the microchip straight out of its socket. It

may take a tug. Pull straight back. When the

old microchip pops out of its socket, lay it

out of the way.

Great work. You are almost done. Take

a break.

Take this time to attach the anti-static wrist

strap to your wrist by wrapping the clear

sticky end around your wrist like a bracelet.

Remove the adhesive strip from the copper

tail and attach it to an exposed aluminium

surface inside the Power Plant chassis.

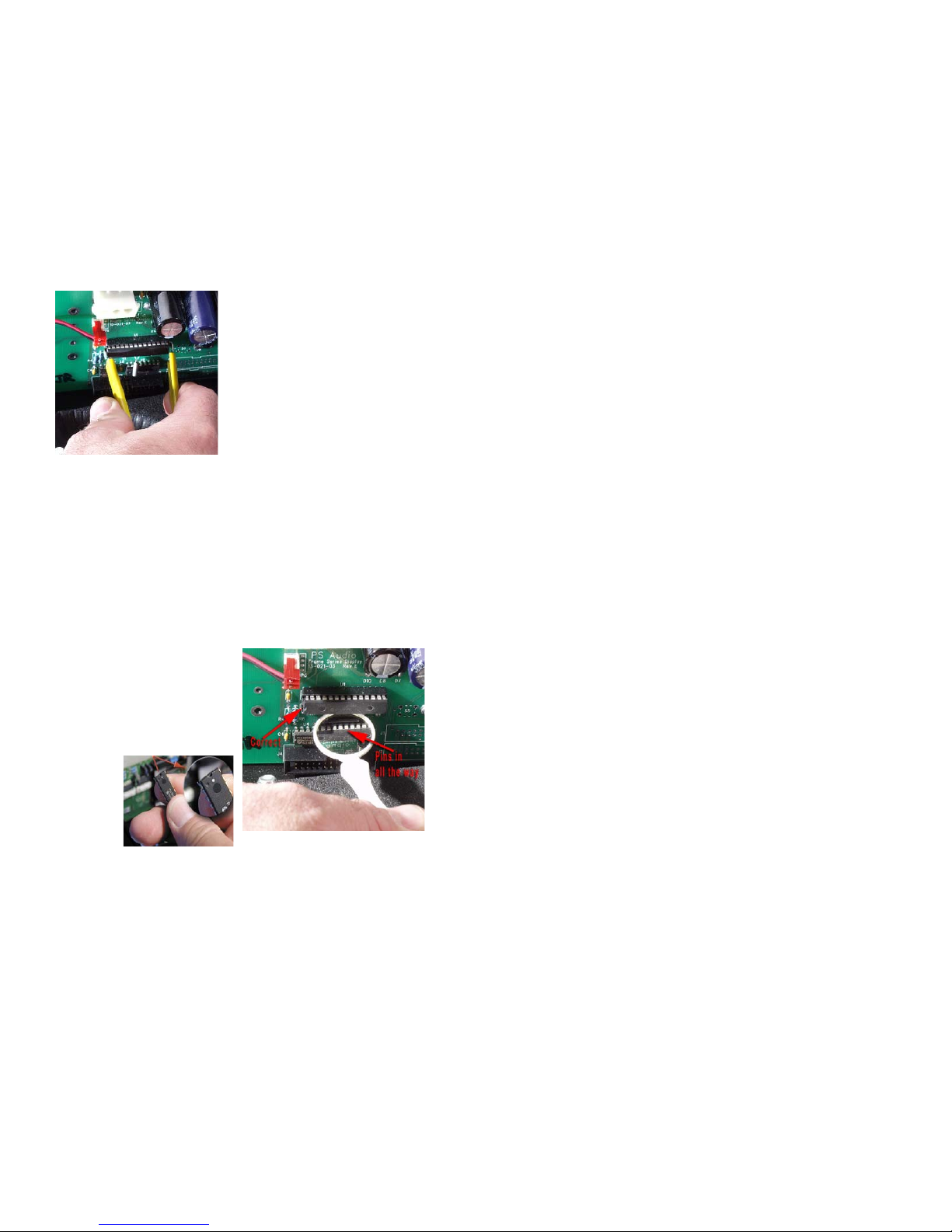

Installing the new front panel microchip

Carefully open the sealed end of the silver

anti-static bag (you are wearing your wrist

strap now, aren’t you?). Carefully remove

the new processor chip from the silver bag.

The chip is pressed to a small piece of black

foam. This special foam protects the chip

from static. Do not remove the chip from

the antistatic foam at this time.

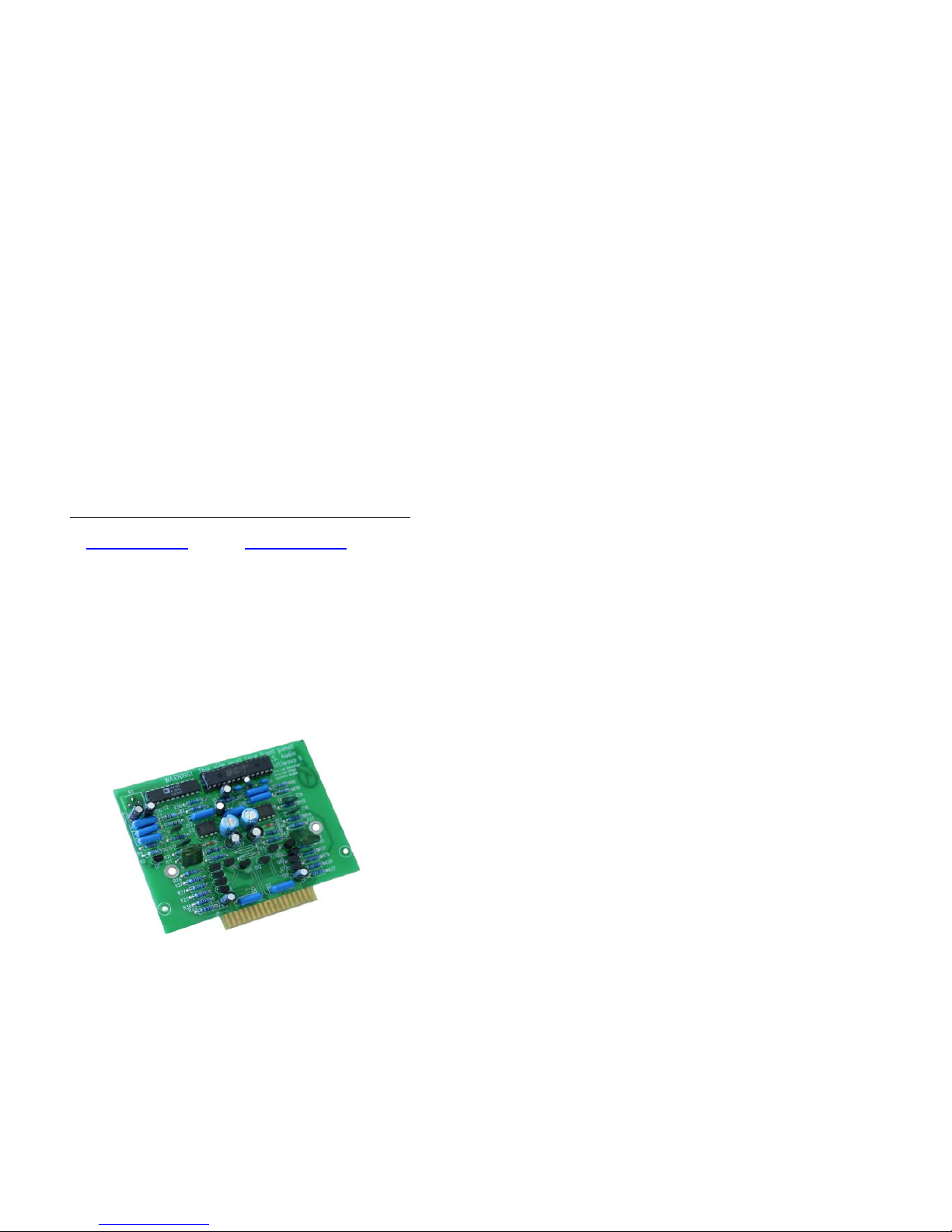

Notice that the chip has a “half moon” on

one side. There

is also a white

dot to help iden-

tify the direction.

Looking from the

rear of the unit,

this dot must face

to the LEFT.

Now, carefully use your fingers to pull the

chip straight out of the black protective

foam. Yep, you can use the chip puller for

this if you like. The key is pulling the chip

straight out of the foam so that we do not

bend any of the little legs.

After you pull the chip out of the foam, lay

it so it rests on its legs on top of the black

foam. It will look a lot like a bug - a healthy

bug with straight legs. If any of the legs are

not straight, use a finger nail to straighten

it.

Do not rush the next step. Please read

this next section again before you go on.

Do you have a light shining inside the Power

Plant? Is it well lit? Do you have your read-

ing glasses on? Just checking.

You are going to next insert the chip into the

socket. Do this by grasping the small sides

of the chip with your thumb and forefinger.

Now, carefully line up the legs of the chip

with the holes in the socket. BE VERY

CAREFUL. Only lightly press the chip into

the socket at this time - just enough for the

socket to hold the chip. You just want to get

the legs started. Do not press hard on the

chip at this time.

Now make sure each leg of the microchip

is inserted in the corresponding socket

hole. That’s what the little dentist’s mirror

is for. You should be able to see the pins

on the top of the socket with your eye. The

dentist mirror will help with the lower set of

pins. Most problems of MultiWave installa-

tion have been found to be people’s failure

to get the bottom row of legs in the socket

properly. Make double sure. It’s easy for

the pins to be in the socket but not be seated

electrically. Make sure the bottom pins look

seated in an identical fashion to the top row

of pins.

4

When you are sure that each leg of the

microchip is straight and lined up correctly,

top and bottom rows, press the microchip

down into the socket. The chip will seat

almost flush into the socket.

Now, use the mirror again to inspect the

microchip and socket. The microchip must

be flush in the socket and no pins should be

bent or coming out of the socket.

Inspect your work

You are almost done!

Carefully inspect you work one more time

before you button up. The items you want to

check will be:

• The new microchip on the front panel

display board is inserted correctly. Use that

mirror if you need to!

Replace the transformer

Reverse the procedure you went through to

remove the transformer. As long as it is sit-

ting on its foam pad, insert the bolt through

the hole, thread the nut back on and tighten.

Make the sure the transformer is firmly

mounted in place and that its orientation is

such that the power connector will easily

reconnect to the front panel board.

Reconnect the power cable from the trans-

former to the front panel board. Make sure

that all the wires in the unit look ok.

Make sure the transformer is tight.

Replace the top cover

Make sure the holes in the top cover line

up with the PEM threaded hardware in the

chassis and then place the screws back in

and tighten the cover in place.

Testing the Power Plant

To make sure everything is tip-top, perform

the following tests:

• Plug the Power Plant into a power source.

Do not plug anything into the back of the

unit at this time.

• Next, press the front panel power button.

The Power Plant front panel should indi-

cate [Sin] If it does, the Power Plant is fully

operational and you are now a certified

PS Audio MultiWave II+ upgrade installer.

We are proud of you, but you may want to

keep your day job.

• Don’t forget to remove the anti-static wrist

strap before leaving you work area.

YOU’RE DONE! Really. But keep that den-

tist mirror close by. Who knows what micro-

chips or teeth might need inspecting.

NOW, hold on to your favorite listening chair

and experience MultiWave II+. We are quite

sure you will be as amazed as we were the

first time we listened. Use Clean Sweep

and do a full system clean after every-

thing’s turned on and ready to go.

Its benefitrs become addicting after a while

so Clean Sweep the system before every

serious listening session.

If you have any questions about the instal-

lation process, stop and contact us. We are

here to help.

MultiWave II+ Operation

Notice of MultiWave II+ operation:

Any turntable or equipment with AC

synchronous motors, such as some cooling

fans should not be used with MultiWave

patterns. This type of equipment must be

used with 60Hz sin mode.

We recommend the use of the sine wave

[sin], or TubeWave™ [tub] with any type of

tube based audio products.

There are five available display modes on

the front panel of the Power Plant. The

Mode button will cycle through the following

five modes:

1. Waveform setting

2. Frequency generated (sin mode only)

3. Voltage produced

4. Wattage produced

5. Display blanking mode

6. Clean Sweep

Waveform setting

This mode will display the name of the

5