PSM 500 Series User manual

1

PSM INSTRUMENTATION LTD

SERIES 500

PRESSURE TRANSMITTERS

USER MANUAL

Issue 1 date 18th August ‘97

SECTION TITLE PAGE

1Introduction 3

2Specifications

Model coding 3

4

3Transmitter Installation Mechanical 5

4DrawingsTransmitter Installation Electrical 6

5

Commissioning 6

6

Fault Finding 7

Burrell Road Industrial Estate

Haywards Heath, West Sussex RH16 1TW, UK

Tel: +44 (0)1444 410040 Fax: +44 (0)1444 410121

Http://www.psm-sensors.co.uk E-mail: sales@psm-sensors.co.uk

7

3

1. INTRODUCTION

Series 500 absolute/gauge pressure transmitters are intended for

applications across a wide range of processes from ultra low to medium

pressure duties.

Different constructions and materials are available to suit a particular duty

The measurement principle is based on a precision rated diaphragm

and linear variable differential transformer (LVDT) combination.

On all models the pressure chamber houses a rated pressure element

to which the process pressure is directly applied. Backing plates are

provided to protect against pressure overloads.

The pressure element is attached to a ferro magnetic core which is located in

the centre (null point) of a high resolution linear variable differential

transformer(LVDT). When voltage is applied to the primary coil, any

movement of the core due to pressure on the measuring element develops a

voltage in the two secondary coils. The output signal from these two coils is

then conditioned within the transmitter electronics to provide a standard

process control signal output, which, using the adjustments provided, may be

set by the user to the process requirements.

2. SPECIFICATIONS -General

Mechanical

Electronics Housing: Stainless steel to IP65

Pressure housing: 316 St Stl

Diaphragm material: Hastelloy C, / St Stl./ Inconel (model

dependant)

Process connections: refer to model coding

Electrical connections: Standard DIN type connector.

Electrical

Maximum error: +/-0.25% (including the effects of

non-linearity and hysteresis

Range adjustment: 30 to 100% of nominal input range

Zero adjustment: +/-20 % of nominal input range

Signal output: 4 to 20 mA dc 2 wire

Power supply: 9 to 32 V dc

Performance

Operating temperature: -20 to +100 deg C

Temperature effect: Better than 0.02% FS per deg C

Humidity: 0-95 deg C RH non-condensing

For Models, Input ranges, overload capabilities and arrangements see the

following model code table:

4

500G

500A Gauge Pressure Transmitter

Absolute Pressure Transmitter

H

I

S

Hastelloy C Diaphragm -Ranges 0.5 m Wg to 50 m Wg

Inconel Diaphragm -Range 10 bar G

PH15-4 Stainless Steel Diaphragm-Ranges 30 bar to 400 bar G

500G/ T33 / H 4 / 3 m Wg

0.5

1

2

4

8

16

32

50

10b

30b

40b

100b

200b

300b

400b

0.5m H2O

1m H2O

2m H2O

4m H2O

8m H2O

16m H2O

32m H2O

50m H2O

10 bar G

30 bar G

40 bar G

100 bar G

200 bar G

300 bar G

400 bar G

Nominal

range

THE SERIES 500 IS

NOT APPROVED

FOR USE IN HAZARDOUS AREAS

T2

T5

T6

T7

T11

T12

T13

T14

T18

T22

T31

T32

T33

T36

T38

T39

T40

T41

T42

T43

T44

DN25 PN16 flange mounting.

Threaded process connection 1/2” BSP male

1” ANSI 150lb flange mounting to BS1560.

Threaded process connection 1/2” NPT male

Hygienic 2” IDF.

Hygienic 2” RJT

Hygienic 2” Triclover.

Hygienic 2” SMS.

DN50 PN16 flange mounting.

Threaded process connection 1” BSP female.

Hygienic DIN 50mm to 11851

Threaded process connection 1/2” BSP female

Threaded process connection 1/4” BSP female.

Threaded process connection 1/4” NPT female.

Threaded process connection 1/2” NPT female.

Threaded process connection 3/4” NPT female

Threaded process connection 1” NPT female

Threaded process connection 1/4” NPT male.

Threaded process connection 1/4” BSP male

Threaded process connection 3/4” BSP female

.2” ANSI 150lb flange mounting to

BS1560........................................................

5

3. TRANSMITTER INSTALLATION MECHANICAL

Pre installation checks

The Transmitter is normally manufactured, calibrated and tested in accordance

with the users specific requirements. It is recommended that prior to

commencing installation, the specification of the instrument as supplied is

checked to ensure it is in accordance with actual installation requirements.

Checks should include nominal and actual ranges set, signal output, power

supply requirements and process connections. The relevant information will be

engraved on the transmitter body.

Transmitter Mounting

The Transmitter is generally specified with the appropriate fittings to mount

directly to the pipework or process plant Optional brackets are available if

required.

System Piping

The size of the process connection to the pressure chamber will depend on what

was specified at the time of manufacture. Do not overtighten the pressure

connection or insert any objects through the entry hole since this may result in

damage to the sensitive pressure element.

In general it should be ensured that the pipework and valves used are compatible

with the process in terms of materials and pressure ratings. For liquid level

duties long pipe runs should have a gradient to assist in clearance and line size

should be 1/4" minimum. Where isolation valves are fitted they should be as

close to the transmitter as practical.

38mm

(1.5")

59mm (2.32")

51mm

(2.0")

36mm (1.42")

FITTING M17

FITTING M12

53mm (2.1")

47mm

(1.85")

6

GREEN

Ground

by carefully levering it out using

removed from the housing

the slots provided.

Terminal block may be

ZERO

Z

RED

positive

1

R

RANGE

BLACK

negative

2

positive

1

negative

2

Ground

Maximum output load = Supply Voltage -9

0.002

4. TRANSMITTER INSTALLATION ELECTRICAL

Electrical connections

Connections are made via an industry standard DIN plug. The cabling may be of

screened, flexible or mineral insulated type dependant upon the application

requirements, maximum conductor size 1.5mm.

Prior to any connection it should be ensured that the supply voltage is correct for

the transmitter otherwise damage may result.

Where other devices are to be included in the signal loop for 2 wire 4 to 20mA

output transmitters, the total loop impedance may not exceed the figure given by

the following equation:-

5. TRANSMITTER COMMISSIONING

Under normal circumstances the instrument will have been supplied with range

and zero controls preset according to the users specifications, so, no adjustment

should be necessary. However, it may be when the transmitter is installed,

trimming of zero and/or range settings are necessary. It may also be that the

transmitter is to be reset for a different application.

Access to the zero and span adjustment potentiometers is provided by undoing

the plastic locking ring at the rear of the body.

7

Where practical all adjustments should be made with the transmitter installed on

the process and the range and zero settings validated by measurement of the

output signal at 0 and 100% of the process pressure. Where it is not practical to

vary the process pressure to suit, an alternative pressure source may be

employed, this should be an high accuracy device such as an air driven dead

weight tester, laboratory digital pressure standard, water or mercury column.

Range & Zero adjustments

The zero should be adjusted firstly, the instrument is of the 'live zero' type

therefore for when no pressure is applied the output signal should be 4.00mA .

Once this is achieved the range potentiometer should be adjusted with the

required max. pressure applied to the instrument until the output signal is 20mA.

It is recommended that the zero be rechecked after range adjustment

Routine Maintenance

The design of these transmitters is such that no routine maintenance is required

except for periodic examination of gaskets and security of pressure and electrical

connections

.

6. FAULT FINDING

These transmitters are sensitive and accurate measuring instruments and have no

mechanical wearing or contacting parts. If installation procedures have been

followed correctly the instrument should give satisfactory operation over a long

period.

In cases of failure or poor operation following installation or in normal service

the following check list may assist in isolating the cause of any problems.

1Are the range details of the transmitter correct for the duty?

2Fully check impulse piping and wiring installation, have any leaks

developed or are there any poor electrical connections?

3Is the transmitter isolation valve (if fitted) fully in the open position?

4Is there pressure in the process and is it of the correct order?

5Is the correct power supply applied to the transmitter and is it actually

present at the transmitter terminals?

6Check the output from the transmitter at the receiving instrument.

7 If all the foregoing are found to be in order then it will be necessary to

isolate the instrument and remove it from process.

Check that no sludge or foreign matter has collected in the transmitter pressure

chamber. Any deposits can normally be seen clearly at the entrance to the

pressure housing. Do not use any tools or other pointed objects to clean inside

the chamber, this should only be done flushing with suitable solvents

Should the problems persist consult PSM Service department

on 01444 410040 or return to the factory for examination.

Table of contents

Other PSM Transmitter manuals

Popular Transmitter manuals by other brands

Vaisala

Vaisala HMT370EX user guide

Thorne & Derrick

Thorne & Derrick KATflow 100 operating instructions

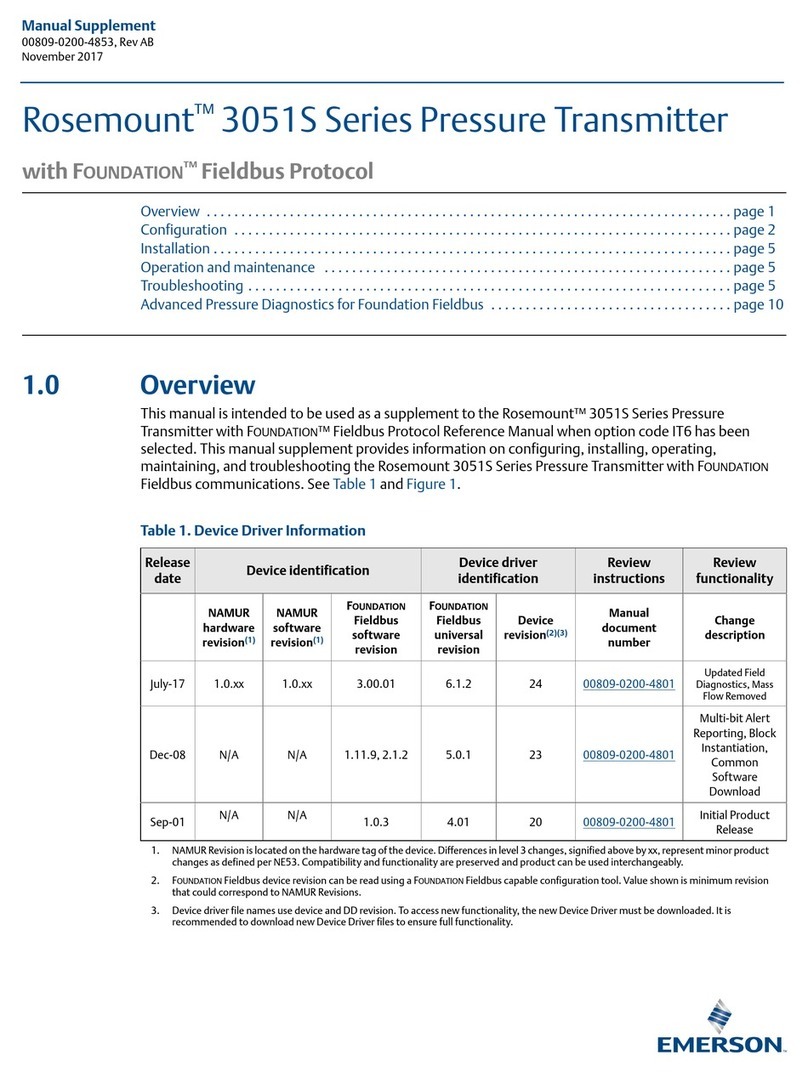

Emerson

Emerson Rosemount 3051S Series Manual supplement

Honeywell

Honeywell PEHA FU-BLS Installation and operating instructions

Williams Sound

Williams Sound WIR TX75/b user guide

Scosche

Scosche FLYTUNES BTT instructions

Greystone Energy Systems

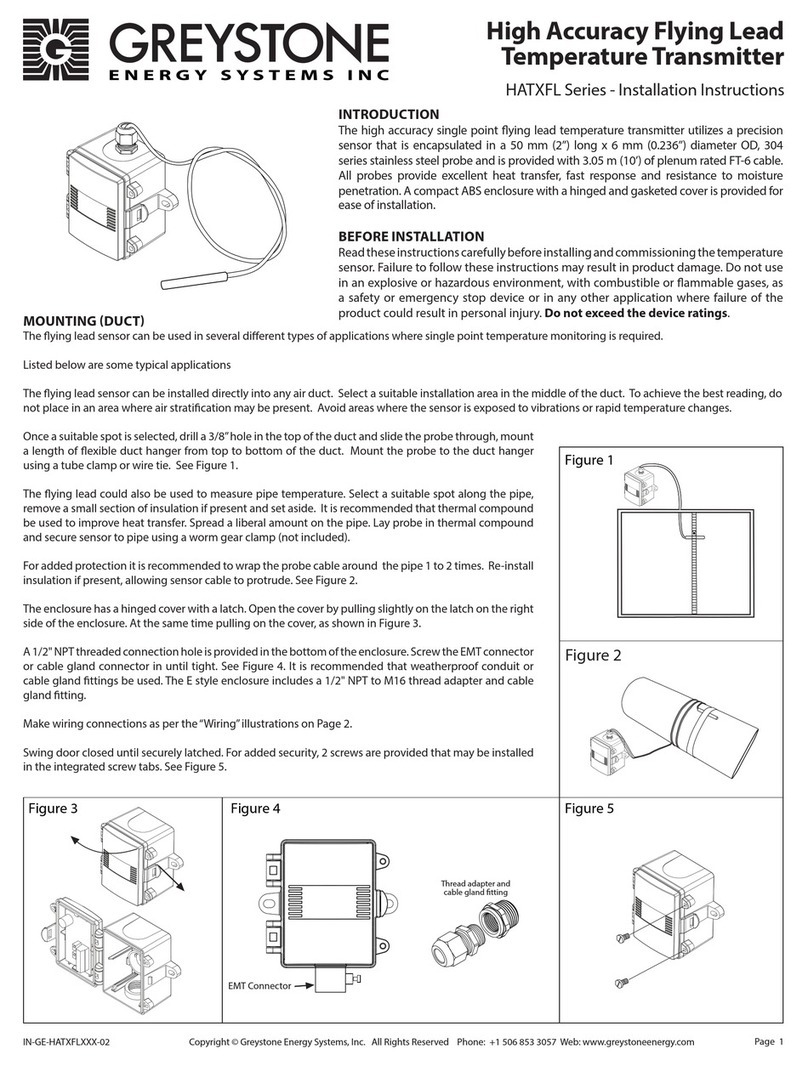

Greystone Energy Systems HATXFL Series installation instructions

Siro

Siro BF315 manual

Heystar

Heystar HS-ZSD14-RF01 Instruction book

PCE Instruments

PCE Instruments Aeroqual 900 Series user guide

Energometrika

Energometrika EYD38 Operation manual

Emerson

Emerson Rosemount Ultrasonic 3107 quick start guide