PTM ADVANCE SUPER USB User manual

2

Dear customer, thank you for buying this PTM product.

We advise you to read this manual carefully

in order to use the product at best.

SAFETY AND MAINTAINANCE INFORMATION

Never open the protection box of the scale.

Should the scale be damaged, or should liquids have soave in, have the scale checked by a service point.

Never pull the cables in order to disconnect the scale, but unscrew the connectors in the right way.

If the device is provided with an electro-valve control box, remind that this is equipped with a fuse for

protection against power supply inversions and current overflowing. In case the fuse breaks down, replace it

with an equivalent one.

Do not lay the device cables (e.g. load cell cables, data transmission cables, cables to control relay boards,

etc.) near supply cables of other electric or electronic devices.

Supply the device with tensions consistent with the technical features of the product.

Have installation and maintenance work carried out by qualified staff.

Working on the electro-valve control box, by making connections or adjustments which are not authorized by

PTM, is prohibited.

Do not lay the cables which are connected to the scale near moving mechanical parts.

Once you have finished working with the device, we suggest you store it on its holder.

Before cleaning the machine with high-pressure water, protect the scale against possible water infiltrations.

We also remind you to be extremely careful and not expose electronics, cables and other optionals to direct

water jets.

It is possible to clean the scale outside by using a soft and damp cloth, avoiding solvent or abrasive

substances, sharp or cutting objects which can damage the device.

Do not expose the scale to temperatures higher than the limits indicated in the technical features.

In order to reach a longer duration, do not expose the scale directly to atmospheric events, such as rain,

snow, frost, etc.

Never unscrew the grounding clamp which can be found on the protection box of the scale.

Do not use sharp or cutting tools to press the keys.

In case of installation, maintenance and reparation of the scale or the load cells, carry out a weight check /

calibration before making the weighing system operating.

Should the scale be equipped with data saving through USB Pen Drive or Memory Card, insert the saving

device in the correct way.

Before carrying out installation, maintenance and reparation works on the scale or the load cells, disconnect

all the machines which could be connected to the weighing system.

Before carrying out installation, maintenance and reparation works on the system, disconnect the power

supply.

Should the scale be equipped with relay boards, never connect the board directly to electric engines, devices

with a higher tension than 110V, etc.

During the charge of the machine battery, disconnect the power supply cable from the scale.

Before carrying out welding on the machine, disconnect all the cables from the scale.

In case of welding on the machine, place the grounding clip near the welding point, in order to prevent

electric current from passing through the load cells.

In case of welding on the device/machine, disconnect the electro-valve control box and the electronic

equipment, by unplugging the power supply cable, all the electro-valve cables and the connection cable to

the handheld remote control.

We suggest NOT to use electro-valves which have the connection to the body of the electro-valve itself.

All responsibility for installation, maintenance and reparation works falls on the person who carried them out.

3

The constructor of the machine on which the device is installed takes on the responsibility to fix the parts of

the device properly, in order to prevent any dangerous contact of the operator with the dangerous area. In

particular, if the device can control electro-valves, when the operator pushes a button, he is supposed to be

aware of the corresponding movement on the machine.

It is responsibility of the constructor of the machine on which the device is installed to:

oEvaluate risks and safety of the system

oProvide the correct power supply on the device, in order to guarantee the correct functioning of the

device in full respect of the regulation EN 60204-1.

oIf the device controls electro-valves directly, supply the symbols of the controls that you find on the

device, so that they are conformed to the directive.

oCorrectly describe the functioning of the different keys and of the valves associated, so that the

machine on which the device is installed can work in the correct way.

Any change and/or alteration on the hardware or software made on the product, on the device or on the

security systems of the product, if not expressly authorized by PTM S.r.l., makes any responsibility of the

constructor concerning "CE" conformity drop.

ATTENTION!

Do not use high-pressure devices to clean the weighing scale and the load cells.

PTM s.r.l. declines any responsibility in case the regulations above are not observed, and invites the

operator to the correct use of the device.

4

INDEX

FUNCTIONS AND FEATURES....................................................................................................................................5

TECHNICAL FEATURES.............................................................................................................................................7

OPTIONALS.................................................................................................................................................................7

WEIGHING SCALE STRUCTURE...............................................................................................................................8

KEYS FUNCTIONS......................................................................................................................................................9

TO START..................................................................................................................................................................10

MULTIPLE CHANGE OF A PARAMETER................................................................................................................14

HELP ..........................................................................................................................................................................15

ENTRY OF TEXT AND NUMBERS ...........................................................................................................................16

COMMUCATION WITH SOFTWARES......................................................................................................................17

MENU .........................................................................................................................................................................18

MAIN MENU ...............................................................................................................................................................19

SUBMENU..................................................................................................................................................................20

PROGRAMMING........................................................................................................................................................37

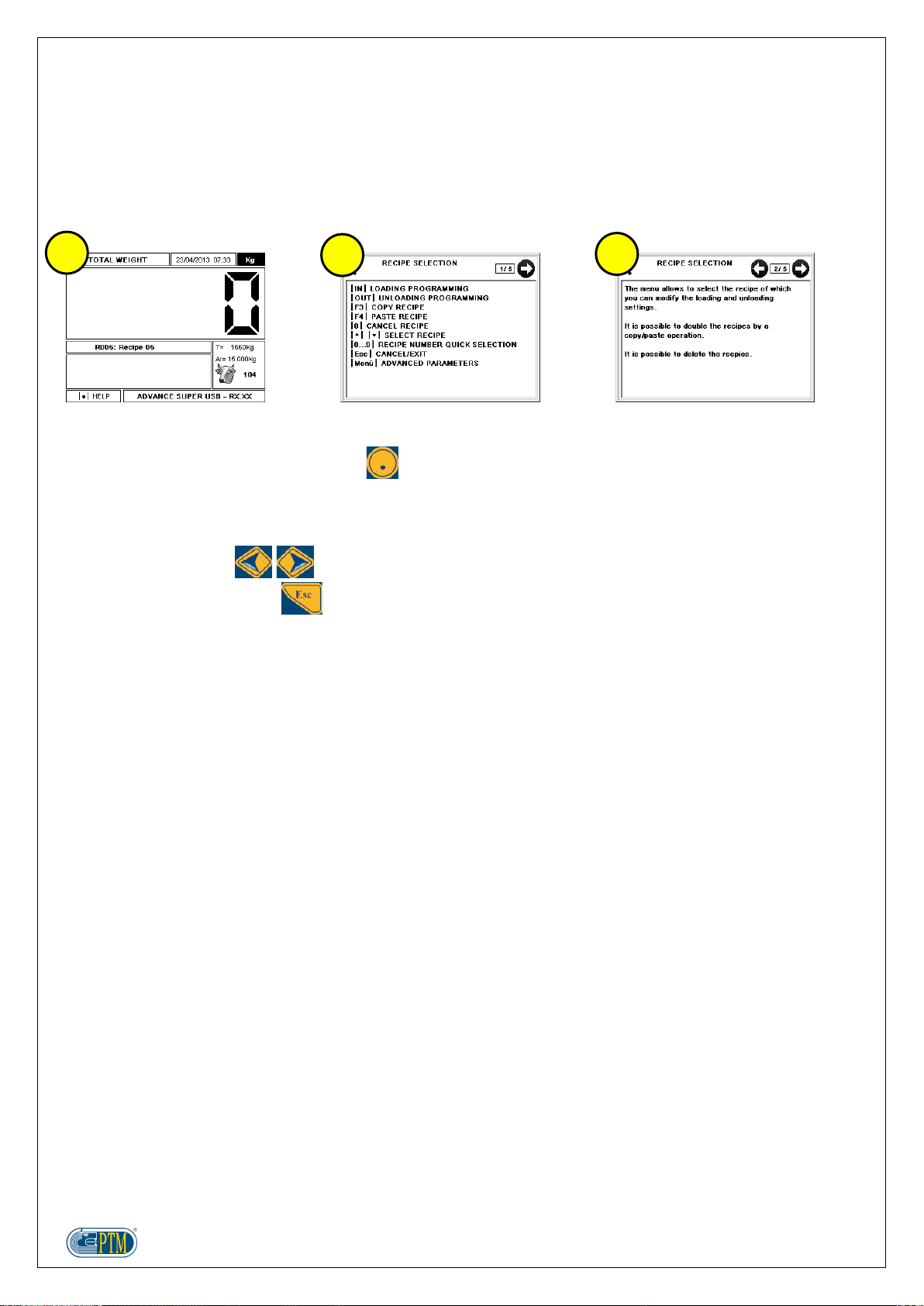

RECIPE SELECTION.................................................................................................................................................37

LOADING PROGRAMMING......................................................................................................................................44

UNLOADING PROGRAMMING.................................................................................................................................44

NEW RECIPE.............................................................................................................................................................45

CHANGE RECIPE......................................................................................................................................................50

LOADING OPERATION.............................................................................................................................................55

UNLOADING OPERATION........................................................................................................................................62

CHANGES BLOCK THROUGH PIN CODE ..............................................................................................................66

ACCESS TO THE CODE MENU................................................................................................................................67

CODE LIST.................................................................................................................................................................68

PRINT EXAMPLES ....................................................................................................................................................77

OPTIONALS...............................................................................................................................................................79

CONNECTORS PLAN ...............................................................................................................................................80

TROUBLE SHOOTING ..............................................................................................................................................81

PTM IN THE WORLD.................................................................................................................................................83

DISPOSAL REGULATIONS .....................................................................................................................................84

DECLARATION OF CONFORMITY ..........................................................................................................................84

WARRANTY...............................................................................................................................................................85

5

FUNCTIONS AND FEATURES

The weighing indicators from the series ADVANCE SUPER USB are specific for the management of loading and

unloading operations on Unifeed mixer wagons.

This kind of electronics allows to program and manage up to 150 recipes, with a maximum of 99 components, and

30 components per recipe.

By means of the "PTM Multilink" connecting system, it is possible to connect different optional devices

simultaneously (e.g. printer, weight repeater, remote control, additional relays for Topcut management, mixer, etc.).

The series ADVANCE SUPER USB includes weighing computers with the following features:

Possibility to give a name to components

Memorization of 99 components

Possibility to give a name to groups

Memorization of 100 unloading groups

Possibility to give a name to recipes

Memorization of up to 150 recipes

Possibility to load up to 30 components per recipe

Possibility to unload up to 50 groups per recipe

Total weight screen with the following details: date and time, name of the recipe to load, recipe total, ration

per animal, number of animals

Recipe selection screen with the main details of each recipe: recipe total, ration per animal, number of

animals, mixing time and number of components

Quick selection of the recipe to load

Possibility to manage recipes by selecting the order of the components from a loading list

Management of a numeric keyboard, with the same writing mode of cell phones

Online Help for each screen/function of the scale

Automatic backup of the changes made on components, groups and recipes upon inserting the USB

pendrive

Automatic backup of loading and unloading data upon inserting the USB pendrive

Possibility of digital printing in CSV format, for consumptions and loading and unloading operations.

Overcharge control system

Possibility to prevent the access to some menu, under menu and functions to unskilled and unauthorized

staff (through a PIN code). It is possible to manage to 20 users.

Zeroing through external input or keyboard

Loading break through external input or keyboard

Loading stop through external input or keyboard (optional)

Simultaneous connection of more repeater displays/optionals

Management of the recipe mixing during the loading

Possibility to specify for each component break time and alarm duration after the loading

Possibility to specify for each group the alarm duration after the unloading

Possibility to manage international measurement units

Available weight divisions: 1-2-5-10-20

Calibration through load cells data

Calibration through load cells chart

Calibration with sample weight

Possibility to set out a threshold for manual dosage

Connection of PTM Multilink peripheral devices

Possibility to use additional I/O modules

Control on possible programming conflict between outputs

Self-detection of the number of relay boards connected

Connection to the printer (by request)

Possibility to set out the automatic unloading

Management of component consumptions

6

Proportional recalculation of the quantities of the recipe components in case of rest from the previous

unloading (it can be enabled/disabled for each single recipe)

Proportional recalculation of the quantities of the recipe components in case of overload of the first

component (it can be enabled/disabled for each single recipe)

Proportional recalculation of the unloading quantities in case of overload (it can be enabled/disabled for each

single recipe)

Management of the automatic load of the components from SILO (option)

Management of the MAINTENANCES of MIXER WAGON (option)

Contrast adjustment

Brightness adjustment

Integrated clock

Detection of supply tension

Multilanguage

Possibility to show the weight in reverse mode

Backup of the changes made on components, groups and recipes, made on the weighing computer

Backup of the last 800 loadings and unloadings carried out by the weighing computer

Backup of the settings and calibration of the weighing computer

7

TECHNICAL FEATURES

High sensitivity membrane keyboard

Cast aluminium casing

Protection class: IP 68 with plug-in connectors

Size: L 258 X H 212 X P 75 mm

Weight: 2000 gram ca.

Display: LCD backlit Black/White 320x240 pixel/dot (5.7") with 16 grey levels

Display visible in full sunlight

Memory: Eeprom non volatile

Clock / Calendar

Available weight divisions: Kg. 1 –2 –5 –10 –20

Resolution: 135.000 dd

Operating conditions: - 30 + 70 C°

Relative humidity: 95 %

Power supply: from 10 to 32 V dc

Absorbed power: 4 VA max

Load cells in parallel connection: Max 12 (350 Ω)

Load cell power supply: 5 Vcc

Margin of reading error: +/- Kg. 1 out of Kg. 10.000

Display data field: +99999 ; -99999

Measuring range: ± 2 mV; ± 20 mV

Conversion speed per second: 10 / sec.

No. of RS232 serial outputs: 1 fixed; 2 optional

Consumption: 12V –ca 250 mA (in case of 4 connected load cells)

Protection against radiofrequency interferences

Elimination of power supply interferences

Signalling of low tension

OPTIONALS

Repeater Displays: MV6, AV20-5, Big Display, AV40-5

Portable Displays: AV50/AV80

Multilink TR60: RF Antenna for portable Display AV50/AV60/AV65/AV80

Multilink TR61: RF Antenna (automatic load of the components)

4in-12out Board: Board 4 inputs 12 outputs (automatic load of the components)

16out Boards: Board 16 outputs (automatic load of the components)

Multilink Drive 8: I/O board

Multilink RF7: RF Antenna for Radio control

Multilink Printer Mod. P255/P256/P260/P261

Multilink Drive 8: I/O board #2

Multilink Drive 8: I/O board #3

Multilink Drive 8: I/O board #4

Inverter

Power supplier

8

WEIGHING SCALE STRUCTURE

1. Identifying plate: In this area of the keyboard there is the identifying plate where the scale model is

indicated.

2. Display LCD 320x240 with 16 grey levels: LCD Graphic display where all information of the weighing

scale are indicated, here all the different steps of the weighing operations are indicated. To make the

access to the end user easier, the scale is equipped with interactive graphic.

3. Numeric Keyboard: Numeric keyboard for the insertion of numbers and letters.

4. Function keys: In this keyboard area there are some function keys, among them there is the tare zeroing

key and the partial weight zeroing key.

5. Shift keys: In this area of the keyboard there are some keys used to shift among the different menus of the

scale.

6. Connctors: There are four connectors for the junction to the power supply, to the load cells, to the

optionals and to the USB pen-drive.

7. Male coupling: Scale fixing support. Together with the weighing kit the female coupling is supplied.

8. Serial Number: Serial Number of the scale. In case of service, please communicate to PTM or to the

authorized dealer this number to allow the product identification.

9. EC Identifying plate: This is the identifying plate of the weighing scale. In case of service, please

communicate to PTM or to the authorized dealer this number to allow the product identification. Please, do

not remove or damage this plate.

5

7

9

6

4

3

2

1

8

9

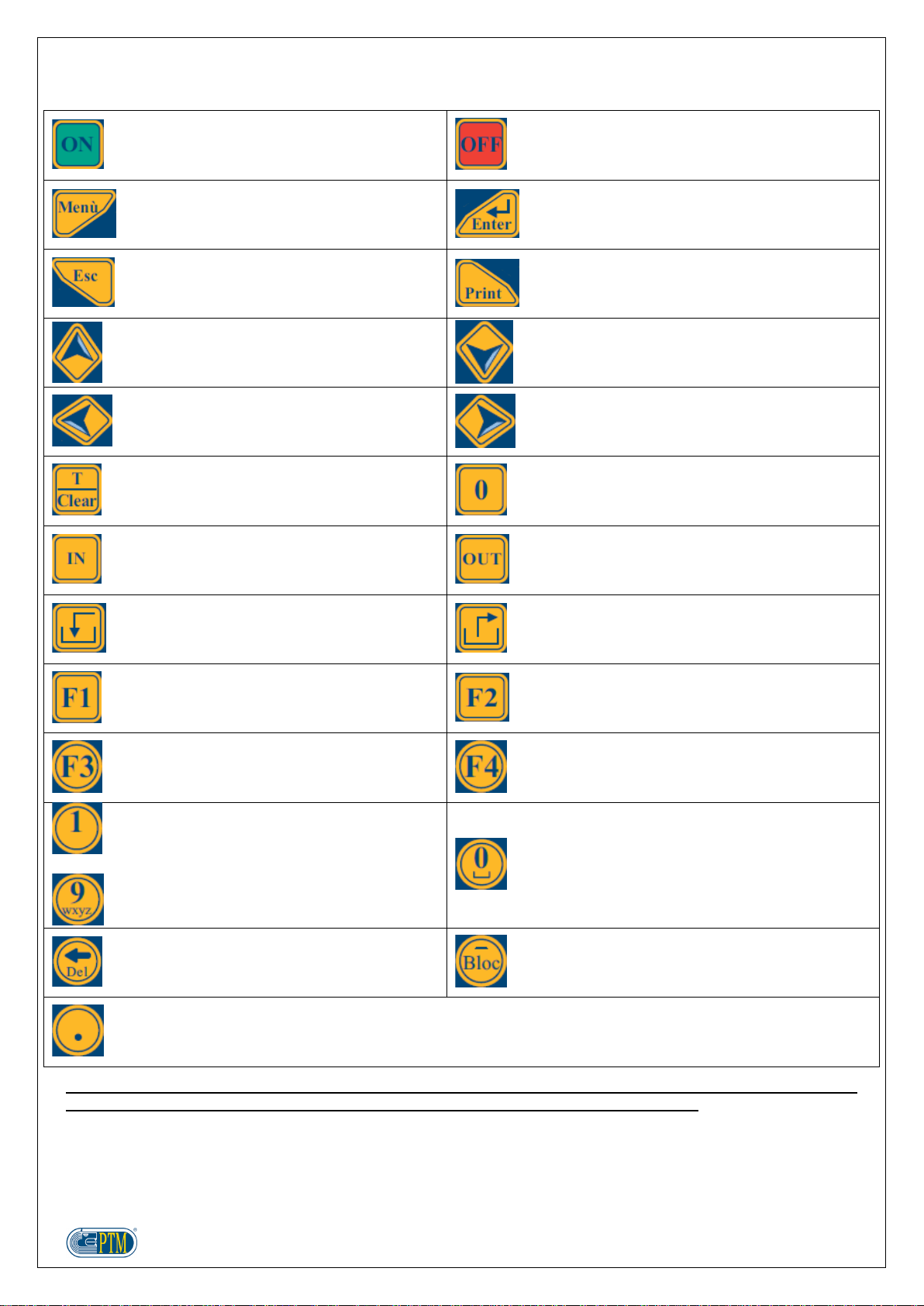

KEYS FUNCTIONS

ON

OFF

ACCESS TO USER MENU

ADVANCED PARAMETERS

ENTER

EXIT

PRINT

SHIFTING THE CURSOR UPWARDS

MOVING TO THE NEXT COMPONENT

MOVING TO THE NEXT GROUP

SHIFTING THE CURSOR DOWNWARDS

MOVING TO THE PREVIOUS COMPONENT

MOVING TO THE PREVIOUS GROUP

SHIFTING THE CURSOR TO THE LEFT

SHIFTING THE CURSOR TO THE RIGHT

TARE ZEROING

TOTAL WEIGHT RECALL

PARTIAL WEIGHT RECALL

PARTIAL WEIGHT ZEROING

RECIPE SELECTION MENU

LOADING PROGRAMMING

RECIPE SELECTION MENU

UNLOADING PROGRAMMING

START OF THE LOADING OF THE SELECTED

RECIPE

START OF THE UNLOADING OF THE SELECTED

RECIPE

ACTIVATION / DEACTIVATION OF THE

TOPCUT FUNCTION (IF AVAILABLE)

VISUALIZATION OF MULTILINK MODULE ALARMS

(IF AVAILABLE)

CHANGE ALL VALUES

CHANGE WRITING MODE (CAPITAL LETTERS,

SMALL LETTERS, NUMBERS)

QUICK SELECTION OF COMPONENTS, GROUPS

AND RECIPES

ENTRY OF NUMBER AND LETTERS BY

MEANS OF THE NUMERIC KEYBOARD

ENTRY OF NUMBER “0” OR SPACE

DELETE CHARACTER (DELETE)

ENTRY OF CHARACTER “-“

BLOCKING/UNBLOCKING DURING LOADING AND

UNLOADING OPERATIONS

ENTRY OF DECIMAL POINT

ONLINE HELP

ATTENTION: According to the menu, some keys may have either additional or different functions. For more

information, please read the online help on the scale, or go on reading this document.

10

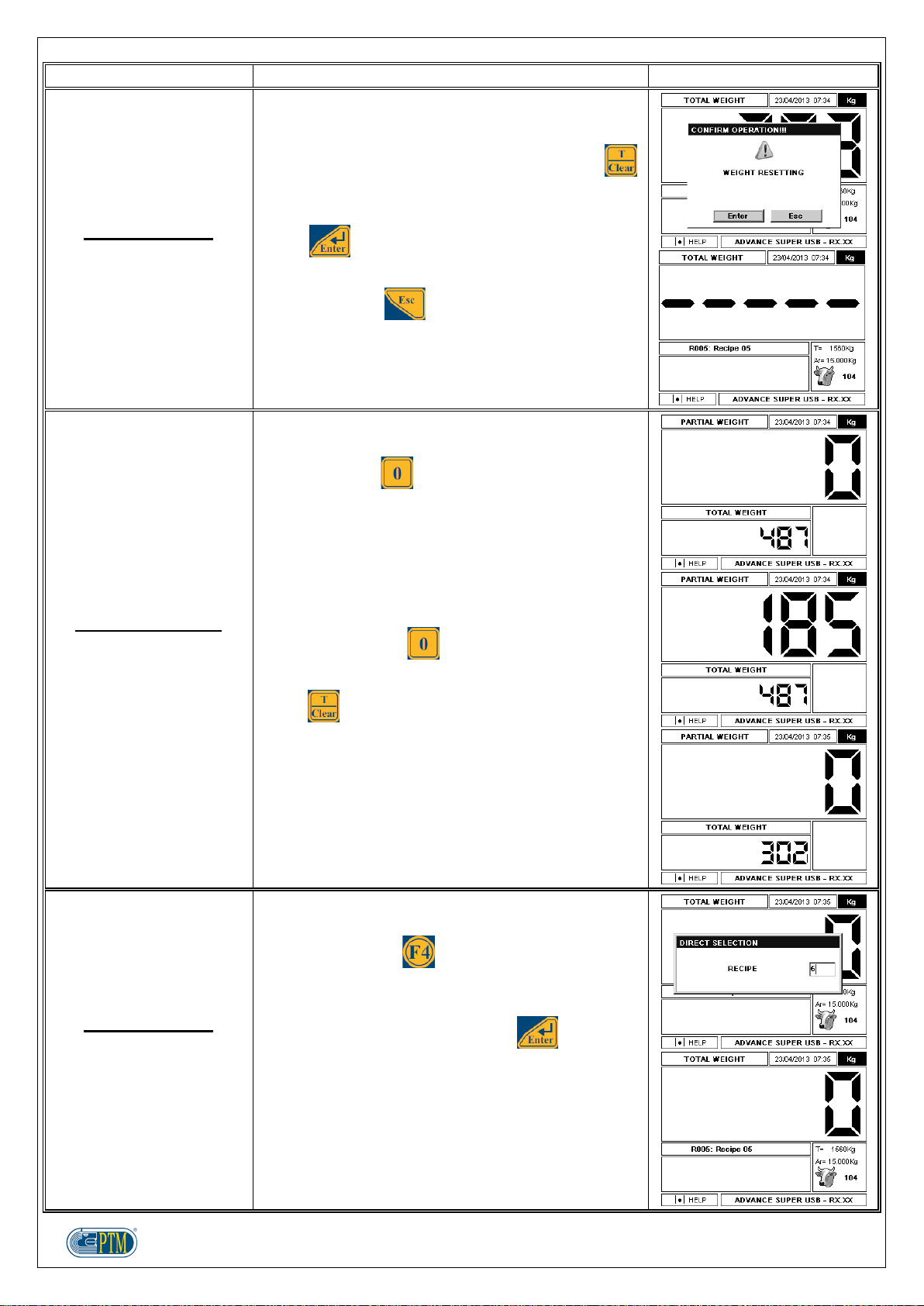

TO START

FUNCTION

OPERATION

DISPLAY

The operations descrive below concern the basic functioning of the weighing computer.

For extra information, please go on reading this document.

Switch ON

Press

Switch OFF

Press

TOTAL WEIGHT

After the introduction, the weighing computer shows the screen TOTAL WEIGHT:

1. Current screen (TOTAL WEIGHT or PARTIAL WEIGHT)

2. Current date and time

3. Measurement unit used by the scale

4. Value of total or partial weight detected by the scale

5. Current selected recipe

6. Summary information regarding the current selected recipe: Total weight to load,

ration per animal and total number of animals

7. Icon showing the status of Topcut knives in the mixer wagon (by request)

8. Key to press in order to visualize the online help of the scale

9. Alarms for Multilink modules (by request)

10. USB Pendrive inserted in the weighing computer

11. Software Release installed on the weighing computer

3

2

1

5

7

8

9

10

11

6

4

11

FUNCTION

OPERATION

DISPLAY

TOTAL WEIGHT

Zeroing the total weight

The screen TOTAL WEIGHT shows the value of total

weight measured by the load cells.

To reset the weight value to zero, keep the key

pressed for 3 seconds, until the confirmation message

appears on the display.

Press to confirm the tare zeroing: the value of

total weight will be reset to zero.

Otherwise, press to cancel the operation.

PARTIAL WEIGHT

Zeroing the partial

weight

It is possible to move from the screen TOTAL

WEIGHT to the screen PARTIAL WEIGHT by

pressing the key .

The value of total weight is displayed in the lower part

of the screen.

When going on with the loading operations, the

display shows the partial weight loaded from that

moment on, while the updated total weight is

displayed in the lower part of the screen.

By pressing the key again, it is possible to reset

the partial weight to zero.

Press to go back to the menu TOTAL WEIGHT.

TOTAL WEIGHT

Direct selection of the

recipe

In order to carry out a DIRECT SELECTION of the

recipe to load, place yourself in the menu TOTAL

WEIGHT and press .

In the superimposed screen it is possible to enter the

number of the recipe to load by means of the numeric

keyboard, and confirm it by pressing .

12

FUNCTION

OPERATION

DISPLAY

RECIPE SELECTION

In order to enter the menu RECIPE SELECTION

press or .

ATTENTION: for more detailed information, please

see the section PROGRAMMING and RECIPE

SELECTION.

TOTAL WEIGHT

Starting the loading of

the recipe

To start the LOADING of the recipe selected in the

menu TOTAL WEIGHT, press .

Should an empty recipe be selected, the display

shows the error message ERROR!!! Recipe Total

Void!!! It is possible to leave this message by

pressing .

TOTAL WEIGHT

Starting the unloading of

the recipe

To start the UNLOADING of the recipe selected in the

menu TOTAL WEIGHT, press .

Like for the loading, should an empty recipe be

selected, the display shows the error message

ERROR!!! Recipe Total Void!!! It is possible to leave

this message by pressing .

TOTAL WEIGHT

Manual TOPCUT

(by request)

If the scale is arranged for the TOPCUT function

(control of knives for grinding the material in the mixer

wagon), the icon showing the status of the knives

appears in the menus TOTAL WEIGHT and PARTIAL

WEIGHT.

It is possible to enable/disable MANUAL TOPCUT

only from the menus TOTAL WEIGHT and PARTIAL

WEIGHT.

It is not possible to leave the menus TOTAL WEIGHT

and PARTIAL WEIGHT as long as the function

MANUAL TOPCUT is not disabled.

For more details, please read the specific section in

the next pages.

13

FUNCTION

OPERATION

DISPLAY

TOTAL WEIGHT

Manual TOPCUT

(by request)

Static

Recipe times

Dedicated times

This mode can be set out in the sub menu MANUAL

TOPCUT, where it is possible to choose among the

following functioning modes:

STATIC

RECIPE TIMES: with the same Knives IN and

Knives OUT times of the selected recipe

DEDICATED TIMES: with Knives IN and Knives

OUT times independent from the times of the

selected recipe

After choosing one of the three available modes, it is

possible to enable it by pressing the key in the

screens TOTAL WEIGHT and PARTIAL WEIGHT.

The word MAN or AUTO appears above the TOPCUT

icon, according to the functioning mode selected.

In the STATIC mode, the TOPCUT icon shows the

word MAN and the knives are activated (IN) and

deactivated (OUT) upon enabling/disabling the mode.

In the modes RECIPE TIMES or DEDICATED TIMES,

the TOPCUT icon shows the word AUTO and the

knives are activated (IN) and deactivated (OUT)

according to the times set out in the submenu

MANUAL TOPCUT.

These modes can be disabled by pressing ; in

this case the word OFF appears above the icon

TOPCUT.

TOTAL WEIGHT

MULTILINK

(by request)

Module alarms

In case the weighing computer is connected to any

Multilink modules, and there communication problems

with the scale, the icon is displayed in the

screen TOTAL WEIGHT.

By pressing it is possible to visualize the scrren

ENABLED ALARMS, with the list of Multilink modules

having communication problems with the scale; in this

way it is possible to identify the source of the fault

immediately.

To leave, press .

14

MULTIPLE CHANGE OF A PARAMETER

In some menus and for some parameters, it is possible to make a single change to set out a value for all the

associated positions in the menu.

For instance, in the menu LOADING PROGRAMMING it is possible to modify the value LOADING ALARM % for

all the components of the recipe, by entering the value 20% only once, instead of entering it for each component.

It is possible to enable the multiple change with single entry as follows:

1. press

2. in the screen MODIFY ALL VALUES use the numeric keyboard to enter the value you want to give the

parameter for all the elements in the menu

3. confirm by pressing , or cancel by pressing

In the explanation of the next sections the following description will be indicated, every time it is possible to carry

out the multiple change of the parameter with single entry:

With multiple change of the parameter

1

3

2

15

HELP

The weighing computer Advance contains some screens to help the user better understand:

the functions of the keys

the functioning, the settings and the options.

The Help screens are contextual, and contain descriptions concerning the menu which the user is visualizing.

1. The function HELP is available in the menus showing the sign “|.| HELP” at the bottom on the left. In order

to visualize the HELP pages, press .

2. The keys, as well as their function in the menu, are described in the first page.

3. The next pages describe the functioning of the menu, the settings and the options which can be set out.

To scroll the pages, use .

To leave the online help, press .

1

2

3

16

ENTRY OF TEXT AND NUMBERS

It is possible to enter text and numbers by means of the numeric keyboard.

By repeatedly pressing the keys, it is possible to enter other characters than the ones present on the keyboard.

In some menus it is possible to change the writing mode by pressing :

Capital letters ABC (123)

Small letters abc (123)

Numbers 123

In the following you'll find the character corresponding to the number of pressures of the key in CAPITAL

KEY

x1

x2

x3

x4

x5

x6

x7

x8

x9

x10

x11

x12

.

,

?

!

1

A

B

C

Ä

Á

À

Â

Ã

Ç

2

D

E

F

Ë

É

È

Ê

3

G

H

I

Ï

Í

Ì

Î

4

J

K

L

5

M

N

O

Ö

Ñ

Ó

Ò

Ô

Õ

6

P

Q

R

S

Š

7

T

U

V

Ü

Ú

Ù

Û

8

W

X

Y

Z

Ÿ

Ý

Æ

Œ

Ø

Å

Ž

9

and SMALL mode:

KEY

x1

x2

x3

x4

x5

x6

x7

x8

x9

x10

x11

.

,

?

!

1

a

b

c

ä

á

à

â

ã

ç

2

d

e

f

ë

é

è

ê

3

g

h

i

ï

í

ì

î

4

j

k

l

5

m

n

o

ö

ñ

ó

ò

ô

õ

ð

6

p

q

r

s

š

ß

7

t

u

v

ü

ú

ù

û

8

w

x

y

z

ÿ

ý

æ

œ

ø

å

9

17

COMMUCATION WITH SOFTWARES

The weighing computer Advance Super USB can work with the software SUPER DATA MIX or PTM

MANAGEMENT, which allows the exchange of programmings and loading and unloading data, the best

management of the quantities of material, and the control on the operator's work on the wagon.

Here under you'll find some useful advice to communicate with the program.

In order to communicate with the program, it is necessary to get a USB pendrive (supplied as standard

equipment with the scale), and get in the total weight menu.

In order to download data from the program into the weighing computer, get in the total weight menu and

put the USB pendrive in the specific connector.

In order to export loading and unloading data, as well as changes made on groups and recipes, get in the

total weight menu and put the USB pendrive in the specific connector.

Check that the USB pendrive has been put in the weighing computer in the right way.

Do not switch off the weighing computer while sending/receiving data.

Here is the detailed procedure for sending/receiving data:

Create the programmings with the software Super Data Mix or PTM Management

Send the programmings from the software Super Data Mix or PTM Management to the weighing computer

by inserting the USB pendrive in the specific connector.

Get in the total weight menu and insert the USB pendrive.

Wait for the data to be automatically downloaded.

Take out the USB pendrive and carry out the loading/unloading operations.

On the weighing computer it is possible to create or modify components, groups and recipes; all changes

will be then exported to the USB pendrive and imported into the program Super Data Mix or PTM

Management.

Wait for the data to be automatically downloaded upon putting the USB pendrive in the specific connector.

ATTENTION: if the communication between scale and software fails, and data go lost, they can be retrieved as

backup data from the internal memory of the scale (see BACKUP USB).

18

MENU

It is possible to access the following screens:

TOTAL WEIGHT

PARTIAL WEIGHT

MENU

SUBMENU

RECIPE SELECTION

LOADING PROGRAMMING

UNLOADING PROGRAMMING

according to the following scheme:

19

MAIN MENU

FUNCTION

OPERATION

DISPLAY

MAIN MENU

In the MENU you'll find the list of the submenus which

can be selected, in order to access some of the

functions of the scale.

You can access this screen from the TOTAL WEIGHT

by pressing .

MAIN MENU

Submenu

Use the keys to move the cell between the

submenus:

COMPONENTS

GROUPS

COMPONENTS CONSUMPTIONS

RECALCULATION ACTIVATION

SILO (Option)

MAINTENANCES (Option)

MANUAL TOPCUT (by request)

PRINT TO USB (enabling through code)

CONTRAST

BACKLIGHT

WATCH

BATTERY

LANGUAGE

WEIGHT IN REVERSE

USB BACKUP

BACKUP USB PARAMETERS

By pressing it is possible to access the

underlined submenu.

By pressing it is possible to go back to the

menu TOTAL WEIGHT.

MAIN MENU

Shifting the cursor

In the following screens:

MENU

SUBMENU

RECIPE SELECTION

LOADING PROGRAMMING

UNLOADING PROGRAMMING

it is possible to shift the cell:

to the left

to the right

upwards

downwards

20

SUBMENU

FUNCTION

OPERATION

DISPLAY

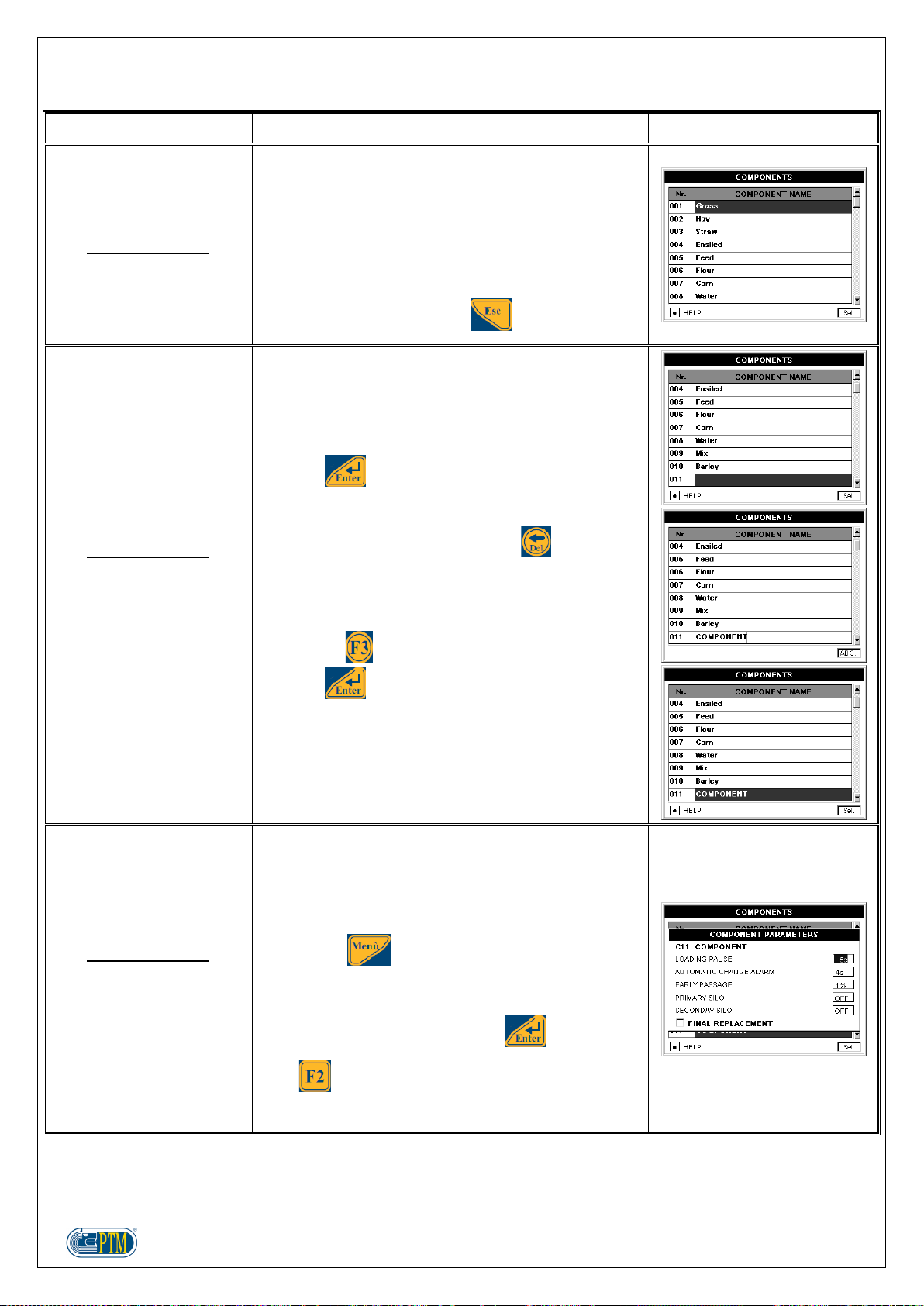

COMPONENTS

The submenu COMPONENTS allows to manage

components, which will be used in the loading

operations of the single recipes.

The names of the components can be entered by

means of programmings with the softwares SUPER

DATA MIX or PTM MANAGEMENT, or on the

weighing computer directly.

To leave this submenu, press .

COMPONENTS

Modify

Create

Erase

It is possible to modify, create or erase a component

as follows:

place the cell in the column COMPONENT NAME,

on the line of the component to create, change or

erase

press

in order to create a new component, it is necessary

to select an empty line

make the wished changes: press , if you wish

to cancel the component; use the numeric

keyboard to change the name (or create it, if the

selected component is new). While modifying the

name, it is possible to change the writing mode by

pressing

press to confirm the changes

COMPONENTS

COMPONENT PARAMETERS

Loading pause

For each component it is possible to set out a break at

the end of the component loading, that is a waiting

time counted down at the end of the component

loading.

Access to the screen COMPONENT PARAMETERS

by pressing .

In the superimposed window it is possible to enter the

value for LOADING PAUSE by means of the numeric

keyboard, and confirm by pressing .

With multiple change of the parameter.

It is possible to enter values between 0 and 999.

Table of contents

Other PTM Accessories manuals

Popular Accessories manuals by other brands

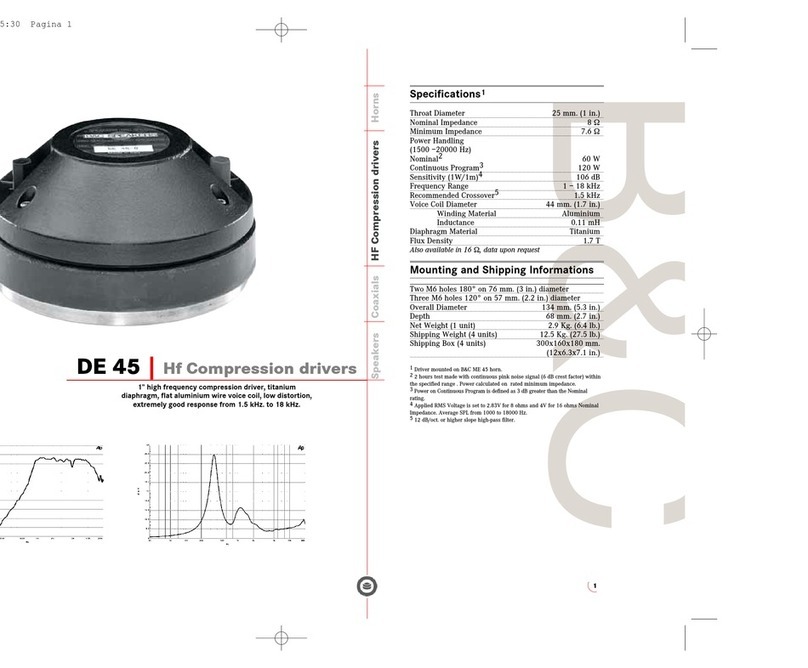

B&C Speakers

B&C Speakers Hf Compression Drivers DE 45 Specification sheet

UltraLux

UltraLux RFWDB INSTRUCTIONS FOR EXPLOITATION

Foerster

Foerster CIRCOGRAPH DS operating instructions

Wonbo

Wonbo Smart Doorbell A3 owner's manual

Emerson

Emerson Rosemount 214C quick start guide

inventum

inventum HB75 instruction manual

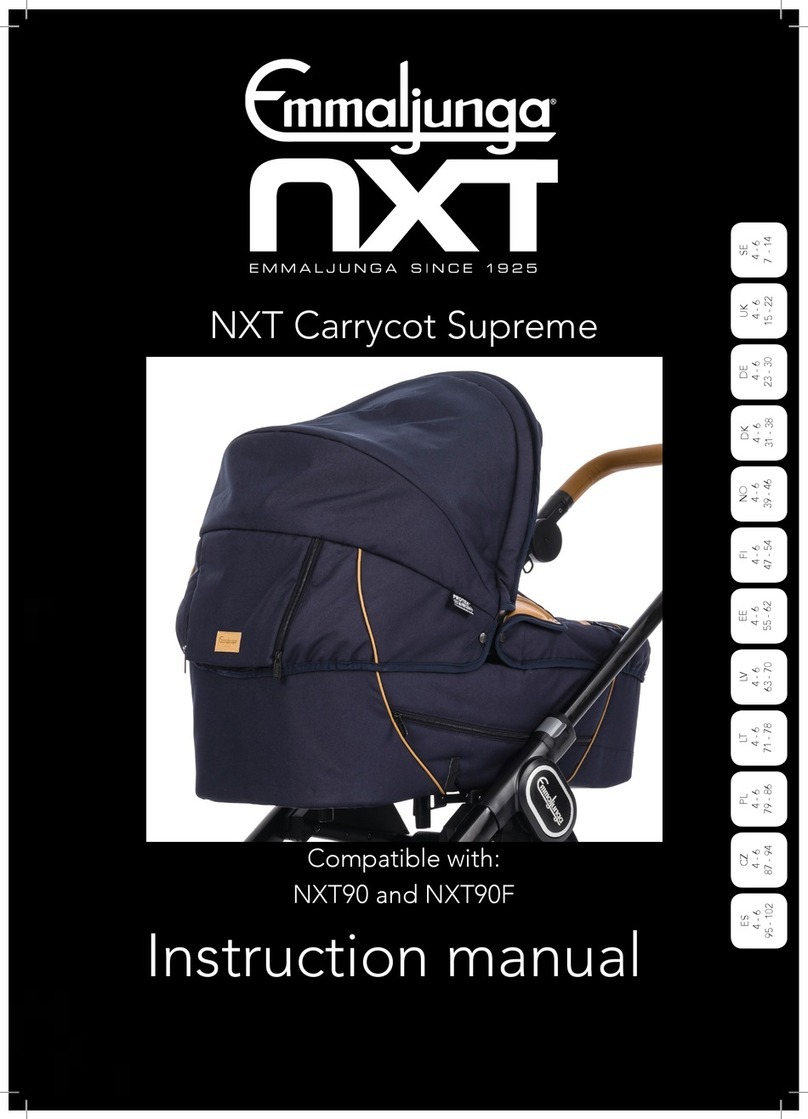

Emmaljunga

Emmaljunga NXT Carrycot Supreme instruction manual

ring

ring Doorbell Pro manual

Silvercrest

Silvercrest 284941 Assembly, operating and safety instructions

Aardvark

Aardvark Direct Pro Q10 owner's manual

BONA SPES

BONA SPES VIKING SP16W Instructions for use

ETC

ETC Echo Dual Tech Ceiling-mount Vacancy Sensor installation guide