pullman Ermator T7500 User manual

T 7500, T 10000, T 11000

EN Operator's manual 2-24

DE Bedienungsanweisung 25-45

FR Manuel d'utilisation 46-66

NL Gebruiksaanwijzing 67-87

Contents

Introduction..................................................................... 2

Safety..............................................................................9

Assembly...................................................................... 11

Accessories.................................................................. 11

Operation...................................................................... 12

Maintenance................................................................. 13

Troubleshooting............................................................ 16

Transportation, storage and disposal........................... 17

Technical data.............................................................. 19

Declaration of Conformity............................................. 21

Introduction

Owner responsibility

WARNING: Processing of concrete and

stone by methods such as cutting, grinding

or drilling, especially during dry operation,

generates dust that comes from the material

being processed, which frequently contains

silica. Silica is a basic component of sand,

quartz, brick clay, granite and numerous

other minerals and rocks. Exposure to

excessive amount of such dust can cause:

Respiratory disease (affecting your ability

to breathe), including chronic bronchitis,

silicosis and pulmonary fibrosis from

exposure to silica. These diseases may be

fatal;

Skin irritation and rash.

Cancer according to NTP* and IARC* */

National Toxicology Program, International

Agency for Research on Cancer.

Take precautionary steps:

Avoid inhalation of and skin contact with

dust, mist and fumes.

Wear and ensure that all bystanders

wear appropriate respiratory protection such

as dust masks designed to filter out

microscopic particles. (See OSHA 29 CFR

Part 1926.1153)

To minimize dust emissions, use water

to bind the dust, when feasible. If dry

operation is necessary, use an appropriate

dust extractor.

It is the owner’s/employer’s responsibility that the

operator has sufficient knowledge about how to use the

product safely. Supervisors and operators must have

read and understood the Operator’s Manual. They must

be aware of:

• The product’s safety instructions.

• The product’s range of applications and limitations.

• How the product is to be used and maintained.

National/Local regulations could restrict the use of this

product. Find out what regulations are applicable where

you work before you start using the product.

Product description

The product is a dust extractor with a suction hose. Air

with dust is suctioned into an inlet valve through the

suction hose. The air decreases in speed by a cyclone

which cause the dust particles to move apart from the

air. Small dust particles and air goes through a 2 filter

system. Large dust particles are collected in the cyclone

and fall through the bottom flap into a plastic bag.

Intended use

The product is used to clean construction areas by

collecting up dry and non flammable dust in indoor

environments.

The product can be connected to medium and large

surface preparation equipment such as grinders.

The product is intended for commercial use, for example

in hotels, schools, hospitals, factories, shops, offices

and rental businesses

Note: The explosion limit value for the not flammable

dust is >0.1mg/m3.

Dust storage system

All Pullman Ermator T-Line Dust Extractors are to be

used with Longopac. Only change Longopac after the

filter cleaning cycle has been completed.

2966 - 003 - 11.04.2022

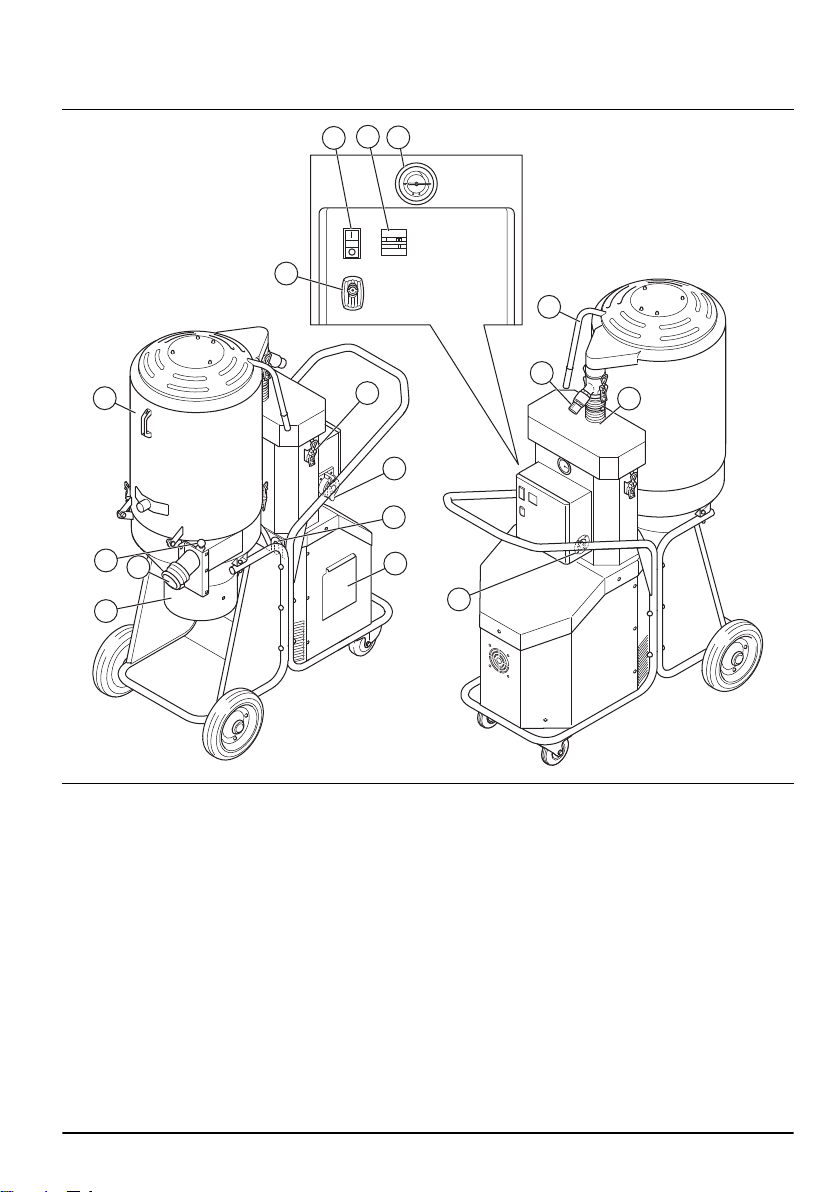

Product overview T 7500 and T 8600

h

0 0 0 01

1

2

9

3

15

10

14

16

11

12

8

7

5

4

6

13

1. Pre-filter

2. Jet Pulse handle

3. Hepa filter

4. Lock to electricity box

5. On/Off

6. Hour meter

7. Manometer

8. Longopac connection

9. Pressure release valve

10. Socket inlet

11. Socket outlet

12. Inlet valve

13. Inlet

14. Utility hatch

15. Toggle fastener

16. Tie down lug 2X

966 - 003 - 11.04.2022 3

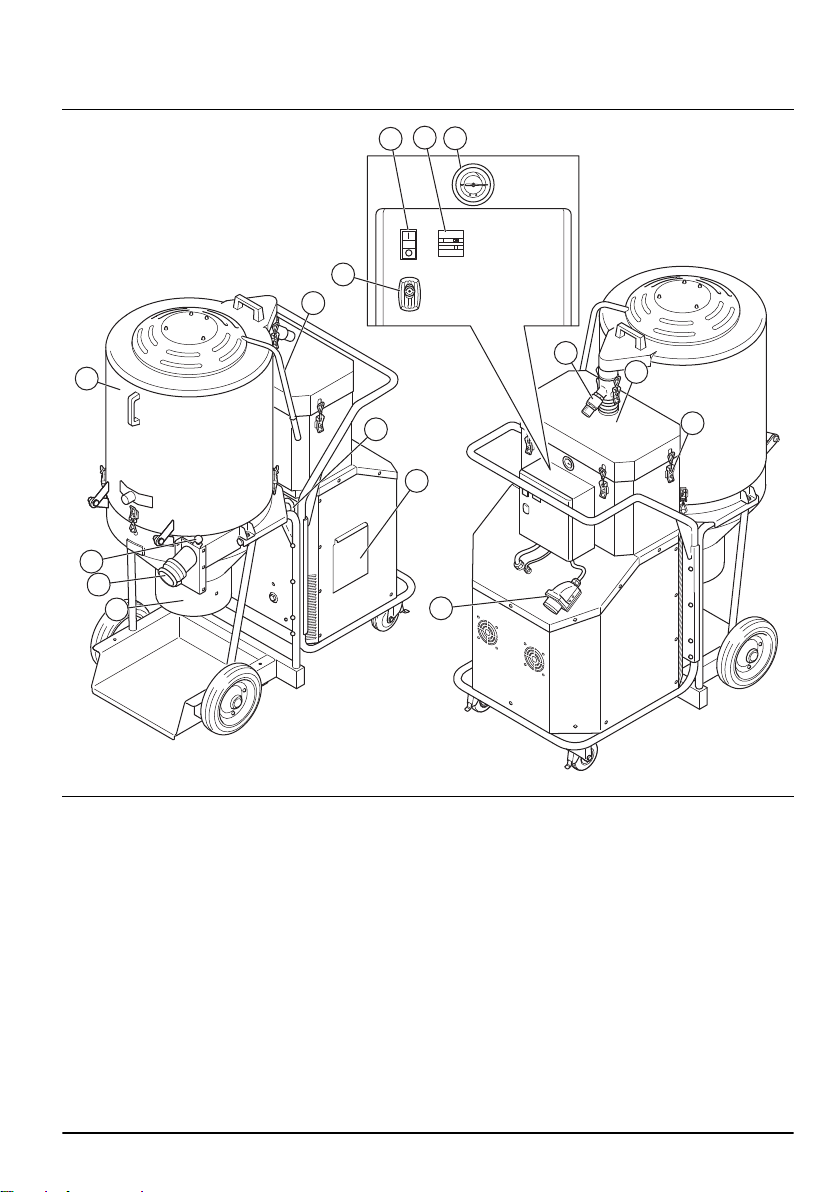

Product overview T 7500

h

0 0 0 01

1

2

9

3

14

13

15

10

11

8

7

5

4

6

12

1. Pre-filter

2. Jet Pulse handle

3. Hepa filter

4. Lock to electricity box

5. On/Off

6. Hour meter

7. Manometer

8. Longopac connection

9. Pressure release valve

10. Socket inlet with phase converter

11. Inlet valve

12. Inlet

13. Utility hatch

14. Toggle fastener

15. Tie down lug 2X

4966 - 003 - 11.04.2022

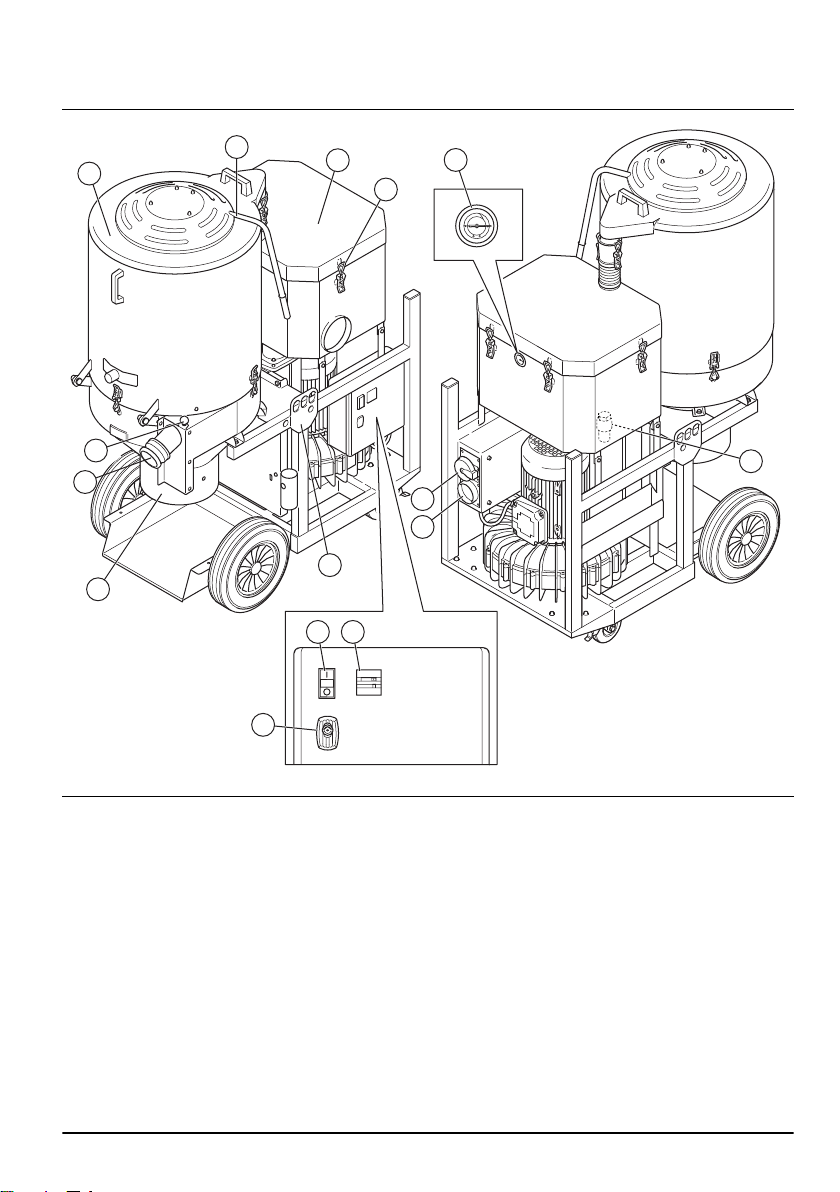

Product overview T 10000

1

15

13

10

11

8

3

2

9

h

0 0 0 01

7

56

4

12

14

1. Pre-filter

2. Jet Pulse handle

3. Hepa filter

4. Lock to electricity box

5. On/Off

6. Hour meter

7. Manometer

8. Longopac connection

9. Pressure release valve

10. Socket inlet with phase converter

11. Inlet valve

12. Inlet

13. Utility hatch

14. Toggle fastener

15. Tie down lug 2X

966 - 003 - 11.04.2022 5

Product overview T 10000

1

16

14

12

8

3

2

9

10

11

h

0 0 0 01

7

56

4

13

15

1. Pre-filter

2. Jet Pulse handle

3. Hepa filter

4. Lock to electricity box

5. On/Off

6. Hour meter

7. Manometer

8. Longopac connection

9. Pressure release valve

10. Socket inlet

11. Socket outlet

12. Inlet valve

13. Inlet

14. Utility hatch

15. Toggle fastener

16. Tie down lug 4X

6966 - 003 - 11.04.2022

Product overview T 18000

h

0 0 0 0 1

1

2

3

14

12

8

15

11

10

9

5 6

4

7

13

1. Pre-filter

2. Jet Pulse handle

3. Hepa filter

4. Lock to electricity box

5. On/Off

6. Hour meter

7. Manometer

8. Longopac connection

9. Pressure release valve

10. Socket inlet

11. Socket outlet

12. Inlet valve

13. Inlet

14. Toggle fastener

15. Tie down lug 4X

966 - 003 - 11.04.2022 7

Product overview T 11000

h

0 0 0 0 1

1

2

13

7

11

8

10

14

9

5 6

4

3

12

1. Pre-filter

2. Jet Pulse handle

3. Hepa filter

4. Lock to electricity box

5. On/Off

6. Hour meter

7. Manometer

8. Longopac connection

9. Pressure release valve

10. Socket inlet with phase converter

11. Inlet valve

12. Inlet

13. Toggle fastener

14. Tie down lug 4X

Symbols on the product

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the product.

Always use an approved breathing mask.

Always use approved ear protection.

8966 - 003 - 11.04.2022

Always use approved eye protection.

Product liability

As referred to in the product liability laws, we are not

liable for damages that our product causes if:

• the product is incorrectly repaired.

• the product is repaired with parts that are not

from the manufacturer or not approved by the

manufacturer.

• the product has an accessory that is not from the

manufacturer or not approved by the manufacturer.

• the product is not repaired at an approved service

center or by an approved authority.

Safety

Safety definitions

Warnings, cautions and notes are used to point out

specially important parts of the manual.

WARNING: Used if there is a risk of

injury or death for the operator or bystanders

if the instructions in the manual are not

obeyed.

CAUTION: Used if there is a risk of

damage to the product, other materials or

the adjacent area if the instructions in the

manual are not obeyed.

Note: Used to give more information that is necessary

in a given situation.

General safety instructions

WARNING: Read the warning

instructions before you use the product.

• Always exercise care and use your common sense.

If you get into a situation where you feel unsafe, stop

and seek expert advice. Contact your dealer, service

agent or an experienced user. Do not attempt any

task that you feel unsure of!

• Read the operator´s manual carefully and

understand the instructions before using the product.

Save all warnings and instructions for future

reference.

• Make sure that you read and understand the

instructions for the main product manual to ensure

that you know what personal equipment to wear,

what safety equipment to use and how to work in

a safe mode.

• Keep in mind that it is you, the operator that is

responsible for not exposing people or their property

to accidents or hazards.

• The product can be a dangerous tool if used

incorrectly or carelessly, which can cause serious or

fatal injury to the operator or others.

• The product must be kept clean. Signs and stickers

must be fully legible.

• This product is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge.

• This product produces an electromagnetic field

during operation. This field can under some

circumstances interfere with active or passive

medical implants. To decrease the risk of serious

injury or death, we recommend persons with medical

implants to speak to their physician and the medical

implant manufacturer before operating this product.

• Keep children and unauthorized persons away from

the product when in use.

• Operators shall be adequately instructed on the use

of the product.

• Never use this product if you are fatigued, while

under the influence of alcohol or drugs, medication

or anything that could affect your vision, alertness,

coordination or judgment.

• Do not handle plug or product with wet hands.

• Never use a product that is faulty. Carry out the

safety checks, maintenance and service instructions

described in this manual. Some maintenance and

service measures must be carried out by trained

and qualified specialists. Refer to instructions in

Maintenance on page 13

.

Electrical Safety instructions

WARNING: Read the warning

instructions that follow before you use the

product.

• The dust extractor is equipped with a safety thermal

protector to prevent motor from overheating. Should

thermal protector activate, turn off machine, unplug

power cord and check for full dust bag, vacuum hose

clog or filter blockage. It may take up to 45 minutes

for the thermal protector to reset.

• Before using the dust extractor make sure that the

power & voltage corresponds with the voltage shown

on the machines rating plate, including extension

cords.

• Connect to a properly grounded outlet only. Refer to

Grounding instructions on page 12

.

966 - 003 - 11.04.2022 9

• Improper connection of the equipment-grounding

conductor can result in a risk of electrical shock.

Check with a qualified electrician or service person if

you are in doubt as to whether the outlet is properly

grounded. Do not modify the plug provided, if it will

not fit the outlet have a proper outlet installed by a

qualified electrician.

• If using an extension cord make sure the cord rating

is suitable for this machine.

• Cables damaged through crushing or splitting can

be dangerous if used and should be replaced

immediately.

• Do not use with damaged cord or plug. If the

machine is not working as it should, has been

dropped, damaged, left outdoors or dropped in

water. Make sure it is repaired by a qualified person

to avoid hazard.

• Regularly inspect cord and plug for damage. Do not

use with a damaged cord or plug.

• Do not pull or carry by cord, use cord as handle,

close a door on cord, or pull cord around sharp

edges or corners. Do not allow equipment to run

over cord. Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp

the plug.

• Do not leave machine when plugged in. Unplug cord

from outlet when not in use and before cleaning or

servicing machine.

Safety instructions for assembly

WARNING: Read the warning

instructions that follow before you assemble

the product.

• Turn off all controls before unplugging. Do not

unplug by pulling on cord. To unplug, grasp the plug.

• Unauthorized modifications and /or accessories may

lead to serious injury or death to the user or others.

• Always use genuine accessories.

• Use only attachments as described in this manual.

Use only manufacturers recommended attachments.

• Make sure that the assembly area is firm, so the

product does not tip over. Risk of personal and

material injury.

• Be careful, the toggle fasteners can cause damage

to the operator when assemble the product.

Safety instructions for operation

WARNING: Read the warning

instructions that follow before you use the

product.

• The product must not be used in environments

where explosive gases may be present. This will

pose a serious risk of explosion.

• Do not pickup anything that is burning or smoking,

such as cigarettes, matches or hot ashes.

• The high vacuum suction at the inlet can cause body

injury.

• Be very careful when you move the product in dark

areas. The product is heavy and there is a risk of

injury if the product falls or moves too quickly.

• Be very careful when you move the product on a

surface with a slope. The product is heavy and there

is a risk of injury if the product falls or moves too

quickly.

• The machine can suddenly move if it is not parked

on horizontal surface. The center of gravity changes

when the machine is filled with dust, which may

affect the parking brake function. Only park on

horizontal surfaces.

• Do not put your hand on top of the primary tank

during filter cleaning, there is a risk of pinching.

• Do not use to pickup flammable or combustible

liquids, such as gasoline, or use in areas where they

may be present.

• Do not allow a build-up of dust, hair and anything

that may reduce airflow.

• Keep hair, loose clothing, fingers and all parts of

body away from openings and moving parts.

• Do not use the product without dust bag and/ or

filters in place. Replace collection system and/or

filters as described in this manual.

CAUTION: This machine is designed

for picking up dry, non-flammable dust and

debris in an indoor environment. It is not

suitable for picking up liquids.

CAUTION: This product is for indoor

use only.

CAUTION: This product shall be stored

indoors only.

Personal protective equipment

WARNING: Read the warning

instructions that follow before you use the

product.

• Always use approved personal protective equipment

during operation. Personal protective equipment

does not give you full protection but it decreases the

degree of injury if an accident occur. Speak to you

servicing dealer for recommendations about which

equipment to use.

• Risk of dust dispersion - Use personal equipment.

Unhealthy dust can be spread during filter change.

Accordingly, the user should wear protective

10 966 - 003 - 11.04.2022

glasses, protective gloves, and a breathing mask

conforming to protection class FFP3.

• Long-term exposure to noise can result in permanent

hearing impairment. Always use approved hearing

protection. Listen for warning signals or shouts when

you wearing hearing protection. Always remove your

hearing protection as soon as the engine stops.

• Use approved protective gloves when you do

maintenance on the product.

• Use tight-fitting, heavy-duty and comfortable clothing

that permits full freedom of movement. Do not wear

shorts.

Safety instructions for maintenance

WARNING: Read the warning

instructions that follow before you use the

product.

• Make sure the engine switch is in the Off position.

Disconnect the product from the wall outlet.

• Do not modify the product from its original design.

• All repairs must be performed by a qualified

service person. Use only manufacturer-supplied or

equivalent replacement parts.

• Make sure that you use correct fuse when you do

servicing on the product.

• Use approved protective equipment. Refer to

Personal protective equipment on page 10

• Do not make a hole in the Hepa filter. A broken Hepa

filter can disperse dust.

Assembly

Introduction

CAUTION: Only use extension cable

with correct rated value for this product. Only

connect to an outlet that is correct grounded.

CAUTION: Always clean the prefilter

before change of bag collection system.

General

Do a check that the following accessories are included:

• The hose with end fittings

• Steel tube

• Floor Nozzle

• Cable ties

If 1 of the parts is missing, speak to your local Pullman

Ermator service agent .

Make sure to dispose the package and the used product

components in correct procedure. Refer to local disposal

regulations. Make sure to recycle.

Accessories

Extension cables

WARNING: Only use an extension cord

that can handle the machines rated current

with corresponding plugs.

Approved for machines > 250V: SO, SOO, ST, STOand

STOO

Approved for machines < 250 V: All types

Model Distri-

bution

box

A B C D E F G H

T7500

230V

NO 1

T7500

230V DIST

YES 1 1

T8600

480V

YES 1 1 1

966 - 003 - 11.04.2022 11

Model Distri-

bution

box

A B C D E F G H

T10000

480V

YES 1 1 1

T18000

480V

YES 1 1

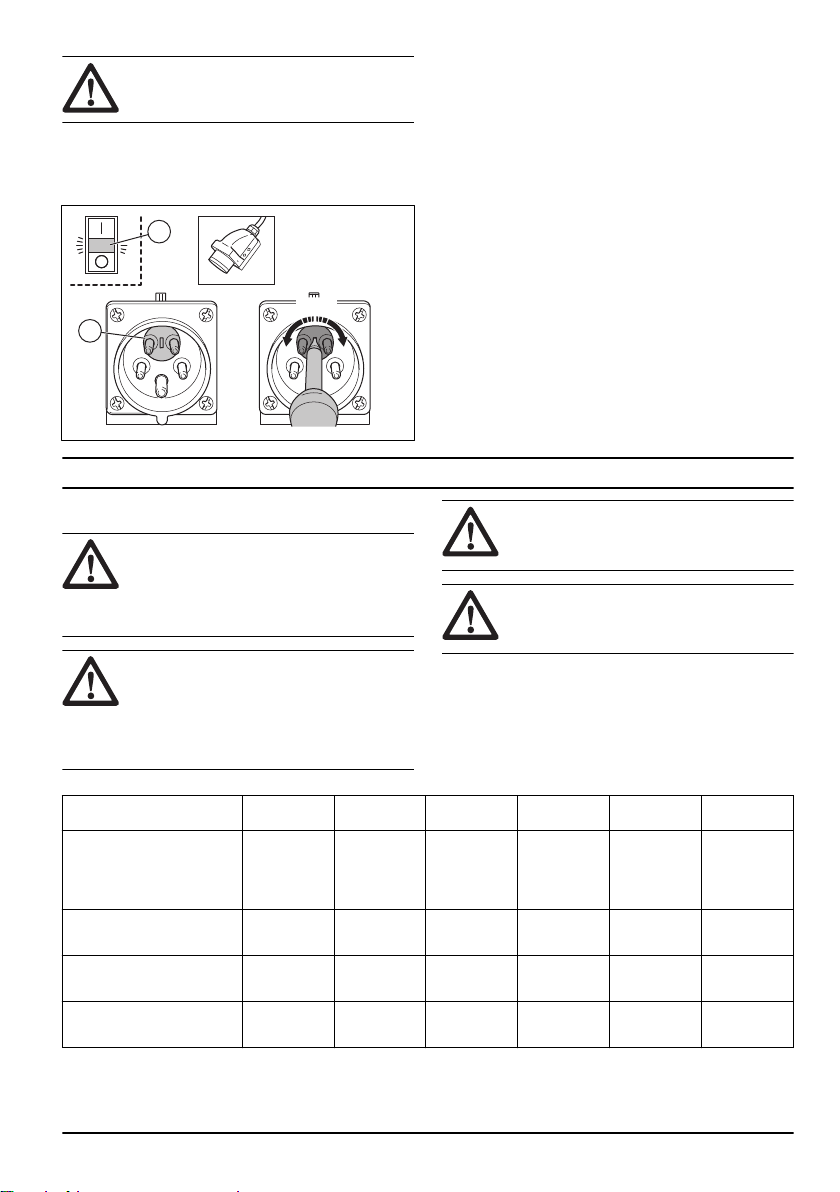

Pullman Ermator T-Line Dust Extractor are supplied with

Hubbell inlets and receptacles.

Part no Hubbell part no Standard Description

A HBL4100R9W IEC 60309 FEMALE RECEPTACLE, 100A, 3-PHASE, 250V, 4 Wire.

B HBL4100B9W IEC 60309 INLET MALE, 100A, 3-PHASE, 250V 4 Wire.

C CS8175 Twistlock ®INLET MALE, 50A, 3-PHASE, 480V, 4 Wire, Grounding.

D CS8169 Twistlock ®RECEPTACLE FEMALE, 50A. 3-PHASE, 480V, 4 Wire,

Grounding.

E HBL7774WO Twistlock ®Well plate

F HBL460B7W IEC 60309 INLET MALE, 60A, 3-PHASE, 480V, 4 Wire

G HBL460R7W IEC60309 RECEPTABLE FEMALE, 60A, 480V, 3-PHASE, 4 Wire.

H CS8375 Twistlock ®INLET MALE, 50A, 3-PHASE, 250V, 4 Wire.

Operation

Before use

WARNING: Before using the dust

extractor make sure that the power and

voltage corresponds with the voltage shown

on the machines rating plate, including

extension cords.

WARNING: Connect to a properly

grounded outlet only. Refer to

Grounding

instructions on page 12

Grounding instructions

WARNING: The dust extractor must

be grounded. If it should malfunction or

breakdown, grounding provides a path

of least resistance for electric current to

reduce the risk of electric shock. The dust

extractor is equipped with a cord having

an equipment-grounding conductor and

grounding plug. The plug must be inserted

into an appropriate outlet that is properly

installed and grounded in accordance with

all local codes and ordinances.

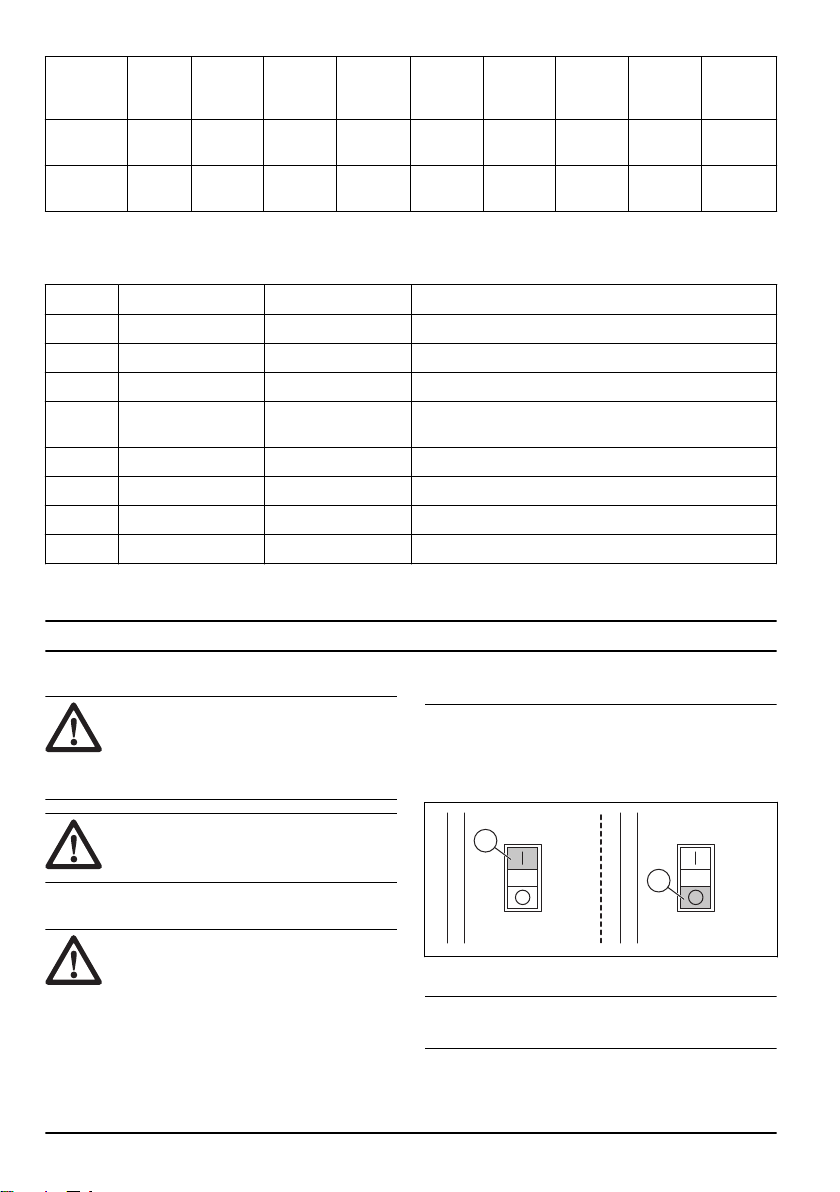

To start and stop

Push the green button (A) to start the dust extractor.

Push the red button (B) to stop the dust extractor.

A

B

Phase converter

Note: Not applicable to variants sold in Australia or

New Zealand.

12 966 - 003 - 11.04.2022

WARNING: Electrical work must be

done by an approved electrician.

If the red lamp (A) between the red and the green button

lights up, there is a phase error. Switch 2 of the phases

to reset (B). This is a safety measure to make sure that

the pump does not start to blow.

B

A

180°

Maintenance

Introduction

WARNING: Use personal safety

equipment, refer to

Personal protective

equipment on page 10

, during service. Dust

can be exposed during maintenance and

service.

WARNING: Most accidents involving

machines occur during trouble shooting,

service and maintenance as staff have to

locate themselves within the risk area of the

machine. Prevent accidents by being alert

and by planning and preparing the work.

WARNING: The motor should be

switched off during operations described in

this chapter unless otherwise stated.

WARNING: All checks involving electric

components should only be performed by a

licensed electrician.

Maintenance schedule T-Line Dust

Extractor

The maintenance intervals are calculated from daily use

of the product. The intervals change if the product is not

used daily.

Maintenance Before each

use

Daily Weekly When suc-

tion is low

6 months or

1000h

12 months

or 2000h

Look for signs of wear,

damage or loose connec-

tions of the controls before

the unit is connected.

X

Do a check that the Longo-

pac is correct.

X

Do a check of the filter

cleaning mechanism.

X

Do a check of the dust

hose and the connections.

X

966 - 003 - 11.04.2022 13

Maintenance Before each

use

Daily Weekly When suc-

tion is low

6 months or

1000h

12 months

or 2000h

Do a check of the wheels.

Look for damage and bad

connections.

X

Clean the pre-filter. X

Replace the pre-filter. X X

Replace the Hepa filter X X

To clean the dust extractor

It is important to clean the dust extractor to prevent

circulation of dangerous dust. Always clean the dust

extractor before it is moved from the work area.

WARNING: Turn the motor switch to

its OFF position and disconnect the cord

from the wall outlet before you clean or do

maintenance to the product.

• All equipment once used must be regarded as

contaminated and be treated thereafter.

• All parts that are contaminated after service work

must be disposed in a correct procedure in plastic

bags. Refer to local regulations.

• Use correct personal equipment when you clean the

product. Refer to

Personal protective equipment on

page 10

.

• Clean the external surface with a moist cloth.

• Clean the filters and the dust extractor in applicable

area.

• Vacuum the pre-filter from the inside. Always use

dust extractors with Hepa filter and a soft brush to

not damage the filter.

• Do not use water on electrical components.

• Do not clean the dust extractor with high pressure

(air or water).

• Do not put tools on the surface of the filter, it can

cause damage to the filter.

• Do not make a hole in the Hepa filter, it can cause a

health risk.

Filter change

WARNING: Use personal safety

equipment, refer to

Personal protective

equipment on page 10

, during filter change.

Dust can come out during filter change.

WARNING: Always turn the motor

switch in the Off position and disconnect the

cord from the wall outlet during filter change.

WARNING: Be careful, the toggle

fasteners can cause damage to the operator

when assemble the product.

To clean the pre filter

The filter must be cleaned from time to time. This

must be done before changing the plastic bag collection

system and should also be done when work is

completed or when there is poor suction..

CAUTION: Avoid hitting or dragging

items across the filter surface as this will

damage the filter.

CAUTION: Do not use water to clean

the filters.

1. While running the dust extractor, seal the inlet using

the inlet plug or the inlet valve.

2. Let the dust extractor build up vacuum for 5

seconds, then quickly push and hold down the Jet

Pulse handle for 5 seconds.

3. Repeat step 2 five times. It is important to let the

dust extractor rebuild the vacuum in between every

repetition.

4. If suction remains poor, the filter should be replaced.

Only replace plastic bag after cleaning the filter.

The pre filter

Only use Pullman Ermator filters. Performance and

filtration efficiency can only be assured with original

filters.

WARNING: Do not replace only one

tube. If one is broken, it is necessary to

replace the complete filter.

To change the pre filter

1. Loosen the 2 toggle fasteners between the tank and

the lower cyclone.

2. Loosen the 2 toggle fasteners at the hose

connection between the tank and the Hepa filter

cover.

14 966 - 003 - 11.04.2022

3. Rotate the tank forward.

4. Rotate the filter plate anticlockwise 10 degrees and

carefully turn the filter and holder upside down.

5. Put a plastic bag above the filter unit.

6. Lift out the filter carefully in the bag and close it.

The bag must be discarded. Refer to local disposal

regulations.

7. Put on a new complete filter package in reverse

order.

To change the Hepa filter

CAUTION: Do not clean Hepa filter,

trying to clean a Hepa filter will destroy it.

When installing the replacement filter, make

sure to not touch the inside of the filter. Any

kind of force/damage on the inside of filter

media will destroy the new filter..

CAUTION: Do not to touch the inner

surface of the filter when installing a

replacement Hepa filter. Damage to the

inner surface of the filter can make it

unserviceable.

1. Loosen the toggle fasteners on the filter cap and

remove it.

2. Carefully lift the filter into a clean plastic bag.

Note: This bag must be properly disposed.

3. Insert a new filter in reverse order.

To install a new Longopac dust bag

WARNING: Always clean the prefilter

before you replace the Longopac dust bag.

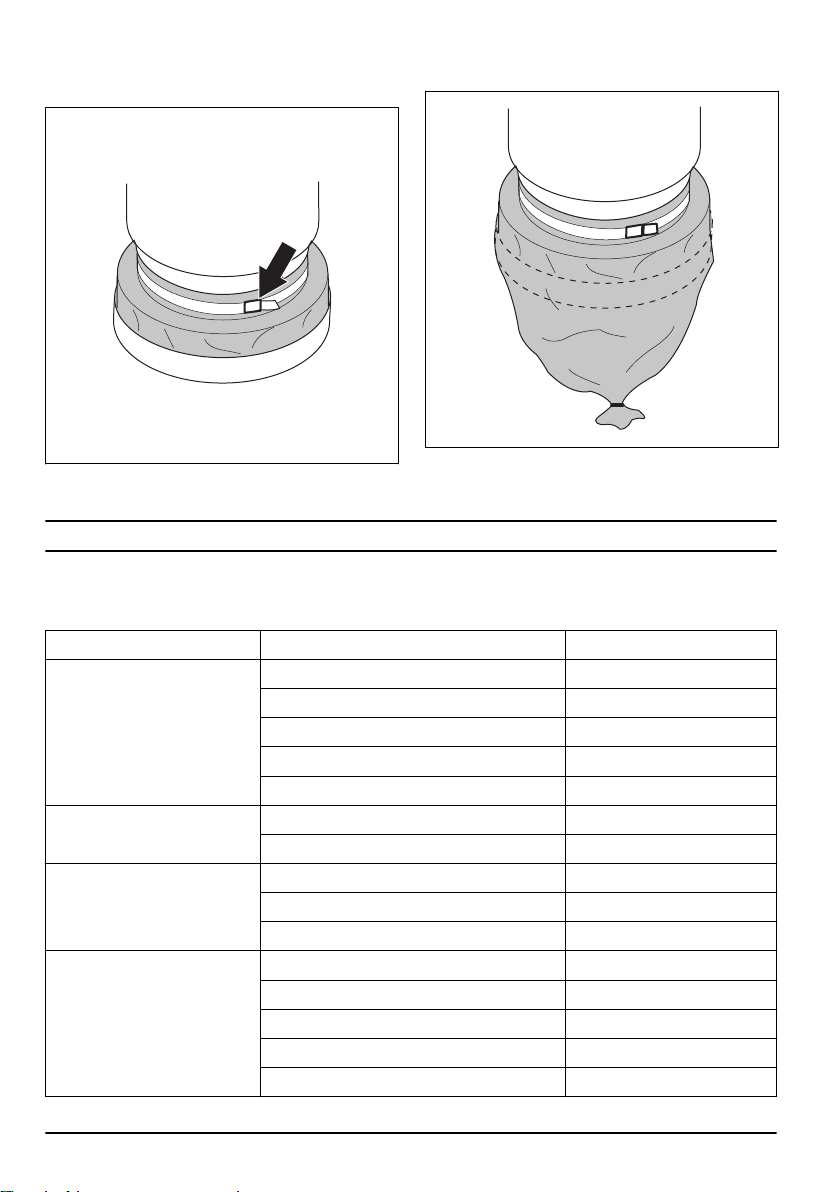

1. Put the Longopac dust bag in the holder.

2. To attach the Longopac dust bag holder, twist the

Longopac dust bag holder until the pins engage in

the slots.

3. Pull the Longopac bag up from the holder and put it

around the container.

966 - 003 - 11.04.2022 15

4. Tighten a strap around the Longopac dust bag and

the container to attach the bag correctly to the

container.

5. Pull the Longopac dust bag down on the outer side

of the bag holder.

6. Close the bottom of the Longopac dust bag with a

cable tie.

Troubleshooting

Troubleshooting schedule

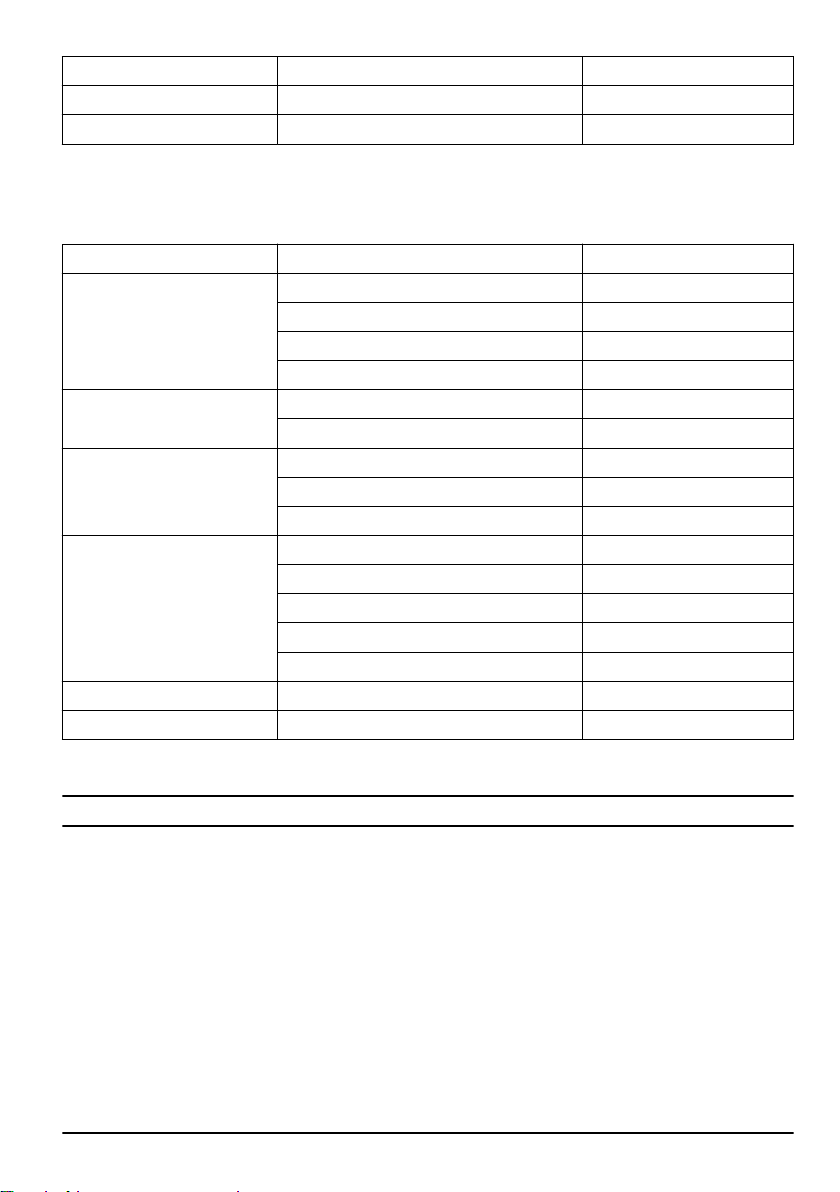

Issue Cause Solution

Motor does not start

No power Plug in machine

Cable defective Replace cable

Switch defective Replace switch

Contactor combination defective Replace contactor combination

Phase error (red lamp lights up) Switch 2 phases

Motor stops immediately after

starting

Wrong fuse Connect to correct fuse

Shortcut in cable/machine Order service

Motor runs but there is not suc-

tion

Hose not connected Connect hose

Hose blocked Clean hose

No dust collection bag Fit dust collection system

Motor runs but there is poor suc-

tion

Hole in hose Replace hose

Filter clogged Clean filter/ Replace filter

Loose top cover Adjust

Dirt in the flap Clean the flap

Defective gaskets Replace affected gaskets

16 966 - 003 - 11.04.2022

Issue Cause Solution

Dust blown from motor Wrongly assembled or damaged filter system Adjust/ Replace filters

Abnormal noise Order service

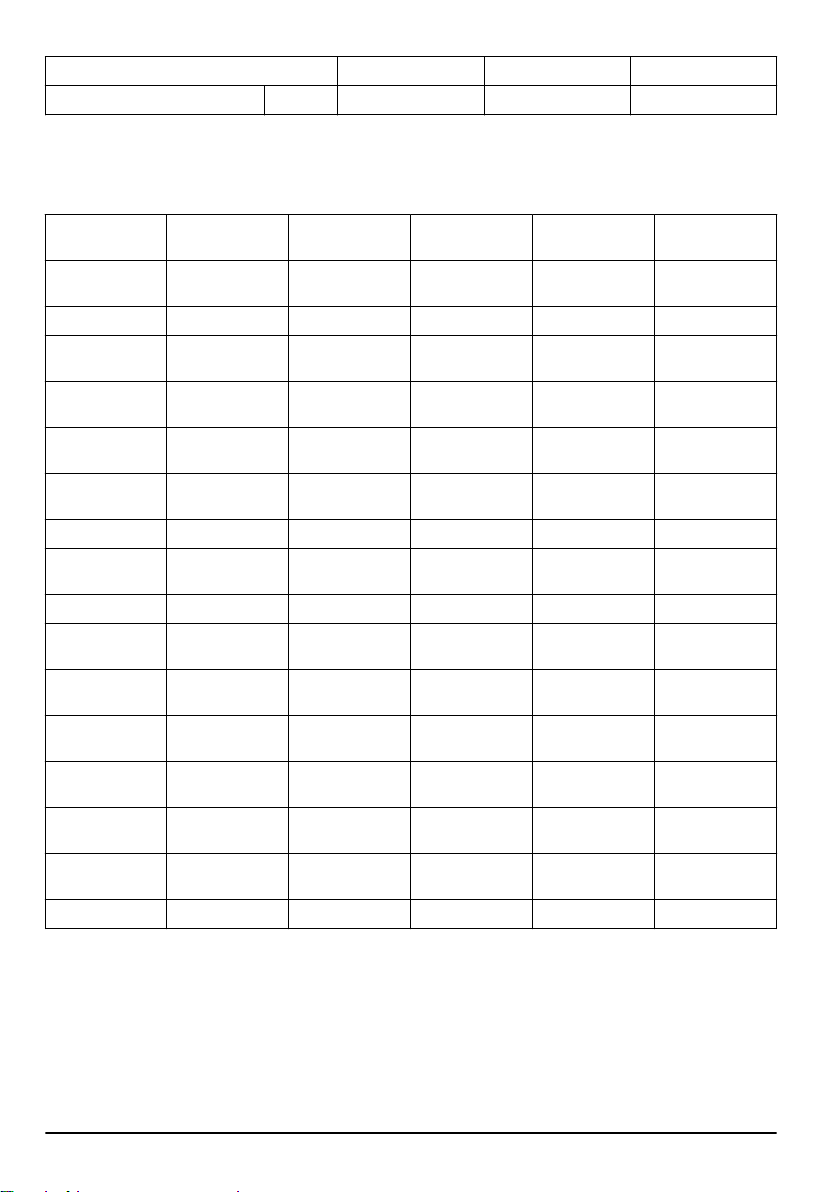

Troubleshooting schedule

Issue Cause Solution

Motor does not start

No power Plug in machine

Cable defective Replace cable

Switch defective Replace switch

Contactor combination defective Replace contactor combination

Motor stops immediately after

starting

Wrong fuse Connect to correct fuse

Shortcut in cable/machine Order service

Motor runs but there is not suc-

tion

Hose not connected Connect hose

Hose blocked Clean hose

No dust collection bag Fit dust collection system

Motor runs but there is poor suc-

tion

Hole in hose Replace hose

Filter clogged Clean filter/ Replace filter

Loose top cover Adjust

Dirt in the flap Clean the flap

Defective gaskets Replace affected gaskets

Dust blown from motor Wrongly assembled or damaged filter system Adjust/ Replace filters

Abnormal noise Order service

Transportation, storage and disposal

Transportation of the product

• Make sure that the Longopac bag is empty before a

transportation.

• Make sure that the Longopac bag is attached to the

product during transportation.

• Use ramps or winches to lift the dust extractor to

make sure that movements are safe. Get aid if you

are not sure about how to lift heavy equipment.

• Attach the product safely during transportation in

order to prevent transport damage and accidents.

Use the tie down lugs on both sides of the product.

• Engage the locking caster safely on the wheels.

• If possible, do the transportation of the product

during good weather conditions.

• If possible, use a closed vehicle during

transportation of the product.

Storage of the product

• The product must be stored inside away from

outdoor elements.

• Do not expose the product to rain or moisture.

• Attach the locking casters safely.

• Disconnect the product from the power source.

• Store the product and the equipment in a dry area

with no frost or excessive heat.

• Store all equipment in an locked area, so that it is

out of reach of children and unauthorized persons.

966 - 003 - 11.04.2022 17

Disposal of the product

• Obey the local recycling requirements and applicable

regulations.

• When the product no longer is used, send it to a

Pullman Ermator dealer or discard it at a recycling

location.

18 966 - 003 - 11.04.2022

Technical data

Technical data

Data T 7500 T 10000 T 11000

Energy efficiency level IE3 IE3 IE3

Voltage (3 phase), V 380-415 380-415 380-415

Frequency, Hz 50 50 50

Power (max), kW (HP) 5.5 (7.4) 11 (14.7) 11 (14.7)

Plug amperage, A 16 32 32

Number of poles, p 2 2 2

Rated RPM, min-1 2890 2890 2890

Max altitude above sea level, m 1000 1000 1000

Ambient air temperature, °C -20 - +40 -20 - +40 -20 - +40

Max operating temperature, °C 155 155 155

Rated efficiency (%) at rated load

(%)

75 89.6 89.6 89.6

50 88.9 88.9 88.9

The power losses ex-

pressed in percent-

age (%) of the rated out-

put power at the fol-

lowing different operat-

ing points for speed (%) ver-

sus torque (%)

90/50 4.7 4.7 4.7

50/100 7.9 7.9 7.9

50/50 3 3 3

50/25 1.8 1.8 1.8

25/100 N/A N/A N/A

25/25 1.1 1.1 1.1

Airflow (max), m3/h (cfm) 600 (353) 900 (530) 1100 (648)

Vacuum (max), kPa (psi) 28 (110) 30 (120) 30 (120)

Main hose, m (ft) 10 (3) 10 (3) 10 (3)

Inlet diameter, mm (in.) Camlock 76 (3) 76 (3) 102 (4)

Pre-filter, % >99.5%@1um >99.5%@1um >99.5%@1um

Pre-filter area, m (in.) 2.9 (31.2) 3.9 (41.9) 4.9 (52.7)

Hepa filter 99.99%@0.3um 2 3 4

Total Hepa filter area, m 2 (ft2) 5 (53.8) 7.5 (80.7) 10 (107.6)

Sound level, dB(a) 74 74 78

Dust collection system, type Longopac Longopac Longopac

Dimensions (L*W*H) mm (in.) 1245x686x1753

(49.1x27.1x69.1)

1400x736x1727

(55.2x29.0x68.0)

1400x788x1804

(55.2x31.1x71.1)

966 - 003 - 11.04.2022 19

Data T 7500 T 10000 T 11000

Weight, kg (Ibs) 206 (454) 336 (741) 361 (795)

Technical data

Data T 7500 No dist

box

T 7500 Dist box T 8600 T 10000 T 18000

Voltage (3

phase), V

200-230 200-230 380-415 480 480

Frequency, Hz 60 60 50 60 60

Power (max) HP

(kW)

10 (7.5) 10 (7.5) 11.5 (8.6) 16.9 (12.6) 24.1 (18)

Plug amperage,

A

50 100 16 50 60

Airflow (max),cfm

(m³/h)

353 (600) 353(600) 388 (660) 480 (815) 1206 (710)

Vacuum (max),

psi (kPa)

110 (28) 110 (28) 110 (28) 120 (30) 120 (30)

Main hose, ft (m) 32 (10) 32 (10) 32 (10) 32 (10) 32 (10)

Inlet diameter, in.

(mm) Camlock

3 (76) 3 (76) 3 (76) 3 (76) 4 (102)

Pre-filter, % >99.5%@1um >99.5%@1um >99.5%@1um >99.5%@1um >99.5%@1um

Pre-filter area, in.

(m)

2.9 (31.2) 2.9 (31.2) 2.9 (31.2) 41.9 (3.9) 52.7 (4.9)

Hepa filter

99.99%@0.3um

22234

Total Hepa filter

area, ft2 (m2)

53.8 (5) 53.8 (5) 53.8 (5) 80.7 (7.5) 107.6 (10)

Sound level,

dB(a)

74 74 74 74 78

Dust collection

system, type

Longopac Longopac Longopac Longopac Longopac

Dimensions

(L*W*H) in. (mm)

49.1x27.1x69.1

(1245x686x1753)

49.1x27.1x69.1

(1245x686x1753)

49.1x27.1x69.1

(1245x686x1753)

55.2x29.0x68.0

(1400x736x1727)

55.2x31.2x71.1

(1400x788x1804)

Weight, Ibs (kg) 460 (209) 460 (209) 454 (206) 723 (328) 815 (370)

20 966 - 003 - 11.04.2022

This manual suits for next models

2

Table of contents

Languages:

Other pullman Ermator Vacuum Cleaner manuals

pullman Ermator

pullman Ermator w350 User manual

pullman Ermator

pullman Ermator W250P Technical manual

pullman Ermator

pullman Ermator S1400 User manual

pullman Ermator

pullman Ermator S 25 User manual

pullman Ermator

pullman Ermator S-Line Series User manual

pullman Ermator

pullman Ermator S 25 User manual

pullman Ermator

pullman Ermator HTC 26D User manual

pullman Ermator

pullman Ermator I940T User manual

pullman Ermator

pullman Ermator HTC 30D User manual

pullman Ermator

pullman Ermator I2000ESD User manual