pullman Ermator S-Line Series User manual

ORIGINAL OPERATING

INSTRUCTIONS

S-Line Dust Extractor

S13

S26

S36

Rev. 5 2017-05-10

READ ALL INSTRUCTIONS BEFORE USE

Introduction

Dear Customer,

Thank you for choosing Pullman Ermator as your supplier.

We hope that the S-Line dust extractor will be to your satisfaction and meet your expectations.

Pullman Ermator have manufactured professional dust extractors since 1966 and has over the years

acquired a genuine technical knowledge in this area. We are continuously striving to improve our

products in our product segment and will continue to supply the market with new equipment.

Notice!

These instructions are only for S-Line Dust Extractors.

The S-Line Dust Extractors are designed to clean construction areas and be connected to small

electrical machines such as drills, grinders etc. The machine is suitable for picking up dry, non-

flammable dust and debris in and indoor environment. It is not suitable for picking up liquids.

The S-Line Dust Extractors are intended for both household and commercial use.

Pullman Ermator will not be held responsible if the dust extractor is used for other applications

or been used in ways other than those outlined in this instruction manual.

Please pay particular attention to the safety regulations.

Read the complete instruction manual before using your dust extractor.

All spare parts used with the dust extractors must be those specified by Pullman Ermator.

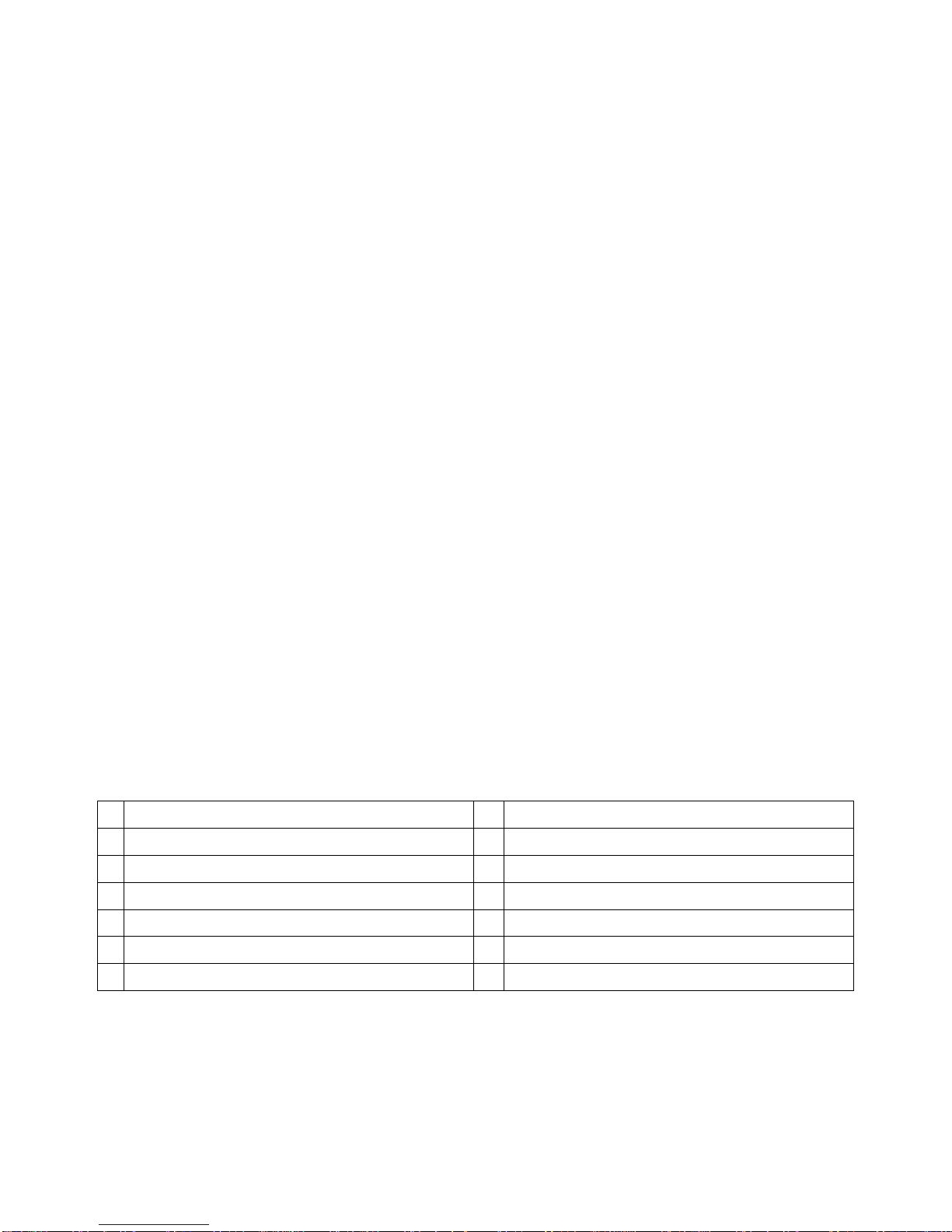

Table of contents

1

SAFETY INSTRUCTIONS

8

WARRANTY

2

UNPACKING

9

PROBLEM SOLVING

3

FUNCTION

10

TECHNICAL DATA

4

FILTER CLEANING

11

PLUGS

5

DUST STORAGE SYSTEM

12

DECRALATION OF CONFORMITY

6

FILTER CHANGE

13

EXPLODED VIEWS

7

SERVICE

14

CONTACT INFO

1. SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should always be followed, including the following:

WARNING –To reduce the risk of fire, electric shock or injury:

•Cables damaged through crushing or splitting can be dangerous if used and should be replaced immediately. Risk

of personal injury.

•Make sure the assembly area is firm, so the dust extractor does not tip over. Risk of personal and material injury.

•Risk of pinching when handling the toggle fasteners.

•The machine must not be used in environments where explosive gases may be present. Serious risk of explosion.

•Improper connection of the equipment-grounding conductor can result in a risk of electrical shock. Check with a

qualified electrician or service person if you are in doubt as to whether the outlet is properly grounded. Do not

modify the plug provided with the machine. If it will not fit the outlet. Have a proper outlet installed by a qualified

electrician.

•Before using the machine, make sure that the power & voltage corresponds with the voltage shown on the

machines rating plate.

•Do not leave machine when plugged in. Unplug cord from outlet when not in use and before cleaning or servicing

machine.

•Do not use outdoors or on wet surface, this machine is for indoor and dry use only.

•Do not allow to use as a toy. Close attention is necessary when used by or near children.

•Use only as described in this manual. Use only manufacturers recommended attachments.

•Operators shall be adequately instructed on the use of the machine

•This machine is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge.

•Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped, damaged, left

outdoors or dropped in water. Make sure it is repaired by a qualified person.

•Do not pull or carry by cord, use cord as handle, close a door on cord, or pull cord around sharp edges

or corners. Do not run the machine over cord. Keep cord away from heated surfaces.

•Do not unplug by pulling on cord. To unplug, grasp the plug. Not the cord.

•Do not handle plug or machine with wet hands.

•Regularly inspect cord and plug for damage. If cord is damaged, it must be replaced by a qualified

person in order to avoid hazard.

•Do not put any object into openings. Do not use with any opening blocked (accept during filter cleaning

procedure). Keep free of dust, hair and anything that may reduce airflow.

•Keep hair, loose clothing, fingers and all parts of body away from openings and moving parts.

•Turn off all controls before unplugging.

•Do not use to pick up flammable or combustible liquids, such as gasoline, or use in areas where they

may be present.

•Do not pick up any type of liquids.

•Do not pick up anything that is burning or smoking, such as cigarettes, matches or hot ashes.

•Use extra care when cleaning on stairs.

•Do not use without dust bag and/or filters in place. Replace collection system and/or filters as described

in manual.

•If using an extension cord make sure the cord rating is suitable for this machine.

•Do not modify machine from its original design.

•Keep children and unauthorized persons away from machine when in use.

•All repairs must be performed by a qualified service person. Use only manufacturer-supplied or

equivalent replacement parts.

•Do not expose machine to rain or moisture. Store indoors only.

•Connect to a properly grounded outlet only. See grounding instructions.

THERMAL PROTECTION

•The dust extractor is equipped with a safety thermal protector to prevent motor from overheating.

Should thermal protector activate, turn off machine, unplug power cord and check for full dust bag,

vacuum hose clog or filter blockage. It may take up to 45 minutes for the thermal protector to reset.

GROUNDING INSTRUCTION

•The dust extractor must be grounded. If it should malfunction or breakdown, grounding provides a path

of least resistance for electric current to reduce the risk of electric shock. The dust extractor is equipped

with a cord having an equipment-grounding conductor and grounding plug. The plug must be inserted

into an appropriate outlet that is properly installed and grounded in accordance with all local codes and

ordinances.

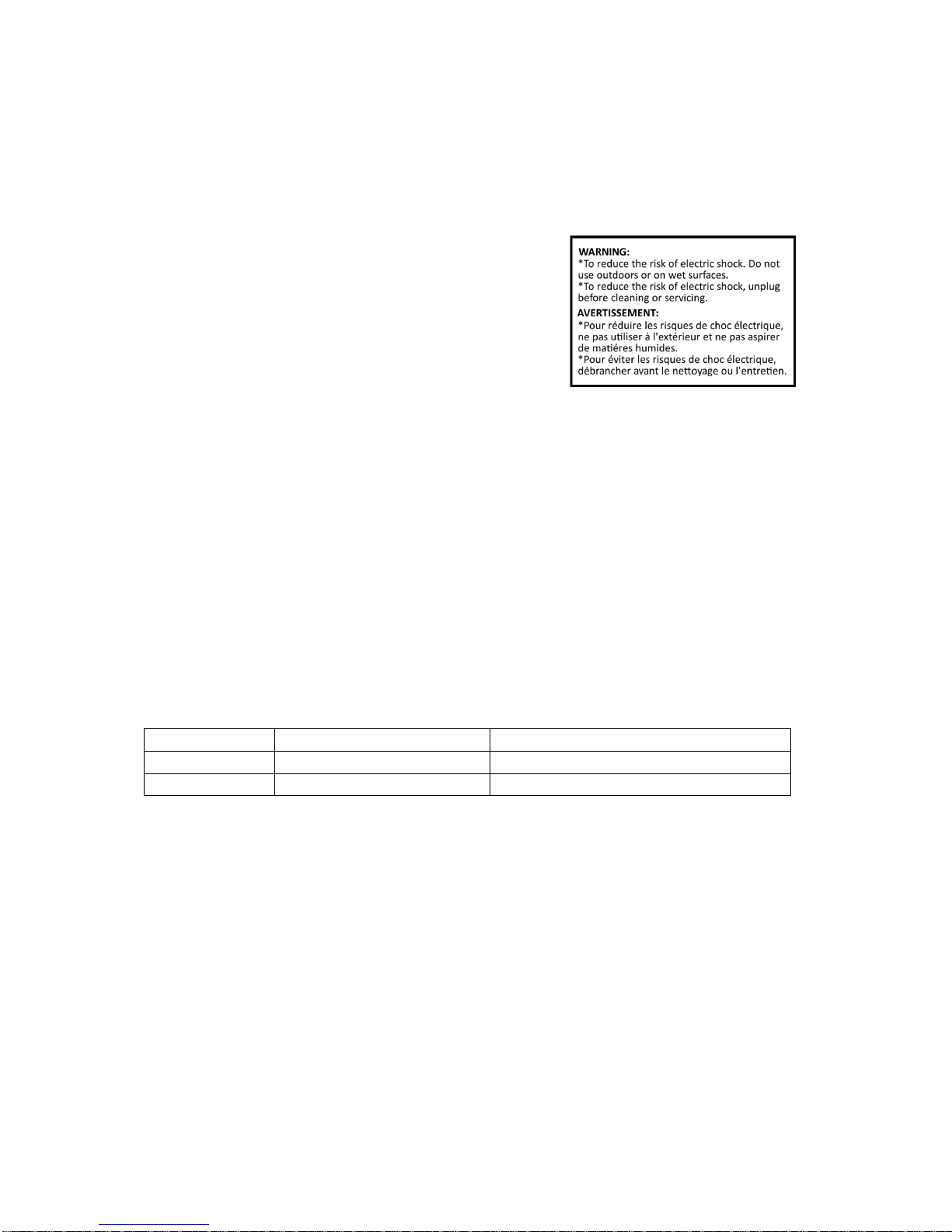

SAFETY LABEL

•The following label appears on the machine, next to the

machines rating plate. Replace label if it is missing,

becomes damaged or illegible. Failure to follow this

warning label may result in fire, electric shock or injury.

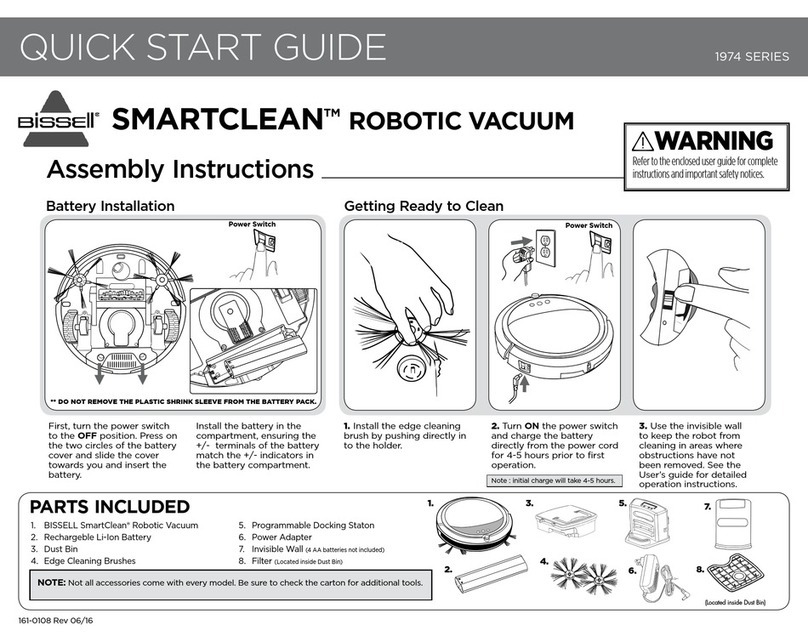

1. UNPACKING

When unpacking the machine, please check that the following accessories are included:

•The hose with end fittings.

•Wand.

•Floor nozzle.

If any of the above-mentioned parts are missing, please contact your local distributor or our sales representative.

For models that do not already have the front casters assembled due to packaging limitations. Assemble the front

casters using the using bolt or nut and washer that are included in the package depending on your application.

Protect the environment:

Please dispose of packaging materials and used machine components in an environmentally safe way according

to local disposal regulations. Always remember to recycle.

1. FUNCTION

The machine is designed for vacuuming and separating dry, non-combustible dust with an

explosion limit value of 0.1mg/m3.

The dust extractor is started by the switch.

Type

Models without automatic start

Autostart function models

Red switch 2 step

0: Motor off, 1: Motor on

N/A

Black switch 3 step

N/A

0: Motor off, 1: Motor on, 2: Automatic start

Dust-laden air is then sucked through the inlet valve at high speed via the suction hose. The air is slowed down

by the cyclone and coarse dust particles are separated out, partly by centrifugal force and partly by gravity. Air

and finer particles then pass through the double filter system where separation is made. The machine is designed

for filter cleaning by reverse air pulse.

The separated dust accumulates in the cyclone until the machine is switched off, when it drops through the

bottom flap into the plastic bag. The filter cleaning process is not completed before it is clear that the dust inside

the tank has fallen down into the collection bag. In some extreme cases the adhesive ability of the dust must be

broken manually. This can be done by hitting the dust through the bag or tapping the tank using i.e. a rubber

hammer.

Automatic start function: When you use the dust extractor together with another machine, there is an

electrical outlet on the dust extractor. Connect the machine to this outlet. Then when you start it up the dust

extractor will also start after

1

orms

11

. 1-2 seconds. When you turn it off, the dust extractor will continue to run

for approximately 10 seconds. To empty the hose. Then stop

4. FILTER CLEANING

The filter must be cleaned from time to time. This must be done before changing the bag collection system and

should also be done when work is completed or when there is poor suction.

Procedure: Cover the inlet, if applicable, use attached cover. First let the machine build up vacuum for four to

five seconds then quickly push down on the key and release it. Repeat the procedure five times. It is important to

let the machine rebuild the vacuum in between every repetition.

Turn off the motor and wait until it stops completely, then uncover the inlet.

If suction remains poor, the pre-filter needs to be replaced. If suction still remains poor afterwards, the Hepa

filters needs to be replaced. See instructions in chapter 6. FILTER CHANGE.

5. DUST STORAGE SYSTEM

The dust extractors are mainly equipped with Longopac system for effective dust storage or a regular plastic bag

system depending on model. Longopac is a 22 m long plastic tube that will be divided into plastic bags using the

zip ties attached with the machine.

To assemble a new Longopac bag: Release the belt holding the last bag. Remove the holder, put in a new

Longopac bag & pull out the inner end upwards. Assemble the holder on to the machine and strap the opening

facing upwards with the belt. Pull down the outside end and close it using a zip tie.

All dust extractors can be used with original Pullman Ermator dust bags for single use. Also all models can be

fitted with the longopac system.

Only change Longopac or regular bag after filter cleaning cycle have been completed.

6. FILTER CHANGE

Risk of dust dispersion –Use personal safety equipment

Unhealthy dust can be spread during filter change. Accordingly, the user should wear protective glasses,

protective gloves, and a breathing mask conforming to protection class FFP3.

Wear breathing mask Wear ear protection Wear protective glasses

Pre-filter

Loosen the 3 clamps and remove the top. Take the bag from the new filter.

Lift out the filter and place it gently in a plastic bag. This bag must be properly disposed.

Insert a new filter.

Important:

If you are removing the Pre-filter in order to clean it. Hitting the filter with force or use of compressed air will

destroy the filter. It can handle water, but high pressure water cleaning will destroy it.

Hepa Filter

Loosen the two nuts on each filter cover cap. Carefully lift the filter into a clean plastic bag, use the bag from the

new filter. This bag must be properly disposed. Insert a new filter in reverse order.

Important:

Hepa filters can’t be cleaned, trying this might destroy it. When installing the replacement filter, make sure to

not touch the inside of the filter. Any kind of force/damage on the inside of filter media will destroy the new

filter.

WARNING

Remember to switch off the machine and pull the plug out of the outlet before servicing.

7. SERVICE

•When cleaning and servicing the machine, you must switch off the machine and remove the plug from

the outlet.

•Avoid cleaning with a high pressure cleaner. If necessary, do not direct at the openings on the machine,

especially the opening for cooling air.

•Before moving the machine from the work area, the machine must be cleaned.

•All other equipment must be regarded as contaminated and be treated thereafter.

•If possible, use a special suitable room.

•Proper personnel protective equipment must be used. Dust can be spread when the coarse filter and the

absolute filter are replaced that can be hazardous to health. Accordingly, the user should wear protective

glasses, protective gloves, and a breathing mask conforming to protection class FFP3.

•All parts which are contaminated after service must be properly disposed of in plastic bags according to

all regulations.

•If the machine has to be used for other purposes, it is extremely important that the machine is cleaned,

to avoid the spread of hazardous dust.

•Do not puncture the Hepa filter. Risk of dust dispersion.

Replacement parts, Filters and Dust collection system

Part no:

Description

S13

S26

S36

1376013

Longopac (4-bags)

1

1

1

1276008

Plastic bags (25-pcs)

1

1

1

201000016

Pre-filter S13

1

N/A

N/A

201000016a

PTFE Pre-filter S13

1

N/A

N/A

200900050

Pre-filter S26

N/A

1

N/A

200900050a

PTFE Pre-filter S26

N/A

1

N/A

200900051

Pre-filter S36

N/A

N/A

1

2000900051a

PTFE Pre-filter S136

N/A

N/A

1

200700070

HEPA FILTER S-LINE

1

2

3

200700070a

HEPA FILTER S-LINE USA

1

2

3

8. WARRANTY

All Pullman Ermator devices and accessories have a 12-month factory warranty for material and manufacturing

defects. The warranty extends to 36 months when returning the attached warranty slip. Do not attempt to repair

the suction apparatus without the consent of the manufacturer.

The warranty does not cover defects which are the result of normal wear and tear, negligence, defective use,

unauthorised repair or the suction apparatus being connected to the incorrect voltage.

In the event of any complaint, the suction apparatus or an agreed part of it must be returned to us or our

authorised representative for warranty examination and for any warranty repair or replacement.

9. PROBLEM SOLVING

The dust extractors are designed and manufactured for severe environments and tasks, but the user must note that

the machine must be protected from knocks and blows. Filter, seals, attachments, and connections are carefully

adapted and selected with regard to the operator’s work environment. Therefore, the operator and service

personnel must treat the machine with care in order for it to work correctly for many years.

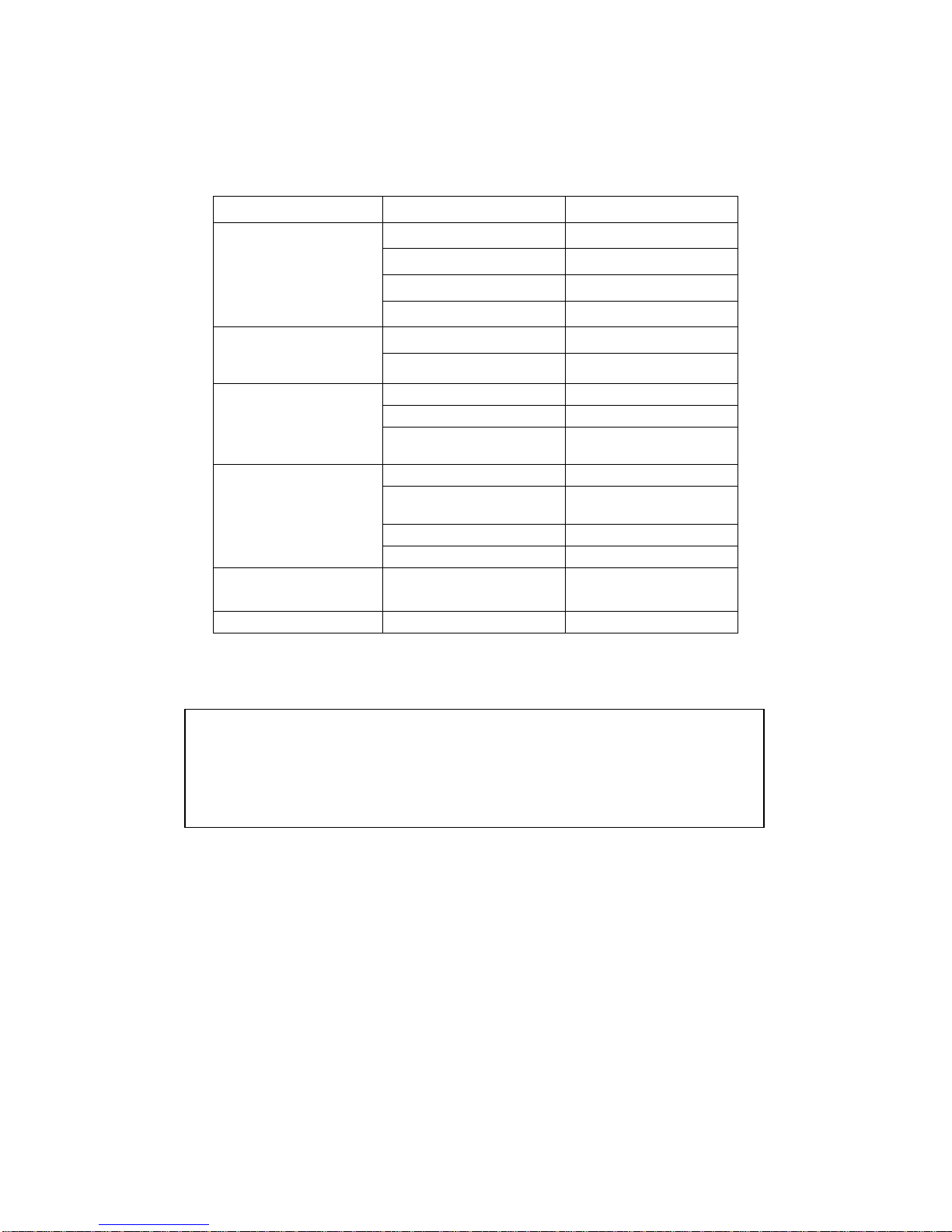

Issue

Cause

Solution

Motor doesn’t start

No power

Plug in machine

Cable defective

Replace cable

Switch defective

Replace switch

Soft start defective

Replace soft start

Motor stops

immediately after

starting

Wrong fuse

Connect to correct fuse

Shortcut in cable/machine

Order service

Motor runs but there is

not suction

Hose not connected

Connect hose

Hose clogged/blocked

Clean hose

No dust collection bag

Fit dust collection

system

Motor runs but poor

suction

Hole in hose

Replace hose

Filter clogged

Clean filter/Replace

filter

Loose top cover

Adjust

Defective gaskets

Replace affected gaskets

Dust blown from motor

Wrongly assembled or

damaged filter system

Adjust/Replace filters

Abnormal noise

Order service

SAVE THESE INSTRUCTIONS!

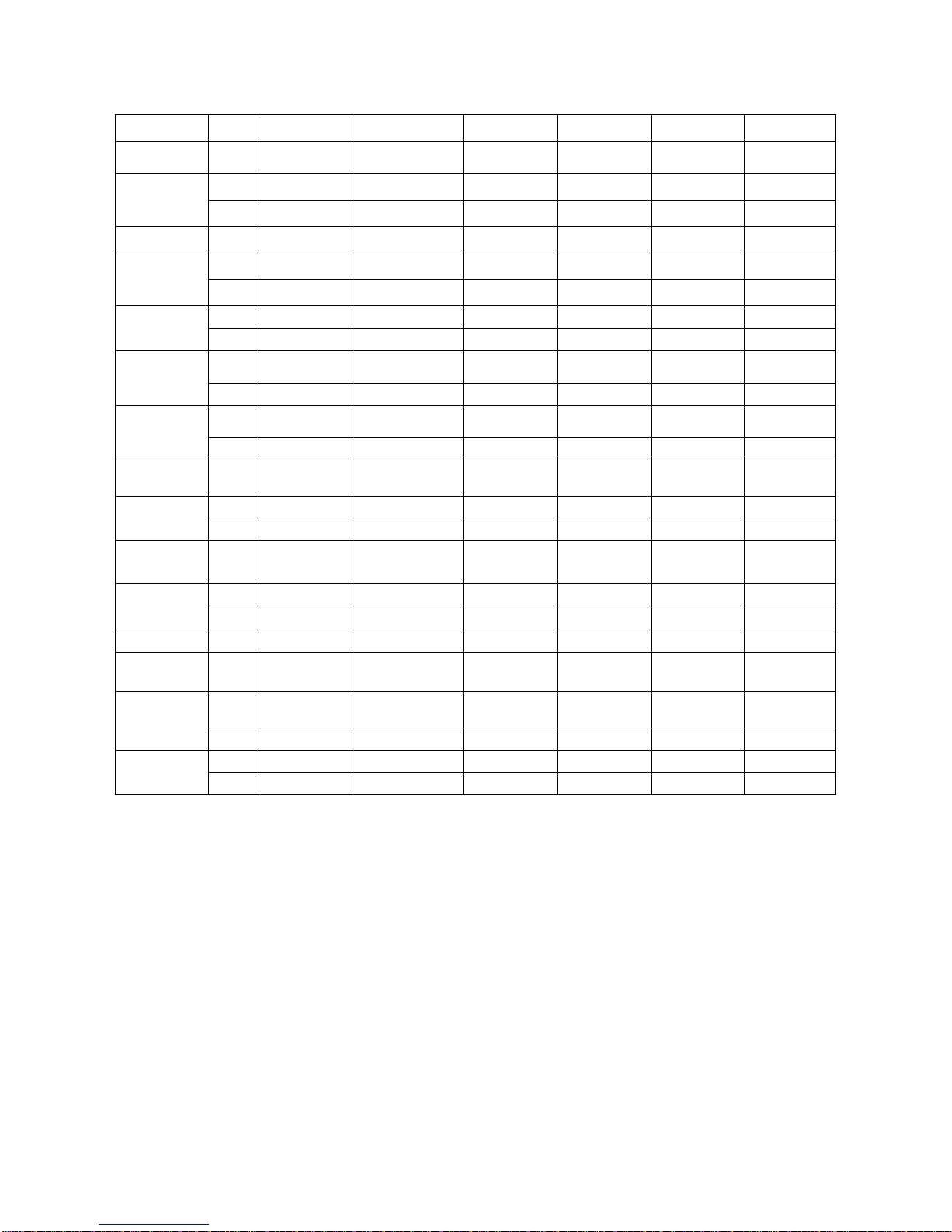

10. TECHNICAL DATA

Data

Unit

S13 120 V

S13 230 V

S26 120 V

S26 230 V

S36 230 V

S36 120 V

Voltage

(single phase)

V

120

230

120

230

230

120

Power (max)

W

1200

1200

2400

2400

3600

2400

HP

1,6

1,6

3,2

3,2

4,8

3,2

Current (UL)

A

8

4

16

8

12

16

airflow (max)

m3/h

200

200

400

400

600

485

cfm

118

118

236

236

354

285

Vacuum (max)

kPa

24

22

24

22

22

18

Inch ”

100

90

100

90

90

72

Main hose

Metric

(mm)

4m x 38

4m x 38

7,5m x 51

7,5m x 51

10m x 63

10m x 63

USCS

13’x 1,5”

13’x 1,5”

24’x 2”

24’x 2”

32’x 2,5”

32’x 2,5”

Inlet

Metric

(mm)

51

51

63

63

63

63

USCS

2”

2”

2,5”

2,5”

2,5”

2,5”

Pre-filter

EN779-F8

%

@1um

>99,5

>99,5

>99,5

>99,5

>99,5

>99,5

Pre-filter area

Metric

1,5 m²

1,5 m²

3 m²

3 m²

4,5 m²

4,5 m²

USCS

16 ft²

16 ft²

32 ft²

32 ft²

48 ft²

48 ft²

Hepa filter

EN1822-H13

%

@0.3um

>99,99

>99,99

>99,99

>99,99

>99,99

>99,99

Total HEPA

filter

area

Metric

1,2 m²

1,2 m²

2,4 m²

2,4 m²

3,6 m²

3,6 m²

USCS

13 ft²

13 ft²

26 ft²

26 ft²

39 ft²

39 ft²

Sound level

dB(a)

70

70

70

70

70

70

Dust collection

system

Type

Plastic bag

Plastic bag

Longopac

Longopac

Longopac

Longopac

Dimensions

(L*W*H)

Metric

(mm)

680x400x1100

680x400x1100

756x546x1275

756x546x1275

840x620x1500

840x620x1500

USCS

26x15,8x43,3 ”

26x15,8x43,3 ”

29x21,5x50,2 ”

29x21,5x50,2 ”

33x24,5x60 ”

33x24,5x60 ”

Weight

Metric

29 kg

29 kg

47 kg

47 kg

63 kg

63 kg

USCS

66 lbs

66 lbs

105 lbs

105 lbs

140 lbs

140 lbs

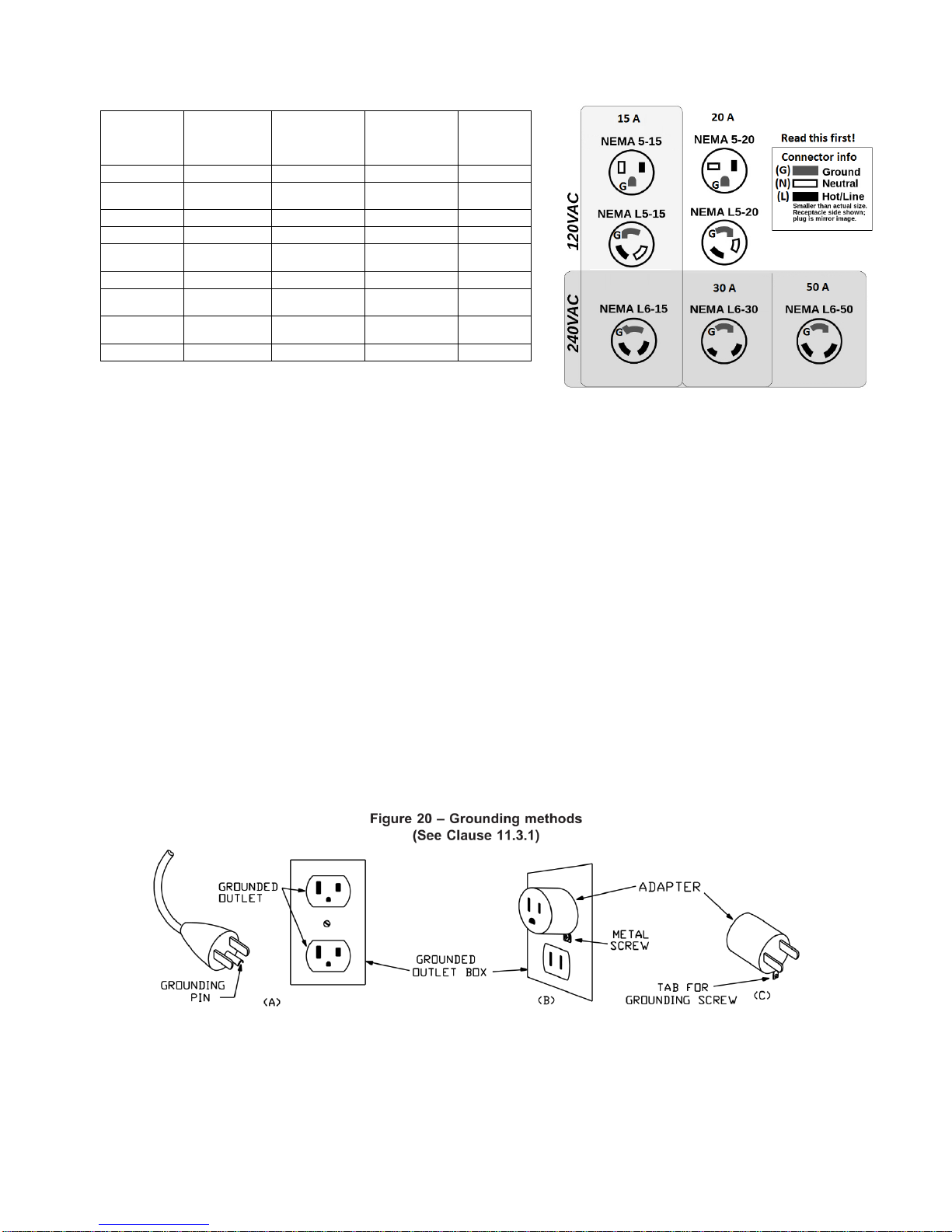

11. PLUGS

MODEL

PLUG TYPE

RECEPTACLE

TYPE

RECEPTACLE

MAX AMPS

CABLE &

PLUG

MAX

AMPS

S13 120 V

NEMA 5-15P

N/A

N/A

15 A

S13 230 V

SOCKET F

GROUNDED

SOCKET F

5 A

10 A

S26 120 V

NEMA 5-20P

N/A

N/A

20 A

S26 230 V US

NEMA L6-15P

N/A

N/A

15 A

S26 230 V

SOCKET F

GROUNDED

N/A

N/A

10 A

S36 120 V US

NEMA 5-20P

N/A

N/A

20 A

S36 230 V

30A

NEMA L6-30P

NEMA L6-30

20 A

30 A

S36 230 V

50A

NEMA L6-50P

NEMA L6-50

35 A

50 A

S36 230 V

IEC 60309 16 A

N/A

N/A

16 A

The grounding methods of S13 120V machine follow

the UL1017 section 11.3.1 part b) as below:

For a grounded, cord-connected appliance rated less than 15 A and

intended for use on a nominal 120-V supply circuit, the instructions in either item 1 or 2:

1) This appliance is for use on a nominal 120-V circuit, and has a grounded plug that looks like the plug

illustrated in sketch A in Figure 20. A temporary adaptor that looks like the adaptor illustrated in sketches B and

C may be used to connect this plug to a 2-pole receptacle as shown in sketch B if a properly grounded outlet is

not available. The temporary adaptor should be used only until a properly grounded outlet (sketch A) can be

installed by a qualified electrician. The green colored rigid ear, lug, or the like extending from the adaptor must

be connected to a permanent ground such as a properly grounded outlet box cover. Whenever the adaptor is

used, it must be held in place by a metal screw.

Exception: In Canada, the use of a temporary adaptor is not permitted by the Canadian

Electrical Code, C22.1.

2) This appliance is for use on a nominal 120-V circuit and has a grounding attachment plug that looks like the

plug illustrated in sketch A in Figure 20. Make sure that the appliance is connected to an outlet having the same

configuration as the plug. No adaptor should be used with this appliance.

The grounding methods of S26 120V, S26 230V, S36 120V US, S36 230V 30A AND S36

230V 50A follow the UL1017 section 11.3.1 part c) as below:

For all other grounded, cord-connected appliances:

This appliance is for use on a circuit having a nominal rating more than 120 V (or This appliance is rated more

than 15 A and is for use on a circuit having a nominal rating of 120 V) and is factory-equipped with a specific

electric cord and plug to permit connection to a proper electric circuit. Make sure that the appliance is connected

to an outlet having the same configuration as the plug. No adaptor should be used with this appliance. If the

appliance must be reconnected for use on a different type of electric circuit, the reconnection should be made

by qualified service personnel.

12. DEKLARATION OM ÖVERENSSTÄMMELSE

12. DECLARATION OF CONFORMITY

12. DECLARATION DE CONFORMITÉ

12. ERKLÄRUNG DER ÜBERSTIMMUNG

12. SAMSVARSERKLRING

Pullman Ermator AB

Industrivägen 10

S-777 34 SMEDJEBACKEN

Försäkrar under eget ansvar att maskinen

Declare under our sole responsibility that the machine

Certifie sous sa

7

orms

7

responsabilité que le produit ciaprès

Versichern auf eigener verantwortung, dass das Produkt

Forsikrer under eget ansvar at maskinen

Model

Serial number

M/F

year

Model

Serial number

M/F

year

S13 120 V

0900058a0001-xxxx

2010-

S36 120 V US

0900242e0001-xxxx

2014-

S13 230 V

0900058 0001-xxxx

2010-

S36 230 V

30A

0900242a0001-xxxx

2010-

S26 120 V

0900256a0001-xxxx

2010-

S36 230 V

50A

0900242d0001-xxxx

2011-

S26 230 V US

0900256b0001-xxxx

2010-

S36 230 V

0900242 0001-xxxx

2010-

S26 230 V

0900256 0001-xxxx

2010-

som omfattas av denna försäkring är i överensstämmelse med standarder:

included in this declaration, follows the provisions of the:

est conforme aux aux

7

orms suivantes:

den folgenden Normen entspricht:

er i overensstemmelse med standarder:

SS-EN 60335-1: 2002+A11+A1+A12+A2+A13+A14

SS-EN 60335-2-69:2009

SS-EN 61000-6-3:2007

SS-EN 61000-6-2:2005

enligt villkoren i/according to/selon/laut/i henhold til vilkårene i

Machine Directive 2006/42/EC

Low voltage Directive 2006/95/EC

EMC Directive 2004/108/EC

SMEDJEBACKEN 2016.04.26 Petra Bengtsson

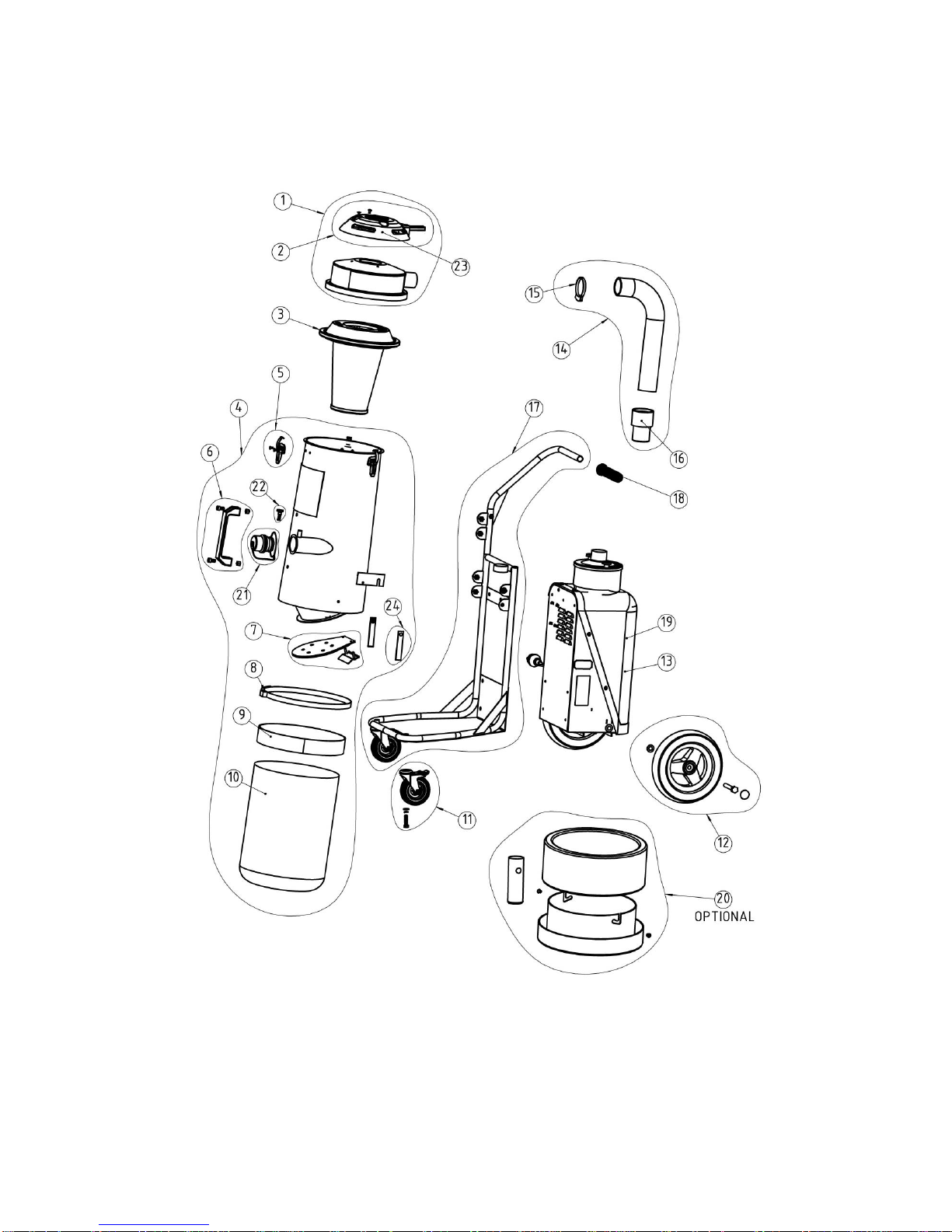

S13 230V, S13 120V

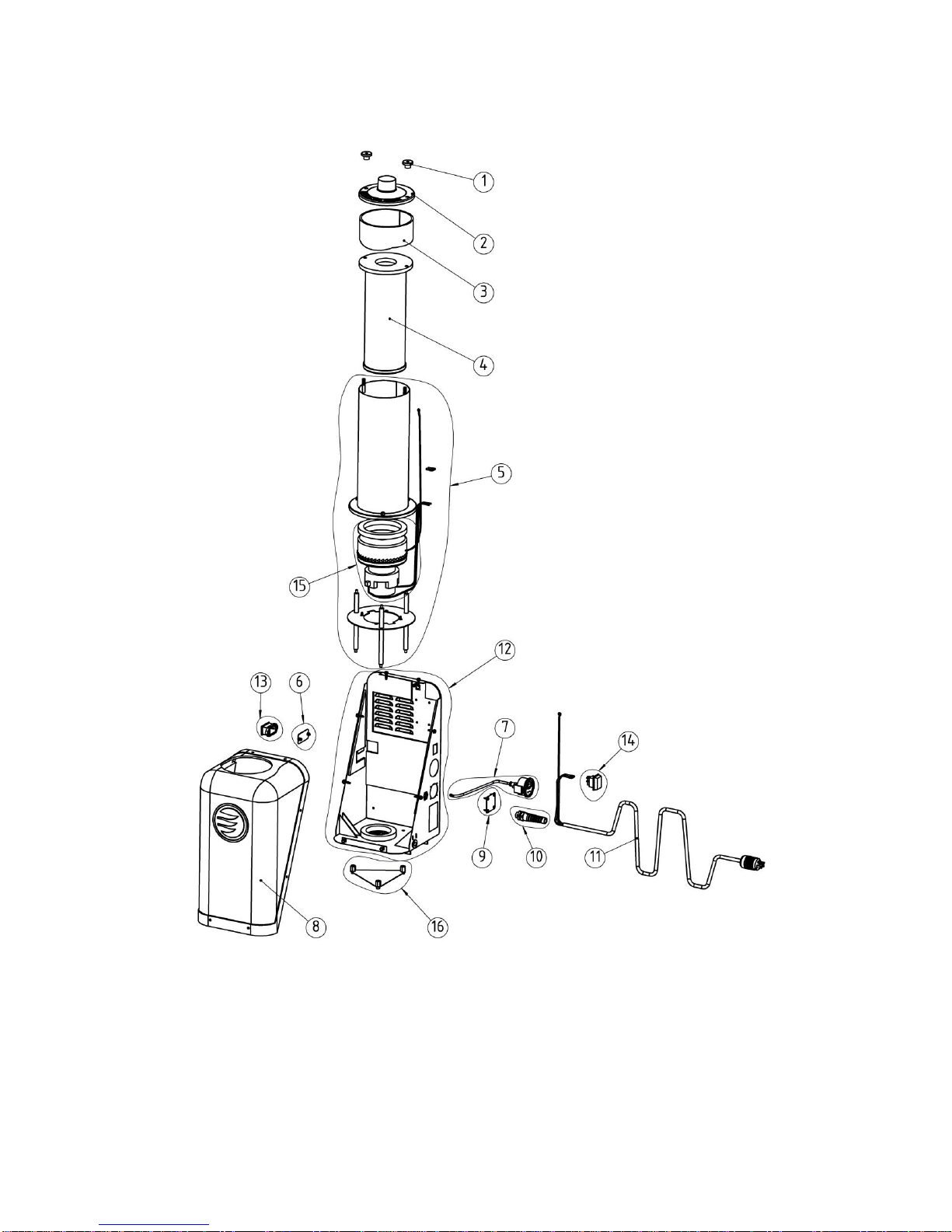

EXPLODED VIEW

ITEM NO.

QTY.

PART NUMBER

DESCRIPTION

1

1

201000117

TOP COVER ASSEMBLY PACKING (ex.S13)

2

1

201000118

CLEAN UNIT KIT

3

1

201000016

FILTER

4

1

201000119

TANK COMPLETE (ex.S13)

5

3

200600799

HOLDER KIT

6

1

201000120

HANDLE KIT

7

1

201000116

FLAP ASSEMBLY KIT

8

1

201100140

BELT PACKING

9

1

201100141

ANTI-SKID PACKING

10

1

12760008

PLASTIC BAG 25PACK

11

1

200800152

FRONT WHEEL KIT

12

1

200800151

REAR WHEEL KIT

13

1

201100146

ENGINE PACK 230V PACKING

14

1

201000123

HOSE KET S13 PACKING

15

1

201100137

HOSE CLAMP60-65MM PACKING

16

1

201100125

HOSE END A51B PACKING

17

1

201000124

WAGON COMPLETE PACKING

18

1

201100138

HANDLE WAGON (ex. S13) PACKING

19

1

201100146a

ENGINE PACK 120V PACKING

20

1

201000115

LONGOPAC KIT PACKING

21

1

201000122

INLET SEAL COMPLETE SET PACKING

22

1

201100139

LOCKING DEVICE PACKING

23

1

201000670

TOP COVER KIT ex. CLEAN UNIT

24

1

201500174

BELT HOLDER KIT (ex.S13)

S13 230V

MOTOR PACKAGE

POS.

QTY

NUMBER

DESCRIPTION

1

2

201100128

NUT

2

1

201000121

FILTER COVER KIT

3

1

201100127

SEALING PACKING

4

1

200700070

HEPA FILTER S-LINE

5

1

201100144

ENGINE TUBE KIT (WITH NIPPLE ) PACKING

6

1

201100129

COUNTER COVER PACKING

7

1

201000764

CIRCUIT BOARD KIT

8

1

200600482

ENGINE COVER, KIT

9

1

200600408

ELECTRICAL OUTLET KIT

10

1

201000141

CABLE FIX KIT (PG11)

11

1

201100132

CORD SET PACKING

12

1

201000134

CHASSI COMPLETE KIT

13

1

201100236

SWITCH PACKING

14

1

200700413

MANOMETER, KIT

15

1

200800060

MOTOR KIT 230V KIT

16

1

201100147

CABLE KIT (ex.S13)

17

1

201000133

COUNTER KIT (OPTIONAL S13)

S13 120V

MOTOR PACKAGE

POS.

QTY

NUMBER

DESCRIPTION

1

2

201100128

NUT

2

1

201000121

FILTER COVER KIT

3

1

201100127

SEALING PACKING

4

1

200700070a

HEPA FILTER S-LINE USA

5

1

201100144a

ENGINE TUBE KIT (WITH NIPPLE ) PACKING US

6

1

201100129a

COUNTER COVER PACKING(STEEL VERSION)

7

1

200700413

MANOMETER, KIT

8

1

200600482a

ENGINE COVER ETL VERSION, KIT

9

1

201100148a

OUTLET COVER KIT (STEEL VERSION)

10

1

201100150

CABLE FIX KIT (PG13)

11

1

201500176

CORD SET PACKING (NEMA 5-15P)

12

1

201000134a

CHASSI ETL VERSION COMPLETE KIT

13

1

201000133

COUNTER KIT (OPTIONAL S13)

14

1

201100151

SWITCH PACKING 120V

15

1

200800227

MOTOR KIT 120V 1200W KIT

16

1

201500175

BOTTOM COVER KIT

ACCESSORIES S13

POS.

QTY

NUMBER

DESCRIPTION

1

1

200900281

HOSE 38mm x 4m

2

1

6324034

KC004 SUCTION PIPE

3

1

1326054

GRD370 FLOOR TOOL

4

1

1340011

D370A RUBBER BLADES

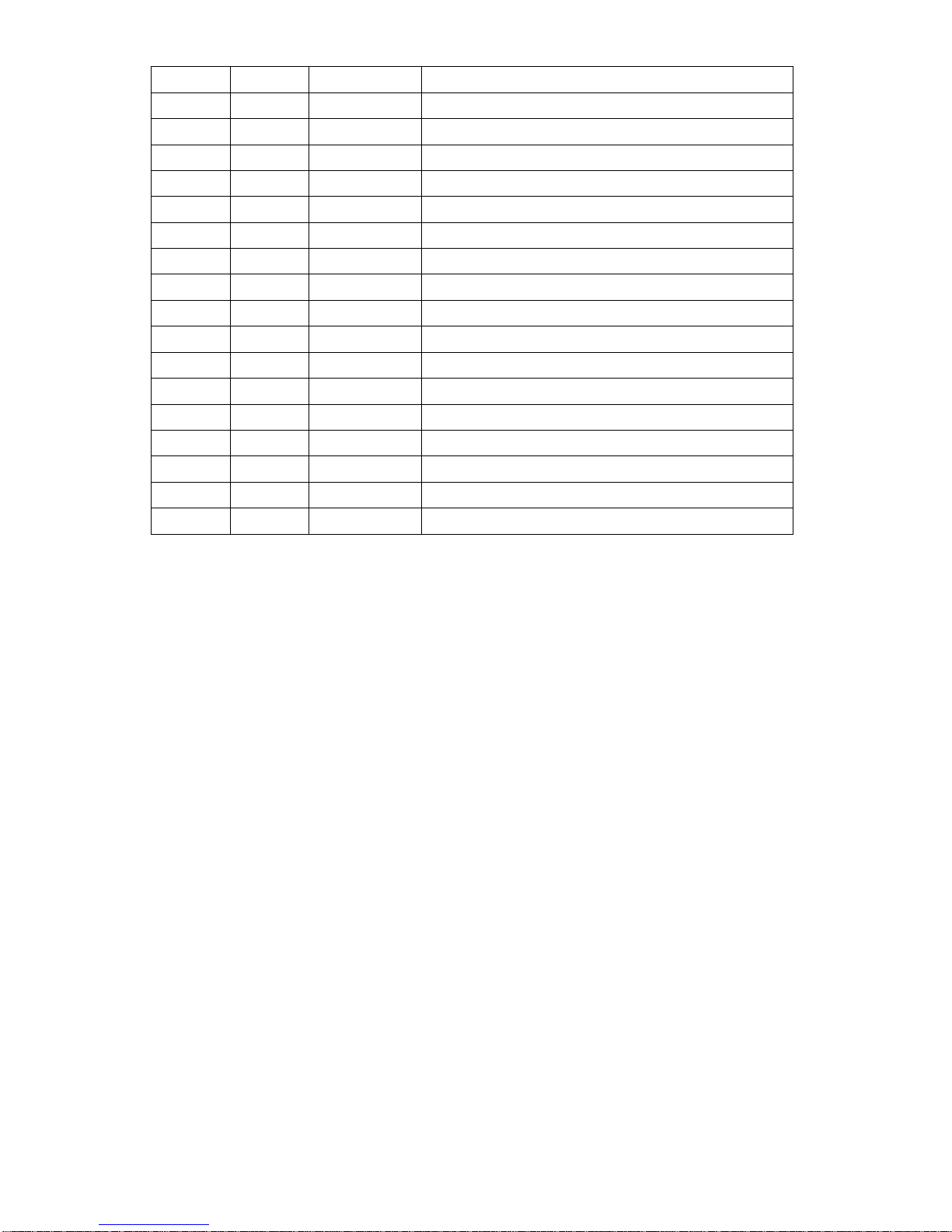

S26 230V, S26 120V, S26 230V US

EXPLODED VIEW

POS.

QTY.

NUMBER

DESCRIPTION

1

1

201000143

TOP COVER KIT (ex.S26)

2

1

201000118

CLEAN UNIT ASSEMBLY PACKING

3

1

200900050

MAIN FILTER

4

3

200600799

HOLDER KIT

5

1

201000129

TANK COMPLETE PACKING (ex. S26)

6

1

201000116

FLAP KIT

7

1

201100140

BELT PACKING

8

1

201100141

ANTI-SKID PACKING

9

1

1376013

LONGOPAC BAG 4 PACK

10

1

201100135

LONGOPAC HOLDER PACKING

11

1

200800152

FRONT WHEEL KIT

12

1

200800151

REAR WHEEL KIT

13

1

201000130

ENGINE PACK KIT PACKING (ex.S26 230V)

14

1

200800153

CLIP HOLDER KIT

15

2

201000144

HOSE KIT S26

16

2

201100137

HOSE CLAMP 60-65 PACKING

17

2

201100125

HOSE END (51MM) PACKING

18

1

201000831

WAGON COMPLETE PACKING

19

1

201000130a

ENGINE PACK KIT PACKING (ex.S26 120V)

20

1

201100139

LOCKING DEVICE PACKING

21

1

201000145

INLET SEAL COMPLETE SET (ex.S26)

22

1

95102

LONGOPAC SEAL CLIPS(60 PCS)

23

1

201000670

PLASTIC COVER KIT (ex. CLEAN UNIT)

24

1

201000130b

ENGINE PACK KIT PACKING (ex.S26 230V US)

S26 230V

MOTOR PACKAGE

This manual suits for next models

9

Table of contents

Other pullman Ermator Vacuum Cleaner manuals

pullman Ermator

pullman Ermator I2000ESD User manual

pullman Ermator

pullman Ermator S1400 User manual

pullman Ermator

pullman Ermator T7500 User manual

pullman Ermator

pullman Ermator S 25 User manual

pullman Ermator

pullman Ermator W250P Technical manual

pullman Ermator

pullman Ermator I940T User manual

pullman Ermator

pullman Ermator HTC 30D User manual

pullman Ermator

pullman Ermator S 25 User manual

pullman Ermator

pullman Ermator HTC 26D User manual

pullman Ermator

pullman Ermator w350 User manual