CAUTION

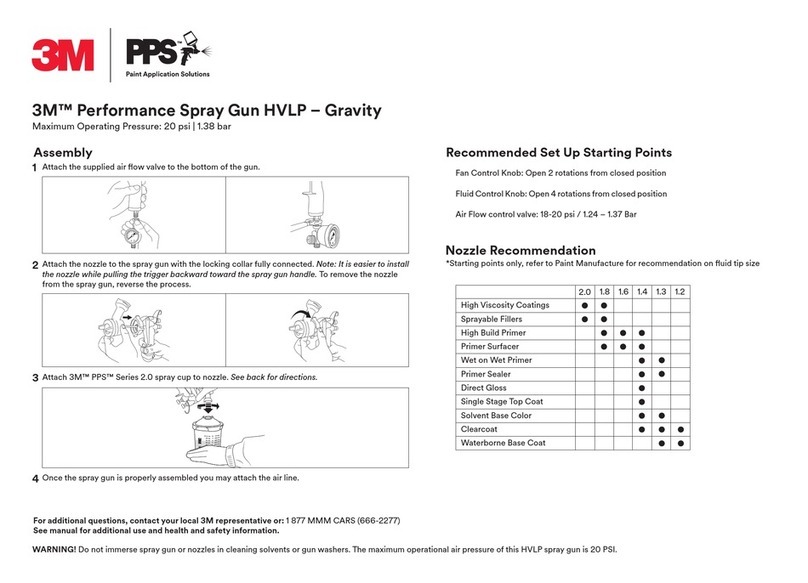

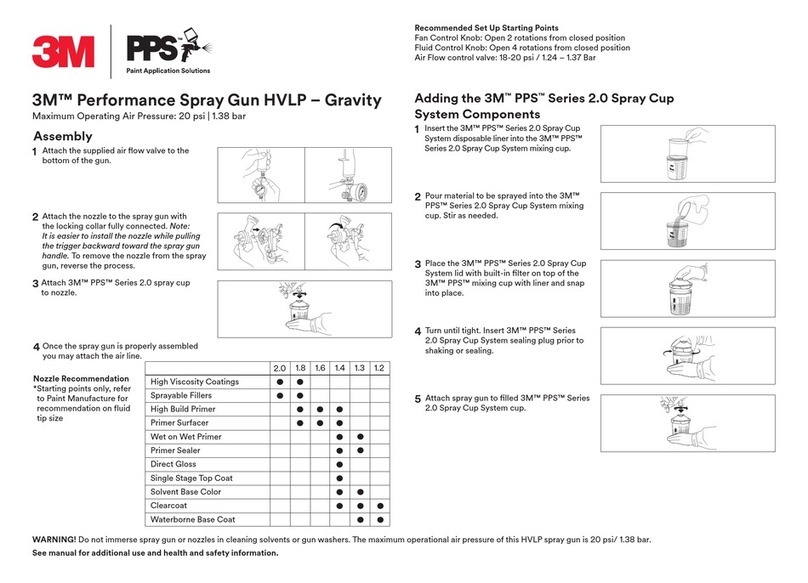

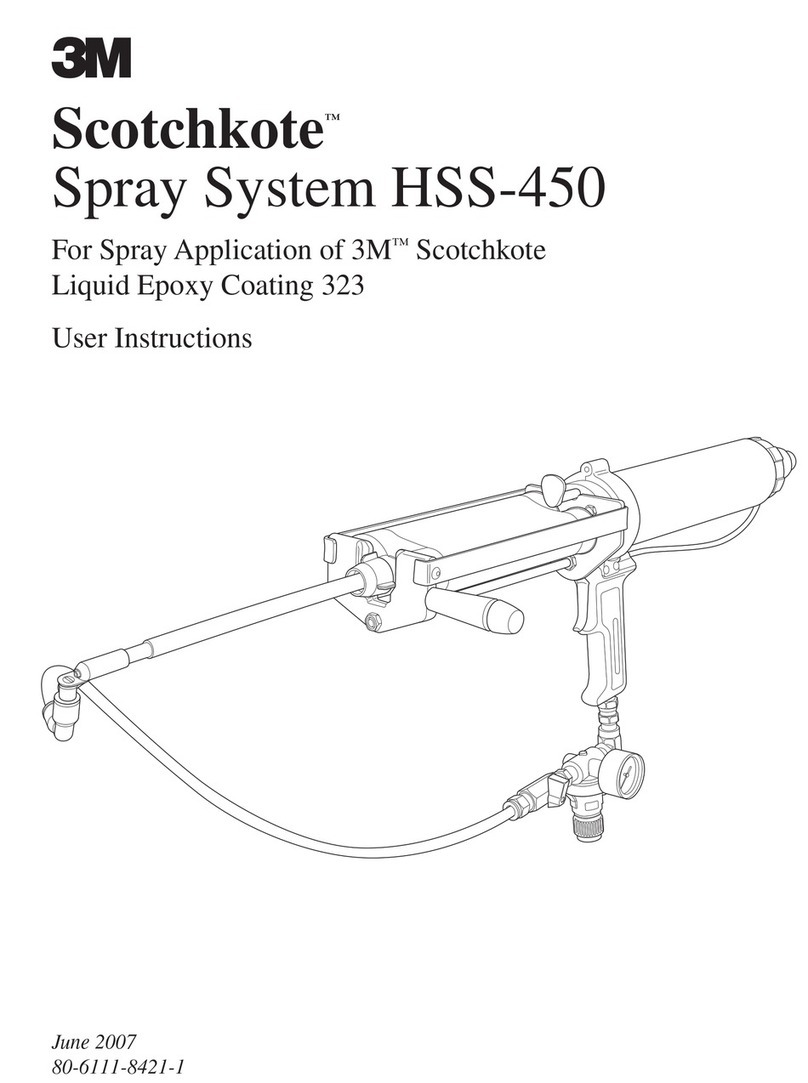

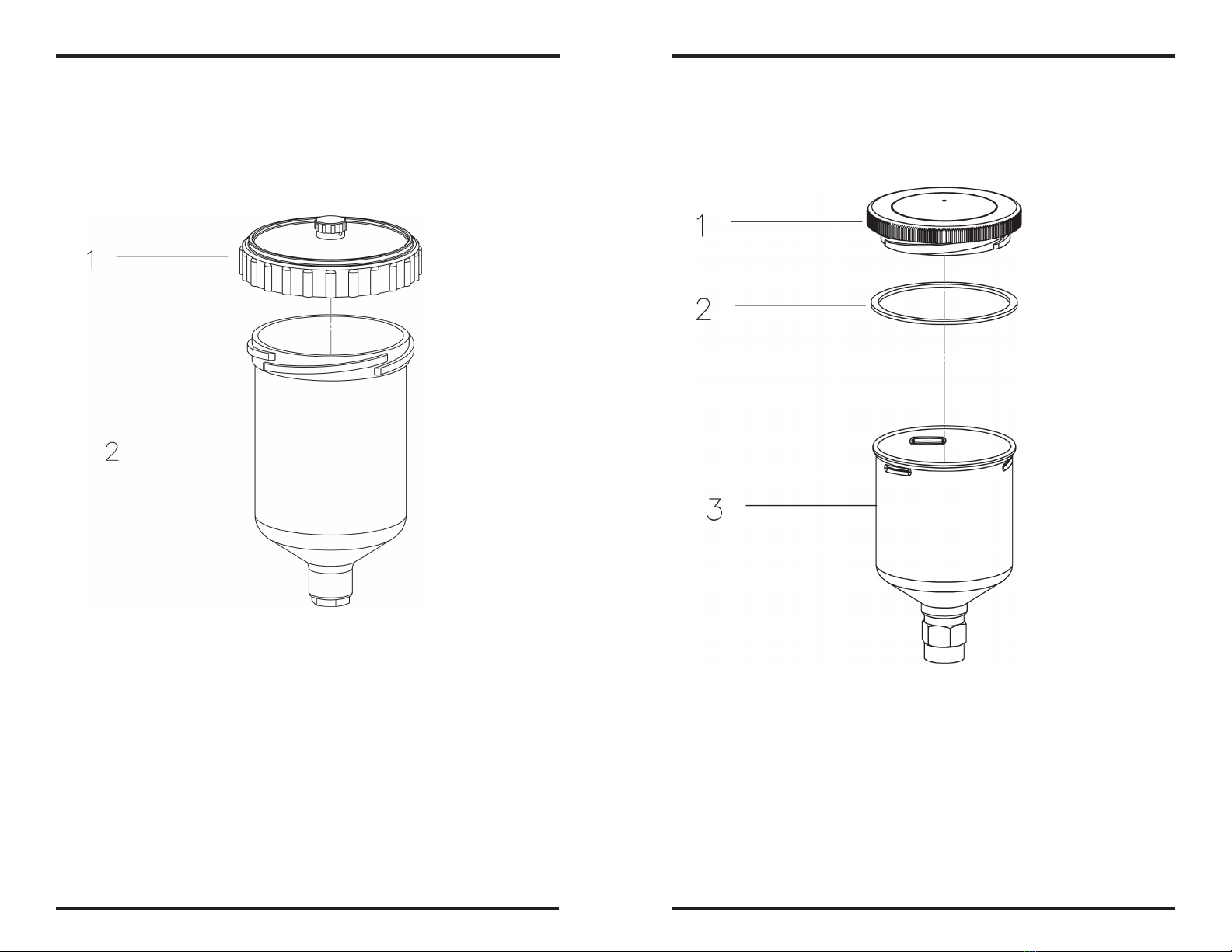

Gun/Cup Installation

The gravity cup threads onto the fluid

inlet fitting at the top of the gravity

spray gun. Hold the cup closer to the

bottom (fitting end) of the cup. Grasping

the cup at the top and applying pressure

may cause the cup to go out of round,

affecting the lid seal. For the aluminum

gravity cups, tighten the cup at the

fitting with your gravity gun wrench.

Cleaning

The cup may be cleaned in a gun

washer or wiped clean. Do not clean

the lid in a gun washer. Wipe clean only.

WARNING

To reduce the risks associated with all residual hazards:

• Read,understand,followandretainforfuturereferenceallsafetystatementsin

each applicable equipment owner’s manual and refer to the applicable Material

Safety Data Sheet and material container label for each material to be sprayed

before using your 3M equipment.

• Thisequipmentistobeusedonlybyprofessionalsfamiliarwiththepossible

applicable safety hazards.

• Donotusethisproductaroundunsupervisedchildren.

• Nevermodifyanypartofthisproduct.

• Alwayscomplywithlocal,state,andnationalcodesgoverningventilation,re

protection, operation, maintenance, housekeeping and disposal plus all safety

statements in applicable owner manuals, MSDS and material container labels.

To reduce the risks associated with chemical exposure:

• Neverpointaspraygunatanyoneelseorplaceanypartofyourbodyinfrontofa

spray nozzle.

• Beforeuse,checksprayequipmentfordamageandproperfunctionandrepair/

replace worn, damaged or malfunctioning components.

• Alwayswearappropriate,approvedpersonalprotectiveequipmentforeye,

skin, respiratory and hearing protection per the applicable MSDS and material

container labels at all times when spraying.

To reduce the risks associated with fire and explosion:

• MustmaintainadequateventilationperapplicableMSDSandmaterialcontainer

labels for each material being sprayed in the work area.

• Allignitionsources,suchassmoking,mustbekeptoutofthesprayarea.

• Alwaysmaintainareadilyavailable,approvedreextinguisherorotherapprovedre

fighting equipment in the spray area.

• Alwayslocateturbineunit/compressorasfarawayfromsprayareaastheair

supply hoses allow.

• NeverusesolventscontainingMethyleneChloride,Trichloromethaneorother

halogenated solvents for any reason to avoid a possible violent, explosive

chemical reaction when exposed to aluminum or zinc (refer to the manufacturer’s

MSDS or contact material supplier if there is any doubt to confirm compatibiltiy).

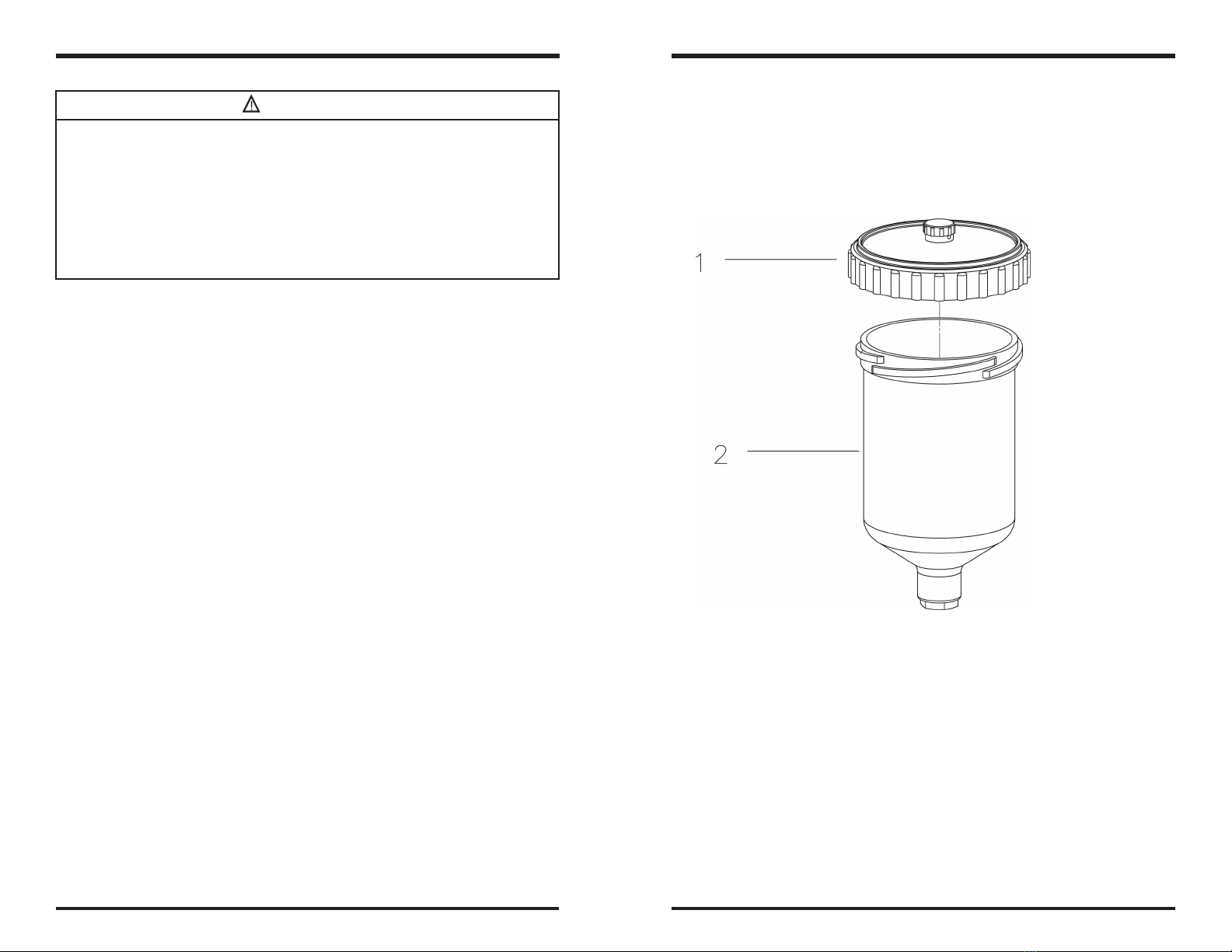

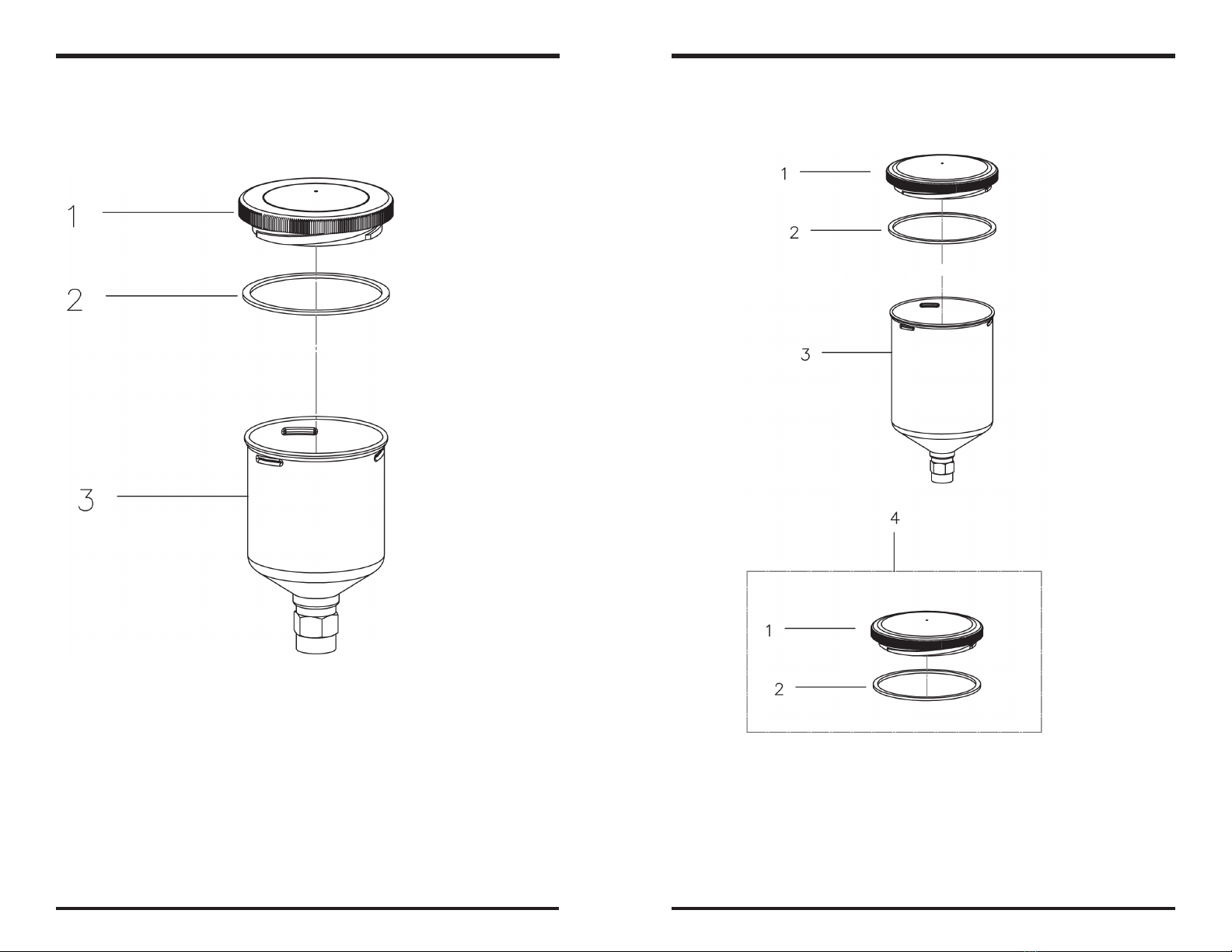

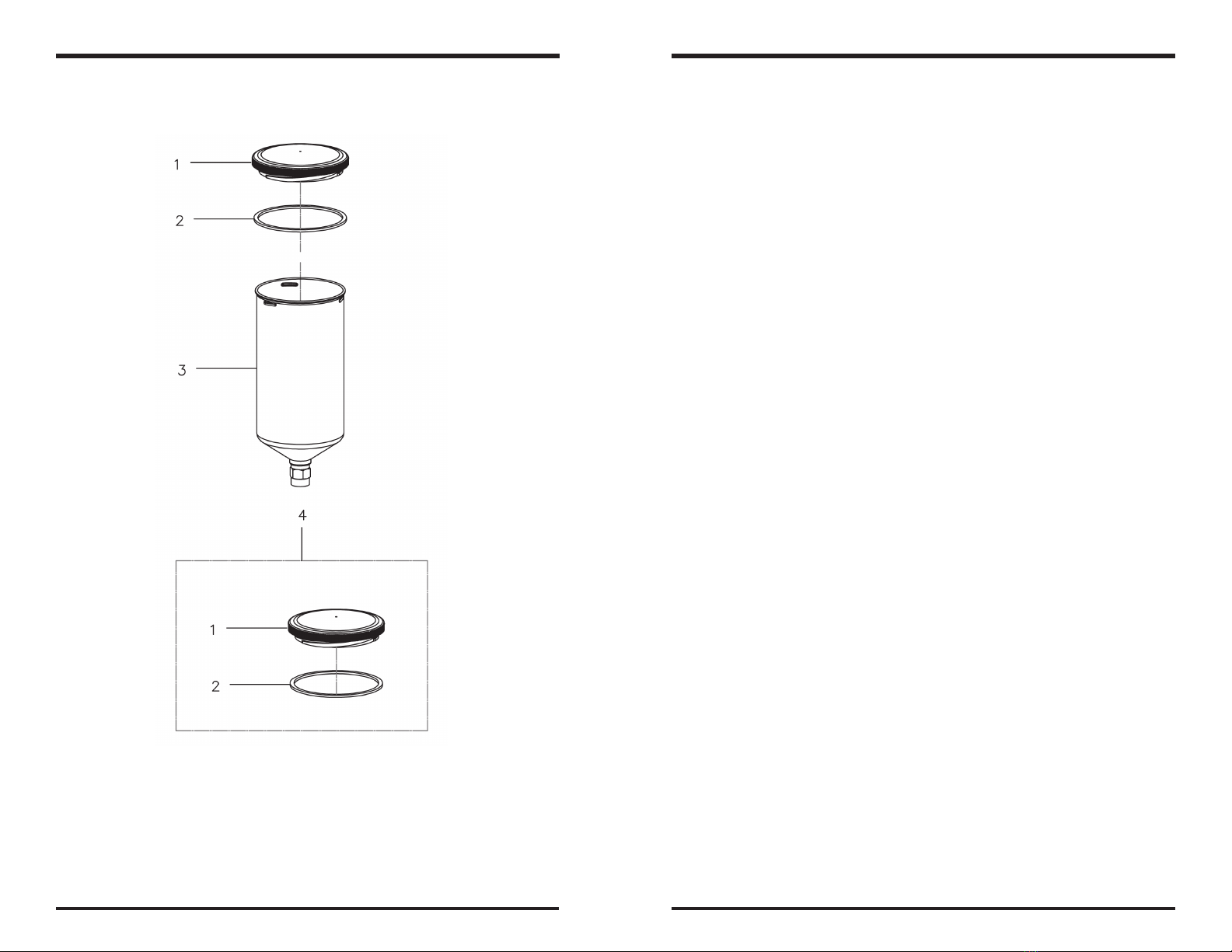

Cup Installation, Cleaning and Maintenance

Note: The lid is a wear part. The sealing

threads and gasket will wear over time.

Gasket Replacement

Rememberthatthecuplidcontains

a gasket. The gasket must be in good

condition and firmly seated to the cup

to prevent fluid leakage. Lubricate

the gasket after each cleaning with

petroleumjelly.Replacethegasketwhen

necessary.

Note: RefertoyourSprayGunOwner’s

Manual for component references and

additional set up instructions.

To reduce the risks associated with lifting and handling:

• Alwayslocateturbineunit/compressorasfarawayfromsprayareaastheair

supply hoses allow.

To reduce the risks associated with environmental contamination:

• Spraymaterials,solventsandothercleaningmaterialsandelectronic

components must be disposed of per federal, state and local regulations.

Note: Your cup may be made from aluminum. Certain solvents containing

Methylene Chloride and Trichloromethane are not chemically compatible with

aluminum.

Read, understand and follow all safety statements as well as wear appropriate,

approved personal protective equipment per the applicable MSDS and material

container labels for cleaning solutions.