PTM Print to Mail Endeavour User manual

Operator’s Manual

ii

iii

Table of Contents

Operator Safety............................................................................................1

Introduction..................................................................................................2

Unpacking and Setup ..................................................................................3

Unpacking ................................................................................................3

Setup ........................................................................................................4

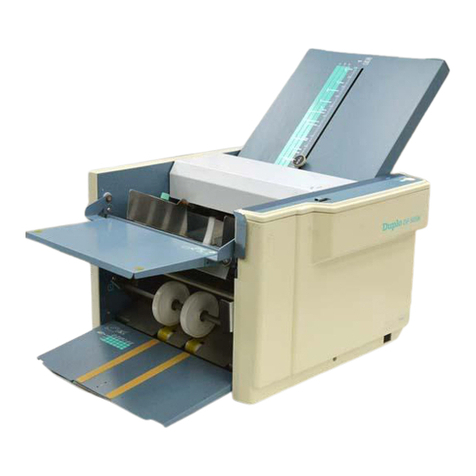

ENDEAVOUR Overview ...............................................................................5

ENDEAVOUR Diagram.............................................................................5

Capabilities...............................................................................................5

ENDEAVOUR Operation ..............................................................................6

Identifying Your Fold.................................................................................6

Feed Table Setup .....................................................................................6

Setting the Paper Guide Width..............................................................6

Setting the Feed Gauge........................................................................7

Loading the Feed Table ...........................................................................8

Setting the Fold Plates..............................................................................9

To set a fold plate: ................................................................................9

Fold Plates..............................................................................................10

Maintenance...............................................................................................11

Troubleshooting .........................................................................................12

Automatically Clearing a Paper Jam ......................................................12

Manually Clearing a Paper Jam..............................................................12

Diagnosing the Paper Jam.....................................................................13

Misaligned Folds ....................................................................................13

Paper Feed Problems.............................................................................14

Double Feeds......................................................................................14

Won’t Feed..........................................................................................14

ENDEAVOURWon’t Run ........................................................................14

iv

1

Operator Safety

Please review and follow all the safety precautions to ensure safe

equipment operation. The user is responsible for safe operating

conditions. Read all operating instructions prior to operating the

ENDEAVOUR.

Warning: Do not attempt to handle the equipment alone. It requires

two people to handle and lift the equipment out of the packaging.

Warning: This unit contains moving parts. Watch for Caution,

Warning, and Electrical stickers detailing proper operating conditions

and user safety.

Never remove guards or product safety switches. Removal of

guards or switches will cause the unit to run improperly and can result

in personal injury.

Keep all hands, fingers and objects away from moving parts.

Never attempt to reach into the ENDEAVOUR while the power is on.

Turn off the ENDEAVOUR and disconnect the power cord before

cleaning or servicing the ENDEAVOUR, and before removing either

fold plate. Injury may occur if proper operating procedure is not

followed.

Plug the power cord into 115 VAC 60 Hz outlet only. Voltage up to

120 volts will not damage the ENDEAVOUR.

The Power Cord and Plug must be accessible at all times for

disconnection.

This unit is equipped with a 3-Wire grounded electrical cord. If the cord

becomes damaged and needs to be replaced, it must be replaced with

an authorized part available through the manufacturer or an authorized

service agent.

All ENDEAVOUR maintenance should be performed only by factory

authorized service personnel using factory authorized replacement

parts. Contact PTM Document Systems for more information.

Keep product away from extreme heat & moisture.

Never operate ENDEAVOUR while tired, drowsy, or under the

influence of medication, drugs, or alcohol. Failure to do so can result in

personal injury.

Never operate unit with loose clothing or jewelry. Contain all long hair

and neck ties prior to operating ENDEAVOUR. Failure to do so could

result in clothing, jewelry, or hair becoming entangled in moving parts.

2

Introduction

The ENDEAVOUR is designed to fold and seal up to 3000 documents per

hour. Patented folding & sealing technologies ensure a good seal on every

form and a clean fold every time whether the paper is perforated or plain.

The adjustable fold plates allow the ENDEAVOUR to meet your changing

document processing requirements. Below are the detailed ENDEAVOUR

specs.

Feed System Bottom Feed Friction Belt

Drive System A.C. Fixed

Electrical 115V AC, 60 Hz, 3A

Paper Sizes Length up to 14”, width up to 8.5”

Fold Patterns 11” Half (V)

11” Letter C

11” Z

14” Half (V)

14” C

14” Return Envelope (EC)

14” Z

14” ECC Z

Speed 3000 Documents Per Hour Fixed Continuous

Dimensions Height 12”, Width 20”, Depth 16.5”

Weight 55 Lbs.

3

Unpacking and Setup

Unpacking

When opening the ENDEAVOUR packaging, inspect it for any shipping

damage. The shipper should be notified at once and the packing materials

saved if there is any serious damage. IMPORTANT- Please retain your

shipping carton and packaging material.

Warning: Do not attempt to remove the equipment from the packaging

alone. Two people are required at all times to move the equipment.

Ensure that the following items are

present in the packaging:

1. This manual (1)

2. ENDEAVOUR (1)

3. AC Power Cord (1)

4. Upper & Lower Fold Plates (1

each)

5. Left and right paper guides

6. Tool Kit

a. Breaker bar & 7/16” Socket

b. 3/16” T-Handle Hex Driver

If any items are missing please

contact PTM Document Systems

before continuing.

Figure 1: Upper Fold Plate

Figure 2: Lower Fold Plate

Figure 3: ENDEAVOUR

4

Setup

Warning: Do not attempt to remove the equipment from the packaging

alone. Two people are required at all times to move the equipment.

Place the ENDEAVOUR on a sturdy table or cart. Check to verify that both

fold plates are properly installed [see Figures 4 & 5]. Both fold plates should

rest snugly on the placement pins.

Figure 4: Upper Fold Plate in

Proper Position

Figure 5: Lower Fold Plate in

Proper Position

Insert the power cord into the ENDEAVOUR first, and then into a standard

115V AC 60 Hz outlet.

The power cord must be accessible for disconnect.

5

ENDEAVOUR Overview

ENDEAVOUR Diagram

Figure 6: ENDEAVOUR Diagram

Capabilities

Your ENDEAVOUR is designed from the ground up to be a versatile

folding and sealing ENDEAVOUR. Its capabilities include:

Folding plain paper and forms from 20 lb paper to 80 lb stock.

Folding all standard fold patterns [see Table 1].

Single fold capability: when the bottom fold plate is in the half fold

position, the upper fold plate can be set to lengths other than the

standard V Fold depending on your special needs.

Feed Tabl

e

Feed Gauge

Cover

Lower Fold

Plat

e

Catch Tray

Control Panel

Switch

On / Off

Paper Guides

Upper Fold

Plate

Reverse

Electrical

Panel

6

ENDEAVOUR Operation

Identifying Your Fold

1. Identify your paper size. 11” forms are the standard letter size; 14”

forms are the standard legal size. Measure the form if necessary.

2. Identify the fold shape from Table 1. Note that ECC Z (EZ) Folds are a

similar shape as the standard Z Fold, but the lengths of the folds are

not equal.

C Fold Z Fold EZ Fold V Fold

Table 1: Fold Types

Feed Table Setup

Setting the Paper Guide Width

Figure 7: Feed Table Diagram

To set the width of the Feed Table Paper Guides [see Figure 9]:

Thumbscrews (4) Power Switch

(by power plug)

Breaker

7

1. Loosen the red Paper Guide adjustment knobs. Don’t fully remove

them. 1-2 turns clockwise will loosen them.

2. Place a ½” stack of the form to be run on the feed table.

3. Line the paper stack up against the stationery paper guide.

4. Push the moveable paper guide up against the paper stack so that all

the paper is aligned and the paper guide is snug against the side of the

stack.

5. Hold the moveable guide in place with one hand and tighten the

adjustment knobs with the other.

Setting the Feed Gauge

Figure 8: Feed Gauge Cross Section View

To properly set the Feed Gauge System [see Figure 8]:

Make sure that the power switch is in the Off position.

1. Remove all paper from the feed table.

Feed Gauge

Adjustment Screw

Move Feed Belt In This Direction With

Y

ou

r H

a

n

d

T

o

F

eed

Th

e

F

o

rm In.

Feed Gauge

Roll

(Sampl

e

Form)

Feed Belt

8

2. Insert the provided 3/16” T-Handle Hex Driver into Feed Gauge

Adjustment Screw.

3. Turn the T-Handle Hex Driver ¼ turn clockwise to loosen the Feed

Gauge Roll.

4. Place one form on the feed table and hand feed the form about 2

inches into the ENDEAVOUR by moving the feed belt with your hand.

5. Turn the T-Handle Hex Driver ¼ turn counter-clockwise.

6. Pull the paper out of the machine. You should feel resistance, but not

too much. Repeat Steps 4-6 until there is a moderate amount of

resistance when pulling the form out. If it feels too tight, turn the T-

Handle Hex Driver ¼ turn clockwise.

7. Return the T-Handle Hex Driver to the toolkit.

Loading the Feed Table

Before loading the feed table, square up the stack of paper you are going to

load by placing it on edge on a flat surface. Place the stack onto the table

so that the front of the stack butts up against the feed gauge cover [do not

push hard].

The proper orientation of the paper when loaded onto the feed table

depends on the type of fold you are using and the layout of your form.

Table 2 shows the order in which folds will be performed when run through

the machine with the right hand paper edge being loaded into the machine

first (red arrow shows paper path).

All forms should be loaded with glue on the leading edge facing up (the

glue is usually visible as yellow, blue or red stripes around the edge of the

form). With Z& EZ Folds you have multiple ways to load the form and still

have glue on the leading edge facing up, either one will work. With EZ

Folds, though, care must be taken to ensure that the upper fold plate is set

to the proper length for the leading fold (the bottom fold plate setting

remains the same either way).

Feed Table Capacities

11” Forms: 150 Sheets

14” Forms: 100 Sheets

9

C Folds

Z Fold

EZ Folds

V Folds

C Folds Table 2: Paper Loading & Fold Order

Setting the Fold Plates

To set a fold plate:

1. Remove the fold plate from the machine.

2. Loosen the thumb screws by turning counter-clockwise

3. Line up the tips on both sides of the paper stop with the appropriate

line on the scale so that the appropriate white line on the scale is just

visible [see Figure 9].

a. If you are doing a V Fold, you do not have to set the paper

stop on the Lower Fold Plate.

4. Make sure that the paper stop is setup square by double-checking that

the scales on both sides show the same fold selected or the same inch

reading.

1

2

2

1

1

10

5. Tighten the thumb screws, being careful that the paper stop does not

slide out of square.

6. Return the Fold Plate to the machine, making sure that it is resting

properly on the placement pins [see Setup Procedure].

a. If you are using a V Fold, replace the Lower Fold Plate

backwards, so that the flat face is facing in and the slot is

facing out.

Figure 9: Paper Stop Alignment

For a custom form, the fold plate scales measure distance in inches from

the fold, so the paper stop can be set to the appropriate measurement. If

you are unclear about the figures to use, you can measure the lengths of

the folds on your form (the distance from the perforations or fold marks to

the edge of the paper) or contact your form supplier for more information.

Fold Plates

The ENDEAVOUR is equipped with adjustable fold plates. The red thumb

screws can be loosened to allow you to move the paper stop to the correct

position for your form and then tightened to hold the stop in place. All

standard folds are marked on the scales of both the upper and lower fold

plates. Set both fold plates to the desired setting (i.e. 11” Z) in order to

perform that fold. See ENDEAVOUR Operation for more information.

Paper Stop Indicator

Point

11

Maintenance

Regular maintenance on the ENDEAVOUR will ensure that it continues to

function properly and will extend the life of the ENDEAVOUR. Perform the

following steps every 10,000 forms or once a month:

1. Disconnect the power cord from the ENDEAVOUR.

2. Remove both fold plates.

3. Vacuum any paper dust or toner that has accumulated on the feed

table and on the rollers.

Make sure that the power cord has been disconnected before

continuing!

4. Open the access panel in the side cover opposite the control panel.

5. Insert the 7/16” socket at the end of the breaker bar over the hex

shaped end on the #3 roller. This bar can now be used to rotate the

rollers.

6. Clean the stainless steel rollers with a household cleaner such as

Oops in order to remove any accumulated toner. As you clean, use the

breaker bar to rotate the rollers so that the entire roller surface is

cleaned.

7. Clean the rubber rollers and the feed belts using a rubber roll

rejuvenator [available at your local office supply store]. Use the

breaker bar to rotate the rolls and feed belt as you clean so that all the

rubber surfaces are cleaned.

8. Return the breaker bar to the tool kit and replace the access panel.

9. Replace the fold plates.

10. Make sure that the power switch is in the Off position.

11. Connect the power cord to the ENDEAVOUR.

12

Troubleshooting

Automatically Clearing a Paper Jam

If paper becomes jammed in the ENDEAVOUR:

1. Remove all paper from the Feed Table.

2. If the Power Switch Breaker has tripped (light is off) then flip into the

on (lighted) position.

3. Remove the Lower Fold Plate.

4. Press the Reverse button.

5. The paper should exit from the back (where the Lower Fold Plate

normally sits). If it does not, try pressing the Reverse button again. If

the paper is not moving or you cannot see it, then you need to

manually clear the jam [see next section].

6. Replace the Lower Fold Plate.

Manually Clearing a Paper Jam

1. Disconnect the power cord from the ENDEAVOUR.

Make sure that the power cord has been disconnected before

continuing!

2. Remove all paper from the Feed Table.

3. Remove the Lower Fold Plate from the ENDEAVOUR.

4. Remove the access panel in the side cover.

5. Place the Breaker Bar socket over the hex end of the #3.

6. Rotate the breaker bar clockwise until the jammed form is out of the

ENDEAVOUR.

7. Replace the Lower Fold Plate.

8. Replace the paper on the Feed Table.

9. Return the breaker bar to the toolkit.

10. Replace the side cover access panel.

11. Make sure that the power switch is in the Off position.

12. Connect the power cord to the ENDEAVOUR.

13

Diagnosing the Paper Jam

Table 3 outlines the different problems that cause paper jams and the

symptoms that will help you to identify the cause.

Problem Double Feed Buckled Form Bad Fold

Symptom Unfold the form

that caused the

jam, you will find

that it is actually

two forms folded

together.

There will be an

extra fold in form

near the correct

fold location.

The form which

caused the jam

will be folded

crooked.

Causes • Bad Feed

Gauge Setting

• Too much

paper on the

feed table

• Wrong fold

plate setting • Feed Table

Paper Guide

set improperly

• Fold Plates

set improperly

Solution

• ¼ Turn CCW

on feed gauge

adjust screw

• Check both fold

plates. Make

sure they are

set to the

correct mark on

the scale.

• Check both

fold plates.

Make sure

that both

paper stops

are square.

Table 3: Paper Jam Diagnostics

Misaligned Folds

If your forms are running through the machine OK but they’re folding a little

bit crooked or are not folding right on the perforation, you need to adjust the

fold plate settings. The location of perforations on forms may fluctuates by

as much as 1/16” in either direction. Because of this fluctuation, it is

sometimes necessary to fine tune the placement of the paper stop on one

of the fold plates.

The first step is to identify which fold plate is misaligned. Watch the form as

it is fed into the machine, and then compare it to the finished form. If you’re

having trouble visualizing which fold is off, refer to the section Loading the

Feed Table above.

Once you’ve identified which fold plate needs to be adjusted, remove it

from the ENDEAVOUR. If the fold is crooked, check to make sure that the

paper stop is parallel to the front edge of the fold plate. Check that the

indicator points on the paper stop indicate the same reading on the two

scales of the fold plate. Also check the feed table to make sure that paper

guides are snug against the paper stack. If the fold is just a bit off of the

perforation, adjust the paper stop by the amount that the fold is off. If the

14

fold is above the perforation, then move the paper stop away from the open

end of the fold plate. If the fold is below the perforation, then move the

paper stop towards the open end of the fold plate.

Paper Feed Problems

Double Feeds

If you’re having problems with two forms feeding at once:

1. Turn the Feed Gauge Adjustment Screw [see Figure 8] ¼ turn

counter-clockwise.

2. Try running the forms again.

3. If the problem persists:

a. Try another ¼ turn on the Feed Gauge Adjustment Screw.

b. Try reducing the size of the paper stack on the Feed Table.

c. Try resetting the Feed Gauge.

Won’t Feed

If the ENDEAVOUR won’t feed forms through:

1. Try reducing the size of the paper stack on the Feed Table.

2. Try resetting the Feed Gauge.

ENDEAVOUR Won’t Run

If the ENDEAVOUR won’t run when the On-Off switch is operated:

1. Check that the ENDEAVOUR Power Switch Breaker, located by the

power plug, is not in the tripped (out) position. If it is, press it in. If the

breaker button will not stay pressed in, wait a minute and try again.

2. Check that the Access Panel on the side cover opposite the control

panel is properly in place.

3. Make sure the power switch by the power cord is in the On position.

4. Double-check that the power cord is properly connected to the machine

and an appropriate socket [see Setup].

5. Check that the wall socket which the machine is connected to is

functioning properly.

15

16

Sales (866) 667-2861

Service (800) 504-4102

Table of contents

Other PTM Folding Machine manuals