PSE LG 05 SS Parts list manual

— 5 GALLON SPOT SPRAYER —

MODEL # LG 05 SS

•5 Gallon Polyethylene Tank

•1.0 GPM Demand Pump

•Lever Handgun

•Rechargeable 12V Battery

•AC Charger w/built in Storage

Compartment

•Telescoping Handle

•Large 8 Inch Wheels

•9 foot coil hose

Assembly / Operation Instructions / Parts

PRECISION SPRAY EQUIPMENT, a divison of Green Leaf, Inc. 9490 N BALDWIN ST FONTANET, IN 47851 www.grnleafinc.com

a division of Green Leaf, Inc

®

PRECISION SPRAY EQUIPMENT

PSE

a division of Green Leaf, Inc

®

PRECISION SPRAY EQUIPMENT

PSE

LG 05 SS

— GENERAL INFORMATION

— WARRANTY / PARTS / SERVICE

— ASSEMBLY

— BATTERY CHARGING

— AFTER SPRAYING

— WINTER STORAGE

After use fill the sprayer part way with water. Star

t

the sprayer and allow clear water to be pumped

through the plumbing system and out through the

spray wand. Refill the tank about half full with

plain water and use a chemical neutralizer such

as Nutra-Sol® or equivalent and repeat cleaning

instructions. Flush the entire sprayer with the

neutralizing agent. Follow the chemical manu-

facturer’s disposal instructions of all wash or

rinsing water.

Drain all water and chemical out of sprayer, pay-

ing special attention to pump and valves. These

items are especially prone to damage from

chemicals and freezing weather. The sprayer

should be winterized before storage by pumping

a solution of RV antifreeze through the entire

plumbing. Proper care and maintenance will pro-

long the life of the sprayer.

— TROUBLE SHOOTING

Pump will not run:

1. Check inline fuse on the wiring harness. If

blown or damaged replace with a new 5 Amp

fuse.

2. Insure the battery is fully charged

3.

Check that the on/off switch is in the on position

4. Insure that strainer located on bottom of tank

is free of debris.

5. Check wiring connections at the battery and

switch, at times these could work loose.

This unit comes fully assembled

— OPERATION

This sprayer is designed to be pulled or pushed

by hand.

Pour solution into the tank and stir to mix. For

liquid chemicals it is possible to mix by spraying

the handgun into the tank.

Turn the switch to the “ON” position and spray by

squeezing the lever on the handgun. The unit is

supplied with a demand pump that will only

operate while the lever on the handgun is

depressed.

It is recommended to charge the battery for 8-10

hours before using, or if the battery has been

stored for 6 or more months without usage. Once

fully charged you should be able to spray 40

gallons of fluid, or 8 consecutive tanks.

To charge the battery…

1. Plug the charger into a 110 Volt AC electrical

receptacle.

2. Insert the plug on the opposite end of the

charger into the charging jack located on the

back panel of the sprayer.

3. Reverse the above steps when charging is

complete.

CAUTION: Never leave the charger connected to

the battery for more the 20 hours, as this may

damage the battery.

The purpose of this manual is to assist you in

assembling, operating and maintaining your

sprayer. Please read it carefully as it furnishes

information which will help you achieve years

of dependable trouble-free operation.

Products are warranted for one year from date of

purchase against manufacturer or workmanship

defects.

Your authorized dealer is the best source of

replacement parts and service. To obtain prompt,

efficient service, always remember to give the

following information:

1. Correct part description and part number.

2. Model number of your sprayer.

Part description and part numbers can be obtained

from the illustrated parts list section of this manual.

Whenever you need parts or repair service, contact

your distributor / dealer first. For warranty work

always take your original sales slip, or other

evidence of purchase date, to your distributor /

dealer.

PRECISION SPRAY EQUIPMENT, a divison of Green Leaf, Inc. 9490 N BALDWIN ST FONTANET, IN 47851 www.grnleafinc.com

a division of Green Leaf, Inc

®

PRECISION SPRAY EQUIPMENT

PSE

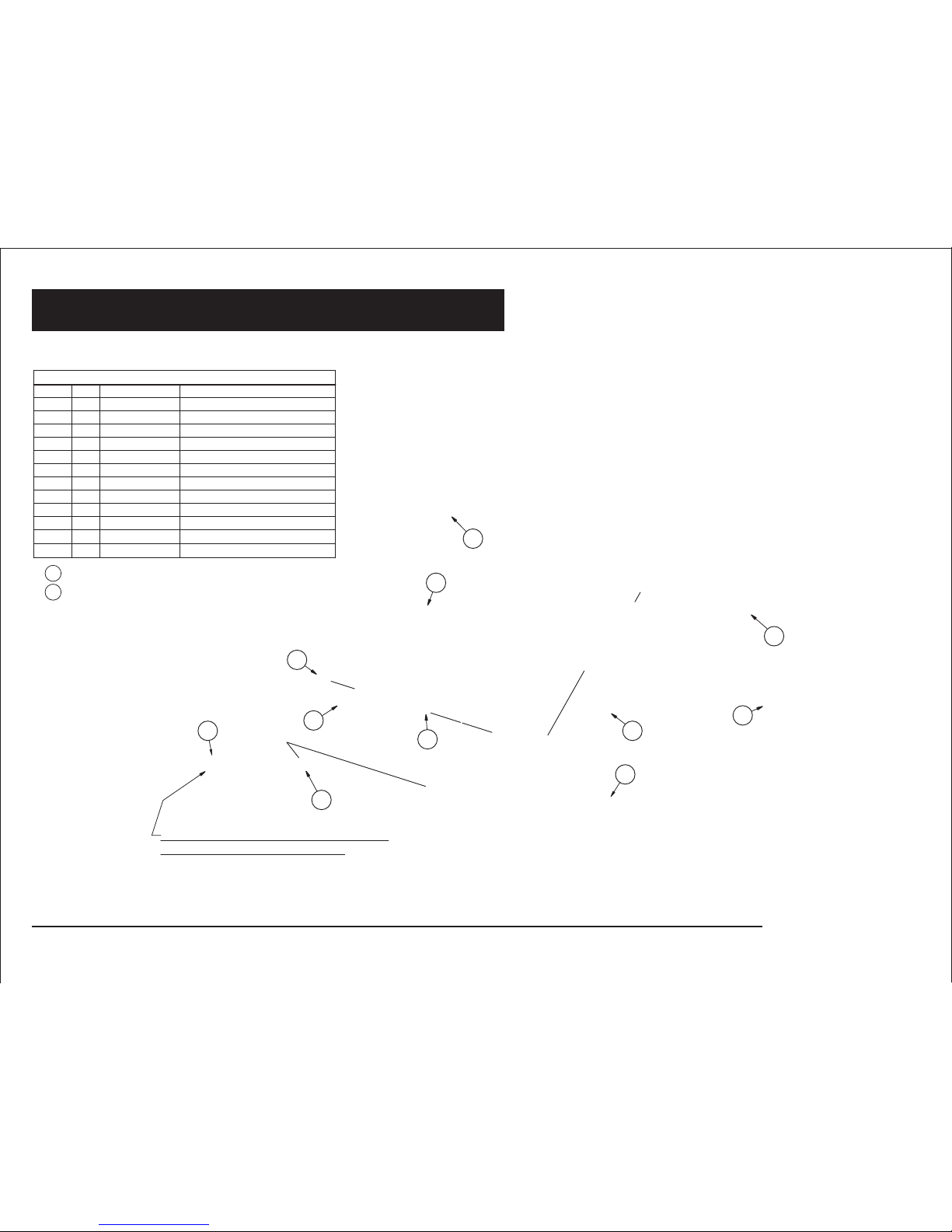

Parts List

DESCRIPTIONPART NUMBER

QTY

ITEM

1 GPM quick disconnect pump

610007

11

12V 5AH/20HR battery size 6FM5

610008

1

2

EL 14 QD P Quick Disconnect Fitting

61002423

Retractable Handle Assembly610006

14

Suction Hose Assembly

610025

15

W 40650 S Strainer Washer

610023

1

6

Pinch Clamp

610022

47

#8 x 3/4" PH TEK Screw

60019928

Back Panel

610002

1

9

Economy Wand Assembly

610012

1

10

Wiring Harness

610010

111

12V DC 500 mA Battery Charger

610009

112

10

1

5

6

3

3

2

9

4

8

7

11 Wiring Harness (Not Shown)

12 Battery Charger (Not Shown)

Strainer should be periodically checked

and cleared of any forign debris

— PUMP, HOSE & BATTERY ASSEMBLY

PRECISION SPRAY EQUIPMENT, a divison of Green Leaf, Inc. 9490 N BALDWIN ST FONTANET, IN 47851 www.grnleafinc.com

a division of Green Leaf, Inc

®

PRECISION SPRAY EQUIPMENT

PSE

Parts List

DESCRIPTIONPART NUMBERQTY

ITEM

5 Gallon Tank

610000

11

5 Gallon Tank Lid

610001

1

2

Back Panel

610002

1

3

Charger Panel Door

6100031

4

φ3/8" Axel Mounting Bracket

61000525

Wheel

61000426

φ3/8" x 14 7/8" Axel

610013

17

φ3/8 Cap Nut Black

61001928

1/4-20 x 1/2" Pan Head Screw

61001769

Wand Clip600151210

Wand Clip Screw

6001522

11

1

4

9

2

10

11

6

8

9

7

5

3

Strainer location

— REAR COMPARTMENT ASSEMBLY

PRECISION SPRAY EQUIPMENT, a divison of Green Leaf, Inc. 9490 N BALDWIN ST FONTANET, IN 47851 www.grnleafinc.com

a division of Green Leaf, Inc

®

PRECISION SPRAY EQUIPMENT

PSE

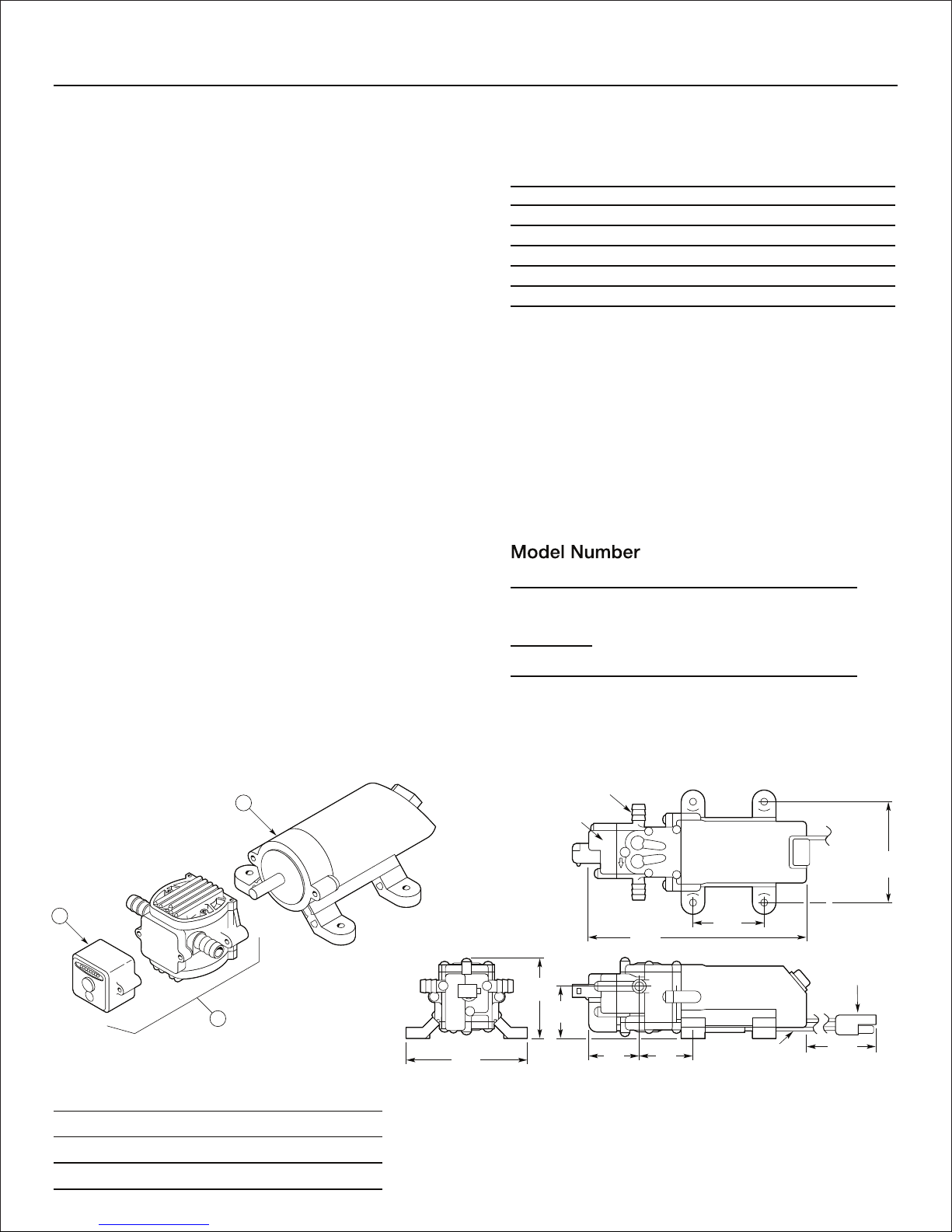

PowerFLO

™

2200 Series

3

1

2

Dimensions Inches (mm)

Specifications

Motor

Type: 12 VDC, permanent magnet, thermally protected,

splashproof

Leads:

2200-2 Model: 18 AWG, 4.5” long w 2-pin connector

Duty Cycle: Intermittent

Pump

Type: 2-chamber positive displacement, self priming,

capable of being run dry

Liquid Temperature: 110°F (43°C) Max.

Priming Capabilities: 4 feet (1.2 m) suction lift

Max Pressure: 40 PSI (2.8 bar)

Pressure Demand Switch:

Shut-Off: 40 ±5 PSI (2.8 ±0.3 bar) factory setting

Turn-On: 25 ±5 PSI (1.7 ±0.3 bar) factory setting

Inlet/Outlet Ports: Quick Disconnect

Weight

1.25 lbs (0.57 kg)

Performance

Materials of Construction

Motor Housing: Nylon 6/6

Pump Housing: Polypropylene

Valves: Viton

Diaphragm: Santoprene

Fasteners: Stainless steel and zinc plated

Pressure/Flow/Amp Draw

PSI Bar GPM LPM Amps

0-3 0.2 1.00 3.7 1.5

10 0.7 0.85 3.1 1.9

20 1.4 0.71 2.6 2.1

30 2.1 0.61 2.3 2.4

40 2.8 0.42 1.6 2.6

Parts List

Ref Part

#Description Number

1Switch Asssembly 5157201

2

Pump Head w Switch Asssembly

5275064

3

Motor with connector, no switch

P39-045B

2.25

(57)

6.89

(175)

1.66

(42)

2.55

(65)

3.94

(100)

1.58

(40)

1.73

(44)

4.5

(114)

Pressure

Demand Switch

3.19

(81)

Quick Disconnect Ports

2-Pin Connector

18 AWG Leadwires:

Blk – Negative

Red – Positive

Ordering

Item # Description

2200-201

1 GPM Demand Pump, Viton Valves,

Santoprene Diaphragm, 40

PSI, Quick Disconect Ports

2-pin molded connector

12 Volt DC Motor-Driven Diaphragm Pumps

Operation Precautions

1. Do not operate pump in an explosive environment.

Arcing from the motor brushes, switch or excessive heat from an improperly cycled motor may cause an explosion.

2.

3Do not assume fluid compatibility. If the fluid is improperly matched to the pumps’ elastomers, a leak may occur.

Do not pump gasoline or other flammable liquids.

4. Intermittent duty is defined as operation and/or frequent starting within a period of time that would cause the motor to

reach its maximum thermal limits.

Once the maximum is obtained, the motor must be allowed to return to ambient temperature before resuming operation.

Troubleshooting Guide

Problem/Causes and Remedies

Pump will not Start

Check:

•Correct voltage (+10%) and electrical connections

•Fuse or breaker

•Pressure switch operation and correct voltage at

switch

•Rectifier or motor for open or grounded circuit

•Locked drive assembly

Pump will not Prime (No discharge with motor running)

Check:

•Debris in strainer

•Restriction (kinks) in inlet/outlet tubes

•Debris or swelling in inlet/outlet valves

Pump will not Shut Off (Output line closed and no leaks)

Check:

•Air trapped in outlet line or pump head

•Correct voltage to pump

•Debris in pump inlet/outlet valves

•Loose drive assembly or pump head screws

•Pressure switch operations/adjustments

Leaks from Pump Head or Switch

Check:

•Loose screws at switch or pump head

•Switch diaphragm ruptured or pinched

•Punctured diaphragm if fluid is present

* Important return safety instructions:

When you return your pump for warranty or repair,

you must always do the following:

1. Flush chemical residue from the pump

(best done in the field).

2.

Tag pump with type of chemicals having been sprayed.

3. Include complete description of operation problem,

such as how pump was used, symptoms of

malfunction, etc.

Since pumps can contain residues of toxic chemicals

these steps are necessary to protect all the people

who handle return shipments, and to help pinpoint the

reason for the breakdown.

PRECISION SPRAY EQUIPMENT, a divison of Green Leaf, Inc. 9490 N BALDWIN ST FONTANET, IN 47851 www.grnleafinc.com

a division of Green Leaf, Inc

®

PRECISION SPRAY EQUIPMENT

PSE

Table of contents

Popular Paint Sprayer manuals by other brands

micronAir

micronAir AU8000 Operator's manual

Fast

Fast UT3P Operation and maintenance manual

Wylie

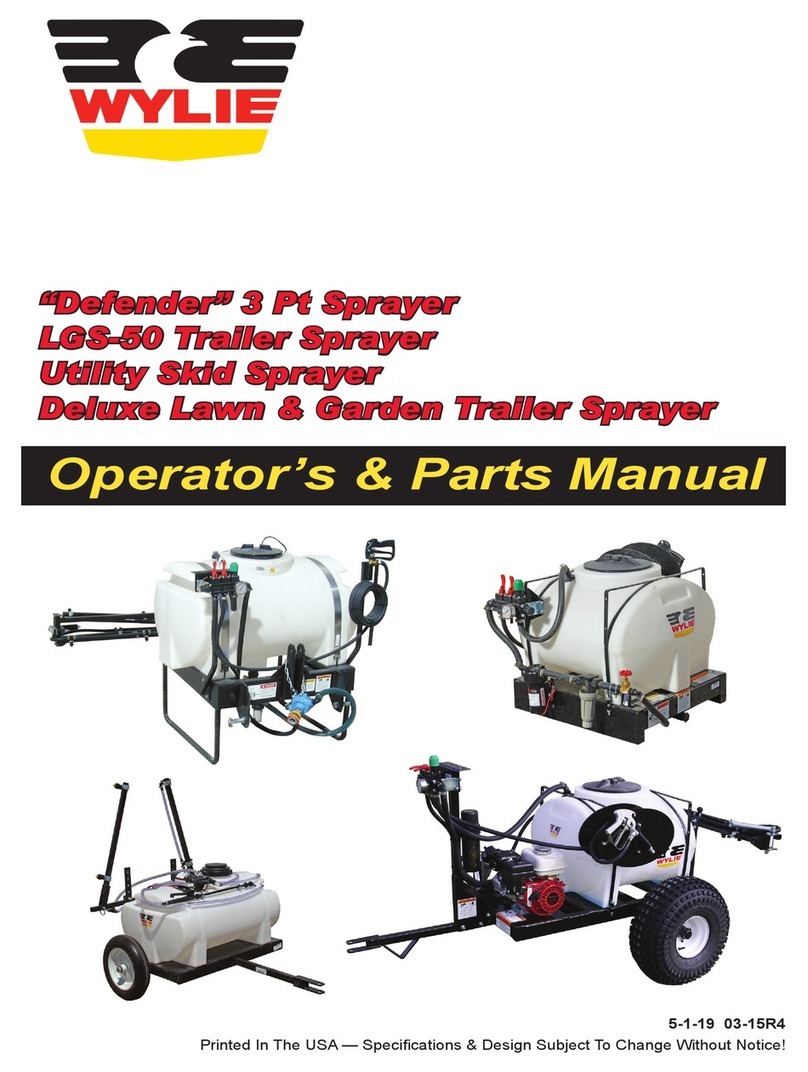

Wylie Defender 3 Pt Sprayer Operator's & parts manual

DeVilbiss

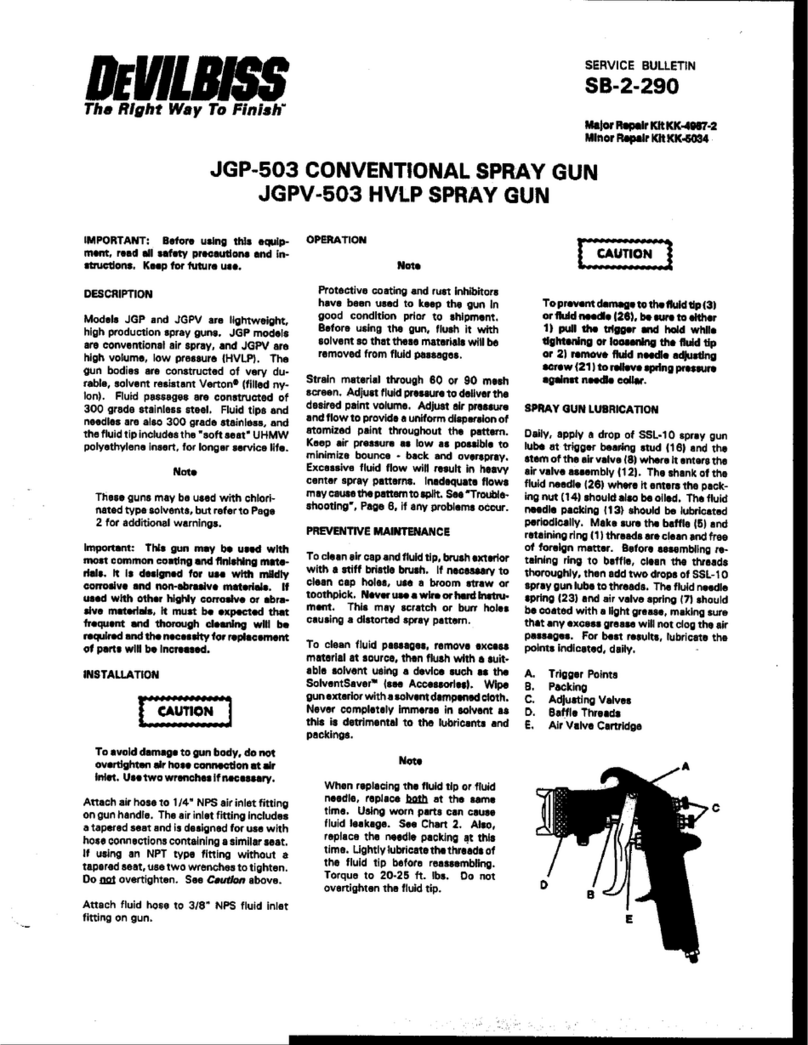

DeVilbiss JGP-503 CONVENTIONAL Service bulletin

Parkside

Parkside PDFP 500 C3 Translation of the original instructions

AG SPRAY

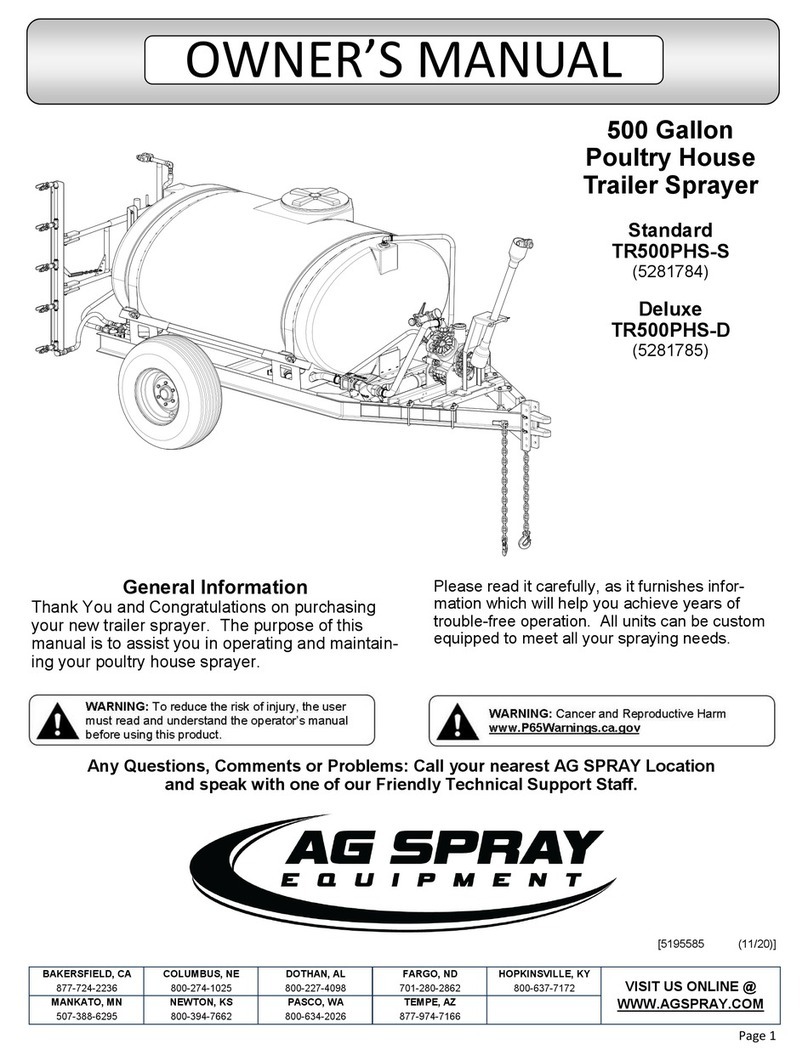

AG SPRAY TR500PHS-S owner's manual