED W RR NTIES (INCLUDING, BUT

NOT LIMITED TO NY IMPLIED W RR NTY OF MERCH NT BILITY OR FITNESS FOR

P RTICUL R PURPOSE) TO THE EXTENT EITHER PPLIES TO PUMP SH LL BE

LIMITED IN DUR TION TO THE PERIODS OF THE EXPRESS W RR NTIES GIVEN BOVE.

Warranty will be VOID if any of the following conditions are found:

1. Sealed motor housing opened.

2. Product connected to voltage other than indicated on nameplate.

3. Cord cut off to a length less than three feet.

4. Pump allowed to operate dry (fluid supply cut off).

5. Pump used to circulate anything other than fresh water, light oils, or other mild liquids at

approximately room temperature.

6. Product abuse by customer.

For Parts or Repair, please contact ........................................................................ 1.888.572.9933

For Technical Assistance, please contact ............................................................ 1.888.956.0000

www.provenp mps.com

TROUBLESHOOTING INFORMATION

ny oral statements about the product made by the seller, the manufacturer, the

representatives or any other parties, do not constitute warranties, shall not be

relied upon by the user and are not part of the contract for sale. Sellers and

manufacturers only obligation, and buyers only remedy, shall be the replace-

ment and/or repair by the manufacturer of the product as described above. NEITHER

SELLER NOR THE M NUF CTURER SH LL BE LI BLE FOR NY INJURY, LOSS

OR D M GE, DIRECT, INCIDENT L OR CONSEQUENTI L (INCLUDING, BUT

NOT LIMITED TO INCIDENT L OR CONSEQUENTI L D M GES FOR LOST PROFITS,

LOST S LES, INJURY TO PERSON OR PROPERTY, OR NY OTHER INCIDENT L

OR CONSEQUENTI L LOSS), RISING OUT OF THE USE OR THE IN BILITY TO

USE THE PRODUCT ND THE USER GREES TH T NO OTHER REMEDY SH LL

BE V IL BLE TO IT. Before using, the user shall determine the suitability of the

product for the intended use, and user assumes all risk and liability whatsoever

in connection therewith.

Some states and countries do not allow limitations on how long an implied warranty

lasts or the exclusion or limitation of incidental or consequential damages, so the

above limitations or exclusions may not apply to you. This warranty gives you spe-

cific legal rights, and you may also have other rights which vary from state to state

and country to country.

The National Electric Code (in the US ) and similar codes in other countries

require a Ground Fault Circuit Interrupter (GFCI) to be installed in the branch

circuit supplying fountain equipment rated above 15 volts. We recommend each

pump be used with a GFCI.

This manual suits for next models

3

Table of contents

Popular Water Pump manuals by other brands

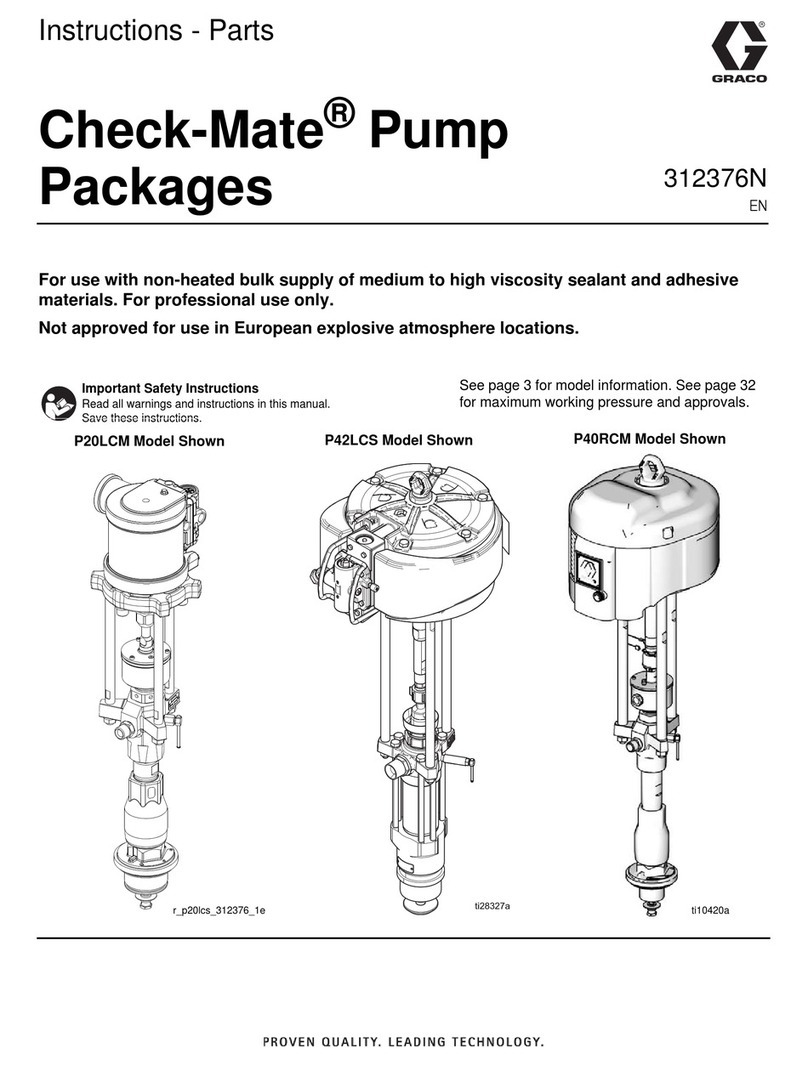

Graco

Graco Check-Mate P20LCM instructions

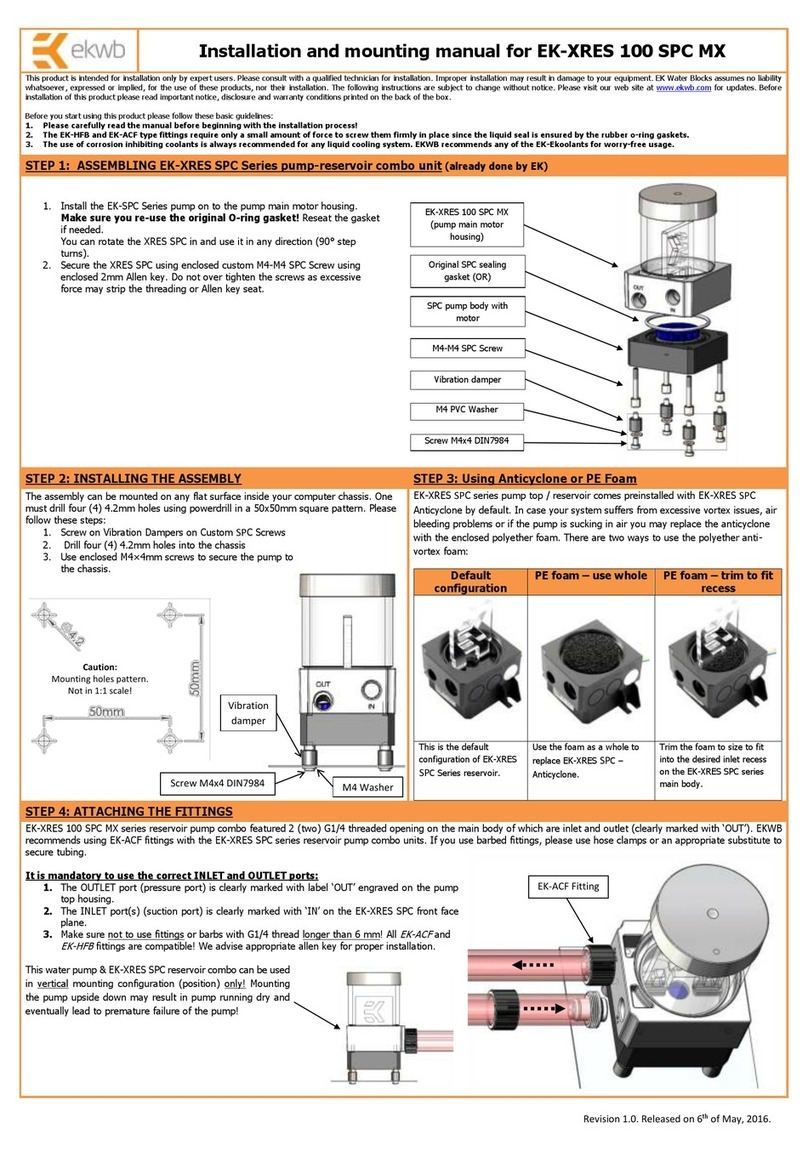

ekwb

ekwb EK-XRES SPC Series INSTALLATION AND MOUNTING MANUAL

Toyama

Toyama TWP40STPX owner's manual

Pfeiffer Vacuum

Pfeiffer Vacuum DuoLine DUO 35 M operating instructions

Renkforce

Renkforce 2302384 operating instructions

Dometic

Dometic PowerPump PP127 Installation and operating manual

Rothenberger

Rothenberger ROAIRVAC 1.5 Instructions for use

Pressure Tech

Pressure Tech Turret Series Maintenance manual

SuperFish

SuperFish BactoDose manual

Grundfos

Grundfos MAGNA3 25-100 (N) Installation and operating instructions

VITO

VITO AGRO VIMB15A instruction manual

STAR Water Systems

STAR Water Systems 3SUEL Quick reference guide