pullman Ermator HTC 26D User manual

1

Revision 3

7

Revision 3

DECLARATION

EG-deklaration om överensstämmelse

EU-declaration of conformit

Tillverkare

Manufacturer

Pullman-Ermator AB

Industrivägen 10

777 91 Smedjebacken

Sverige/Sweden

Produktbeteckning/

Product designation

Stoftavskiljare type HTC 26D och HTC 26D/110V.

Dust extractor type HTC 26D and HTC 26D/110V.

EU-riktlinjer

EU-guidelines

Produkten i fråga överensstämmer med följande EU-riktlinje:

The product in question conforms to the following EU-guidelines:

Maskindirektivet

Machinery directive…………………. 89/392/EEC

EMC-direktivet

EMC-directive…………………... 89/336/EEC, tillägg: 93/68/ECC

LVD-direktivet

LVD-directive…………………... 73/23/ECC, tillägg: 93/68/ECC

Överensstämmelse med dessa riktlinjer dokumenteras genom att följande

standarder tillfredsställs:

Conformity with these guidelines is documented through compliance with the following standards:

Harmoniserade europastandarder

Harmonized European standards EN291-2, EN292-2,

tillägg/annex: EN60335-2-2 ed 3

Nationella standarden

National standards EMCO-TUB(61),NO 202/92

Pullman-Ermator AB

Torbjörn Begntsson

General Manager

8

Revision 3

Introduction

Dear Customer,.

We thank you for choosing HTC Sweden AB as your supplier.

We hope that the vacuume cleaner of model HTC 26D will be to your satisfaction and meet

your expectations.

We have chosen Pullman-Ermator AB as the manufacture of our product. They have been a

manufacture of professional dust extractor since 1967 and have thru the years built up a know

how in this area.

You can always contact us to get information about our product program and Pullman-

Ermator by visit

www.htc-sweden.com or www.pullman-ermator.se .

Notice!

This instruction cover only the vacuum cleaner type HTC 26D.

The vacuum cleaner, HTC 26D can only be used for dry, non explosive material.

If the vacuum cleaner is used for other applications or been used in other ways than

explained in this instruction book, Pullman-Ermator AB will not take any responsibility.

Before using the machine, please carefully read the safety regulations.

Read the complete instruction book before using the vacuum cleaner.

All spare part used for the vacuum cleaner type HTC 26D must be recognized by

Pullman-Ermator

9

Revision 3

Un packing

When unpacking the machine, please check that the vacuum cleaner, hoses and accessories do not have any

transportation damages.

Safety Instructions

Handling

Warning

•Cables damaged through crunching or cracking can be dangerous if used and should be

replaced immediately. Risk of personal injury.

Warning

•Do not connect the machine to an unearthed socket. Risk of personal injury.

Warning

•Make sure the assembly area is firm, so the vacuum cleaner do not tip over. Risk of

personal and material injury.

•

Warning

•Risk for pinch injuries when handling the toggle fastener.

Warning

•The machine must not be use in environments where explosive gases can occur. Large

risk for explosions.

Service

Warning

•Remove the plug from the wall socket when carrying out maintenance work. Risk of

personal injury.

Warning

•Health impairing dust can be spread when the coarse filter and the absolute filter are

replaced. Accordingly, the user should wear protective glasses, protective gloves, and

a breathing mask conforming to protection class FFP3

Warning

•Do not puncture the absolute filer. Risk for dust dispersion.

10

Revision 3

Handling

The machine is for sucking and separating dry, not combustive dust with limit value of

explosion >

>>

>0.1mg/m

3

.

The motor is started by the switch. Dust laden air is then sucked through the inlet valve at

high speed via the suction hose. The air is slowed down by the cyclone and coarse dust

particles are separated out, partly by centrifugal force and partly by gravity. Air and finer

particles then pass through the tube filter where separation is made. The machine is designed

for filter cleaning by reverse air pulse.

The separated dust accumulates in the cyclone until the machine is switched off, when it drops

through the bottom flap into the plastic bag.

Using

Before using must the user be educated in handling the vacuum cleaner and the hazardous

dust.

The machine must be in top position. Place one foot on the trolley. Lift the whole tank-section

upwards along the 2 guides to the extremity, which means above the top and down to the end

position.

Connect the electric plug to an outlet with correct voltage (see the designation plate).

From time to time the filter must be cleaned. This must be done before changing the plastic

bag. Even appropriate when the working is completed or when there is poor suction.

Procedure: Cover the inlet, let the machine build up vacuum for a few seconds then quickly

push down on the key and release it slowly. Repeat the procedures 5-10 times. If suction

remains poor, the filter should be replaced.

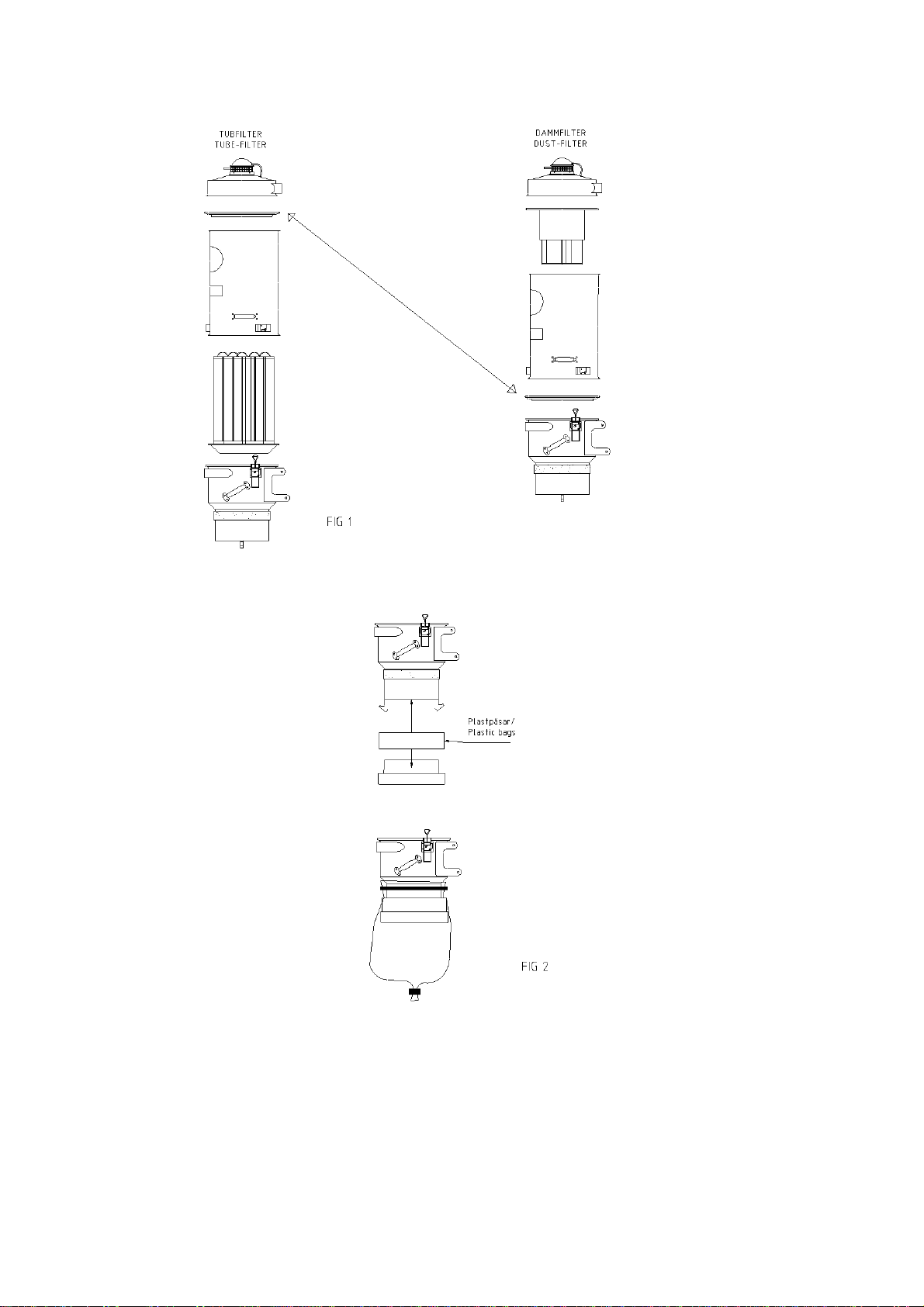

The machine is equipped with a plastic bag of longopack type. When the bag is filled up

change of bag is done by adding a stripes on the plastic bag. Add one more stripes and cut the

bag in between. Adjust the size of bag by pulling down the plastic tube. Change of bag should

only be done after cleaning the filter. Changing the complete longopack is shown in figure 2.

Only use original parts.

By transporting the tank-section must be lowered to the lowest position (security). First clean

the filter and then change the plastic bag. Lowering is performed according to raising.

Change of filter

Risk of dust dispersion - Personal safety equipment

Health impairing dust can be spread during change of filter. Accordingly, the user should wear

protective glasses, protective gloves, and a breathing mask conforming to protection class

FFP3.

Shut off the machine and pull the plug out of the socket.

11

Revision 3

TUBE-FILTER

Loosen the 3 clamps between the upper and lower housing. Lift out the filter and holder and

place it gently on a table. Remove all hose clamps and then remove all (7 pcs) filters.

Insert new filters in reversed order. Tighten the clamps hard.

Only original filter may be used. Se part 6.

MICRO FILTER

Loosen the two nuts on the filter cap., and then carefully lift the filter in a proper plastic bag.

This bag must be taken care of in a proper way. Insert a new filter in reversed order. Check the

sealing, when changing filters, and change defect sealing.

DUSTFILTER

When using dust filter D2800C, perform as follows (see fig 1):

•Loosen the three clamps on the tank and remove the top cover.

•Lift off the ring including sealing.

•Lift off the upper vessel.

•Lift off the tube-filter and replace it with the mentioned ring.

•Reassemble the upper vessel.

•Place the dust filter D2800C between upper vessel and the top cover.

•Tighten the top cover with the three clamps.

Service

When cleaning and servicing the machine, You must switch off the machine and pull out the

plug from the outlet.

•Avoid cleaning with high pressure cleaner. If necessary do not point at the openings on the

machine, especially the opening for the cooling air.

•Before moving the machine from the working area, the machine must be cleaned.

Furthermore must the inlet be locked with the expanding plug attached.

•All other equipment must be regarded contaminated and be treated thereafter.

•If possible use a special suitable room.

•Proper personnel protective equipment must be used.

•All parts after service, which are contaminated, must be taken core of in a proper way in

plastic bags according to all regulations.

•If the vacuum cleaner has to be used for other purposes, it is extremely important that the

vacuum cleaner will be cleaned, to avoid spreading of hazardous dust.

Accessories

PART.NO. DESCRIPTION

1337022 333 C-Polyestrefilter

1337043 336 Cellulose filter

1337055 2800 Filter tube

200700070 HEPA-filter

1220046 Dustfilter complete

1376013 Longopack (4-pack)

Other spare parts, see enclosed spare parts list.

12

Revision 3

Warranty

All Vacuum cleaners and accessories have a 12-month factory warranty for material and

manufacturing defects. Do not attempt to repair the suction apparatus without the consent of

the manufacture.

The warranty does not cover defects which are the result of normal wear and tear, negligence,

defective use, unauthorised repair or the suction apparatus being connected to the incorrect

voltage.

In the event of any complaint, the suction apparatus or an agreed part of it must be returned to

us or our authorised representative for warranty examination and for any warranty repair or

replacement.

Problem solving

HTC 26D are manufactured and made for a severe environment and tasks, but the user must

notice that the machine contents of components which must be protected from hits and blows.

Filter, sealing connections are carefully chosen for the environment of the operator. Therefore

must the machine be treated with knowledge as to work correctly for many years.

Problem Cause Procedure

Motor don’t start No current Connect the machine

Defect switch Change

Motor stops immediately Wrong fuse Connect to proper fuse

Motor runs, but no suction Hose not connected Connect the hose

Hose blocked Clean the hose

No plastic bag Mount plastic bag

Motor runs, but poor suction Damage on the hose Change hose

Blocked filter Change filter

Top cover loose Adjust

Dirt in the flap Clean the flap.

Use protective equipment

Defect sealing Change current sealing

Dust is blowing from motor Defect or loose filter Adjust or change

Abnormal noise Order service

SAVE THESE INSTRUCTIONS!

13

Revision 3

TEKNISKA DATA

TECHNICAL PERFORMANCE

HTC 26 D

230V 110V

MÄRKSPÄNNING 230 VAC, 12 A, 1-fas 110 VAC, 24 A, 1-fas

Voltage

EFFEKTUTTAG max 2600 W (2x1300) 2400 W (2x1200)

Power, max

MAX LUFTMÄNGD 124 l/s

Airflow

MAX UNDERTRYCK 22 kPa

Vacuum

SUGSLANG 7.5 m x ∅50 mm

Hose

INLOPPSRÖR ∅50 mm

Inlet

TUBFILTER Polyester

Tube filters 0.15 m

2

(7x)

FINFILTER 99.95%

Fine filter

1.7 m

2

MIKROFILTER 99.995%

Micro filter 2.4 m

2

(2x1.2 m

2

)

LJUDNIVÅ 70 dB(A)

Sound level

DIMENSION HXBXL 1130(1430)x550x820 mm

Dimensions

VIKT 50 kg

Weight

14

Revision 3

Fig. 1 Byte av filter typ.

Figure 1 Change of filter type.

Fig 2. Byte av Longopack påse

Figure 2. Change of longopack.

17

Revision 3

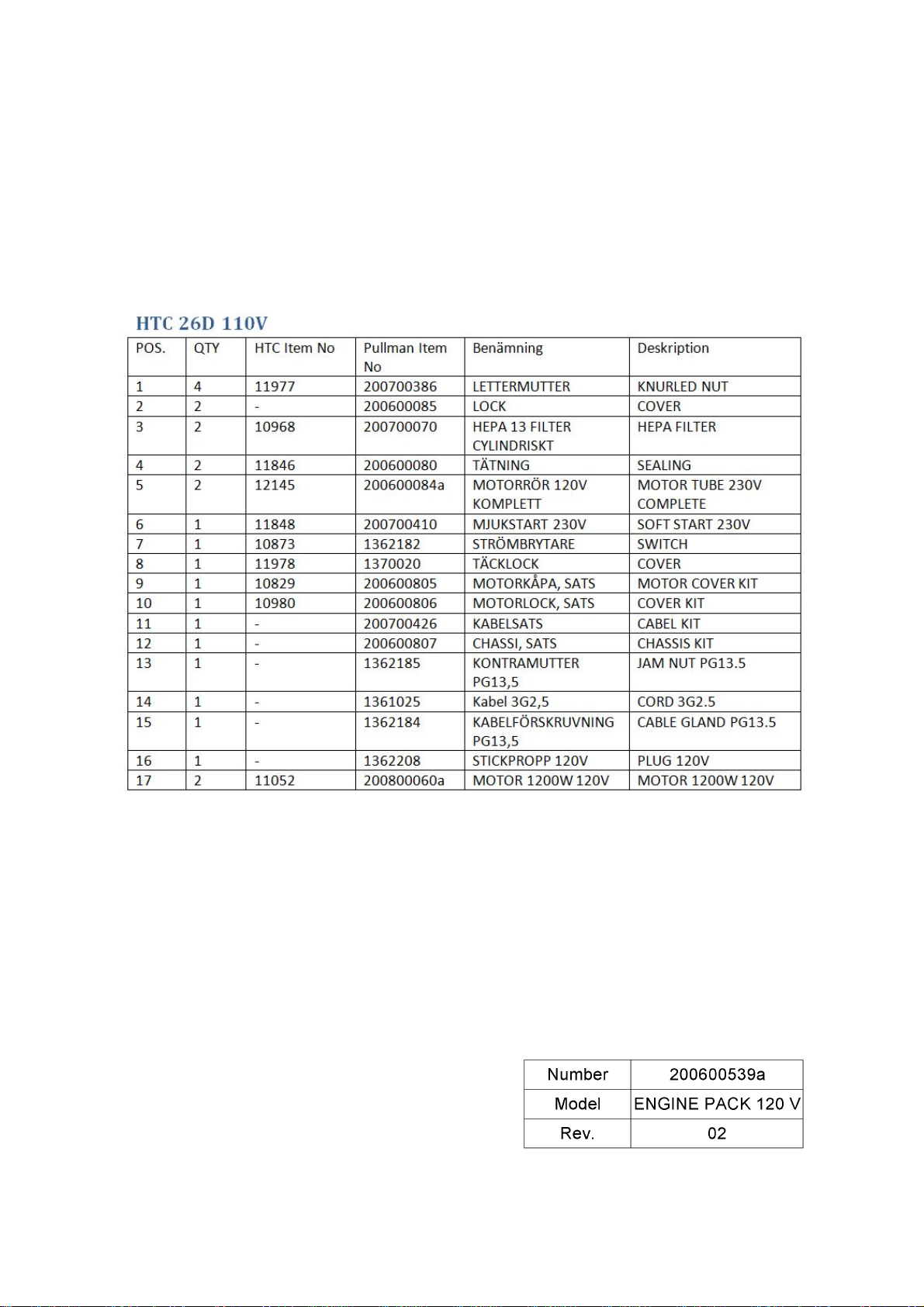

Reservdelar för 120 V modell.

Spareparts for 120 V model.

18

Revision 3

Reservdelar för 120 V modell.

Spareparts for 120 V model.

Pos.

Qty

HTC26D 110V

Description

1 1 200600127 Clean unit

2 1 200600812a Tank top complete

3 1 1351197 Seal

4 1 200500230 Ring

5 1 200600811 Tank complete

6 4 200600819 Handle kit

7 3 200600820 Mount kit

8 7 200600817 Tube filter

9 1 200600813 Filter package complete

10 3 200600606 Excentric lock kit

11 1 200600810 Lower tank complete

12 2 200600654 Clamp kit

13 1 200500172 Flap complete

14 1 200500162 Sheet fastener

15 1 1371001 Belt

16 1 1351145 Anti skid

17 1 1376013 Longopac 4-pcs

18 1 200600536 Longopac holder

19 2 200600797 Wheel kit

20 4 200600821 Slide kit

21 1 200600053a Guide

22 1 200600053 Guide

23 1 200600822 Wagon kit

24 2x0,9 1332037 Hose

25 1 200600539a Engine package 110V

26 2 200600818 Wheel kit

27 3 200600799 Clamp kit

21

Revision 3

Reservdelar för motorpaket 120 V.

Spareparts for engine package 120 V.

22

Revision 3

Reservdelar för motorpaket 120 V.

Spareparts for engine package 120 V.

23

Revision 3

Table of contents

Other pullman Ermator Vacuum Cleaner manuals

pullman Ermator

pullman Ermator S-Line Series User manual

pullman Ermator

pullman Ermator S 25 User manual

pullman Ermator

pullman Ermator HTC 30D User manual

pullman Ermator

pullman Ermator S 25 User manual

pullman Ermator

pullman Ermator w350 User manual

pullman Ermator

pullman Ermator W250P Technical manual

pullman Ermator

pullman Ermator I2000ESD User manual

pullman Ermator

pullman Ermator I940T User manual

pullman Ermator

pullman Ermator T7500 User manual

pullman Ermator

pullman Ermator S1400 User manual