Prozone ECO MASTER User manual

PROZONE WATER PRODUCTS 3004 11TH AVENUE HUNTSVILLE, AL 35805 (256) 539-4570 www.prozoneint.com

ECO MASTER

INSTALLATION AND OPERATION MANUAL

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS.

SAVE THESE INSTRUCTIONS

WARNING: CONFIRM THE ELECTRICAL POWER IS SHUT OFF AT THE MAIN BREAKER

BEFORE INSTALLING THE ECO MASTER.

WARNING: SERVICE SHOULD ONLY BE PERFORMED BY A QUALIFIED POOL SERVICE

PROFESSIONAL TO AVOID RISK OF ELECTRICAL SHOCK, FIRE, OR INJURY.

WARNING: FOLLOW ANY APPLICABLE ELECTRICAL CODES.

WARNING: REPLACE DAMAGED CORD IMMEDIATELY TO AVOID RISK OF ELECTRICAL

SHOCK.

WARNING: MOUNT THE ECO MASTER WHERE IT IS INACCESSIBLE TO CHILDREN, TO AVOID

RISK OF INJURY.

WARNING: MOUNT THE ECO MASTER WHERE IT IS INACCESSIBLE TO ANYONE IN THE SPA.

NEVER ATTEMPT SERVICING WHEN WET.

WARNING: SHORT TERM INHALATION OF HIGH CONCENTRATIONS OF OZONE AND LONG

TERM INHALATION OF LOW CONCENTRATIONS OF OZONE CAN CAUSE SERIOUS HARMFUL

PHYSIOLOGICAL EFFECTS. DO NOT INHALE OZONE GAS PRODUCED BY THIS DEVICE.

VOLTAGE MUST BE DETERMINED BEFORE ECO MASTER IS INSTALLED.

CONNECT ONLY TO A PROPERLY GROUNDED, GROUNDING RECEPTACLE.

DO NOT BURY THE CORD.

A WIRE CONNECTOR IS PROVIDED ON THE UNIT TO CONNECT A MINIMUM NO. 8 AWG

SOLID COPPER CONDUCTOR BETWEEN THE ECO MASTER AND ANY METAL EQUIPMENT,

METAL ENCLOSURES OF ELECTRICAL EQUIPMENT, METAL WATER PIPES, OR CONDUIT WITHIN

FIVE FEET OF THE UNIT.

®

OZONEWATER PURIFICATION SYSTEMS

ADVANCED OXIDATION PURIFICATION

INSTALLATION AND OPERATION MANUAL

ADVANCED OXIDATION PURIFICATION

ECO MASTER

Preparing For Installation

1. For best results, drain the spa and ll with fresh water.

If not, refer to chart for recommended levels.

2. Check for and correct all leaks in the plumbing.

3. Check electrical system. Verify voltage is the same as

prescribed on the side of the Eco Master.

4. Check lters. Clean or replace as necessary.

5. Balance the pH.

6. Shock the spa. The use of Calcium Hypochlorite is

recommended.

7. Eco Master contains an ozonator, injector, and check

valve. Remove any vacuum source (such as an

injector) already installed on the spa.

pH 7.2 - 7.6

Alkalinity 80 - 120 ppm

TDS < 1,000

Cyanuric Acid 30 - 70 ppm

Free Chlorine 0.5 - 1.5 ppm

Calcium Hardness 60 - 400 ppm

Metals 0 ppm

Nitrates/Phosphates < 30 ppm

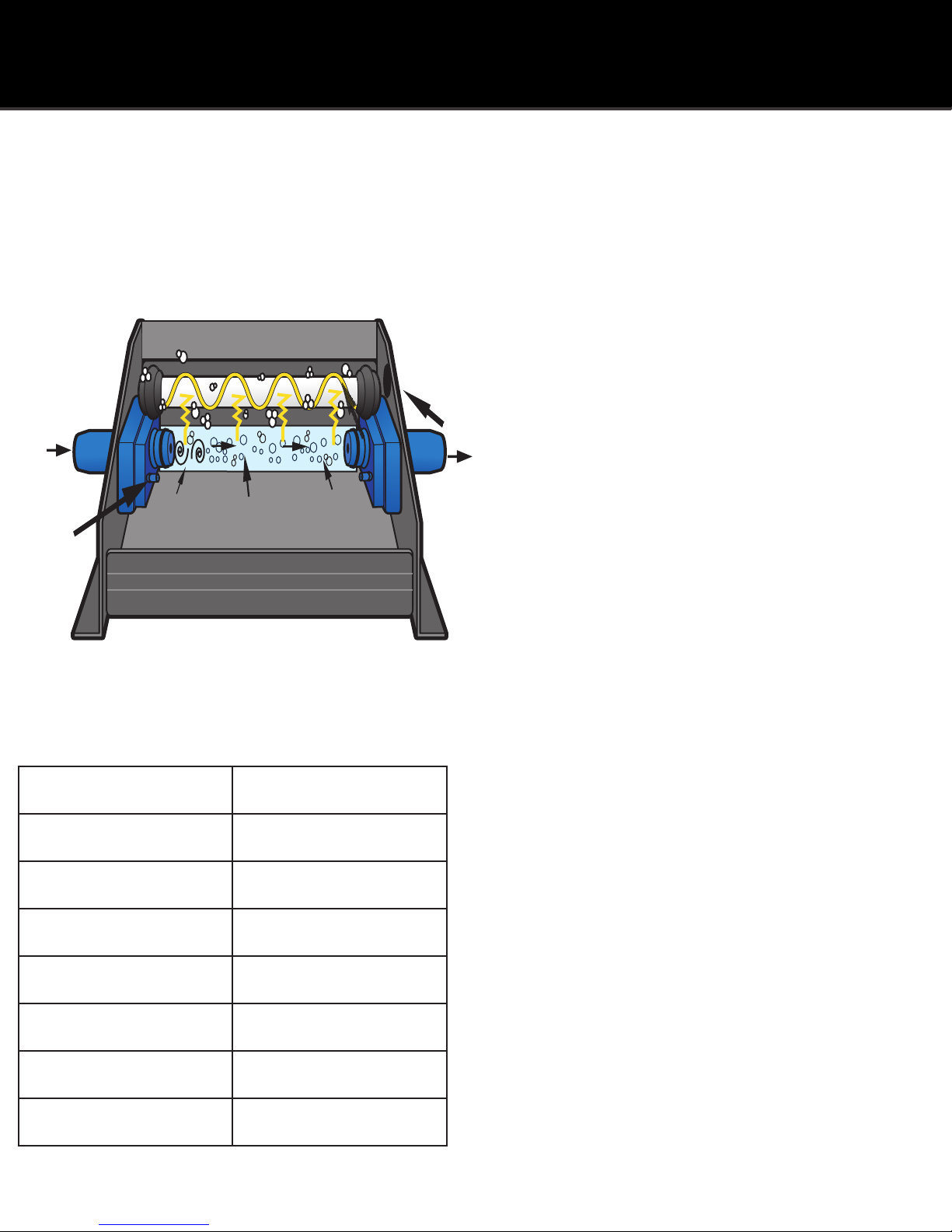

ContaminatedWater Enters

Quartz Mixing Chamber

(3)

Ozone and Hydroxyls

EnterVenturi Injector

(2)

Air Enters Chamber

converting O2to O3

and Hydroxyl Radicals

(1)

Ozone Mixes

With Water

(Oxidation)

(3)

Water is Irradiated By

UV-C (UV Sanitation)

(4)

Ozone is Irradiated in

Water by UV

(Advanced Oxidation)

(5)

Air IsBlastedWith HybridUV-CandVUV

Sanitized Water

Exits the Unit

cutting edge Germicidal UV sterilization in one

compact system, to generate Ozone and Advanced Oxidation Processing (AOP).

Hybrid lamp withProzone’s Eco Master combines its patented

How the Eco Master Generator Works

2

(1) Air enters unit where the Hybrid lamp converts it to

Ozone (O

3

) and Hydroxyl Radicals (OH-)

(2) Water enters unit through the Dynamic Venturi Injector

drawing Ozone and Hydroxyl Radicals from the Hybrid

lamp chamber

(3) Static mixer combines water, ozone, and hydroxyls

in a scrambled ow

(4) Water is irradiated by Germicidal UV which converts

Ozone to Hydroxyl Radicals through Advanced

Oxidation Processing (AOP)

(5) Contaminants are destroyed by intense Germicidal UV,

Ozone, and Hydroxyl Radicals, using up all the Ozone

and adding ORP to the Water

Eco Master Installation For Ozone Ready Spas

The instructions contained in this manual will help ensure a successful installation. It is the installer’s responsibility to make sure

these guidelines are followed.

3

The Eco Master System is designed to operate on either 120 or 240 VAC, 50/60 Hz. Wire system to the circulation

pump or timer. The Eco Master and circulation pump should start simultaneously. Use N.E.C or local code

grounding and installation procedures for spa equipment.

PLUMBING

ELECTRICAL

MOUNTING

It is recommended that the Eco Master be mounted as high as possible, to relieve the pressure on the check

valve. The recommended mounting orientation of the Eco Master is on a vertical surface. The Eco-Master should

never be mounted with the inlet and outlet ttings in a vertical orientation. The ¾” ttings should be horizontal

and level.

The above diagram shows that a dedicated return line for the Eco Master is recommended to limit back

pressure on the system, typically in the footwell or at the lter cavity. Alternatively, if the system cannot be

plumbed to a dedicated return, then the system should return as the last component on an unrestricted line.

The Eco Master requires between 3-10 GPM of water ow for optimum performance. This is accomplished by

installing the Eco Master at a location in the water circulation system, where the pressure at the supply line (P1)

is higher than the back pressure on the system at the return line (P2). Install the Injector prior to the EcoMaster,

as close as possible to the unit. If there is not enough pressure dierence between these two points, then you

will not see bubbles owing in the line at the output of the system. These bubbles are the main indicator of a

proper installation. In addition, consideration should be made for backpressure surges on the return line, as

back pressure may result in temporary leakage from the internal check valve. The back pressure on the

system at the return line should not exceed 10 PSI. The Ozone Line and Check Valve must be connected from

the 1/4” Hose Barb on the EcoMaster to the #1 port on the Injector. This line should include at least one full

loop and be secured as high as possible under the skirt, above the water level if possible.

ECO MASTER

ADVANCED OXIDATION PURIFICATION

INSTALLATION AND OPERATION MANUAL

PROBLEM PROBABLE CAUSE REMEDY

NO LIGHT FROM PROZONE UNIT

NO BUBBLES IN RETURN FITTING OR LINE

(NO INDICATOR OF OZONE)

CLOUDY WATER, FOAMY WATER, OR SCUM

LOOSE WIRING

NO POWER TO UNIT

DEFECTIVE LAMP OR

OTHER INTERNAL COMPONENT

TOO MUCH BACK PRESSURE IN RETURN LINE

UNBALANCED WATER CHEMISTRY

TOTAL DISSOLVED SOLIDS (TDS) LEVEL TOO HIGH

FILTER NOT WORKING

RETURN UNIT TO DEALER

CHECK ALL WIRING CONNECTIONS

CHECK SUPPLY LINE AND RETURN LINE PRESSURES.

RETURN LINE PRESSURE SHOULD NOT BE GREATER

THAN 10 PSI AND SHOULD NOT BE GREATER THAN

SUPPLY LINE PRESSURE. ADJUST ACCORDINGLY.

CHECK READINGS AND BALANCE ACCORDINGLY

REFER TO DEALER FOR PROPER WATER TESTING

CLEAN OR REPLACE FILTER

CHECK VOLTAGE AND POWER SOURCE COMPATIBILITY

TROUBLESHOOTING GUIDE

4

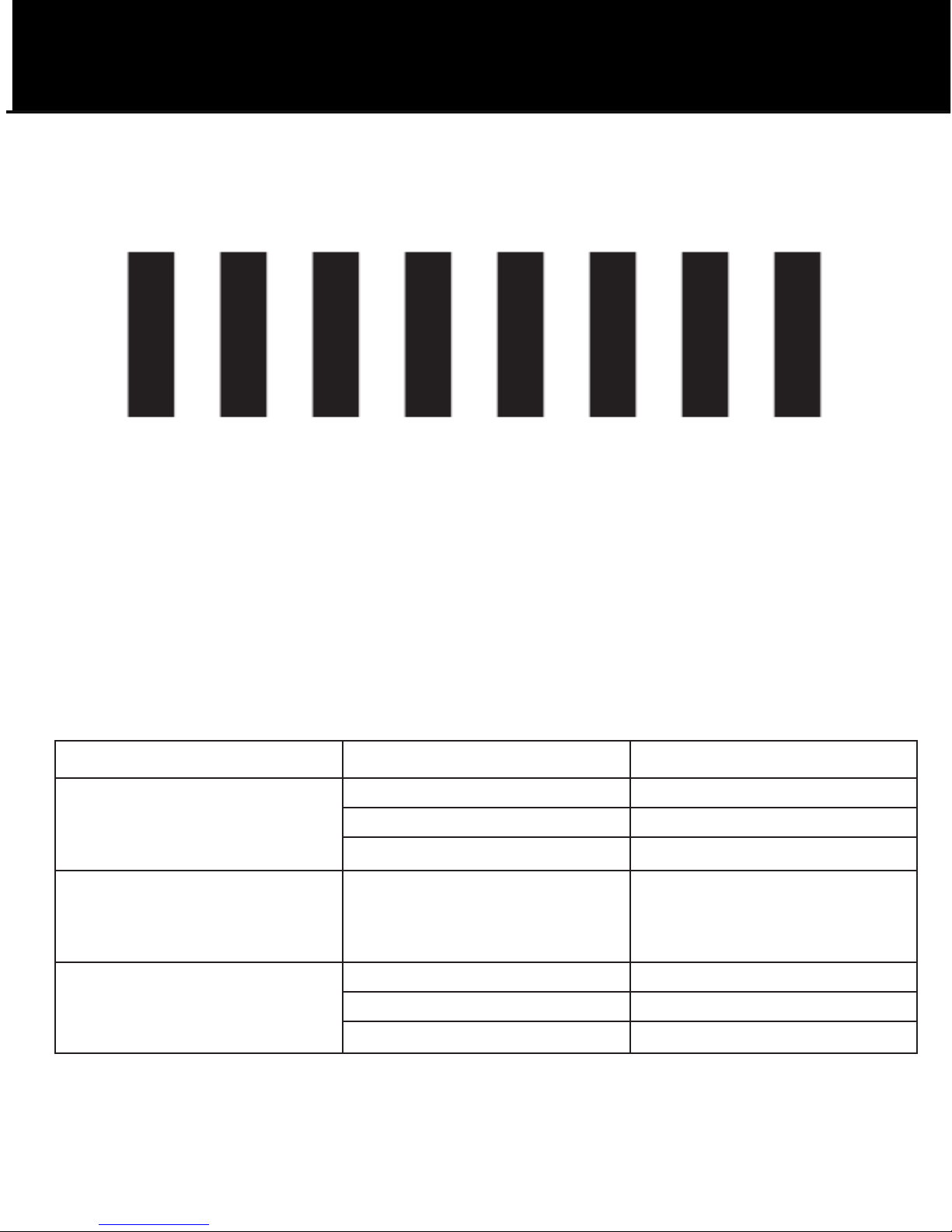

FOAMING GRAPH

The main indicator of a proper installation can be easily veried by observing the outlet tting (opposite the cord

end) and the hose connected to it. Ideally, you will see a “foam” (bubbles) owing out of the system. Any

amount of bubbles indicates ozone gas ow, but you want to see at least an amount of bubbles which can be

easily identied by eye. It may helpful to hold the “foaming graph”, behind the clear tubing, to better see the

bubbles. The bubbles should be relatively small and fast moving. If you can visually observe the ozone gas ow

then you have a good balance of ow and pressure dierential and your installation should function eectively.

PROZONE®Advanced Oxidation Purification Products

LIMITED WARRANTY

PLEASE COMPLETE THIS WARRANTY ONTHE DAY OF INSTALLATIONAND RETURN TO

Failure to return this warranty information will void this warranty

Warranty is offered on this unit for a period of 24 months from date of purchase, and extends only to the original purchaser. If this unit becomes unserviceable

due to defects in materials or workmanship within 24 months from date of purchase, it will be repaired or replaced without charge. Warranty does not apply to

breakage due to obvious misuse. Warranty period for a repaired or replaced unit applies to the original date of purchase of the unit. Manufacturer will repair or

replace based on evaluation of returned unit.

In order to receive warranty service, a Returned Goods Authorization (RGA) number must be obtained from Prozone before returning the product. The RGA

numbermust beissuedpriorto endofwarrantyperiod. Productmustbe returnedwithin30days ofissuanceofthe RGAnumber. If theproductisnot received

by Prozone within 30 days of RGA number issuance, another RGA number must be obtained.

Thiswarrantyalongwiththesalesreceiptmustaccompanytheunitwhenitisreturned. TheRGAnumbermustbeprintedprominentlyonthebottomleftcorner

of the address side of the return packaging. To obtain an RGA number, or for any questions regarding warranty service, please contact:

3004 11th Ave. Tel: 256-539-4570

Huntsville, AL Fax: 256-539-4225

This warranty is void if the unit has been opened, or if the product identification label has been removed or altered. This warranty does not cover damage

resulting from misuse, abuse, accident, fire, flood, lightning or other acts of nature, lack of reasonable care, or subjecting the product to any but the specified

voltage.

Under thetermsof thewarranty,manufacturer assumesnoresponsibility forany injury,lossor damage(direct,indirect, orconsequential) arisingoutof theuse

of or inability to use the product. Manufacturer assumes no responsibility for labor involved in removal of defective part, shipping or installation of new part.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. This warranty is in lieu of all other warranties,

expressed or implied.

RETURNS WITHOUT AN RGA NUMBER WILL BE REJECTED

PROZONE WATER PRODUCTS

3004 11TH AVE, HUNTSVILLE, AL 35805

Date of purchase:___________________ Purchased from:_______________________________________________

Supplier Telephone No.:__________________________ Model Number:____________________________________

Date of installation:______________________________ Installed by: ______________________________________

Name:________________________________________ Telephone No.: ___________________________________

Address:_________________________________________ City:__________________________________________

State:________ Zip: ________________ Email:_______________________________________________________

Residential application:____________________________________________________________________________

_______________________________________________________________________________________________

For manuals and more information, please visit www.prozoneint.com

INSTALLATION AND OPERATION MANUAL

ECO MASTER

ADVANCED OXIDATION PURIFICATION

Table of contents

Other Prozone Lighting Equipment manuals