- 1-

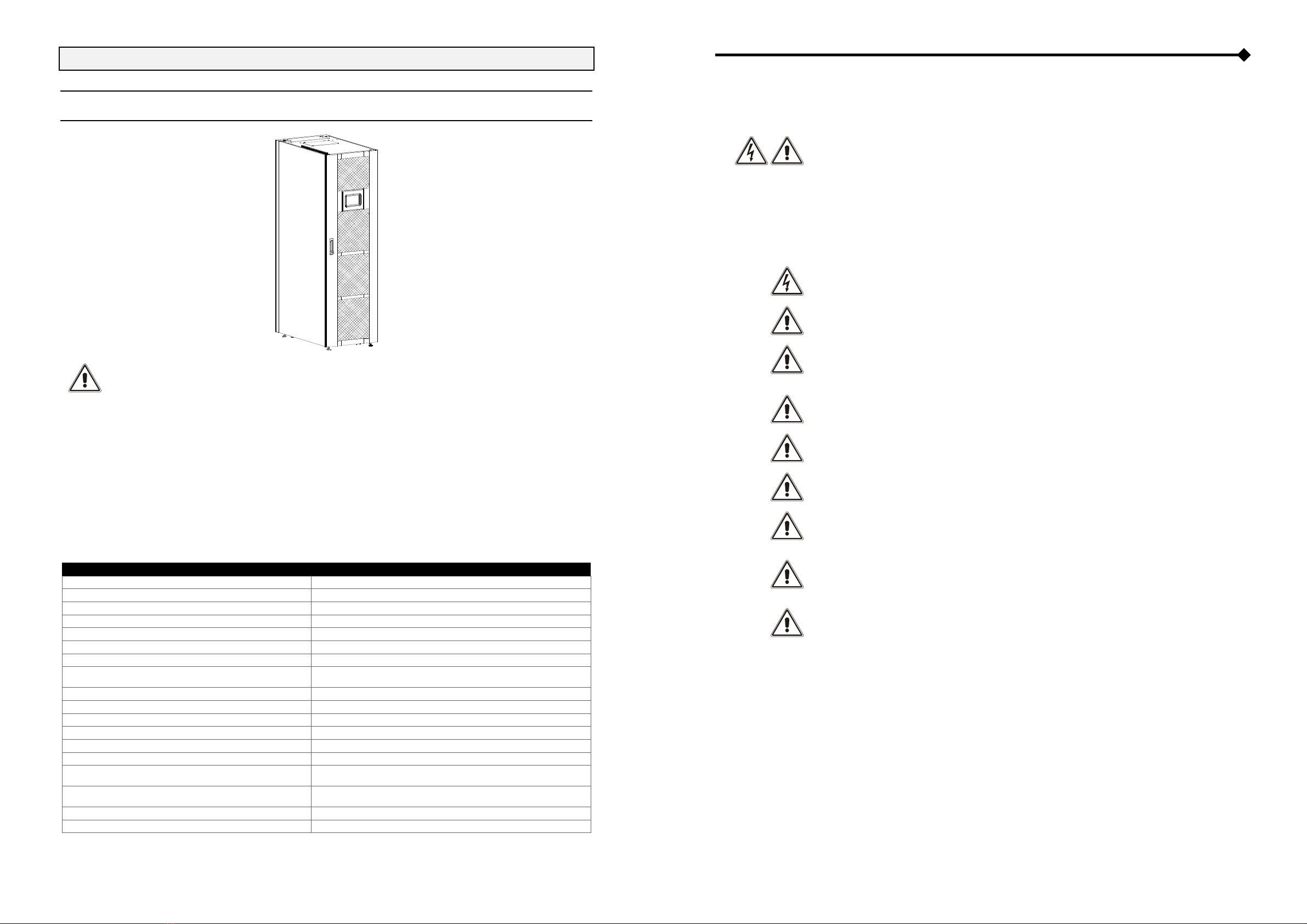

Maxsis RXR130

READ "SAFETY MANUAL" BEFORE STARTING

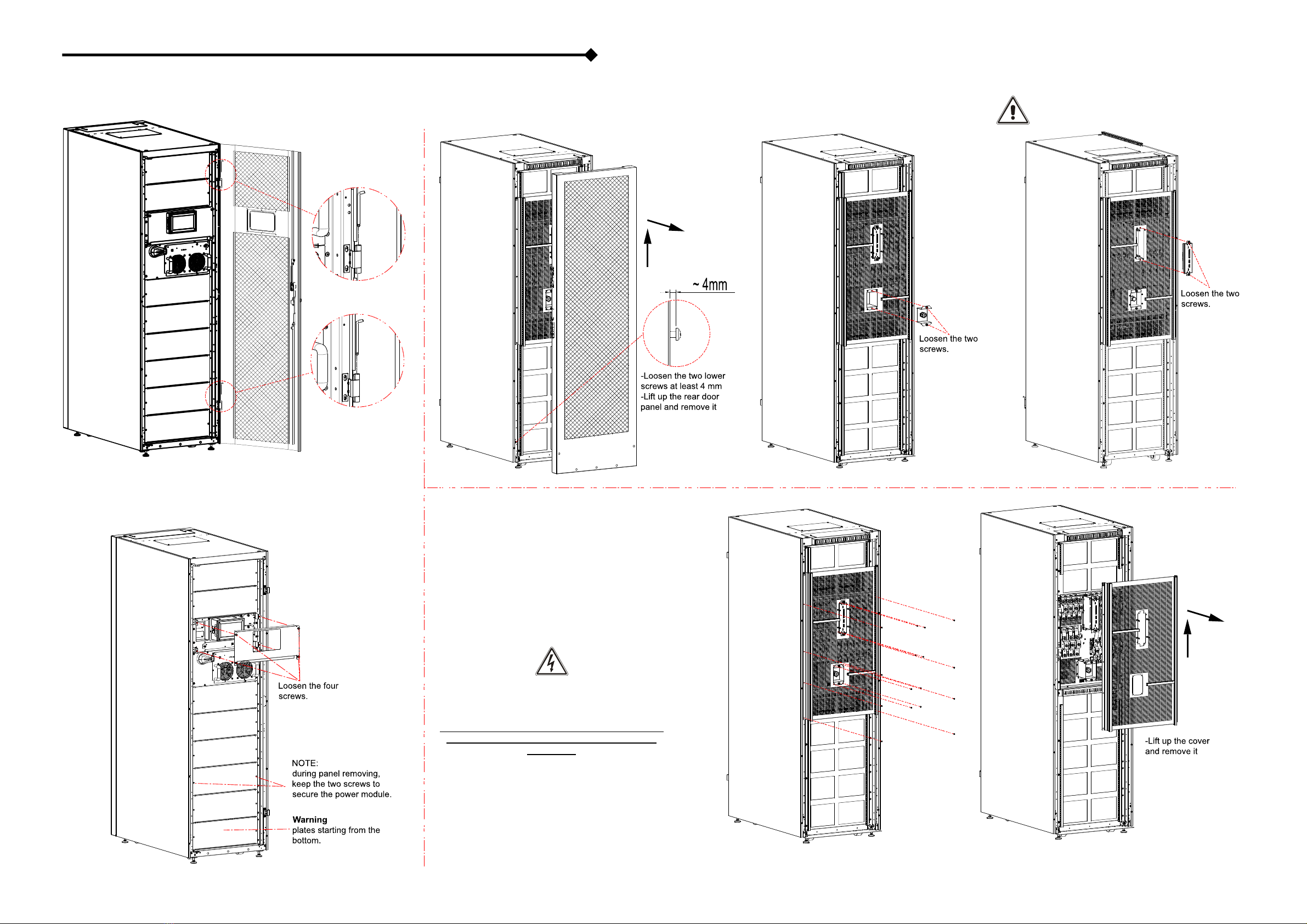

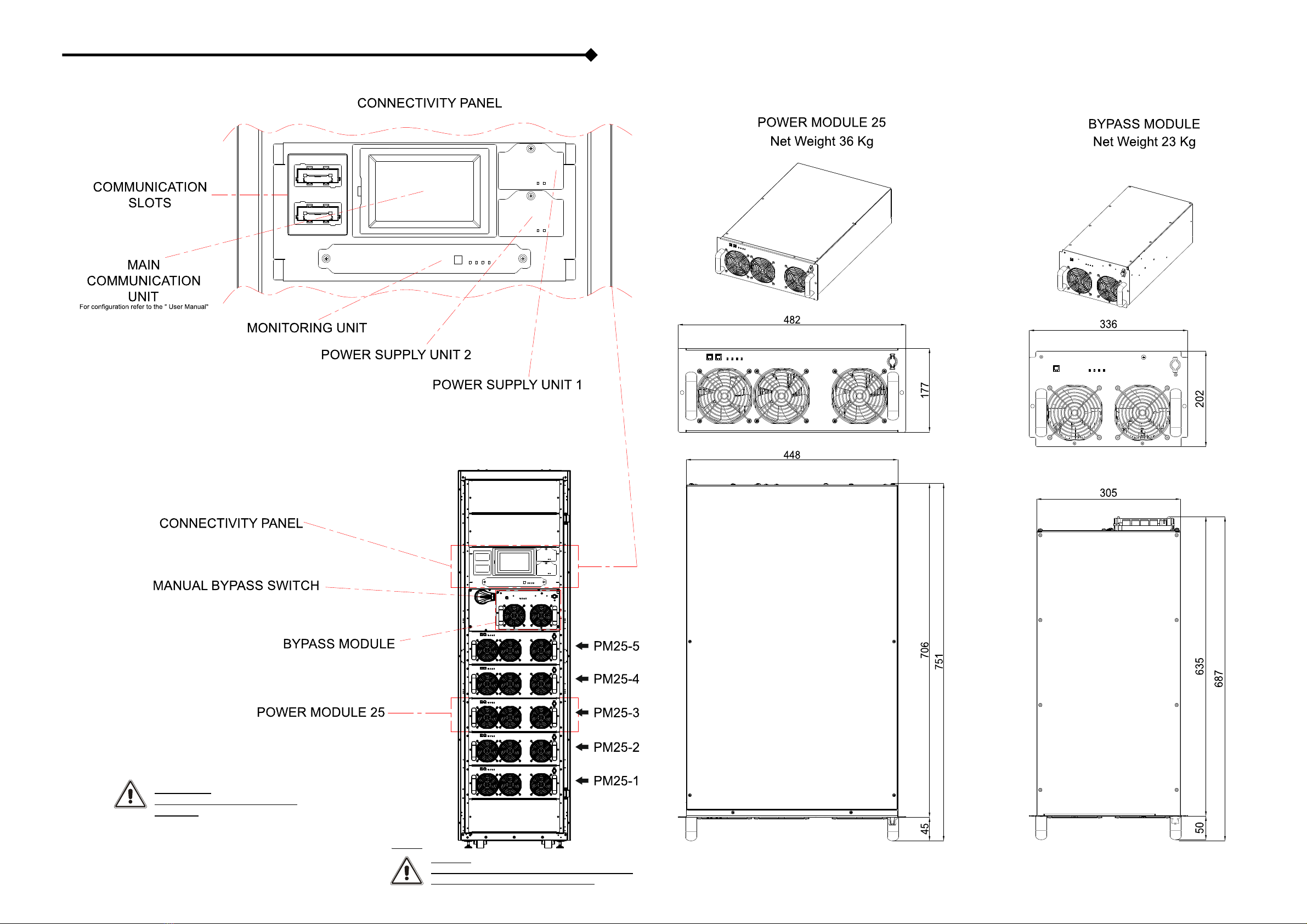

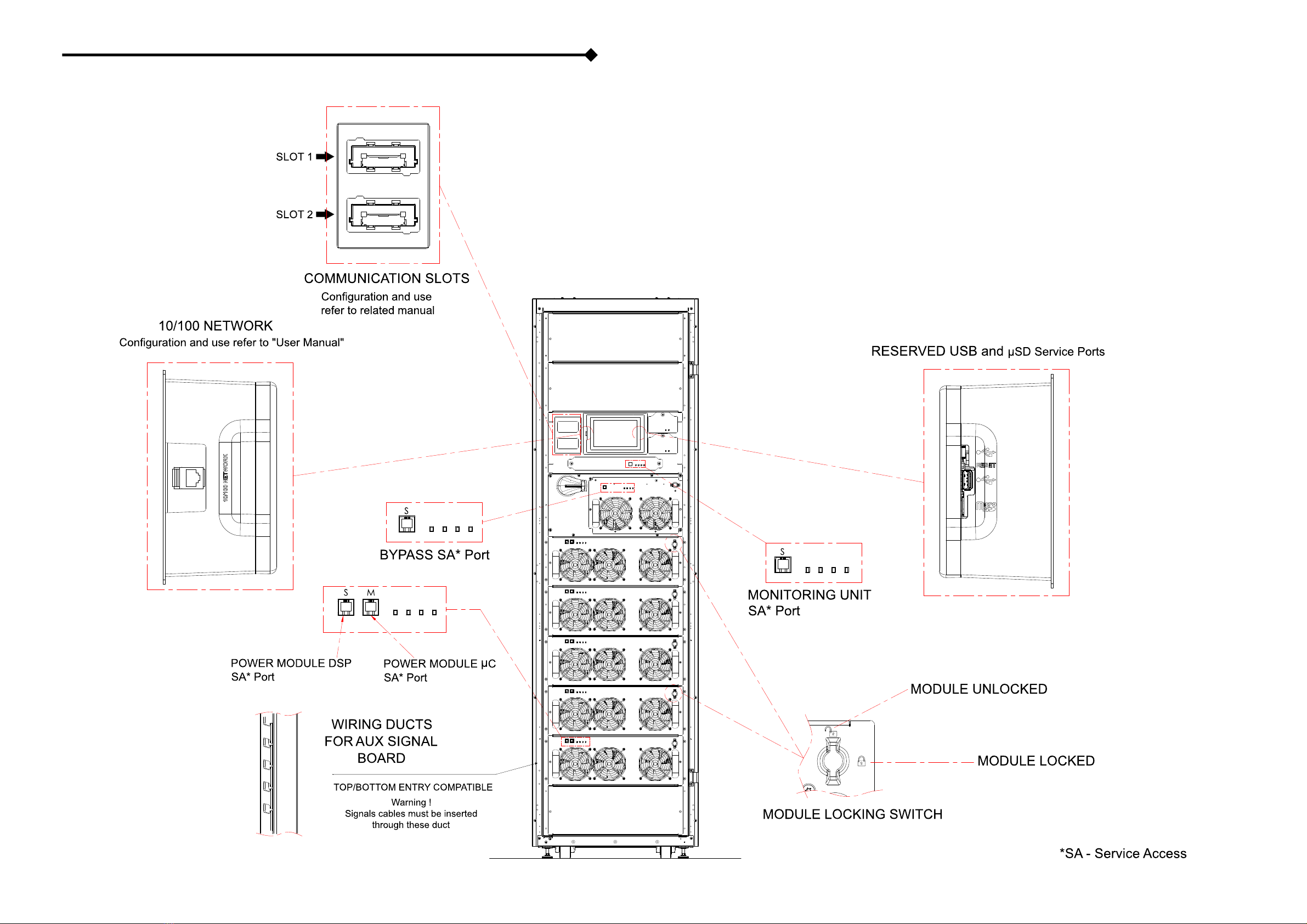

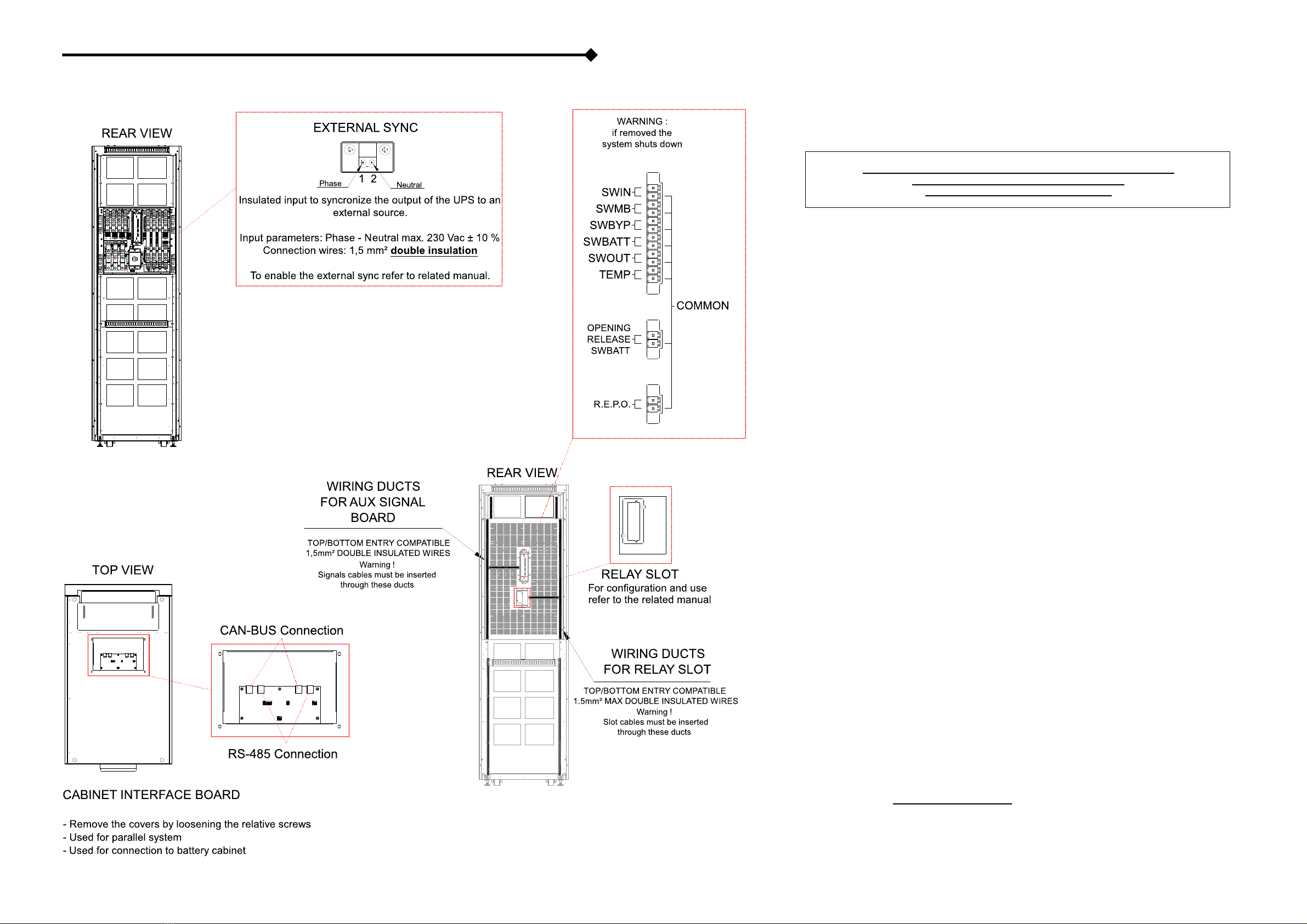

THE MODULAR UPS POWER CABINET INSTALLATION

INSTALLATION ENVIRONMENTS

The Modular UPS Power Cabinet is manufactured for an internal environment.

Essential Requirements:

- avoid dusty environments;

- the relative humidity must comply with the data in the table within this page;

- the operating ambient room temperature must comply with the data in the table within this page;

- avoid environments exposed directly to sunlight and hot air.

To regulate the ambient temperature within the UPS location at the appropriate range, waste heat disposal

systems must be used. Methods which can be used include:

- natural ventilation;

- forced ventilation, recommended if the external temperature is lower (e.g. 20°C) than the temperature at

which you want to operate the UPS;

- air conditioning system, recommended if the external temperature is higher (e.g. 30°C) than the

temperature at which you want to operate the UPS.

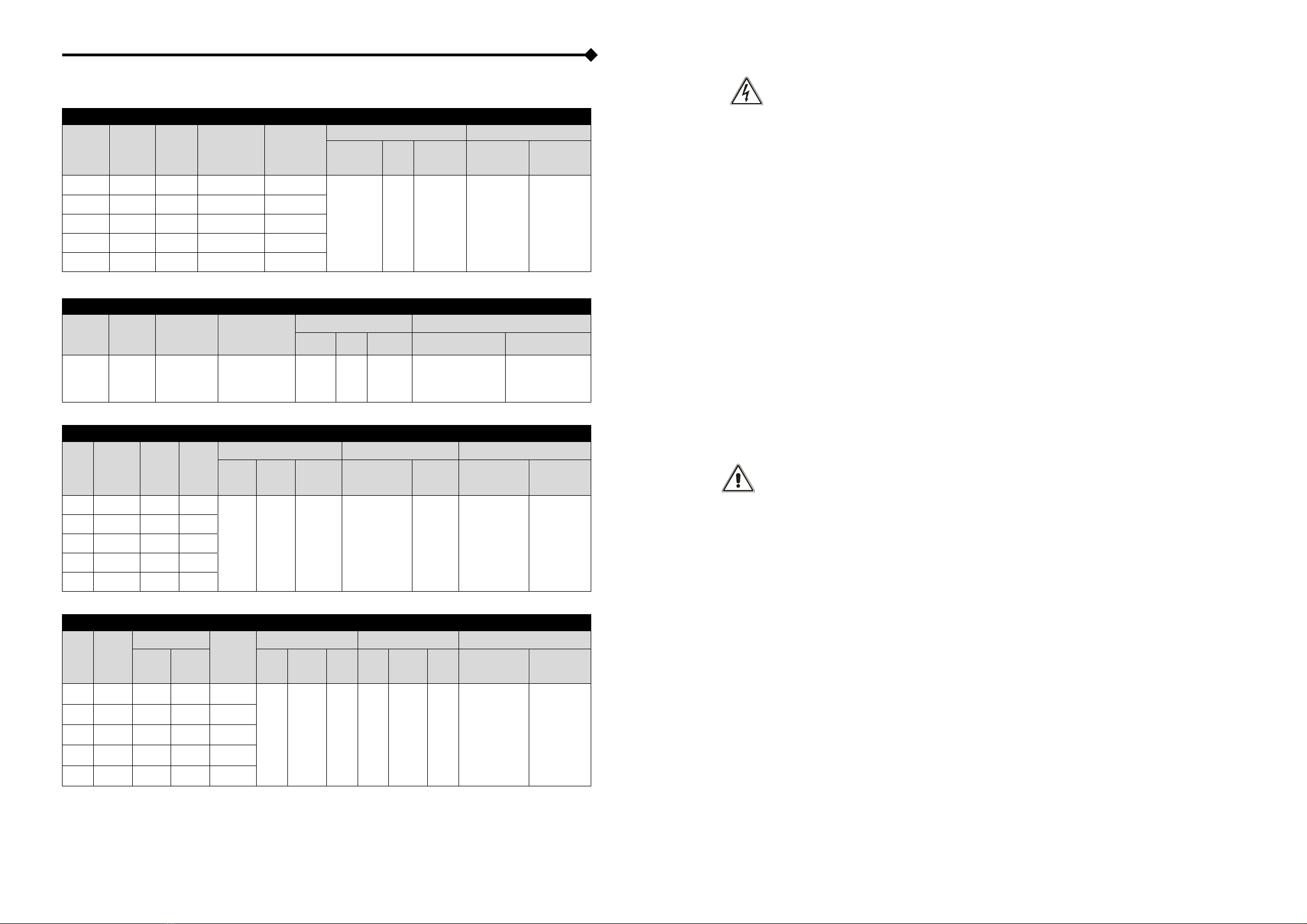

MAIN INFORMATION TABLE

Power [kVA / kW] 125 / 125

V Input [V] 380 – 400 – 415 (3PH + N)

Frequency Input [Hz] 50 - 60

V Output [V] 380 – 400 – 415 (3PH + N)

Frequency Output [Hz] 50 / 60

Operating temperature [°C] 0 ÷ 40

Max relative humidity in operation [%] 90% (without condensation)

Max installation height 1000 mt at nominal power

(-1% power for every 100 m above 1000 m) – max 4000 m

Power loss @ 100% load (1) 5.9 kW - 5073 kcal/h – 20130 BTU/h

Power loss @ 50% load (1) 2.7 kW - 2322 kcal/h – 9220 BTU/h

Max Leakage Current [mA] (2) 550

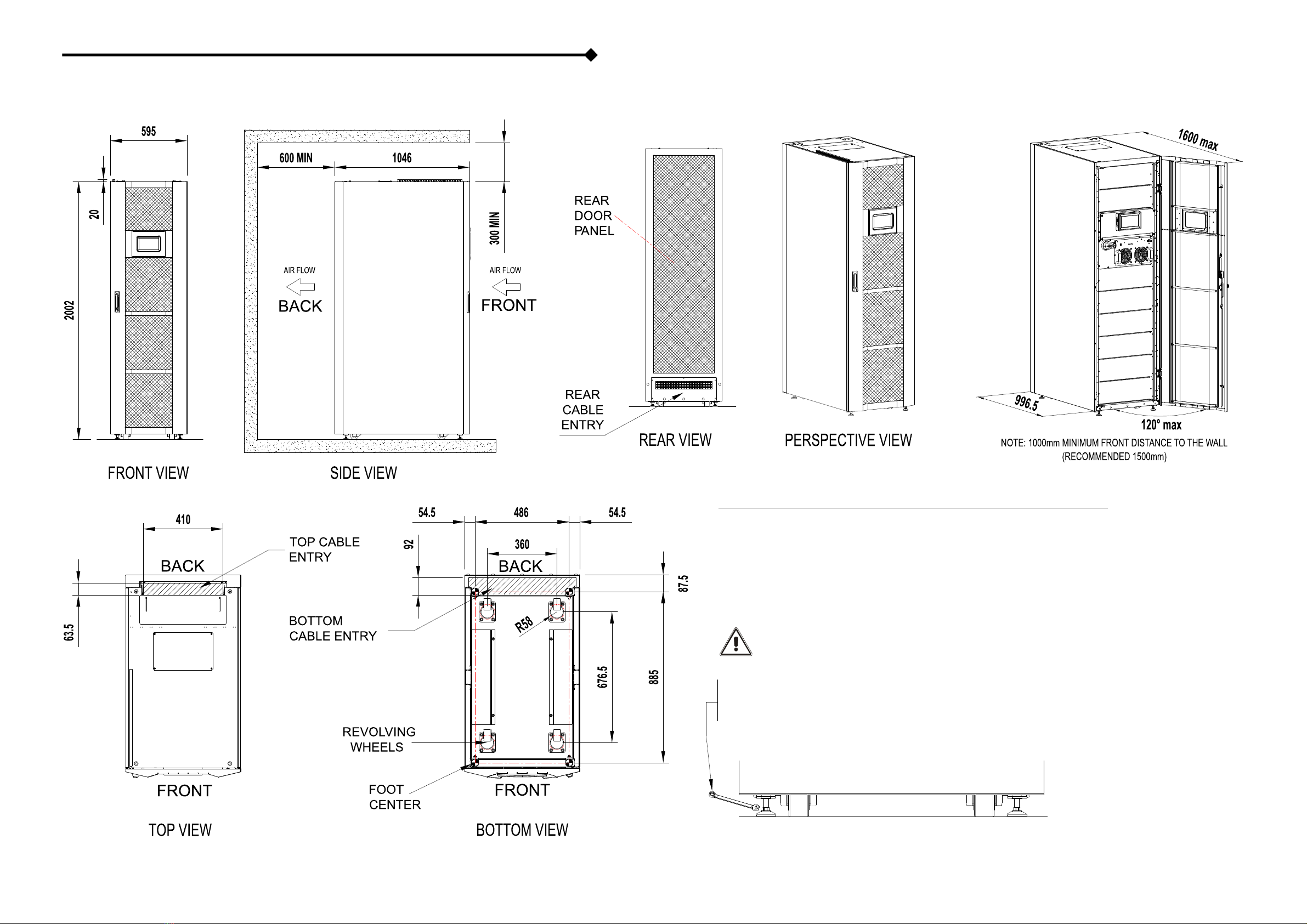

Cabinet Dimension (WxDxH) [mm] 595x1046x2002

Shipping Dimension (WxDxH) [mm] 700x1166x2174

Shipping Weight Power Cabinet [kg] 260

Net Weight without power modules / Bypass module

Included [kg] 240

TOTAL Net Weight with 5 power modules / Bypass module

Included [kg] 420

Air Flow [m3/h] 2710

Degree of protection IP20

(1) 3.97 BTU / h = 1 kcal / h

(2) The load leakage current is added to the one of the UPS on the ground protection conductor

PRELIMINARY INFORMATION FOR INSTALLATION

ALL OPERATIONS DESCRIBED IN THIS SECTION MUST BE PERFORMED BY QUALIFIED AND TRAINED

PERSONNEL ONLY.

Our Company assumes no liability for damages caused by incorrect connections or operations not

contained in this manual.

The following operations have to be performed with the UPS disconnected from the power mains, off

and with all equipment switches open.

Before making the connection, open all cabinet switches and verify that the UPS is completely

isolated from power sources: battery and AC power line. In particular, check that:

- the UPS input line is completely disconnected

- the UPS bypass line is completely disconnected

- the external UPS battery line switch/fuses are open

- all UPS switches are in the open position

- check with a multimeter that there are no dangerous voltages

The first connection to be made is the protective conductor (earth wire), this must be connected to

the bar marked as PE.

The UPS must operate while connected to the earthing system.

The input Neutral must always be connected.

ATTENTION: a three-phase four-wire distribution system is required.

The standard UPS version must be connected to a 3 Phase + Neutral + PE (ground protection) power

line.

Comply with clockwise phase rotation.

Read the battery box manual before connecting the batteries.

Check that the total battery voltage meets the requirements of the UPS (refer to the Battery Box

nameplate).

ATTENTION: the maximum length of the connection cables to the Battery Box is 10 meters.

ATTENTION: After the installation operation is complete, refit the cabinet protection panels using the

appropriate screws.

ELECTROMAGNETIC COMPATIBILITY

WARNING: This is a category C2 UPS product. In a residential environment, this product may cause

radio interference, in which case the user may be required to take additional measures.

BATTERY ROOM VENTILATION

The room where the battery box is located must have enough ventilation to ensure the concentration

of hydrogen produced is within safe limits.

The room should preferably be ventilated naturally; if it cannot be, forced ventilation may be

employed.

Standard EN 50272-2 regarding air exchange provides that the minimum aperture must satisfy the

following equation:

A = 28 x Q = 28 x 0.05 x n x Igas x C10 (1/10³) [cm²] where:

A = area of opening [cm²]

Q = airflow required [m³/h]

n = number of battery cells;

C10 = battery capacity in 10 hours [Ah]

Igas = gas producing current [mA/Ah]

according to the standard:

Igas = 1 in backup charging for VRLA type batteries

Igas = 8 in fast charging for VRLA type batteries

NOTE: read the User Manual before using the Maxsis RXR.

NOTE: some images contained in this document are for information purposes only and may not faithfully

demonstrate the parts of the product they represent.