Puhui HH-G01 User manual

USER MANUAL OF ENGRAVING MACHINE

双头雕刻机使用说明书

This user manual is applied to HH-G01

目录 CONTENTS

1.重要事项 IMPORTANT NOTICE

2.技术参数 TECHNICAL PARAMETERS

3.功能介绍 FUNCTION INTRODUCTION

4.安装说明 QUICK SET UP INTRODUCTION

5.操作说明 OPERATING INSTRUCTION

6.设备保养 EQUIPMENT MAINTENANCE

1. 重要事项 IMPORTANT NOTICE

在使用雕刻机前,请认真阅读该使用说明。

Read these instructions BEFORE operating the machine.There are a few things that must be done before

connecting the machine to any power source.

该设备需要连接无油无水的气源,建议使用无油静音空压机。若您现有的空压机不是无油设备,请在连接雕刻机前加装油水

过滤装置。

This machine requires clean, dry, oil-free air. We suggest using an oil free compressor. If your compressor is an oil

type, you MUST have an oil removal filter (coalescing type) in the air supply line to this machine. If you are unsure of

this requirement, please contact your salesman.

2. 技术参数 TECHNICAL PARAMETERS

3. 功能介绍 FUNCTION INTRODUCTION

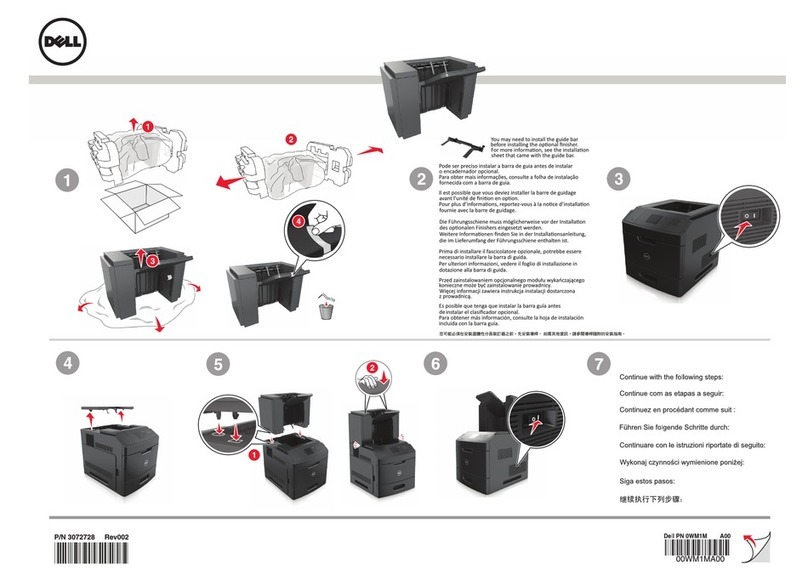

pic.1

1. 气压表 Air pressure gauge

2. BIAS 旋钮 BIAS control knob

3. 工作气压调节旋钮 Air pressure control knob

4. 电源开关 Power On/Off button

5. 雕刻手柄切换旋钮 Handpiece selector knob for 8 and 9

6. 雕刻手柄调速旋钮 Strokes per minute selector knob

7. 辅助压力调节旋钮 Auxiliary air open/close knob for 10

8. 雕刻手柄快速接口Ⅰ Handpiece quick connect fittings Ⅰ

9. 雕刻手柄快速接口Ⅱ Handpiece quick connect fittings Ⅱ

10. 辅助压力快速接口 Auxiliary air quick connect fitting

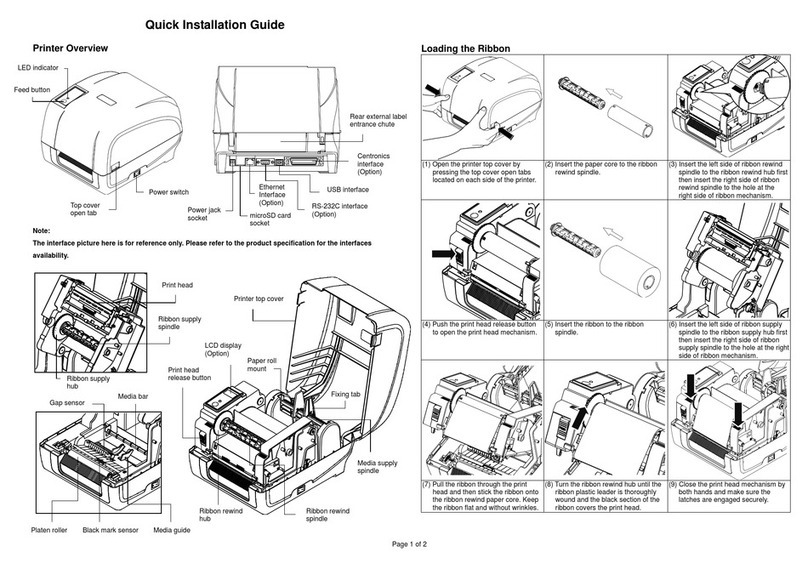

pic.2

11. 过滤气源输入快速接口 Air input quick connect fitting

12. 脚踏开关快速接口 Foot throllte quick connect fitting

13. 电源输入插头 Power connect

14. 保险丝 Fuse

pic.3

15. 气源过滤器固定螺丝 Screw

16. 气源过滤器 Air filter

17. 外部气源输入快速接口 Air filter input quick connect fitting

18. 过滤气源输出快速接口 Air filter output quick connet fitting

pic-4

19. HH-GHP01 雕刻工作手柄 1号Engraving handpiece Ⅰ

20. 装刀夹头 Quick change chuck

21. HH-GHP02 雕刻工作手柄 2号Engraving handpiece Ⅱ

pic-5

22. 气动脚踏开关 Foot throttle

4. 安装说明 QUICK SET UP INTRODUCTION

4.1 外部气源输入须知 AIR SUPPLY REQUIREMENTS

雕刻机需要连接 40 升/分钟 ,8KG 无油无水空压机, 若现有的不是无油无水空压机,请在接入雕刻机前安装油水过滤器。

Engraving machine HH-G01 requires 1.4 CFM(40 liters/min.) at minimum 45 psi(3.1 bar). Maximum input is 125psi(8.6

bar). We encourage reducing the air pressusre from a regulator to 45~60psi (3.1~4.1bar) as this ensures a stable air

pressure supply. The compressed air must be clean, dry ,and oil free. The filter supplied with each unit is a final filter

and is not capable of removing large amounts of water, oil, or contaminants.

气源在没有去油去水状态下接入,将会损坏雕刻机。

If the air supply has excessive water, oil, or contaminants, and additional filter/water trap and coalescing oil removal

filter must be installed ahead of the unit. Oil or water contamination will damage engraving machine.

4.2 气源过滤器的安装 INITINAL SETUP

请将原机配套的气源过滤器安装在设备的右侧 (pic.3 图),将外部气源输入管接入接口 17,原机配有的黑色软管连接接口 18

和接口 11。(pic.2 图,pic.3 图)

Decide where you want to place the machine on your bench and where you would like the air filter located. Make its

location readily accessible so it is easy to drain water from the bowl daily. You may attach the air filter to your

machine, workbench, or wherever you desire. Here we show it attached to the back right side of the machine. Remove

the screw at this location and place the screw through the key hole opening in the filter bracket. Tighten the screw to

secure bracket. The bottom screw in the bracket will position into the slot to keep the filter from twisting.( pic.3 )

If push-to-connect fittings are new to you, they are amazing with the air pressure TURNED OFF, simply insert the hose

all the way into the fitting opening - it stays attached. To disconnect , press in on the white ring while gently pullin the

hose out.

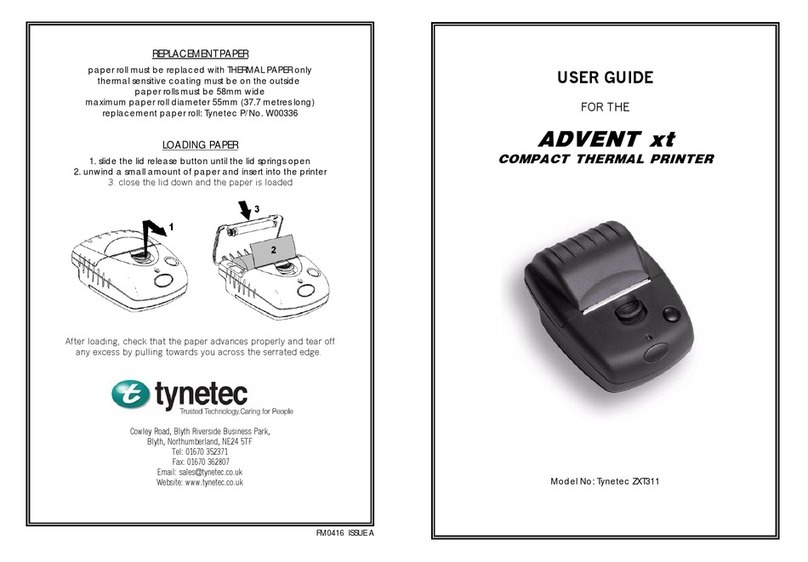

4.3 脚踏开关的安装 CONNECT FOOT THROTTLE

请将原机配套的脚踏开关连接到机身后侧的标有脚踏图标的接口 12(pic.2 图),确保软管已良好的接入接口 12,开机工作

后不会漏气。

Place the foot throttle on the floor in a convenient position. Run the hose to the back of the machine. If you need to

snake the hose through an opening on your bench, make sure the hose is not pinched or kinked. Connect the hose

from the foot throttle to the push-to-connect fitting above the label marked THROTTLE CONNECTION.

NOTE: It is normal to hear air leaking when you depress the foot throttle, this is what activates the handpiece.

4.4 雕刻工作手柄安装 CONNECT HANDPIECE

雕刻机有两个雕刻手柄接口,即接口 8和接口 9(pic.1 图),将原机配有的两个雕刻手柄接入,可通过旋钮 5(pic.1 图)

切换选择需使用的手柄。 将您所需的气动工作手柄(如钉砂手柄,打磨手柄等,需另外购买)接入接口 10(pic.1 图),可通过

旋钮 7(pic.1 图)调节所需的工作气流量,逆时针方向为调大气流量,反之即调小气流量。

There are two fitting to attach impact handpieces. Decide which handpieces you want in postions 1 and 2. Connect

the handpiece hose to the push-to-connect fitting simply by pushing the hose inside the white ring receiver. A

selector knob above the connections lets you select which impact handpiece you want to use, 1 or 2.

NOTE: Make sure selector knob is turend until it stops, either direction.

Auxiliary outlet is a straight flow air supply that is limited to 40psi(2.7 bar). The knob is a twist-open/twist-close valve.

(pic.1)This is where you connect a Rotary Handpiece or other pneumatic tool.

5. 操作说明 OPERATING INSTRUCTION

5.1 雕刻机的调试 HOW TO TUNE ENGRAVING MACHINE HH-G01

接通空压机电源,等待气罐充满,停止工作后,接通雕刻机电源,将工作手柄调速旋钮 6(pic.1 图)调至 23 处,工作气

压调节旋钮 3(pic.1 图)调至 5psi 处,在不踩脚踏的情况下,逐步增加气压到雕刻手柄不出现震动状态后,就可通过脚踏开关

操作控制手柄所需雕刻力度。

By tuning your machine, we mean adjusting the strokes per minute and air pressure for minute and air pressure for

optimum performance. TUNING YOUR MACHINE PROPERLY IS THE SINGLE MOST IMPORTANT OPERATION YOU

SHOULD LEARN.

1. Turn on your air compressor and allow the tank to fill. Wait for the compressor to cycle off and stop running.

2. Turn on the Engraving machine HH-G01 and set the stroke per minute dial at 2300. Using the pressure control knob

on the front of the machine, back the air pressure down to 2 to 5 psi(0.1 to 0.4 bar).

3. Hold the handpiece you have selected to use with the tool holder end up (vertically) next to your ear.

4. Without depressing the foot throttle , SLOWLY increase the air pressure until the handpiece will vibrate , and more

air pressure will make it knock. Slowly add air pressure and when the knocking barely stops, this is considered the

perfect air pressure operating range for that particular handpice.

5.2 脚踏开关的使用 HOW TO USE THE FOOT THROTTLE

原机配套的脚踏开关不同于普通的脚踏开关,它可通过脚踩的角度调节工作时候所需的雕刻力度,当您需要雕刻比较深的花纹

时,可将增加脚踩的角度,增加雕刻力度。 反之,即减少雕刻力度。

The engraving machine HH-G01 foot throttle is operated like an automobile accelerator and NOT like a flexible-shaft

foot control. Begin by placing your foot on the top plate with your heel even with the bottom of the top plate.You

should put the tool in position BEFORE depressing the foot throttle. Never depress the foot throttle and then try to

bring a stroking handpiece to the work! If you need more power when cutting deeper, push more on the foot throttle

to increase the handpiece power. You will soon learn to coordinate your foot action with the need for more power as

you work. A beginner will push the foot throttle down a set amount and try to do the rest by pushing the handpiece

harder, while never changing foot position. This is incorrect and not a safe way to use a handpiece. At the start of the

cut , increase power in a smooth fashion. If you need more power, press more with your foot. As the cut tapers to the

end, reduce the foot pressure gradually as your hand tilts the graver up and out. With a little practice , this hand/foot

coordination will become as natural as driving a car.

5.3 BIAS 旋钮的使用 HOW TO UESE THE BIAS CONTROL

可通过逆时针调节 BAIS 旋钮,减少脚踏开关的脚踩角度达到雕刻的效果,同时您需要的一些雕刻工作(如点刻法),可通

过调节 BAIS 旋钮,在不需踩脚踏开关的情况下,就可以达到连续雕刻的效果。

After you tune the handpiece , notice that the handpiece starts working as you press down on the foot throttle. Add

one or two pounds of air pressure control knob. Now, open the bias control by turning it counter-clockwise and

notice that it does not take as much pressure on the foot throttle to activate the handpiece . The bias control allows

you to adjust the foot throttle action so you can predict the moment the handpiece will start, giving you optimum

handpiece control. This is a feature that one would use for fine detail work such as bulino or shading. By opening the

bias control fully, you will find that the handpiece will start to work without pressing on the foot throttle. You may find

this function useful for some operations such as stippling .

6. 设备保养 EQUIPMENT MAINTENANCE

6.1 雕刻手柄的清洁 KEEPING THE HANDPIECE CLEAN

当您使用手柄一段时间后,发现手柄力度不够,可将手柄的螺丝旋开, 取出手柄中的弹簧和小圆条,用软质不掉屑的纸或布将

其清洁,同时也将手柄内径清洁,完成后即可装回。

The impact handpiece must be kept clean for proper operation. If operation becomes sluggish , erratic , or fails,

cleaning is needed.Remove the piston and spring from the handpiece . Take each , one at a time, and place in a sheet

of wrting or copier paper. Do not use a paper towel , tissue, or newsprint. Holding it between your fingers buff and

polish of any dirt or residue. Folding the paper, use the edge to clean between the piston grooves and the space

between the spring. To clean the handpiece inside , take the writing or copier paper and twist it to a point. Insert the

paper point into the handpiece and rotate paper and handpiece against each other. This will buff and polish the inside

and clean. IMPORTANT NOTE: DO NOT LUBRICATE PISTON, SPRING, OR BORE.

6.2 脚踏开关的保养 FOOT THROTTLE

在使用脚踏开关工作时,应尽可能的保证地板的干净,以免杂质进入脚踏开关,造成其损伤。当停止工作后,请将脚踏开关放

在工作台或工作椅上。

The throttle should require little maintenance, It should be cleaned periodically. OILING: Periodically, place a drop of

oil on the throttle hinges. Keep the floor clean. When you sweep or vacuum, place foot throttle on your bench or chair.

6.3 气源配件的保养 AIR SYSTEM

在您使用雕刻机一段时间后,您应该气源过滤器 16(pic.3 图)里的水清洁赶紧,只需将气源过滤器底部的针头往上按住即可。

也应将雕刻机底部的一个内六角机米螺丝旋开,让水排干净后,再锁上螺丝即可。

If large amounts of water and contaminants are in the air supply to the unit , more frequent attention must be given

to the unit filter. The bowl must be drained frequently to prevent water from entering the rotary valve,hoses,handpiece,

etc. In addtion, the filter element must be cleaned and/or replaced frequently. If moisture is noted in the handpiece or

throttle hoses, shut the unit down immediately and drain the filter bowl.

Then proceed as follows:

6.3.1 Disassemble and clean impact handpiece(s) and reassemble.

6.3.2 Reduce pressure setting to 10 psi and turn unit ON to purge mositure form valves,hoses,etc.

6.3.3 Located on the lower back of the machine is the drain plug to the internal air reservoir. Using a hex wrench,

remove the plug and drain any mositure from reservoir. Replace drain plug.Bfore using machine again,figure out

where the mositure came from and fix the problem. It may require an addtional filter(s) or water trap in the line.

感谢您使用我们的雕刻设备!

THANKS FOR USEING OUR ENGRAVING MACHINE HH-G01 !

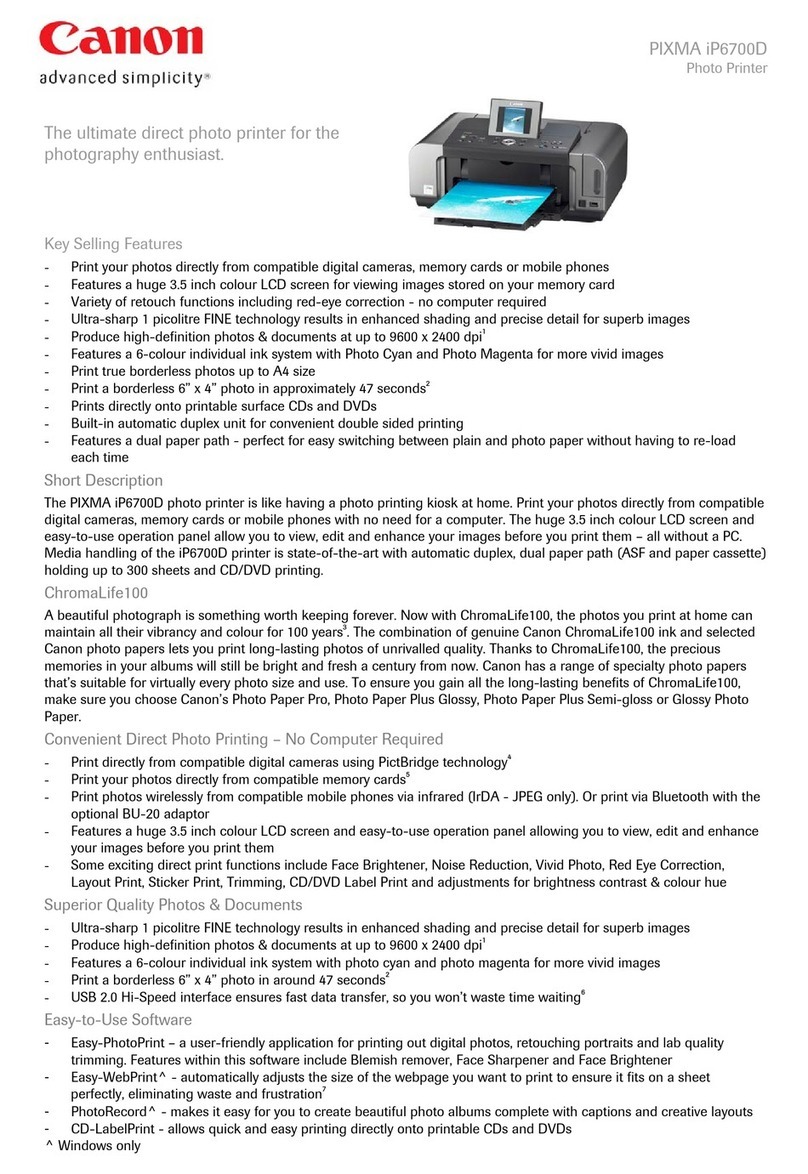

Table of contents

Popular Printer manuals by other brands

Samsung

Samsung SRP-350 Bixolon Operator's manual

Magicard

Magicard Prima 2e instruction manual

Canon

Canon PIXMA MP150 Installation/troubleshooting

Samsung

Samsung CLP-315 - CLP 315 Color Laser Printer manual

Philips

Philips CRYSTAL 660 - NETWORK Installation guidelines

Macherey-Nagel

Macherey-Nagel NANOCOLOR UV/VIS II user manual